Oil boiler bypass location and bad near boiler piping. plus circ air binding. Oh My!

In a nutshell, my neighbor has an oil boiler that was piped incorrectly and missing a crucial part.

The Circ is on the supply side straight out of the top of boiler with no air separator installed at all, an IFC installed in the circ, and a throttled bypass coming off the return and plumbed into the suction side of the circ.

We are working with the technician to correct the lack of an Air Separator. (Not the original installer, they were less then pleasant when called out on the lack of air separator)

More importantly and in the very short term, the circ is constantly becoming air bound as air comes out of solution in the boiler and flows up against the IFC.

I pulled the IFC today so at least the air binding will stop. We'll accept that there will be ghost flow for a little while, but will just have to be ok with that. This is a short term solution and we WILL reinstall an IFC or a separate weighted check valve when the near boiler piping gets fixed.

The fix will be to repipe, leaving the circ on the supply side with a Pumping-away layout pulling from the boiler, through a spirovent with the expansion tank piped in to the bottom of the spirovent as it should be. We are up against a space problem if we do not want to drain the whole system or move the circ to the return (old CI rads and big pipes. Isolating valves at the circ and on the return)

If we get rid of the Bypass line, this frees up room under the circ to pipe in a small loop out of the top of the boiler that would put the Air Separator in the correct location.

If we don't do it that way we need to drain the whole system to move the circ higher up and further away from the boiler.

My main question at the moment:

Is the throttled bypass piping doing anything besides shorting the return to the supply? I thought they were there to protect the boiler from getting shocked with cold return water and were most effective with the circ on the return. The Bypass is throttled with a ball valve. Can we safely, and without causing more problems, eliminate the bypass line?

I'm happy to be wrong about the function of the bypass, but can not wrap my head around its current function other than to reduce supply temp ever so slightly.

Extra info: Boiler also has a coil for domestic water, so High and low limits keep it between 160-180 currently.

Photos show near boiler piping, My thought is to pipe in a 180deg loop out of the top of the boiler to hold the Spirovent. It would go in the area circled in yellow in the below photo.

We would replace the nipple in the top of the boiler with a shorter one, 90 out of that nipple toward the front of the boiler, 90/nipple/tee w/ 3/4" draw-off for bleeding the boiler and then back towards the circ and put the spirovent in that upper horizontal run before a 90 in to the iso valve.

There are other tappings in the boiler right near the supply nipple in the rear of the boiler we could put a vent on as well. But I'm concerned the circ would still get air-bound.

Very open to other solutions too.

Thank you all for any input.

Comments

-

There are some vertical air sep available. Caleffi goes up to only 1", although it is a 14 Cv so flow wise it would work. If the nipple out of the boiler could be shortened you could maybe get a vertical sep in there. Or cut the copper above and move things up?

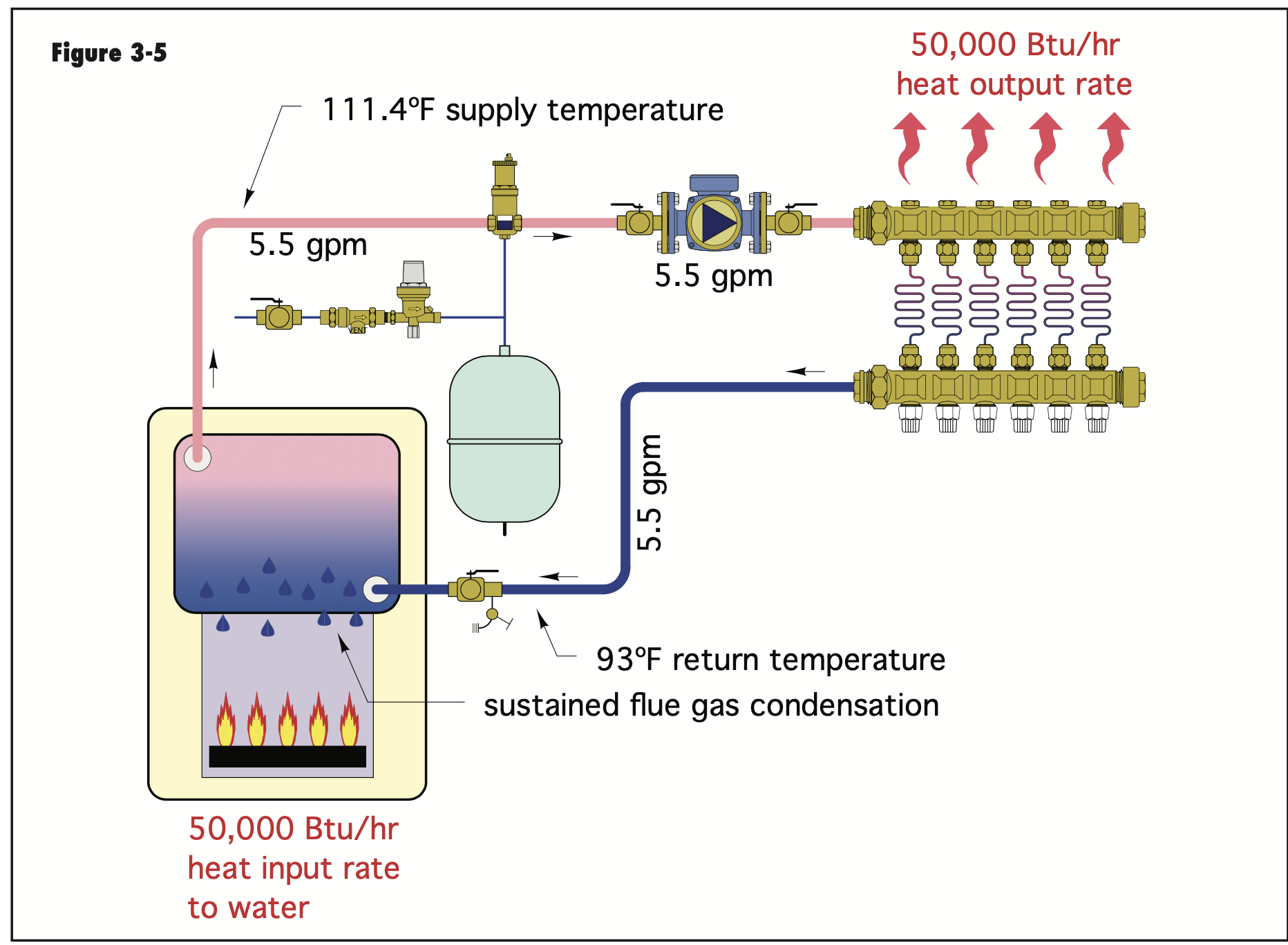

What type of heat emitters. Rarely do you need a boiler bypass with copper fin tube, it is very low mass, heats quickly.

Sometimes cast radiator systems, large piping, high water volume, can keep the boiler running too cold for extended, over 10 minute periods a return protection is a plus.

An example below of how high mass systems drive the boiler operating condition.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

If you have column radiators I’d probably just bleed there and forget about an air separator.

0 -

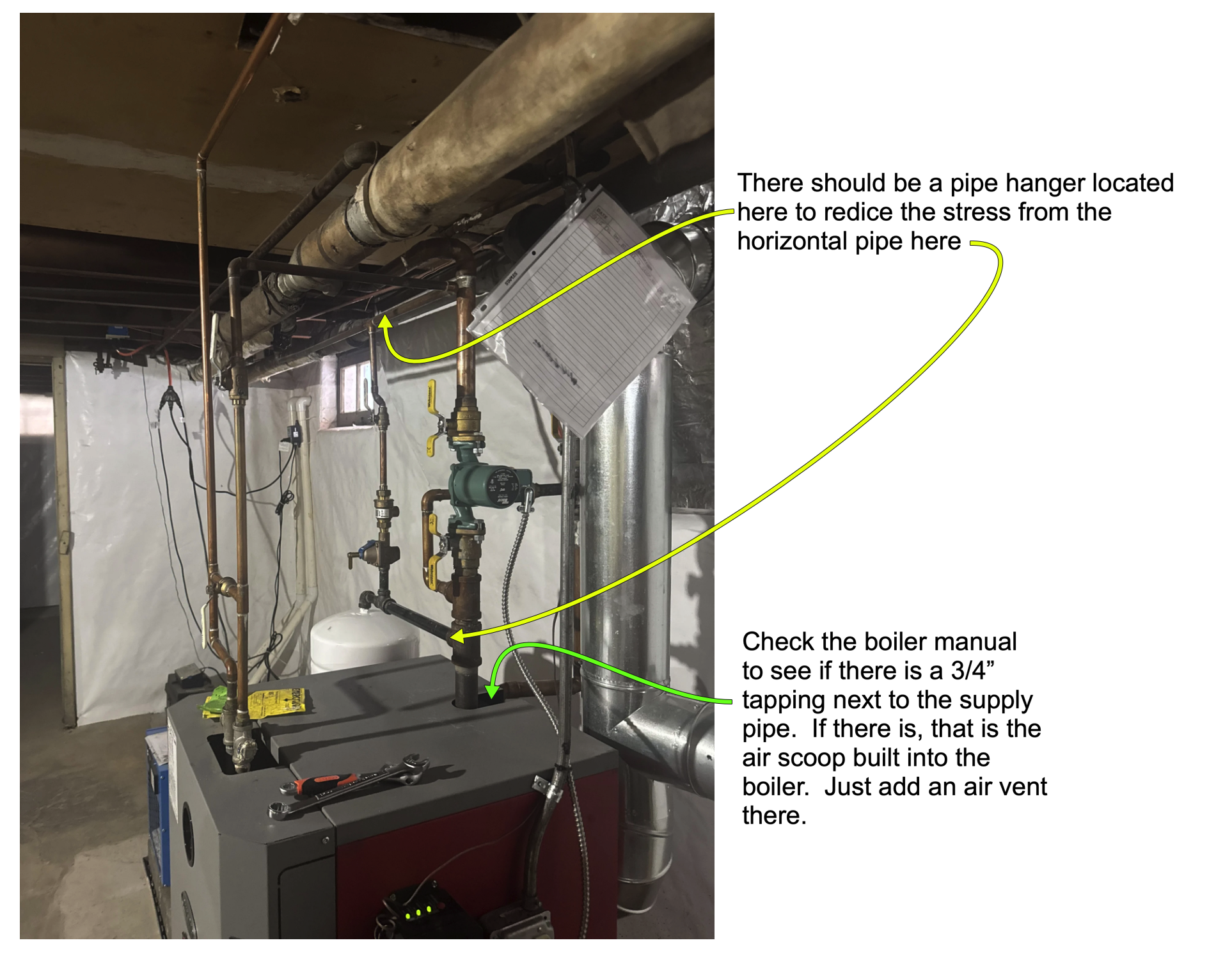

You may not need to add an air scoop or air vent to the external piping. look in the boiler manual to see if there is an air vent tapping built into the boiler.

That is the best air vent location on this system as it is piped now.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

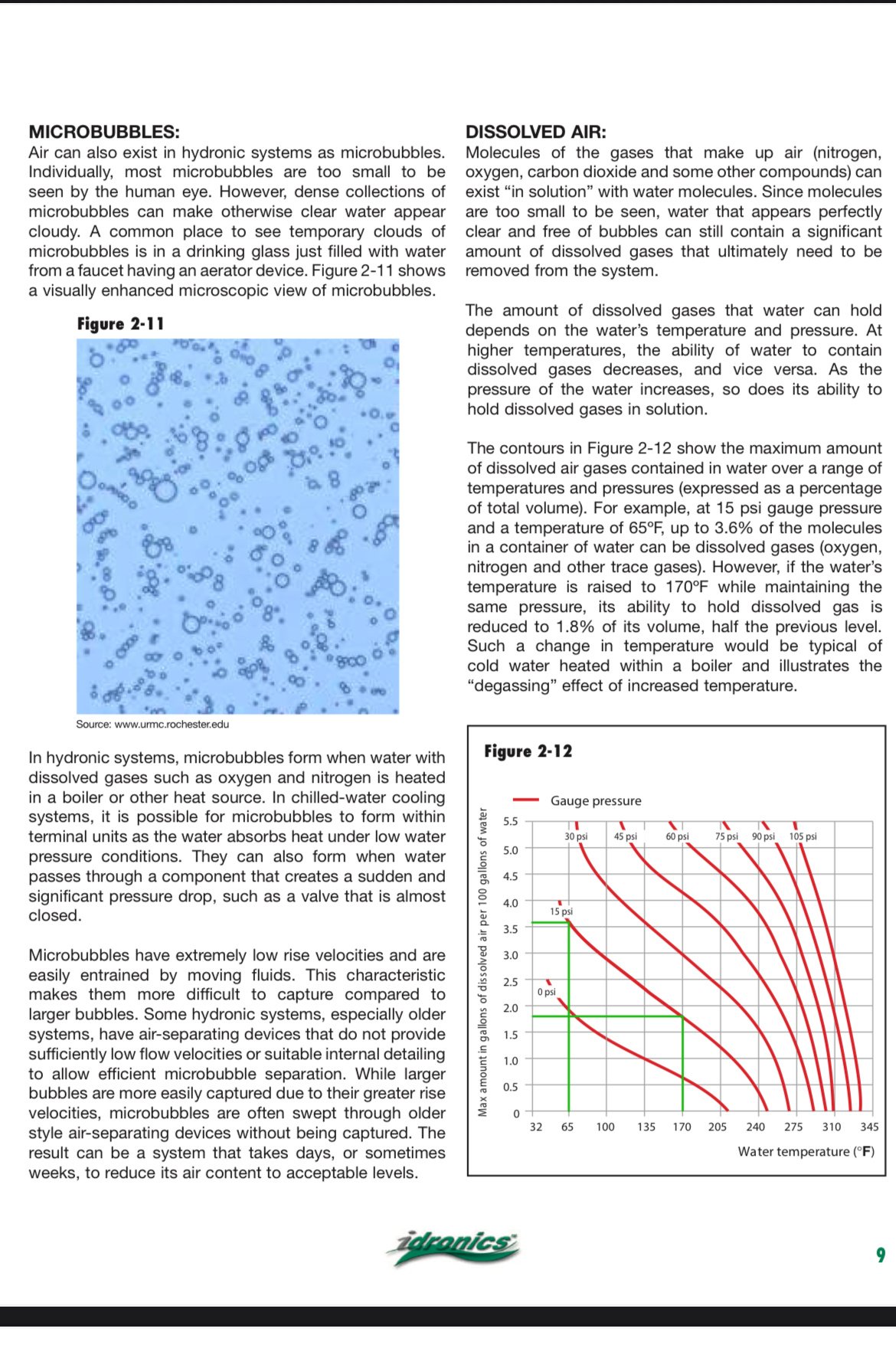

it takes a combination of air removal products to do the best job

High point air vents cannot eliminate the dissolved air micro bubble that form as the water is heated in the boiler

I highly recommend microbubble type purgers to get the best efficiency and life expectancy from any hydronic system

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@hot_rod said: "High point air vents cannot eliminate the dissolved air micro bubble that form as the water is heated in the boiler"

I agree 100% with that statement Bob. The problem is that there will be a major repipe job to put the air purger in the proper location as the piping exists now. I was trying to save some time and $$$ by using the internal air scoop (if it even exists on the boiler). That and Airtrol scoops are what we used 50 years ago before the Spirovent was invented. The large volume of water in that area lends itself to very slow water flow compared to the 1-1/4" pipe's flow rate. That slow moving water will allow even small bubbles to float to the top and collect at that tapping. Micro-bubbles… maybe not, but a large percentage of the air will accumulate and be vented out of the system. And over time it will eventually get most of the dissolved air out.

If there is an easy way to solve the air venting problem, I’m all for it. The general idea is to stop the waterfall noise in the piping when the system is operating with a circulator pump. That internal air scoop will do that for them. Andal less cost. Just an old fart's opinion.

If you find an easy way to add the microbubble air remover, go for it. I recommend them strongly from experience. If you want to try the air vent only and see what happens, you can do that too. But @hot_rod is correct on this point. He has the laboratory and real world experience on this one.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Yes, it comes down to if the juice is worth the squeeze

This is where a technician’s skill enters the fix. Can the piping be easily modified?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

We can see what was there before, and why its a problem now. There must be bleeders on the radiators.

I believe that's a 3 pass boiler, so no internal scoop. The pics are too tight to tell. A repipe with good air elimination is in order. Who sized the 007? I know, it came with the boiler.

As far as the bypass, the Hydrostat has a circulator hold off feature that acts as condensate protection. Using that, and the correct circulator, the bypass could probably be closed. It also has a tankless coil, so the low limit shouldn't be lower than 145° anyway, and that would also shut off the circulator so the boiler can build temperature.

The best route with that setup IMO is P/S piping. Let the secondary circulator run constantly on a heat demand, and the primary circulator will cycle with the circulator hold off feature, or low limit.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements