Wood boiler thermostatic mixing valve help

Looking for some advice,

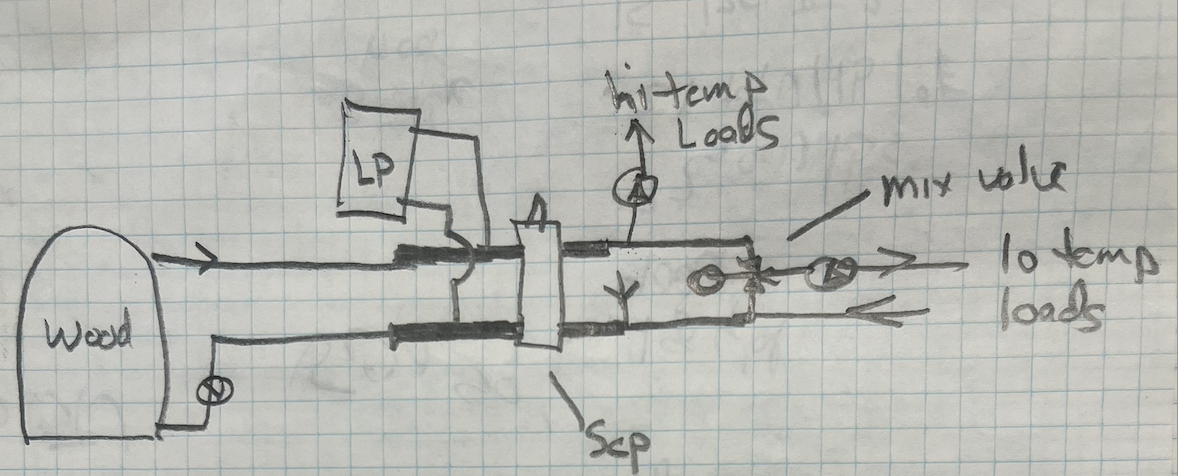

After the help and recommendations I received here, I recently plumbed in a 100 plate heat exchanger behind my indoor wood boiler. The wood boiler is designed for batch burns and is approximately 1800 gallons storage. The design is for a max of 220 degrees at 30 psi. I have a thermostatic mixing valve dictating the supply temp from the wood boiler over to the other side of the room where I have a backup propane boiler (and the brains of the operation) that is designed to kick in when the wood boiler is no longer able to supply 120 degree water.

The way this is working is that anytime there is a call for heat, the propane boiler is firing up and directs nearby pumps to operate. A Relay directs the pump behind the wood boiler to operate to circulate water through the heat exchanger, regardless of if the wood boiler is fired up or not. The required pumps near the propane boiler continue to operate until the wood boiler can no longer supply 120 degrees, and then the pump that draws water over from the wood boiler turns off based on an aquastat direction. The propane boiler fires up each time there is a new call for heat, but once those pumps kick on and brings over hot water from the wood boiler it shuts down once it recognizes it’s getting sufficient hot water.

Overall I’m satisfied with the operation, however this morning when I woke up the temperature on the wood boiler was around 150. I haven’t gotten an exact loss of temp measured yet based on the plate heat exchanger, but I’d bet on 20 degrees (so a supply of 130 if wood boiler temp is 150). Then that water hits the thermostatic mixing valve. The initial supply temp on the boiler is 150 so that aquastat is still allowing water from wood boiler to go. But after the heat exchanger and the thermostatic mixing valve, the temp getting over to the propane boiler is reduced - and this morning I saw the propane boiler fired up for a longer period of time than usual - even though the wood boiler still has 150 degree water in it.

My question pertains to the thermostatic mixing valve behind the wood boiler. Yesterday when the temp was up around 200 on the wood boiler, I actually dialed the thermostatic mixing valve back because it was supplying too hot water over to the propane boiler side and the taco three way mixing valves over there (I actually got flashing warning lights on the taco saying it was getting too hot water to mix). So I dialed it back and it seemed to work fine. This morning however, when the boiler was 150 and after going through the plate heat exchanger - what is that mixing valve going to mix temp wise? It’s always a percentage of what it’s getting through the supply line based on how far I’ve adjusted the thermostatic mixing valve, right ?

What I’d like to do is prolly send between 120-140 degree water over from the wood boiler any time that’s possible. And it should be possible with 150 degree water in the wood boiler, even though it still needs to run through the plate exchanger. But perhaps that mixing valve is now reducing the water to 110, for instance, based on the same setting on the mixing valve I had when the wood boiler was up at 200-220 degrees. Then the propane boiler would need to run to supplement more hot water. BTUs are preserved in the wood boiler that way, and I guess it would supply warm water for a longer period of time, but my goal is to burn as little propane as possible.

a lot of words here to finally get to my question - any ideas on what I’d need to do to maximize efficiency of this system and always send 120-140 degree water over to the propane boiler side with regards to the thermostatic mixing valve? I’m almost thinking I’d need to send a constant temp to the mixing valve from the wood boiler and then make my adjustment on the mixing valve based on that temp?

Comments

-

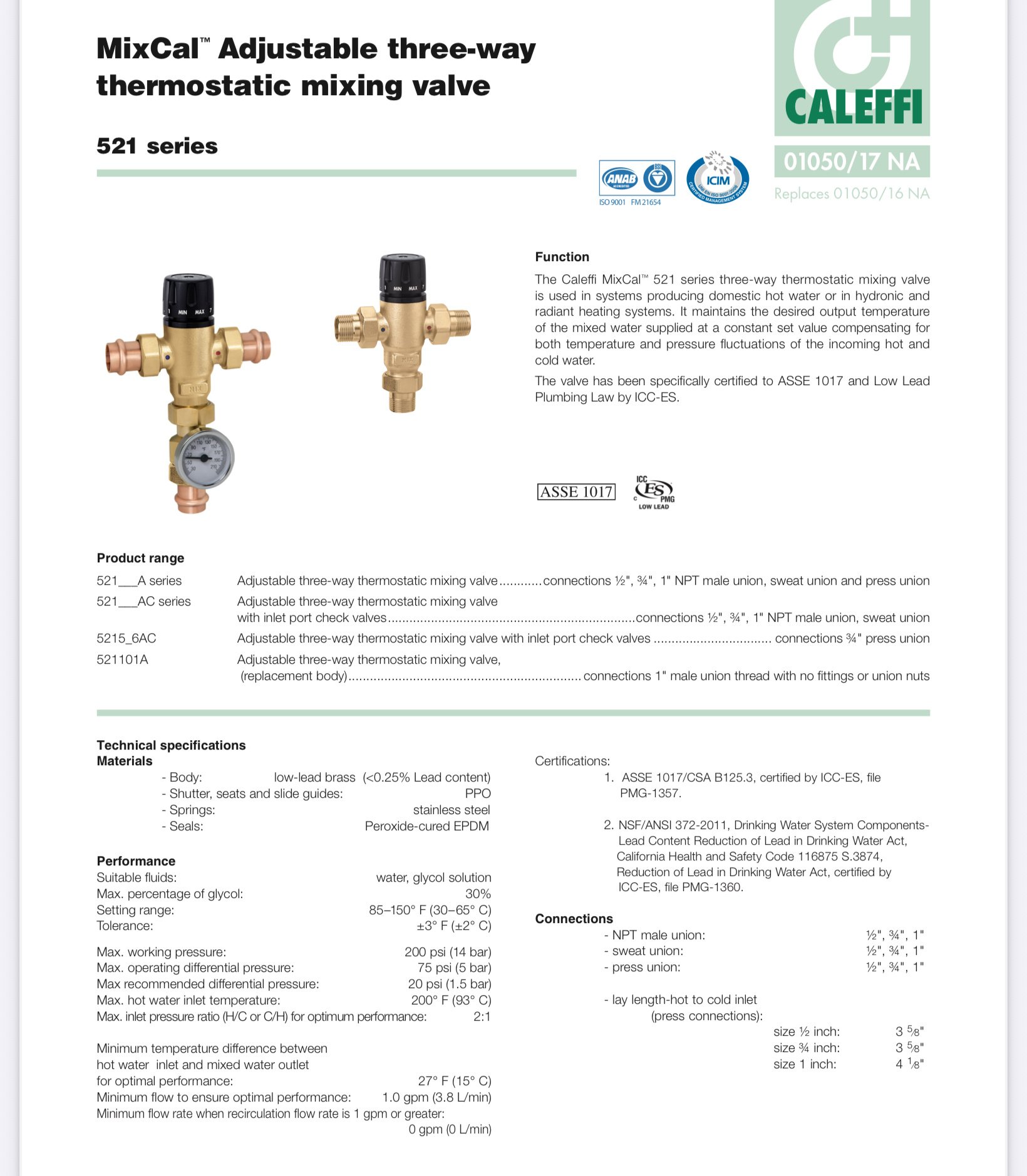

200- 220° is a pretty severe operating condition for a thermostatic mix valve. You might consider a motorized type 3 way. 200F is a common max. temperature for thermostatic valves. Solar rated versions may go to 210°

Most hydronic components are rated to 225° So your pumps, controls, etc are pushing max. operating temperature.

Any reason you can't run the wood boiler at 180° instead of 200- 220° Depending on your altitude you are at the flash point should the pressure on the system drop. Water boils at 208° here in Salt Lake.

To mix down to 150 at the wood boiler that is running 200° you need colder water at the C port. That needs to come back from the system somehow.

Ideally the boilers would be piped so they are hydraulically separated with a primary secondary loop or hydraulic separator. Once the wood falls to the lowest useable temperature, the back up kicks in. No flow goes through the back up from the wood boiler.

It seems like a complicated piping for a simple task? Heat water, circulate to loads.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I don’t really have any way to limit what the wood boiler fires up to. I have a heat dump set up to dump heat after 220. Now that this plate heat exchanger is installed however (with a short loop of 3/4” piping through the wood boiler side of the plate heat exchanger), I sort of doubt that it’d be able to dump the required amount of heat. Before I really get used to the system, im shooting to fire the boiler up to about 200 max (limiting the amount of wood I put in) which would result in about 180 degree water through my 1 1/4” pex lines across the room and to the propane boiler side (where I have a hydraulic separator, etc.)

as far as I’m concerned there is nothing simple about this entire setup… but it’s nice when it’s working…0 -

right now the wood boiler is at 200 and the propane boiler is registering 156 temp (and not fired up). When the wood boiler is down at 150 I might only see 110 temps at the propane boiler (after the wood boiler water has run through the plate exchanger and mixing valve) and I think the propane boiler is needing to fire up at that point to supplement some extra heat). 150 wood boiler water should still be sufficient for all heating demands. If that thermostatic mixing valve were to open up when the wood boiler is down at that temp - I’d still be supplying sufficient water temperatures over to the other side. But since I had it adjusted for the higher wood boiler temps, I believe it’s reducing it too much. I hope I’m making sense and thinking correctly on this.

0 -

All the wiring, relay add on makes me thins someone has struggled with this?

It sounds like you might have way too much wood boiler output for the load? adjusting your burn rate to the actual building load may help, buy that becomes a full time job.

It seems like this mix valve should be able to maintained the adjusted temperature? 150°F?

Where is the sensor that it references?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

yes sir, there are no issues with the Taco three way valves. They are performing as advertised and the sensor is downstream from the supply pumps.

The wiring required quite a bit of thought and some of the relays were required after the plate heat exchanger , which was unfortunately installed after Switzer came out and hooked up his boiler.

There is a pump behind his boiler that was originally just used to circulate water when his wood boiler was firing. After installing the plate heat exchanger we were able to plumb it so that the same pump could be utilized to circulate water through the heat exchanger even when his boiler wasn’t firing, so when there was a call for heat we’d get water circulating through the heat exchanger. Quite a few relays to make this setup work.

I guess my question is whether the thermostatic mixing valve on the back of the boiler simply gives a set percentage of the wood boiler supply temp it’s receiving after going through the plate exchanger, or it actually measures temperature somehow and tries to maintain a set temp? I’d like to be able to get sufficient heated supply water over across the room from the wood boiler when the wood boiler temp is lower ie 150 degrees or less. I would think that I could still get 130 degree water (sufficient) over to the propane boiler when I have 150 wood boiler water. I need to confirm, but I’m thinking I’m only getting about 110 or so to the propane boiler side when the wood boiler is at lower temps, and I’m attributing this to having the same setting on the thermostatic mixing valve at 200 degrees to when it is at lower wood boiler temps.

0 -

If you're referring to the V135 mixer in the first picture, it will always maintain a given setpoint regardless of incoming water temp- that is where the "thermostatic" part comes in. Whether supply from the wood boiler is 120 or 220, setting the valve at 120 with one or the other will always keep it right there. If it is piped wrong, it will do as you describe. Is the only circulator that's moving through that valve on the mixed side pulling through it, or is there a circulator pushing toward either the hot or cold ports holding them closed?

0 -

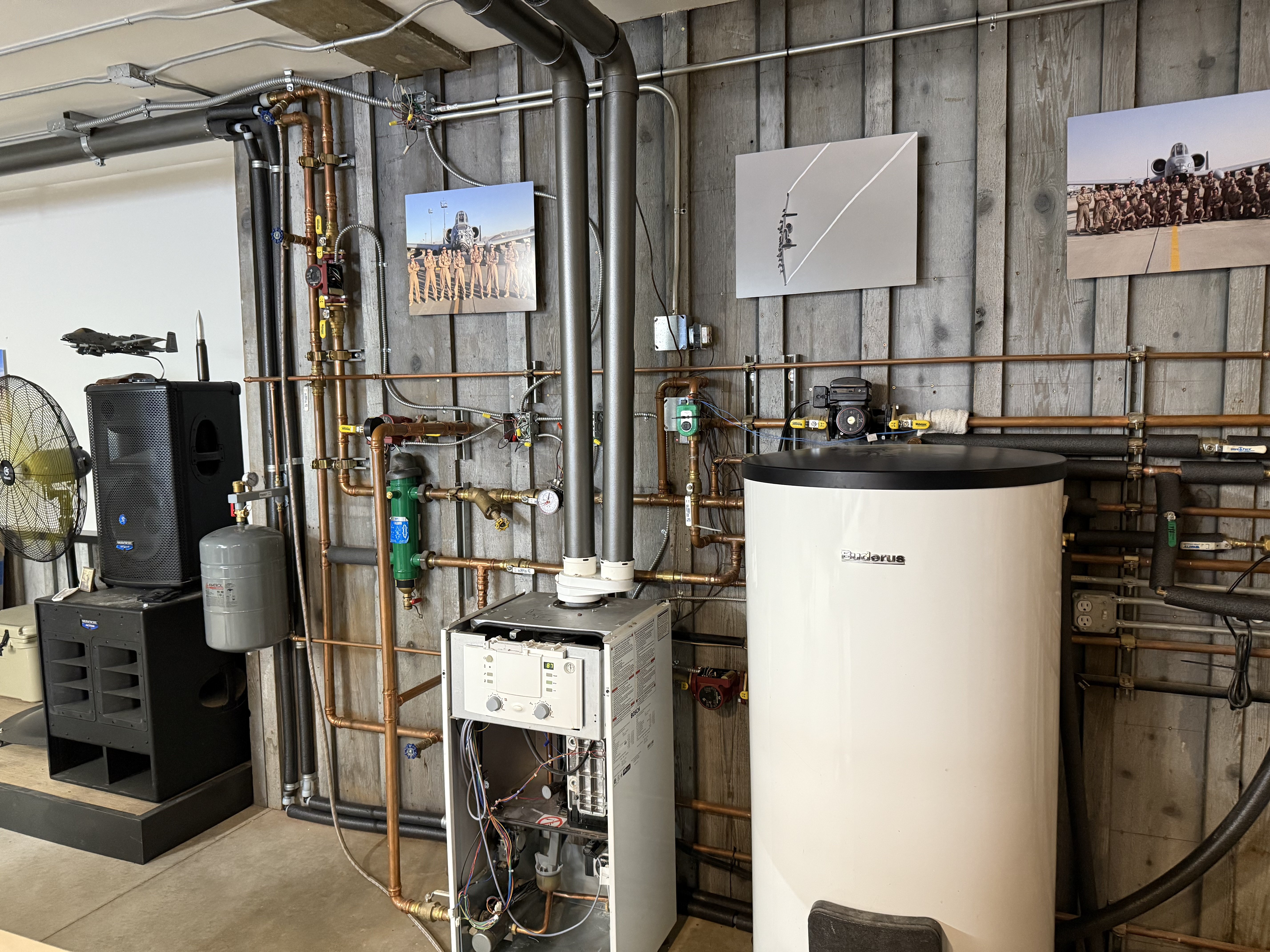

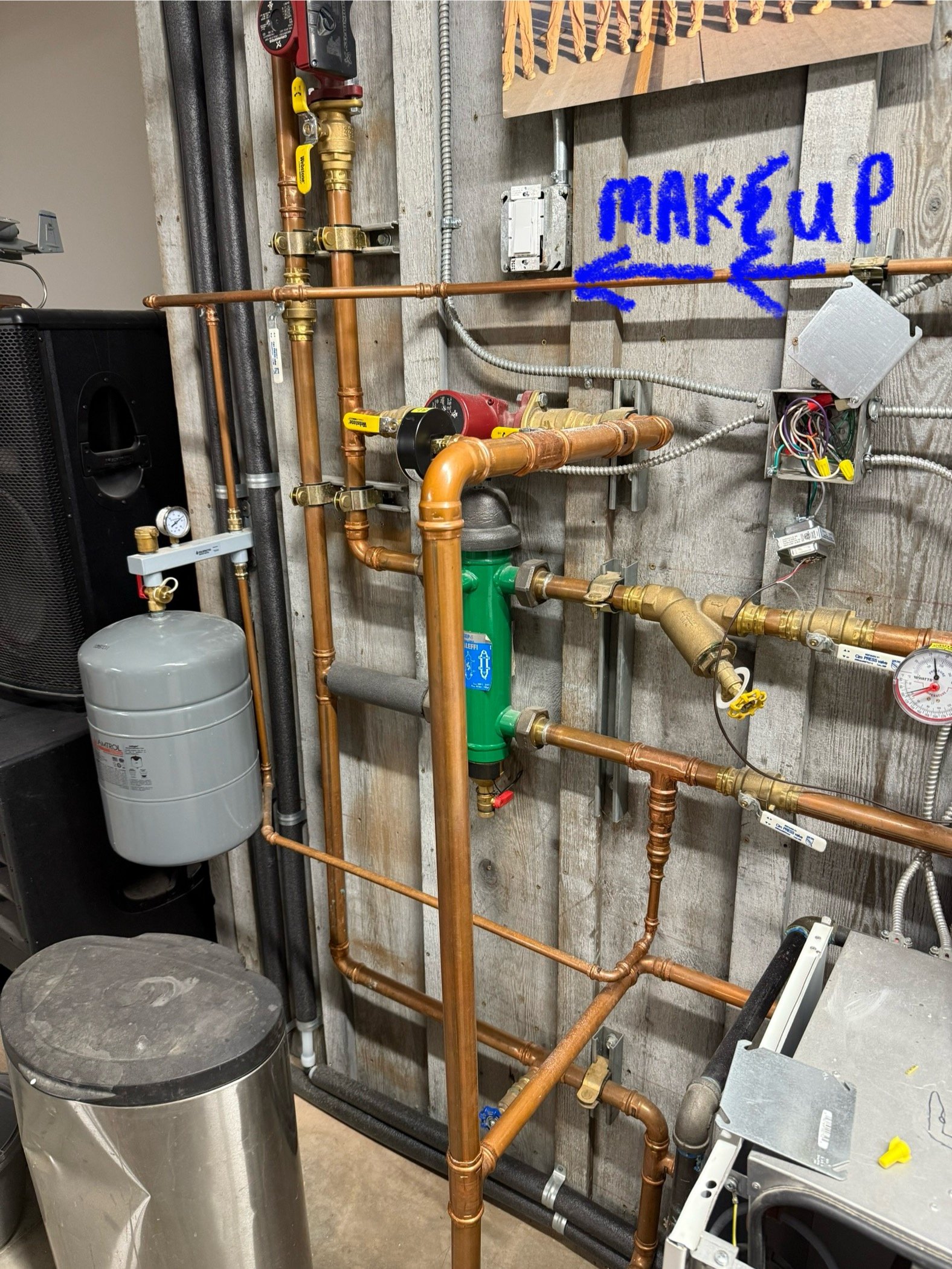

@GroundUpBottom line up front: the pump is pulling water through the thermostatic mixing valve and across the room to the propane boiler. Attached doc’d up pics for reference.

The circulator pump behind the wood boiler is only being used to circulate the hot wood boiler water through that side of the plate heat exchanger.

The return 1 1/4” pex lines with water that has run through the zones and floors comes back behind the wood boiler and T’s. It can either go one way to be mixed into the thermostatic mixing valve; or it can go the other way to run through the plate heat exchanger.

The upper left pump in the second picture kicks on when there is a call for heat and at least 120 degree water is satisfied by the wood boiler. It pulls the water back after it’s run through the thermostatic mixing valve.

The propane boiler temp gauge is still registering high 150’s without firing up. I should be able to dial that thermostatic mixing valve down to show a reading of about 130 over at the propane boiler, and theoretically the thermostatic mixing valve will strive to reach that - letting completely hot water in and not allowing any cold to mix in , when the wood boiler supply is lower?

I really need to put some black tape over the copper piping and see what sort of efficiency or heat loss I’m getting with that heat exchanger.

it’s been piped with a reduction from 1 1/4” wood boiler side down to 3/4” in order to utilize existing recirc pump behind the wood boiler. I did this in order to avoid replumbing entire thing and having the requirement for a separate pump. I figured with a short loop of 3/4” it would push plenty of water through that one side of heat exchanger. Both sides of the heat exchanger get very hot - but I haven’t gotten to measure exact temps yet.

thanks again0 -

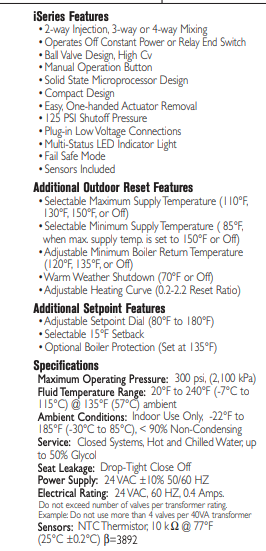

thermostatic mix valves need some temperature differential to regulate properly. Depending on the brand and model it could be as low as 10-12, some require 25-27 degrees.

So basically if you want to blend to 150, the supply to the hot needs to be 170, maybe 177 on some versions

Or if there is no source of 120 degree water on the cold port from the other system, the valve will not mix. some thermostatic valves can shut one or the other port off nearly 100%. These are the scald protection type, usually an ASSE 1070 listed valve.

If supply drops to 155, 160 the valve looses its ability to keep its setpoint. The valve starts to. “Hunt” temperature falls off, sometimes overshoots, possibly it is just right, but it never settles in.

In addition the valve has a minimum flow rate required to mix properly. The larger the valve higher the minimum gpm.

Lastly the pressure differential needs to be within 20 psi typically, between hot and cold, that is more of a DHW issue, however.

An example spec sheet here. Lower left column shows the spec for this mixer.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

@hot_rod I know that some valves do require a significant differential as you mentioned, but we have discussed many times before and I will say again now, that Honeywell/Resideo valves do not fall under that category. This V135 that the OP is using is something that I use with nearly every wood boiler job between 4 and 8 GPM, and can say with absolute certainty that if it is set at 120* using a 180* inlet, it will still supply exactly 120* outlet with a 120-125* inlet when sized and piped correctly. Same goes for any/all of the AM-1/AMX series valves, at least every one I have ever seen anyway which is probably upward of 100 now.

0 -

@Sukhoi29SU sorry I'm having a really hard time seeing and understanding what's going on with the piping. Assuming that upper left circ is what's pulling from the V135 in the other picture, that all looks correct. However it also appears that behind the gas boiler, there may be a crossover between the load side and the source side of the hydraulic separator, potentially creating some pressure against the cold side of the V135. I may be seeing it wrong, but it is something to dig further into.

0 -

Really appreciate all of the help - you both have offered a lot of information over the years that has really helped me out.

the system is working so much better than it was when I first had this thing installed by some guys that didn’t know what was going on and/or simply didn’t care how it turned out. Fortunately I’m just down to some small tweaks at this point.

I think I’ll throw some black tape on some of these copper pipes and measure the temps I’m getting out of the heat exchanger and over near the propane boiler post thermostatic mixing valve at various wood boiler temps. It’s nice to read that the thermostatic mixing valve works that way. I’m impressed that such a small valve with a plastic cap for adjustment is capable of doing such.

0 -

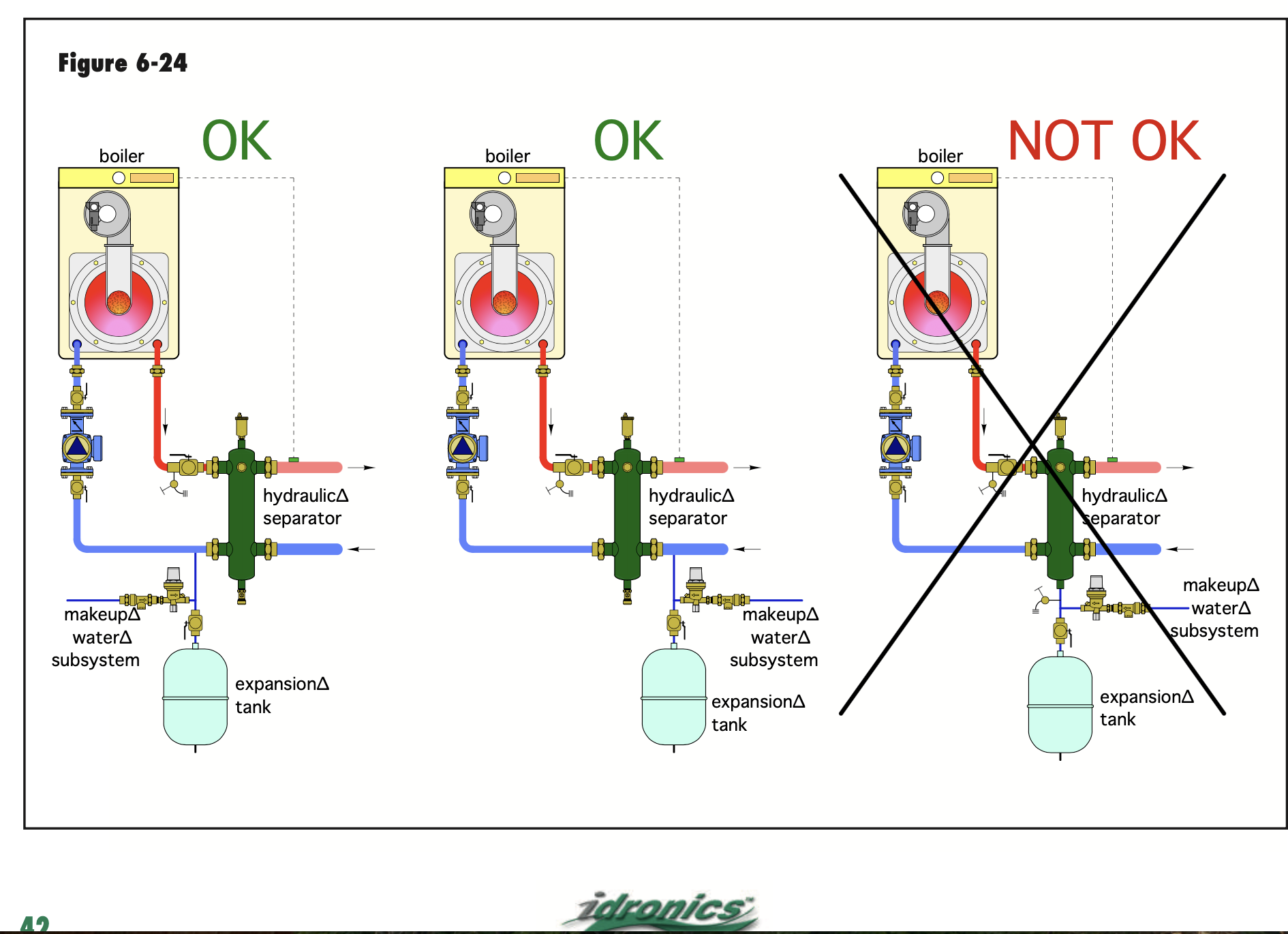

Here are the expansion tank connection suggestions.

The tank could also connect at either of the top Sep connections.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

it looks like I have the second ‘ok’ picture plumbed. I did close off the valve to makeup water and am monitoring pressure. It seemed when I opened the valve to the makeup water that it was getting the propane boiler pressure right up to 30psi and when the wood boiler brought hot water over I was concerned it would trigger the pressure relief valve. It seems to be holding pressure in the green.

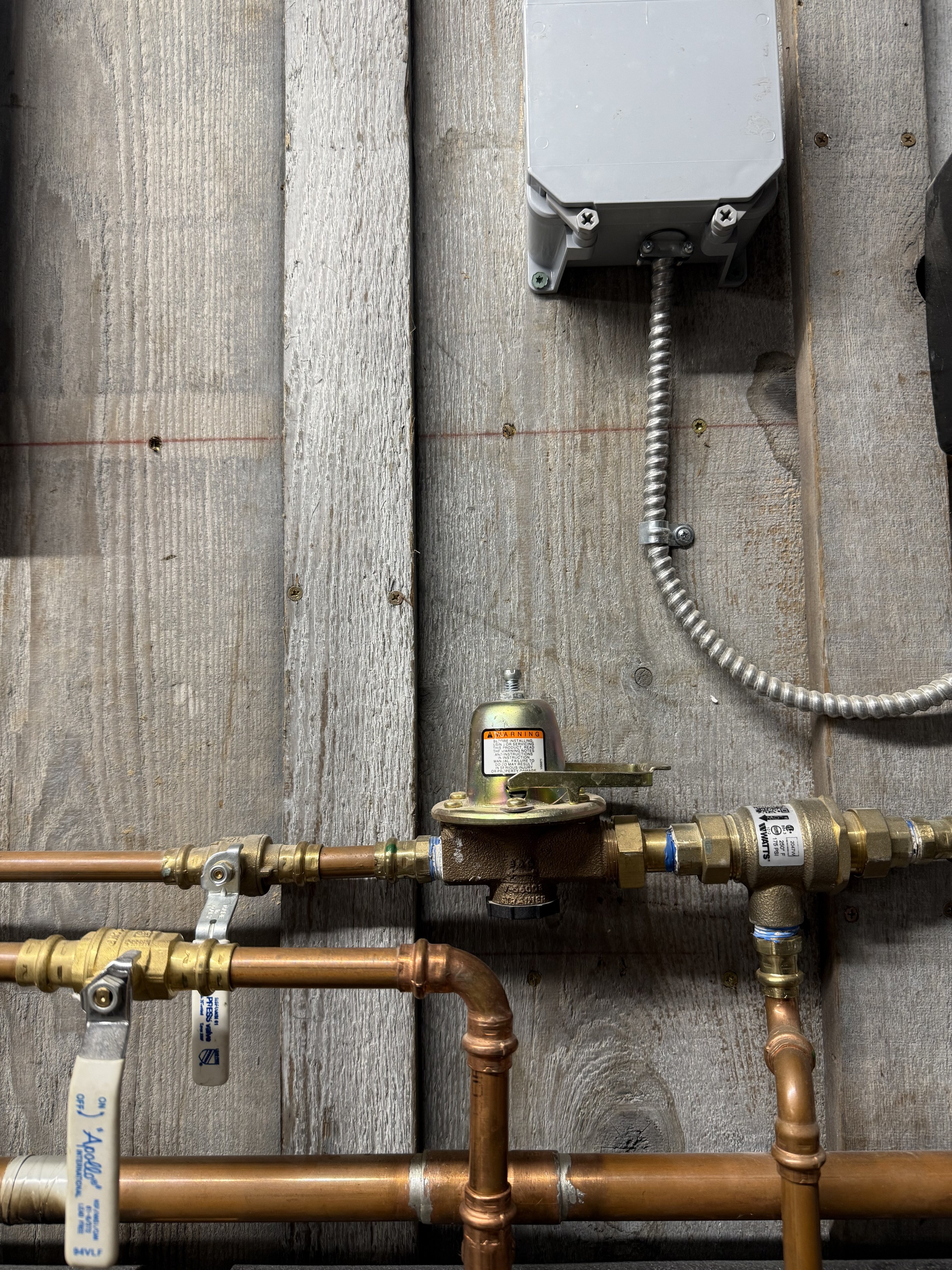

I was considering adjusting the screw in the top of the pressure valve in second picture to reduce the overall pressure of water entering the system? Would I tighten or loosen? Maybe I’d want to set that for 22psi or something rather than 30? 30 is at the top of the green arc on the boiler temp gauge. The pressure on the other side is 70PSI connected to a constant pressure well system.0 -

12- 15 psi is adequate. If you raise fill pressure the expansion tank pre-charge pressure should be adjusted also.

Tanks are usually shipped with a 12 psi charge, but it is always wise to check that.

Loosen the lock nut and CCW on the slotted bolt, to lower pressure.

These hybrid systems can get piping complex!

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

yes sir, there is a lot going on here. 5 manifolds 11 zones, wood and propane boilers with DHW and radiant. Relays and pumps galore.

I think it could have been a lot more simple and cheaper, but I’m enjoying it for now.

I’m glad to at least understand what’s going on in each pipe and pump, now. It’s intimidating to look at and as a result I’ve had a lot of trouble finding local help with it. Thankfully there’s this website…0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements