Boiler Protection with 3-way valve?

Hi everyone!

Learning more about boiler protection for my CG 8 cast-iron boiler.

I finally understood the concept of the minimum temperature needed to prevent condensation and the reason why my boiler control (TekMar 256) is managing this and the boiler is short cycling a bit in mild-weather to maintain this 140 degree minimum YET the building is too hot and consuming unnessary gas to provide this protection.

I learned here on these forums (thanks @Boilerpro_3, @Jeffrey A. Knichel and others) that a Danfoss ESBE Thermic By-pass Valve could help with this situation.

Would this be a solution for my applciation?

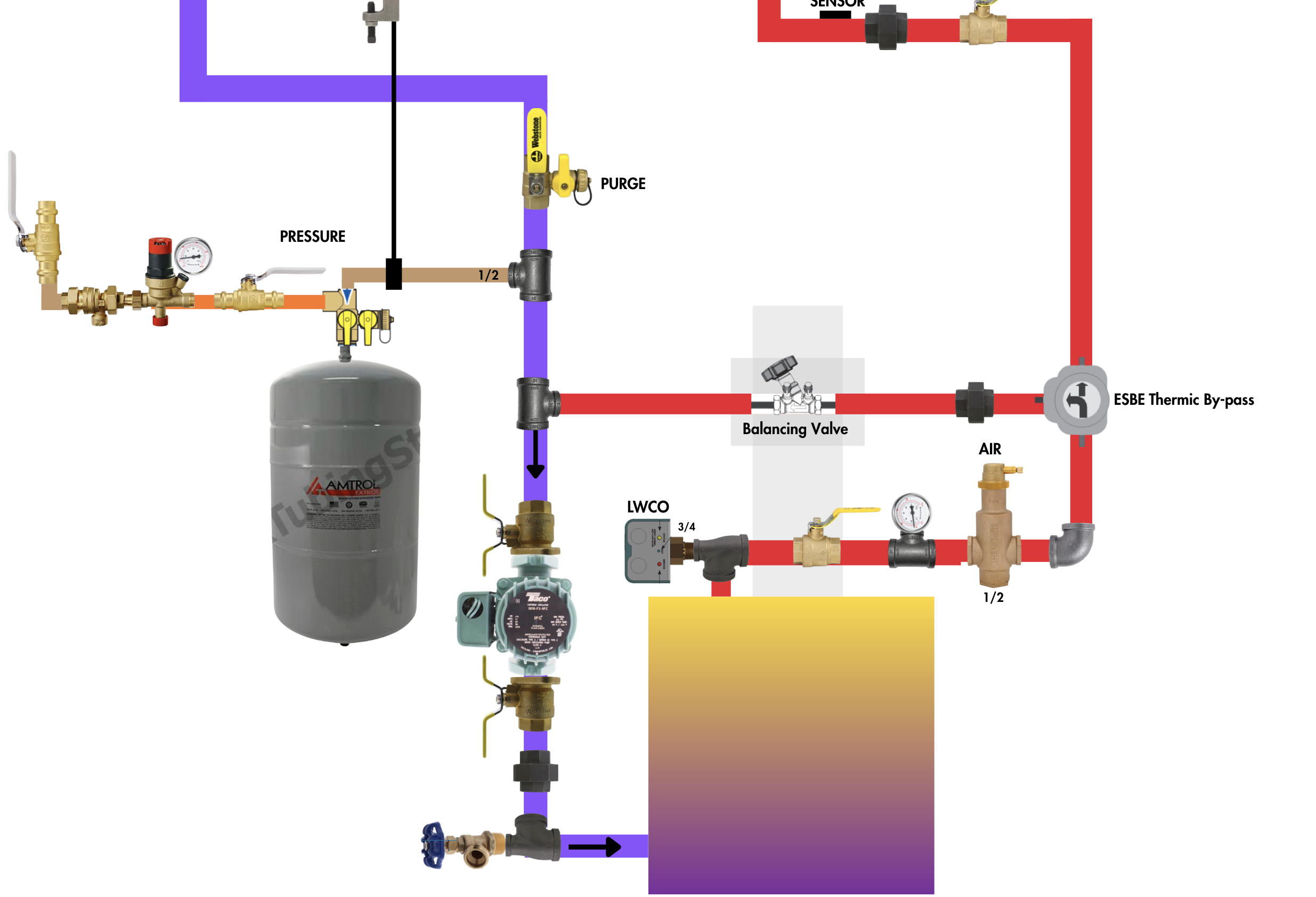

Do I have this arrangement correct?

Thanks for any help!

Nicholas

Comments

-

I'm a bit biased working for Caleffi, but the 280 is an excellent valve for boiler protection. High Cv, union connections, temperature gauge wells, multiple temperature sensors available.

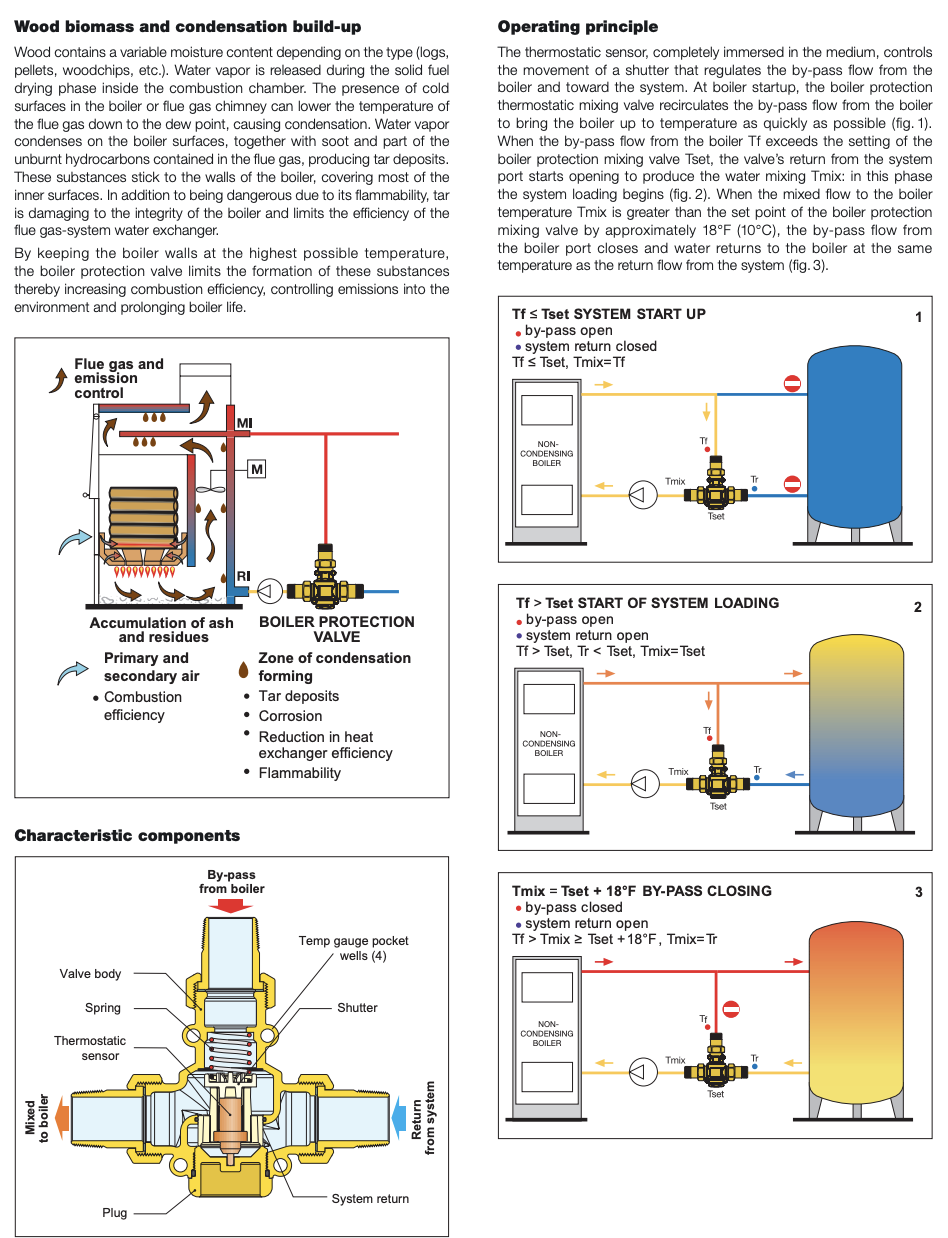

We sell many of these around the world. They are standard equipment on most wood fired and pellet fired equipment to prevent cold operation which leads to creosote formation. So the manual talks about that type of equipment.

Regardless if you use a valve or electronic solution, the boiler needs to operate to maintain that temperature.

But with a protection valve, shut the boiler off, after the heat call cold start will lengthen cycles and boost boiler efficiency compared to short, under 10 minute cycles.

The type of heat emitters matters, copper fin tube rarely need boiler protection.

Cast rads or large high water content, like gravity conversions, really need protection.

Combining zones helps eliminate shoulder season short cycling. But zoning is a selling feature of hydronics :) catch 22.

In mild conditions it will be hard to eliminate short cycles without maybe tricking the boiler with a anti cycle timer for example. Holding the boiler off when there is a call for heat has some consequences. Comfort might be higher on your list that absolute energy savings?

These are all the challenges with fixed output boilers facing a very wide, dynamic heat load throughout the season.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

Thank you @hot_rod .

Yes, fin-tube heat emmiters. Yes, this is the mild season a bit and 140 degrees is plenty warm enough with outside temps in the mid 40's - yet still need to heat the building. I guess I was trying to mitigate the TekMar keeping the boiler at 140 when the building doesnt need the heat. There is no call for heat currently. Just the boiler is on, with contacnt circualtion and the Tekmar keeping the temp up to mitigate condensation.

Basically trying to tame the horsepower of the CG8! I guess the lowest "setting" of 140 degrees for the boiler is still to warm and will just need to accept the loss of $$ in the mild season?

Once colder weather arrives, true call for heat will be made and temps above 140 will be realized?

Would you explain why I woudn't need a bypass for fin tubed?

Thank you!

0 -

yes you are battling a very common occurrence. Over-sized or grossly over-sized boilers make it a no win endeavor.

Boiler block or SWT needs to be above 140F to get return to at least 130. Weil seems comfortable with 130 RWT.

What you may find it the boiler cycles off before return gets warm enough.

Or the heat call goes away before reaching adequate temperature.

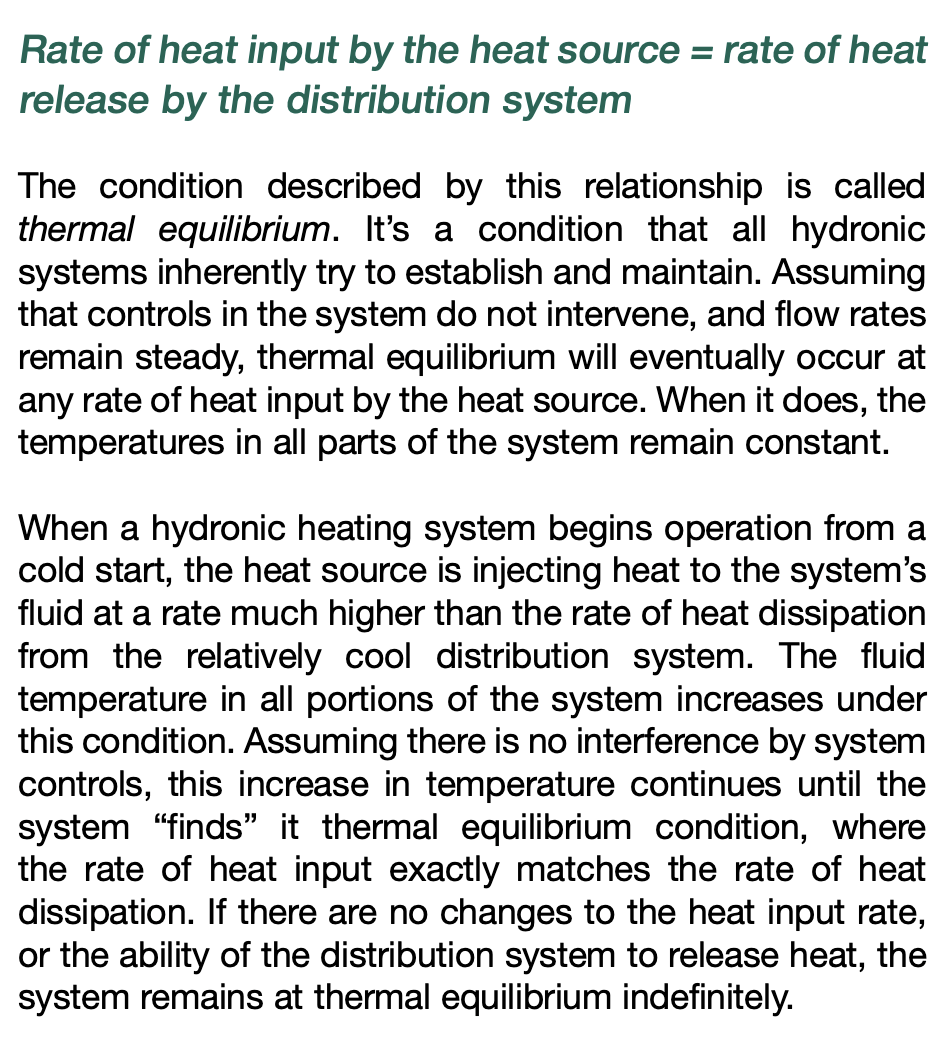

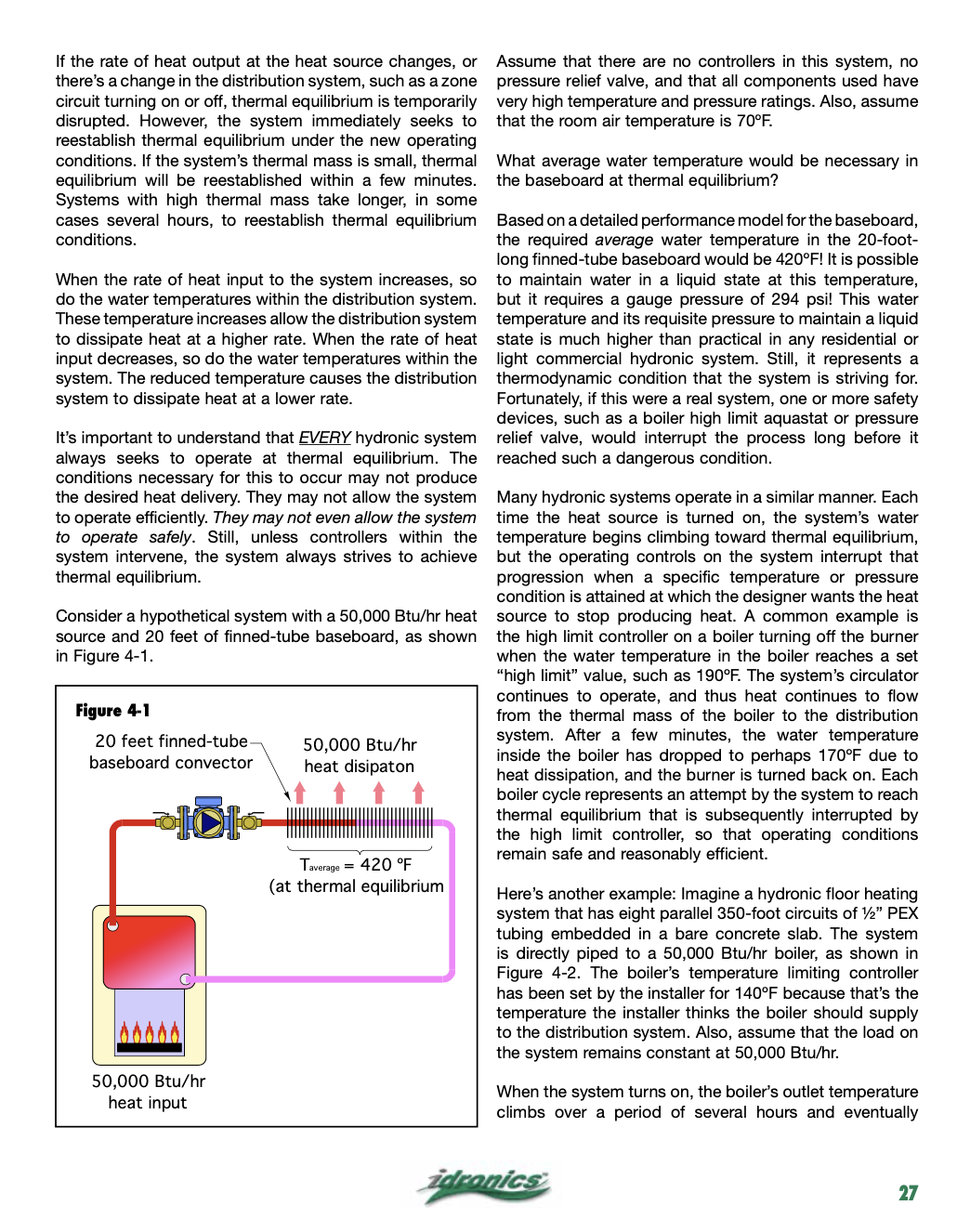

ALL systems strive to reach thermal equilibrium, more about that here. It you are still "always learning"

Or a shortened version

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Thank you, @hot_rod . Yes, always learning! In my case, am I a bit stuck with this scenario with an oversized boiler?

Yestrday in Cincinnati we had an abnormal mild day (high 40's to low 50's). Eventually, due to the outdoor reset setting on the Tekmar 256, the boiler cooled. Inside temps were fine. In the evening., the outdoor temp dropped, eventually triggering the firing of the boiler. The water temp before firing was around 73 degrees. Is this the condition that condensation of flue gasses / heating block danger occurs?

Or is this when the heating block is hot and the return water is cool?

Thank you!

0 -

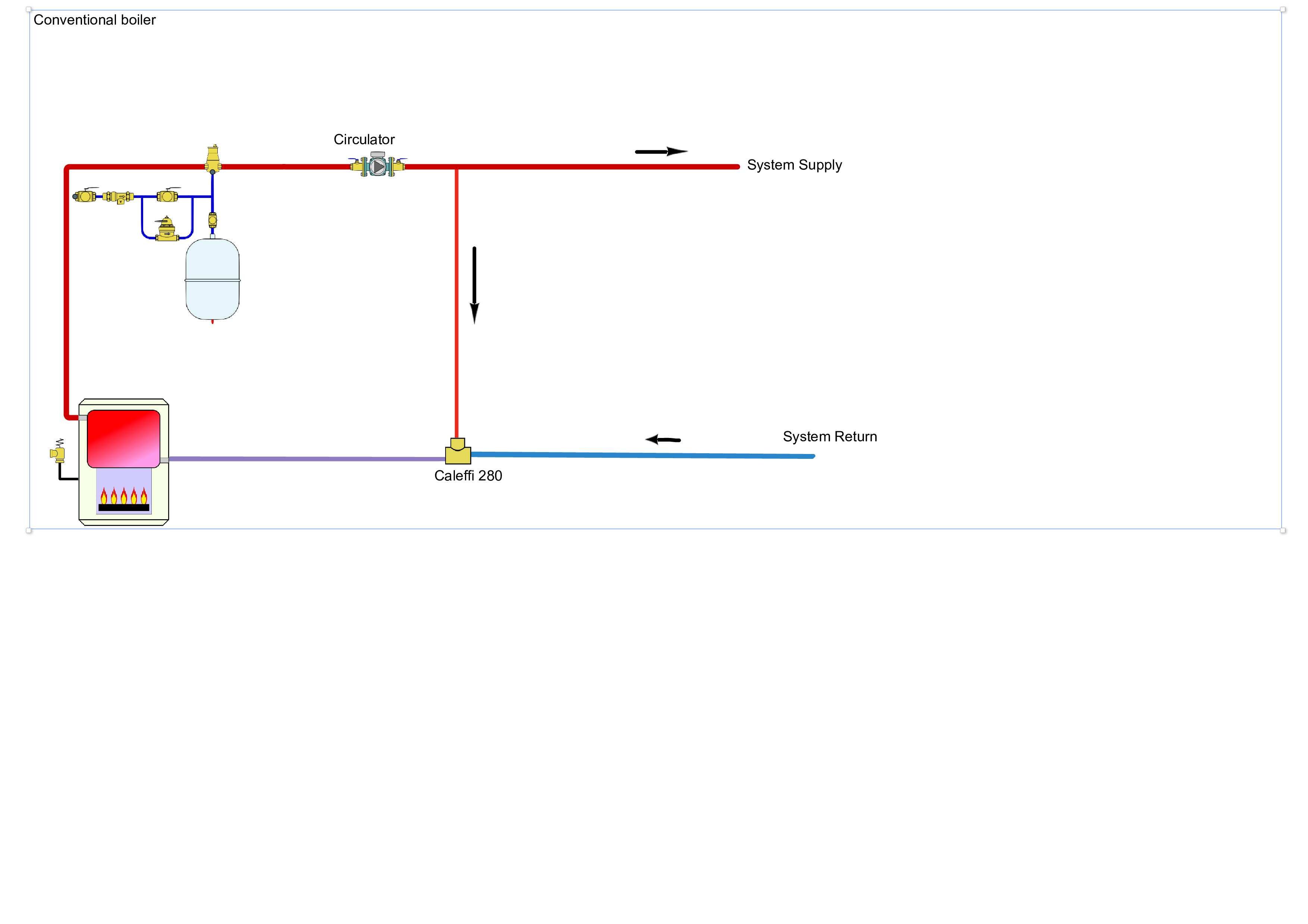

@AlwaysLearning2024 - I installed a Caleffi 280 mixing valve and have been very happy with its performance. This is on a Burnham ES27 which is a cast iron boiler.

But I installed mine on the return side, not the supply side, so that I could be assured that the minimum return water temperature was sufficiently high. I suppose the same effect could be achieved if the temperature drop though the system is known and consistent.

I can't speak to efficiency gains (I also installed an ODR) but I take comfort in knowing that I don't have to worry about condensation from low temperature return water. My setup seems to work fine during all phases of the heating season.

Eric Peterson

1 -

thank you @EricPeterson .

are goi able to share a photo or drawing of the piping for your setup. I’m very curious.

Do you have fin tube heat emitters ?

Thanks!

0 -

@AlwaysLearning2024 - My setup is all cast iron rads, lots of water, in a converted gravity system. So it would take a long time to heat all the water in the system to the minimum return temperature (110F according to Burnham). The Caleffi 115F thermostat element does the trick.

I will work on a drawing or photo.One other difference is that I have the circulator, air separator, water feed, and compression tank all on the supply side of the system (pumping away). Also three zone valves. A bit surprised that no one else mentioned "pumping away".

Eric

0 -

@AlwaysLearning2024 - is your diagram one you created, or something you got somewhere else?

If you created it, what program did you use?

Eric

0 -

Generally WWSD warm weather shut down on the ODR is 68°. So if a call for heat come in, even with outdoor 40- 50 the boiler should fire.

What we like to see is the return to the boiler getting up to 130° within 10 minutes or so.

However on a low load, mild day the boiler may not even need to run 10 minutes to catch up with a low load condition.

So, yes that return temperature could still be low, the rooms all satisfied and the boiler turns off. There is not an easy fix for small, tiny loads on a fixed output boiler.

It is always the case the the distribution, the heat emitters are in control of the boilers operating condition. We interface limits and operating controls to prevent the boiler from operating at unsafe conditions.

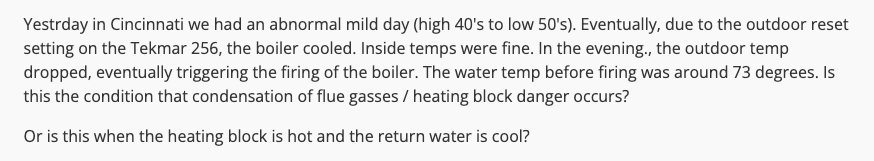

A boiler return valve would just bypass a portion, maybe all the boiler output back to the boiler until it reaches the protection valves temperature, let say 130. Then it starts allowing flow to the distribution. So the boiler always protects itself first, then starts slipping flow to the system. Obviously the boiler needs to runabove 130 to return 130. So the tekmar setting needs to accomodate that.

.

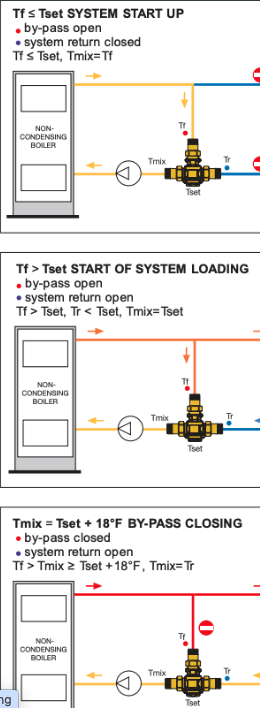

One typical control strategy is, thermostat calls on zone pump or circulator via a relay box. The relay box sends power to the tekmar #7&9 to wake up. It looks at OD and will fire if below the WWSD. With the 256 the boiler loop pump wire through the aquastat control on the boiler itself. There is no boiler pump connection on the 256. Where did you locate the sensor that is connected to #1 &3?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Thank you, @hot_rod .

I have a universal sensor strapped to the supply pipe and connected to terminal #1 and #3 COM.

There is no external thermostat. Just the 256 with the ODR sensor and supply pipe sensor.

The boiler demand is jumped to function in a permanent function.

0 -

-

Yes, pump is running all the time.

0 -

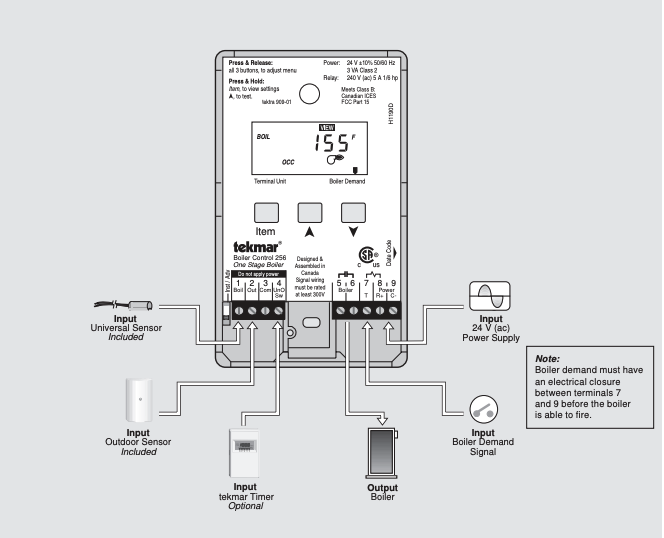

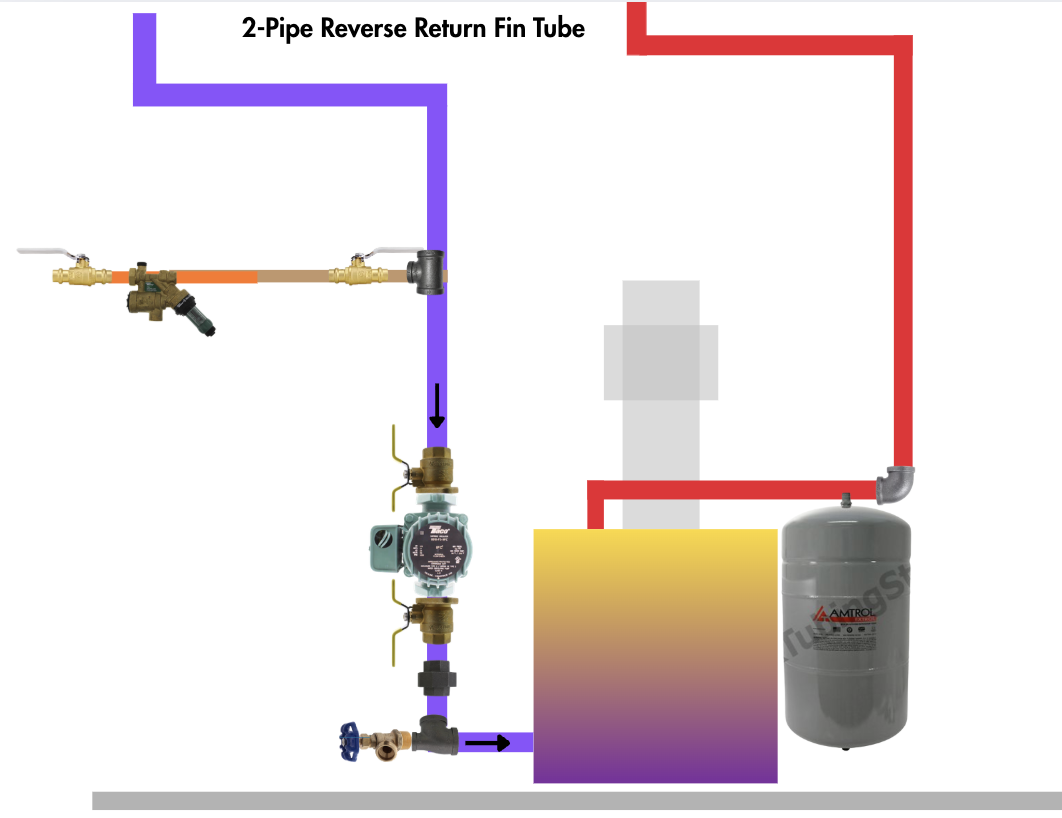

So the system is piped like this drawing, now?

If not, you really don't need a boiler protection valve on low mass fin tube, especially with and over-sized boiler.

I think the concern should be more about short cycling with the over-sized boiler?

If you have multiple zones I would use an Alpha pump or add a bypass valve.

The circ pump should only run when you need flow to the fin tube.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Sorry for the confusion, @hot_rod.

No, the diagram above was simply a suggestion to add a mixing valve to mitigate short cycling nad protect the boiler.

This image is the current configuration controlled by the 256.

0 -

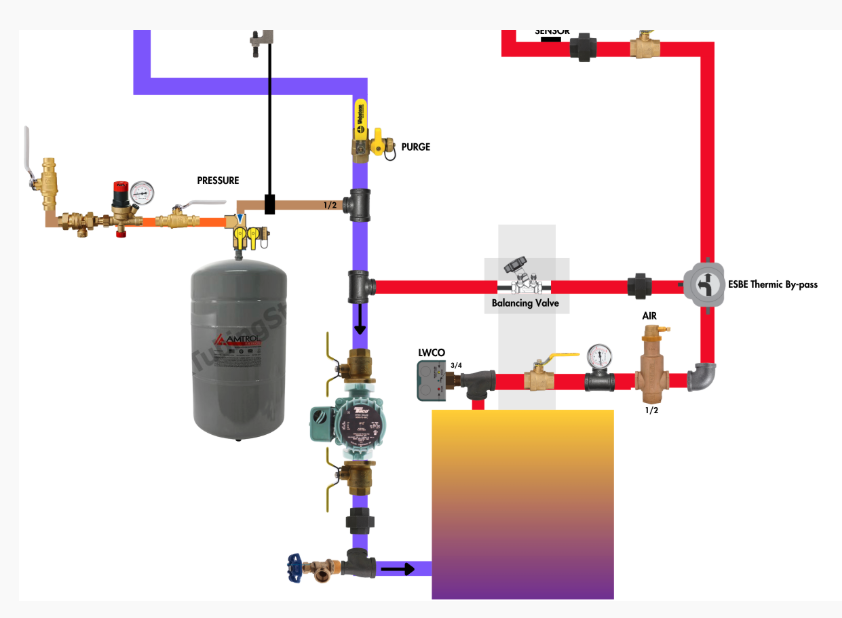

@AlwaysLearning2024 - I created a simple diagram. I have a compression tank rather than an expansion tank, and I left off all the isolation valves as well as some piping I did to bypass the Caleffi (in case it stopped working). But it shows the basic operation, which is very simple.

On cold start the water is in a tight loop through the boiler and the valve. The valve is closed to return water initially, which also means that on the supply side the water does not flow to the system (there is nowhere for that water to go).

As the valve gradually opens, it mixes in cold return water with hot supply water, which also allows some supply water to flow to the system. It continues mixing until the return temperature reaches 115F at which time the valve opens completely and no water is circulating through the tight loop.

I have observed some pump whine when the valve is closed (tight loop) but that was mainly when using an NRF-22 circulator. After switching to a Grundfoss ALPHA 15-58FR there is still some pump noise but it's better than the NRF-22.

—Eric

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements