What type of steam system do I have?

This is my 2nd winter in a 113 yr old house in southeast PA and my first experience with steam heat. The heating system is functional but I'd like to learn more about it and plan for repairs and maintenance. I got the boiler flushed after we moved in as it had been sitting for a year with the sight glass completely opaque. The autofeeder was passing water flooding the boiler so I turned it off and do weekly checks on water level. I also replaced both main vents. The boilers is about 13 yrs old but the header is done wrong. The steam pipes are uninsulated. I plan to tackle both this winter.

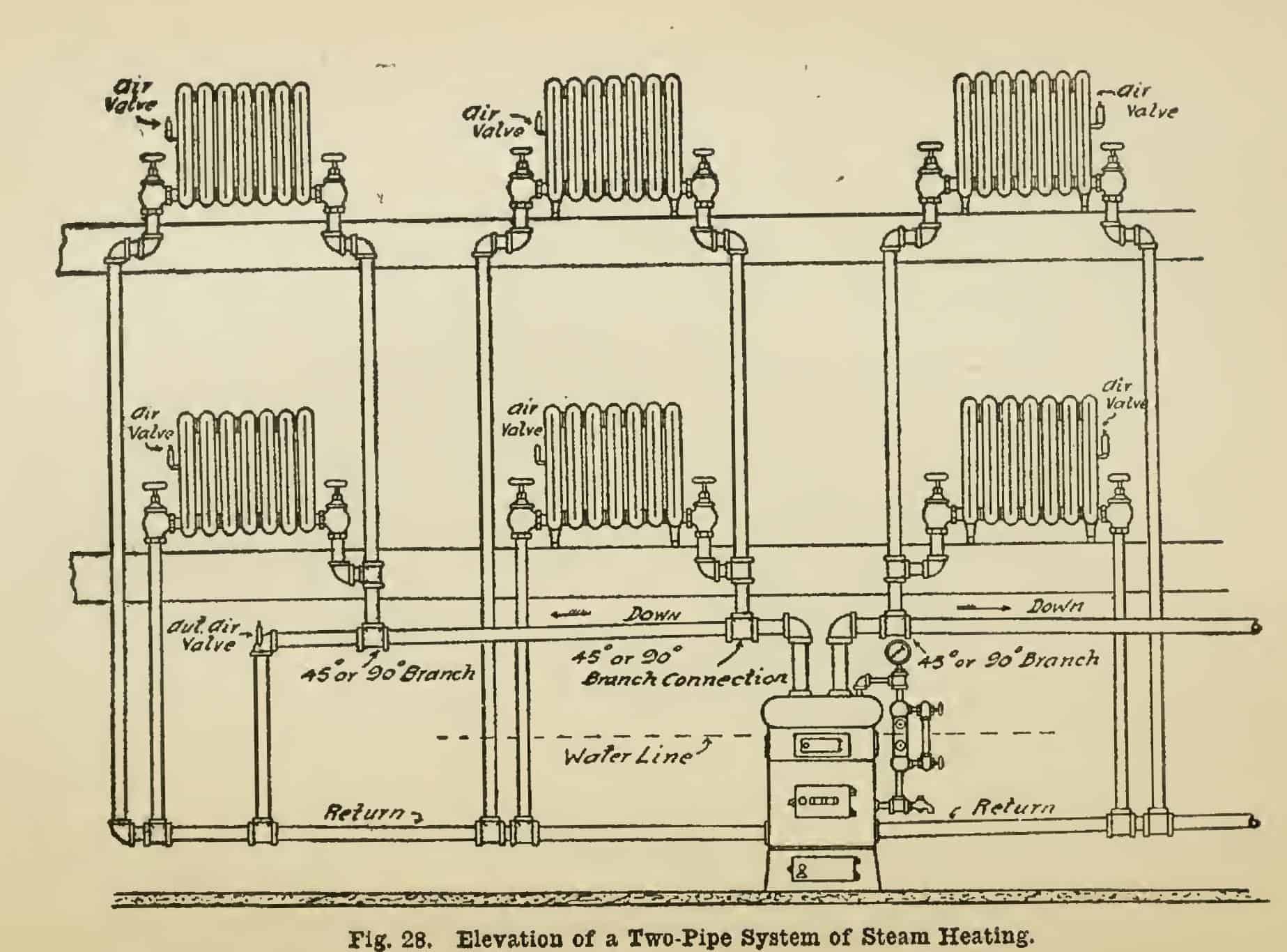

Posting a picture of a typical radiator in my house. It has pipes on both ends and a steam vent as well. Is this a single pipe or a 2 pipe system? I'd posted this in the Radiant Heat section instead of the Steam section accidentally.

Here are some additional pictures from the basement that shows the

Boiler with (incorrectly configured and copper) header.

Main Vent (one of 2)

Another radiator with inlet and outlet pipes as well as an air vent. Followed by picture of the pipes connected to it in the basement.

Comments

-

Two pipe system. Could be a system with orifices in the supply valves. Can't see all the returns. Do all the radiator returns individually drop into the wet return that runs around the basement below the boiler water line?

It looks like a two pipe air vent with a wet return. If it runs quiet with no water hammer I would fix the header in the spring.

If you look up the boiler model # on Weil McLain's web site you can download the manual with the header piping diagram

1 -

@cd1 , in the last pic, are the pipes coming down the wall connected to the radiator return elbows?

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Tough to take a picture of all the returns but this is a picture that shows a section of the wet return with radiator drops.

If this is a 2 pipe system, why would the radiators have a vent but no steam trap? There are about 20 radiators, all with vents(of varying make/model).

@Steamhead Does this picture help answer your question as well??

0 -

Are those inline steam traps on the radiator drops?

0 -

It is 2 pipe air vent. The air gets out through the radiator vents and the condensate drops individually from each radiator through the return to the wet return.

That return needs to be below the water line because the water in the return keeps the steam from blowing through the radiator and in to the return.

I don't think those devices, not sure if they are steam traps or check valves, belong on the wet return. If that went return is above or close to the water line with the new boiler it may have been a misguided attempt to fix that.

In addition to the order of the connections and the copper at the boiler, the 2 mains should come individually down in to the header, they shouldn't be teed together at the ceiling.

1 -

-

@cd1 yes, and as long as that main radiator return is below the boiler's waterline, the check valves are not needed.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

-

-

so I went back and the check valves/in-line steam traps are only on a few return legs on a portion of the wet return that seems to be done with copper more recently. The rest of the wet return is cast iron. I guess I’ll never know why since the previous owner has passed away.

I’m still hoping to figure out why a 2 pipe system would have air vents on each radiator.

0 -

Normally 2 pipe steam has the radiator return connected to a dry return above the water line with no standing water in it so that the air can vent through it and out through a vent on the return. This type of 2 pipe also needs radiator steam traps or orifice plates or a metering valve so the steam in the radiator can't get in to the return. Since this system can vent through the return it doesn't need radiator vents.

In your system the radiator return is connected to a wet return below the water line so that the water blocks the passage of air out of the radiator. This allows the condensate from the radiator to return to the boiler but it does not allow the radiator to vent air so that steam can get in. this is where the radiator vent comes in. it allows the air out of the radiator directly so that steam can get in to the radiator. The water in the wet return also keeps steam from passing out of the radiator and in to the returns so your system doesn't need steam traps(or orifice plates or metering valves) on the radiators because the water seal keeps the steam out of the returns.

1 -

The wet return in your system was partially replaced with copper because black iron wet returns eventually rust out because they are full of water all the time. the steam traps being added were some form of knuckle heading by someone that didn't understand the system.

The water line in modern boilers is much lower than in old coal boilers. It is possible the new boiler has brought that return below the water line which would cause steam to be in the returns. The steam traps may have been a misguided attempt at fixing that. the correct way to fix it is to use a pipe loop to create a false water line that is above that return. this may have been a problem with an older boiler or insane pressuretrol settings and isn't currently a problem.

0 -

-

I have seen that type of system before and they work fine.

Call it 2 pipe air vent with a wet return

Call it a 1 pipe with a separate return

Call it whatever you want they work fine.

I have never seen a picture in a book with a name for that system. But it is a simple system with little to fail. No orifice, no steam trap needed or to fail. The water level seals each radiator from one another.

You do have to keep the steam pressure low or the water will back up into the radiation and flood it and you will get no heat and water in the air vents which will stop the venting.

Maybe someone put check valves on for that issue, but they will do nothing to solve it.

One of the jobs I remember that had this system was in Springfield, MA at Smith & Wesson in the guard house building and it was a constant issue.

The guard house was cold because it was under radiated and had leaking windows and doors and 1940s concrete construction. Plus, the doors were constantly being opened and closed by the constant stream of visitors and guards and truck drivers going in and out.

When they complained to maintenance it was cold they would go over and jack the pressure control. Then they got 0 heat because the radiation was waterlogged. I would go over shut the boiler down. Re adjust the pressure control , knock the water out of the air vents and start it up. Put a nasty note on the pressure control and leave………didn't do any good.

Every time I went there I had visions of who passed through those doors like Elmer Keith or Bill Jordan.

Now, after being in and around Springfield for 150 years they had issues with the MA. gun laws and moved to TN. At least part of it.

2 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements