3 way valve stopping flow?

Hey guys,

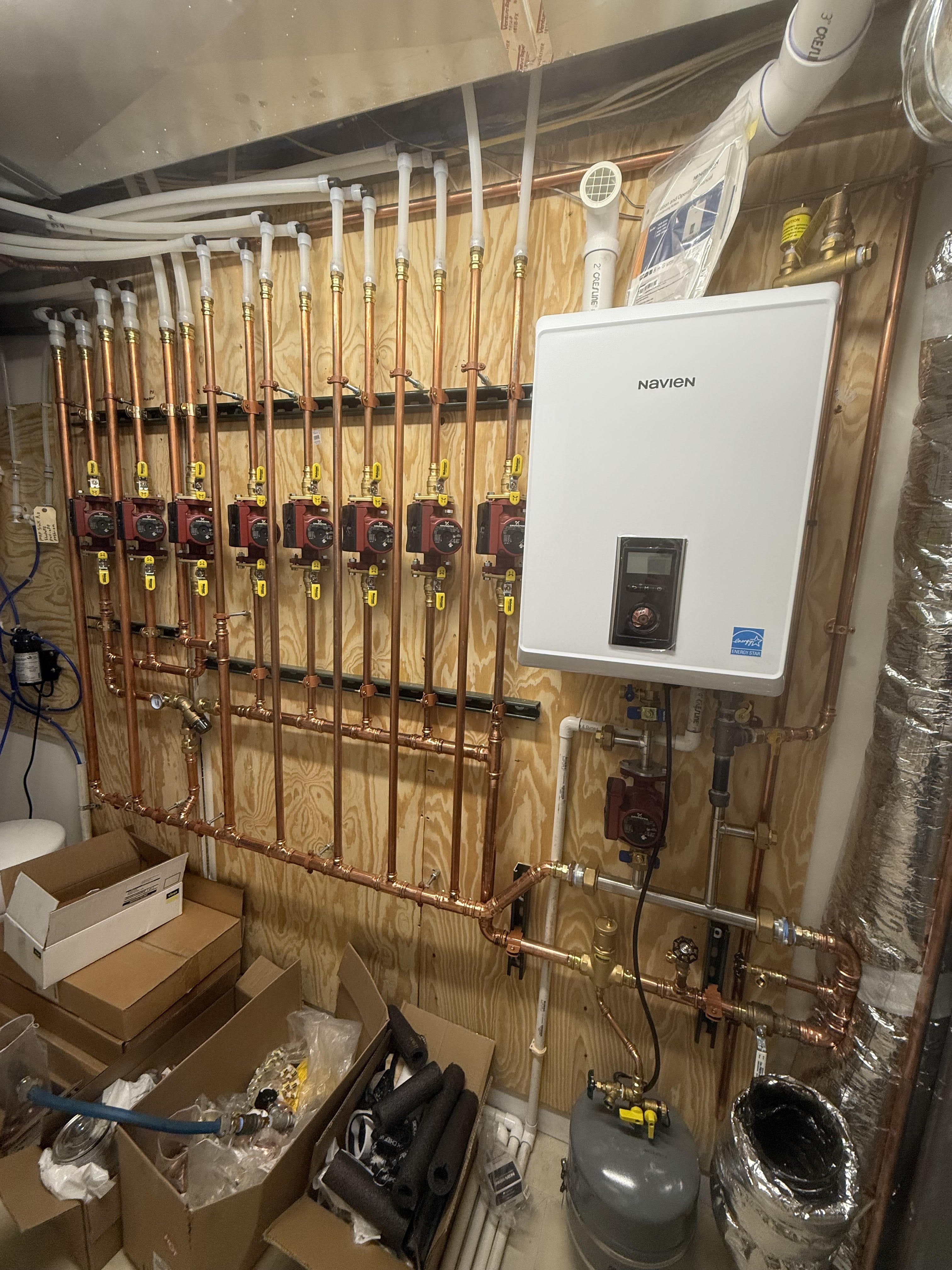

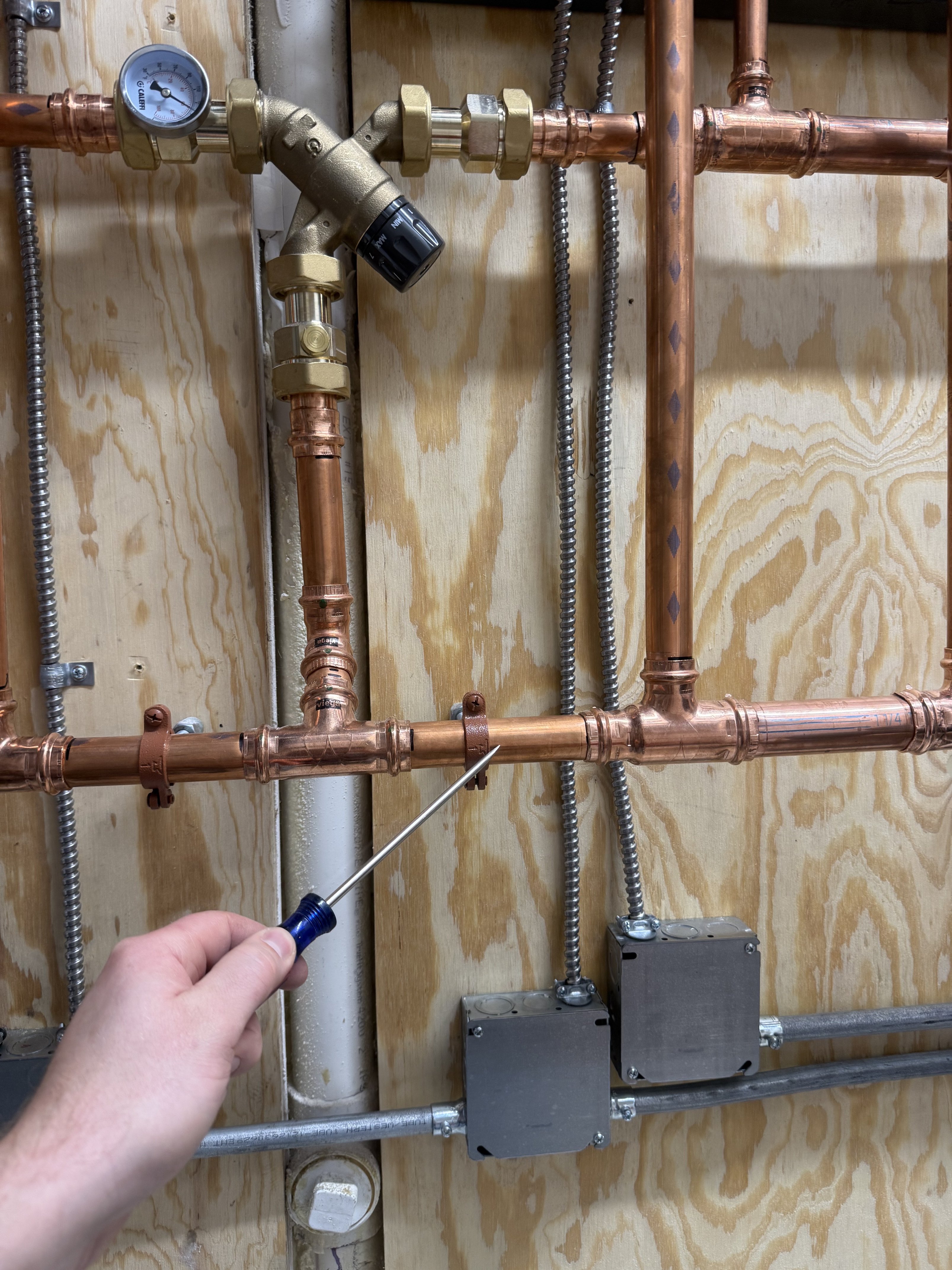

We're piping a mixed temp system, 4 baseboard zones & 3 in floor heat zones. The in-floor zones have 1" S&R to the manifold with 3/8" pex loops. We piped in a Caleffi 520616AC mixing valve with internal checks to control the temp to these zones. When we went to fire up the system there is very minimal if any flow to these 3 low temp zones. I'm thinking the higher temp return water from the baseboards zones is closing the mixing valve, stopping the flow.

Check out the photos of the set up and the drawing of how I plan to re-pipe in a couple days. I was going to add a check valve separating the high temp and low temp returns.

What do you think? Any other insights or critiques?

Comments

-

I would pull the checks and strainers out, leave them out

Any idea of the gpm of those 3 radiant pumps ?

That 520 valve is a 2 cv, so 4 gpm would be about all it could handle without some higher head circs

Remove the checks, put 3 pumps on speed 3 and report back

Checks in all the pumps or just downstream is important

Header piping for all those zone circs may be small

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

@Mikeymike, I think you may be right. Put a check valve before the left three low temp returns and the higher baseboard returns on the right. that would prevent hotter return water from mixing with the return water from the three radiant zones. Not the mixing valve that I would have chosen. A high flow Cv valve, I think would have been better. Merry Christmas to one and all.

0 -

I don't know the gpm of the pumps… 4 gpm doesn't sound great when all zones are calling.

I'm not seeing a high flow in stock for Friday, I'll have to look some more. Either way we'll add that check between the returns. I'll let you guys know how this shakes out on Friday.

Thanks and Merry Christmas.

0 -

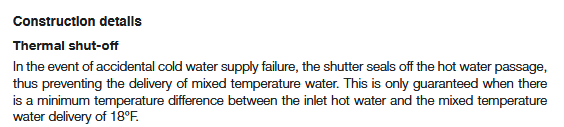

This may explain it.

0 -

@hot_rod advice is spot on, as usual.

Putting an additional check where you suggest will not make any difference IMHO. There is no flow in that direction anyways if you have a check on mixing valve hot side.

Do you have this problem when all pumps are off on the high temp zones?

1" header supplying all those zones is probably not big enough when 2 or more of the high temp zones are circulating, especially with a cV 2 mixing valve that the low temp circs have to work against.

In addition to turning the low temp circulators on high (level 3), you can try turning the high temp pumps to level 1 (but this very well may not be enough flow through those); maybe they already are?

If all that doesn't help, I would consider the 3/4 iSeries ODR mixing valve cV 3.3. Or consider repiping with 3 separate mixing valves, 1 for each of those zones. Those mixing valves can be surprisingly restrictive. Repiping three in parallel will effectively triple the cV? Also triples the failure rate?

0 -

Hey guys thanks for the help on this. We removed the checks from the mixing valve and added a check valve separating the high and low temp returns. Pumps for low temp zones are on high and rocking, we've got good flow at the manifolds. Boiler is set to 160F with low temp zones mixed to 110F.

The mixing valve says 3.5CV on the spec sheet from Caleffi, I'm not understanding how CV and max flow relate to each other, I'll have to look more into it, I was just reading the max flow rates on the valves and selecting by that.

Most of the header is 11/4" then drops down to 1" for the low temp zones. There's a lot of zones here but not a high btu demand, 3 of the high temp zones supply a single 10' baseboard, the other 2 supply a single 16' baseboard. I did size that, although dropping down at the end isn't something we've done before, anything good or bad with that?

1 -

-

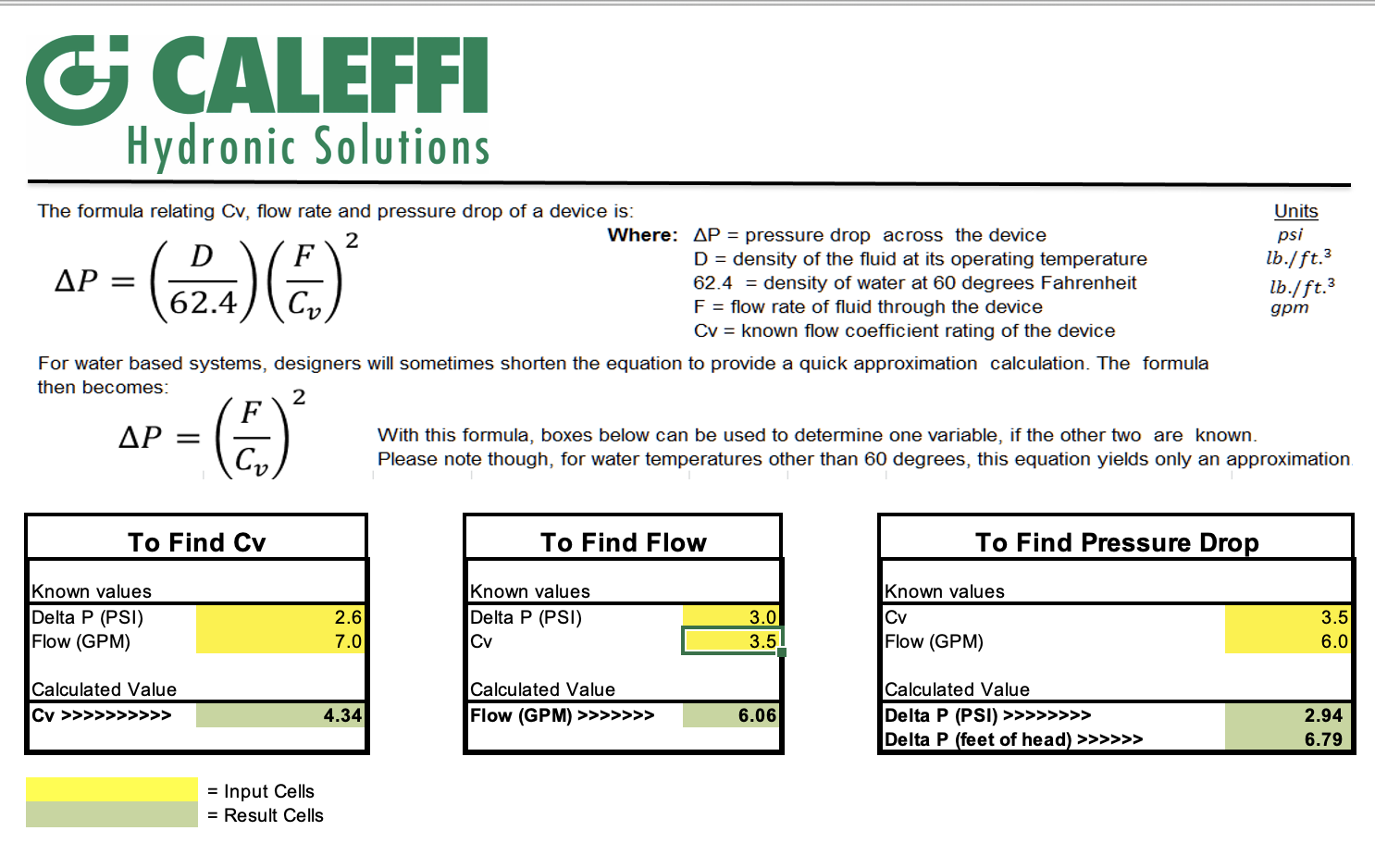

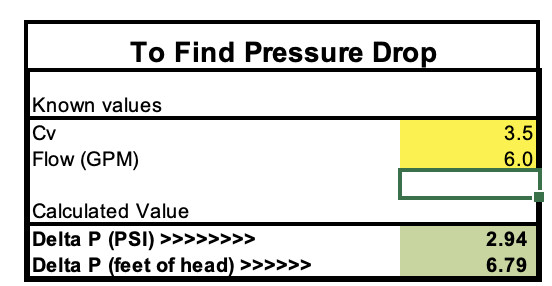

If a valve has a Cv of 3.5 that means if you put 3.5 gpm through the valve you would have a pressure drop across the valve of 1 psi

If you put 2.5 gpm through the valve your pressure drop would be .51psi

If you put 10 gpm through it your pressure drop would be 8.16 psi

0 -

Here is a spreadsheet to do some Cv calcs. Use the 3rd column.

Enter the Cv of the valve, you must have the AngleMix + valve which is the high Cv. The standard AngleMix is 2 Cv.

If you knew the gpm of each of the zone pumps enter that into the formula and you get the pressure drop.

Lets just assume 2 gpm per zone pumpX 3= 6 gpm

IF you could measure the pressure drop across the pumps ad you know the valve Cv, you could get the gpm.

This Cv chart works for any valve or device, ball valves, check valves, zone valve, etc, etc.

I think the 3 way valve is sized adequately.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@hot_rod I made a slight change on your Excel spreadsheet to account for density of the fluids operating temperature, if you're interested. It doesn't really change it much for water.

0 -

Nice, thanks

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements