High Excess Air on Vintage Boiler

Hello Friends,

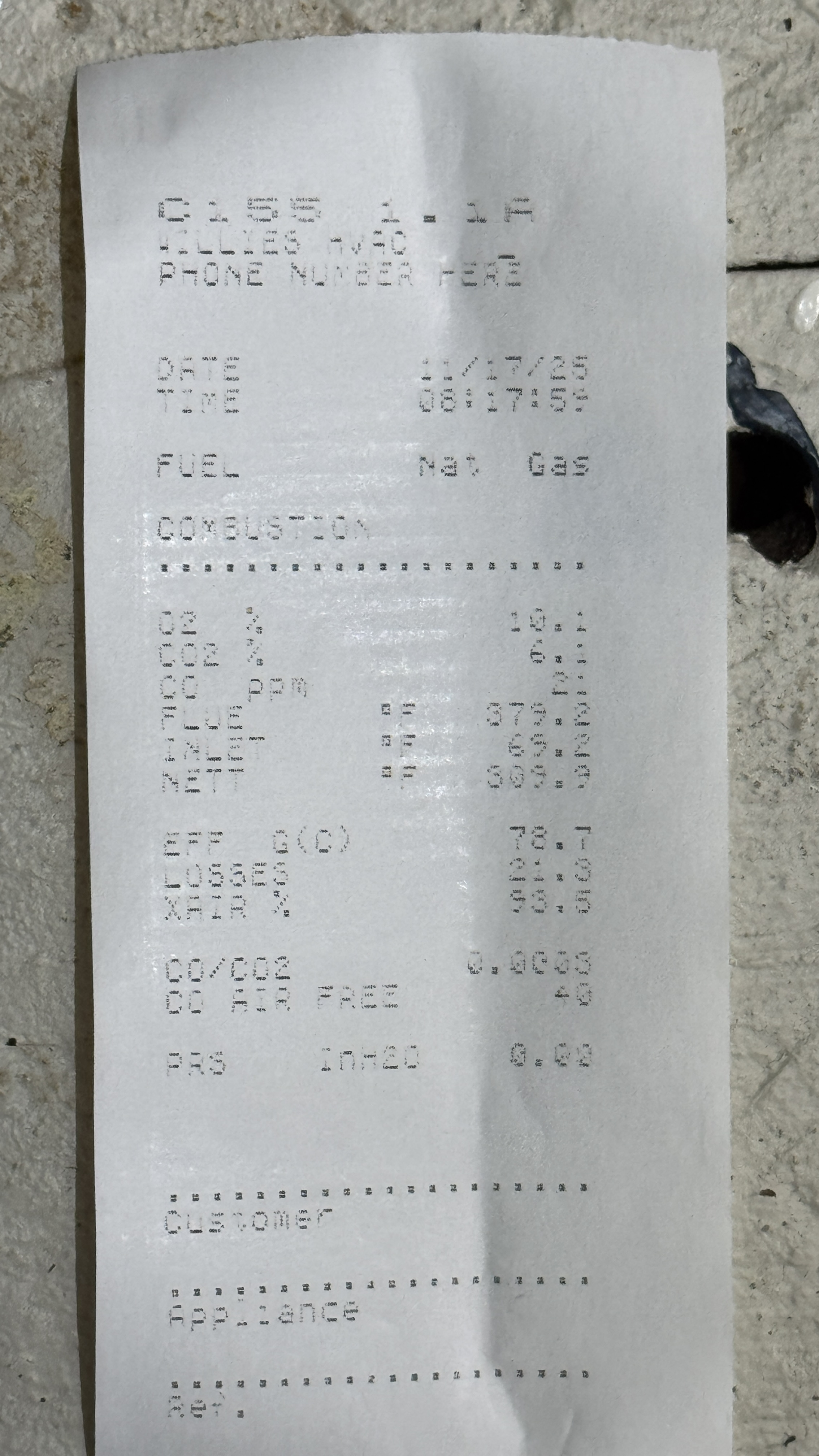

Another heating season is upon us and come the new year, it will mark the 89th heating season my No. 7 Ideal Boiler has heated my 1909 built house (system is still 100% gravity hot water). It was installed as an upgrade by the original owner, owner 2 lived with it for 60 years, and now I’m approaching 3 years with it. I have my own combustion analyzer and I test this beauty every month during the heating season just to make sure everything is on the up and up. I am having no heating issues and stats come back decent (for an 88 year old boiler) except for high excess air. Which I understand from Google means heated air traveling up the chimney. This has always been high from day one when I first tested it back in April 2024.

My questions for the experts here:

-Is this “bad” for a vintage boiler (coal converted to gas) compared to a modern day gas cast iron boiler to have such high excess air? (93.5%) See pictures/video link down below*

-Is there anything I can do to get this number down lower?

-Maybe the air vents are open too wide on the atmospheric burners?

-Is this a “just leave well enough alone” type situations due to age and the system operating without fail?

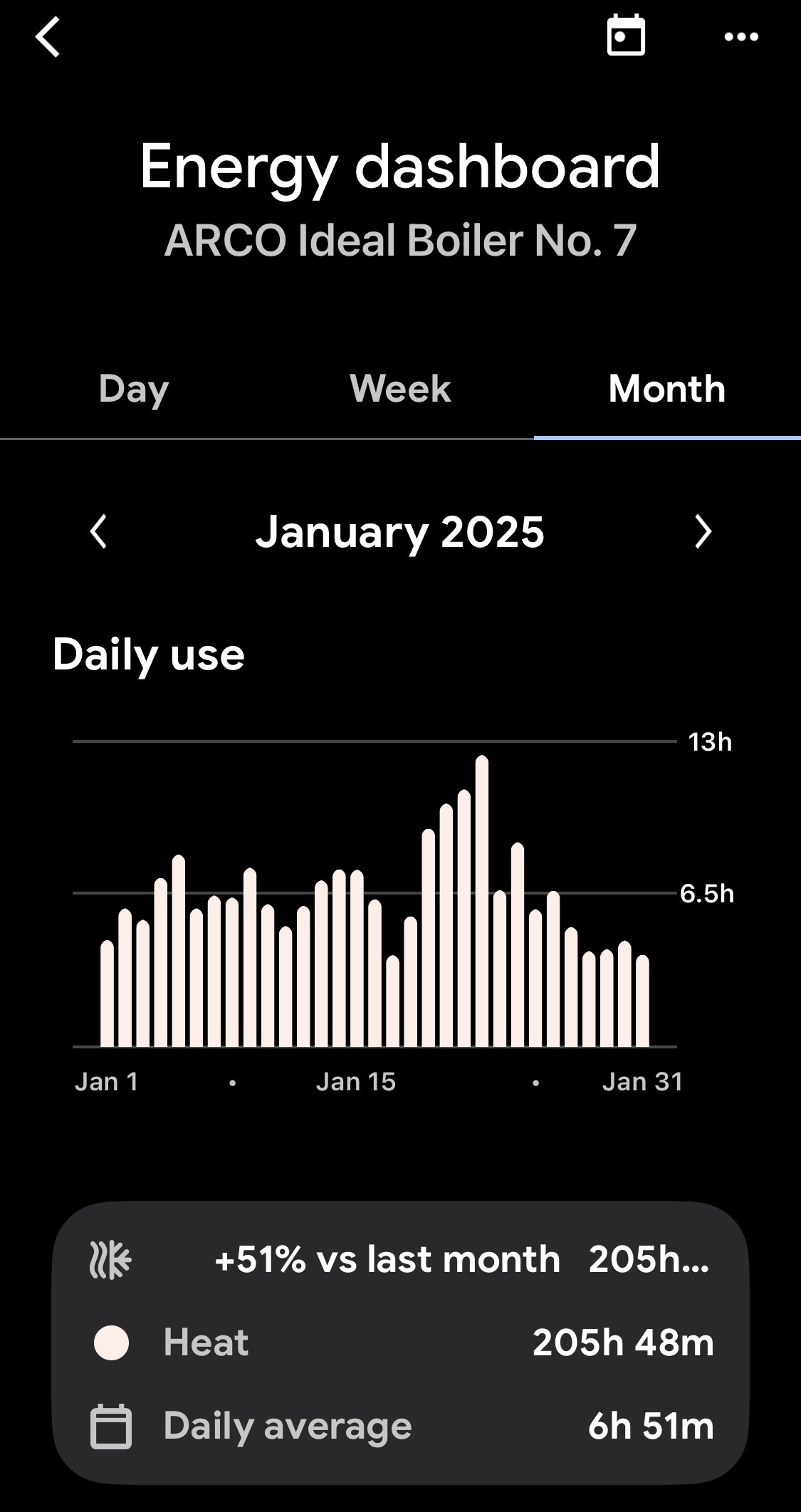

This is all anecdotal info and I claim no scientific measures here, but my usage and operating costs are more than manageable. My highest gas bill living in my home has been $258 (Jan 15th-Feb 15th 2025 bill, 30.7 MCF) and that’s during the coldest month/polar vortex and that’s shared with my fireplace (used regularly), water heater, and stove. Talking with previous owner (she’s 91 and sharp as a tack) tells me her 60 years in the house she never had ridiculously high heating bills either (and that’s with raising 5 daughters in the house). People assume I must have $600 heating bills but that simply isn’t the case. My home is insulated very well, attic, walls, and basement rim/floor joists. Except for extreme cold weather days, my boiler typically only has to run twice in a 24 hr period (morning cycle 4am 72°, and evening cycle 4pm 72°). My set back temp is 65°.

fyi - anything seen in photos were done by deadmen so please allow grace that I may not be able to answer any follow up “why is that install like that?” type questions.

I appreciate any insights! Thank you all for your time and expertise.

-Willie, (located in central Michigan)

Smart thermostat: Google Nest

See video of the beast operating here:

Lifelong Michigander

-Willie

Comments

-

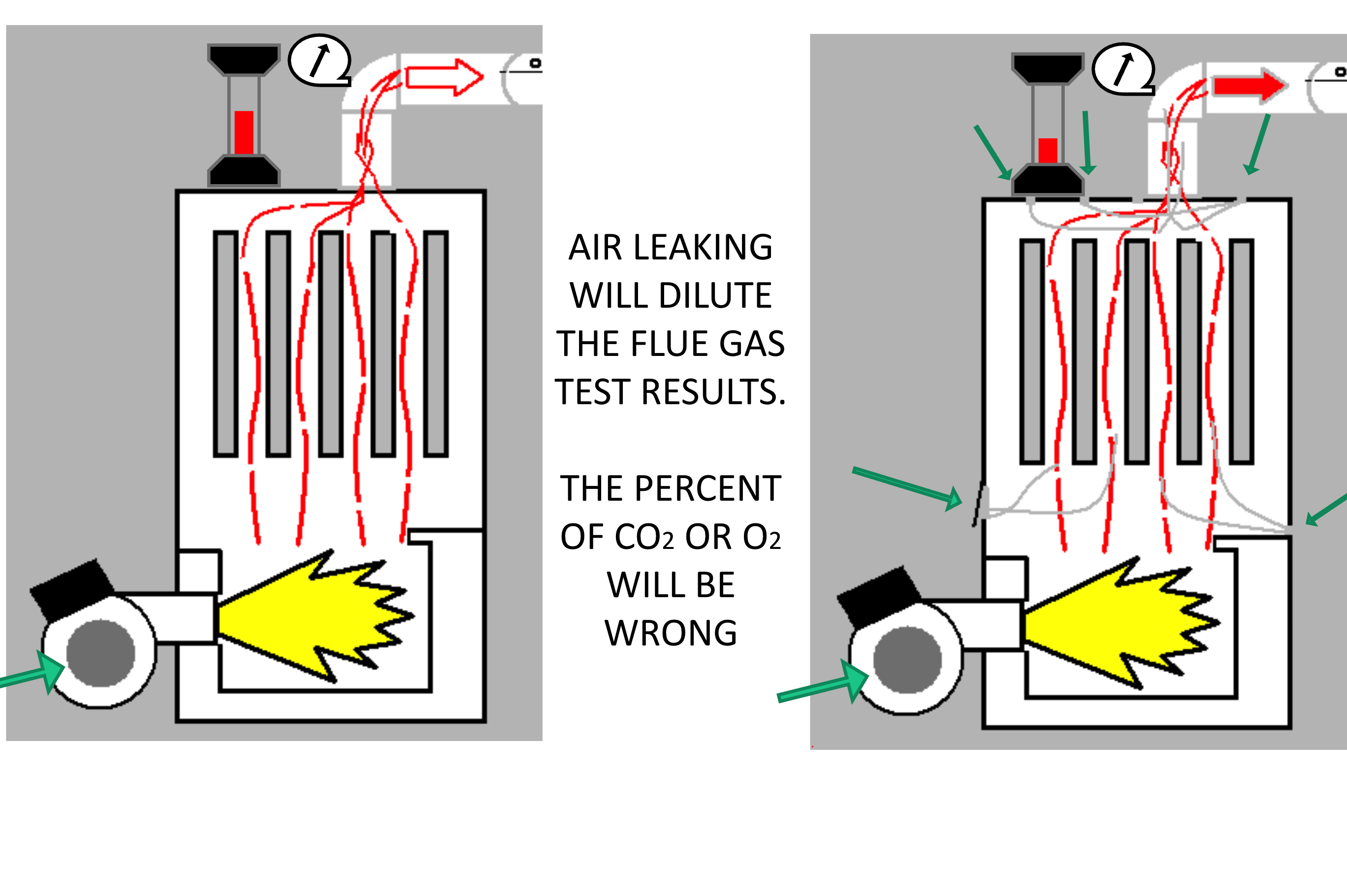

Excess air that is measured at the vent connector may not actually be a byproduct of combustion but air infiltration from the cleanout door and the fire door (fire door if it were coal fired). there are no gaskets or seals on those doors and after 90 years of heating and cooling off the connection may actually be somewhat leaky. This illustration of a combustion test I used in my one day oil burner seminar illustrates how leakage will change the actual numbers

Your combustion analyzer assumes that all the air that is measured in the flue gas sample came from the combustion air inlet of the burners. that there are no leaks in the heat exchanger so the only "air" in the connector pipe is byproducts of combustion like the illustration on the left (Green Arrow). I have a feeling that your boiler may actually be more like the illustration on the right with some leakage thru the fire door, clean-out door, and some leaks between the boiler sections from asbestos gaskets that have gone away over the years. (Many green arrows)

By measuring that additional air from all those gasket leaks your excess air may not be all combustion byproducts, but infiltration air mixed with combustion byproducts.

To test my theory prop the draft regulator open full to reduce the draft thru the boiler. This may actually allow combustion byproducts to leak out those gaskets. Take your test when that barometric is fully open and see if the excess air is reduced. This was a procedure we used to obtain the higher efficiency readings after we modernized an old coal boiler or furnace with a new Carlin or Riello, to show the higher efficiency of the new burner.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

-

-

309 net stack temp will keep your efficiency up even when combustion efficiency is not great. That is a good stack temp.

Boiler looks in remarkable good shape.

You could be leaking some air into the boiler but I would suspect the old burner is just not mixing the gas and air as well as it could..

Your CO is pretty low so I would try closing the air down very slightly. Marke or measure where the air shutters are set before adjusting so you can put it back to where it is if you have to. Make small adjustments at a time.

You want to keep the Co under 50 in the stack and a CO2 of 8% would be great. I could see you getting it to 80% efficiency.

Have you ever removed and cleaned the burners?

1 -

I have not because honestly I can't figure how to get them out and once again I'm dealing with deadmen's great work. They don't really twist out like they do with more modern burners. God forbid the thing cracks. And HVAC companies in my area are hit miss for willing to work on my boiler sadly. One company would not even change out the thermocouple. They just wanted to sell me a new boiler. It's actually why I became so versed on my boiler and bought my own testing equipment (and taught myself how to change a thermocouple with help from Youtube).

Lifelong Michigander

-Willie

3 -

-

I think there is also a damper between the vertical vent and the draft hood (or is that a barometric damper that I can't quite see how it works) that can be moved to affect the draft through the appliance.

You have to break either the main union or the 3 unions and take off that plate to remove the burners I think.

Those cocks on each burner adjust the firing rate of each burner.

Even for someone that really has a lot of experience adjusting combustion this looks like it is pretty complex.

0 -

@TheUpNorthState88 Said: "

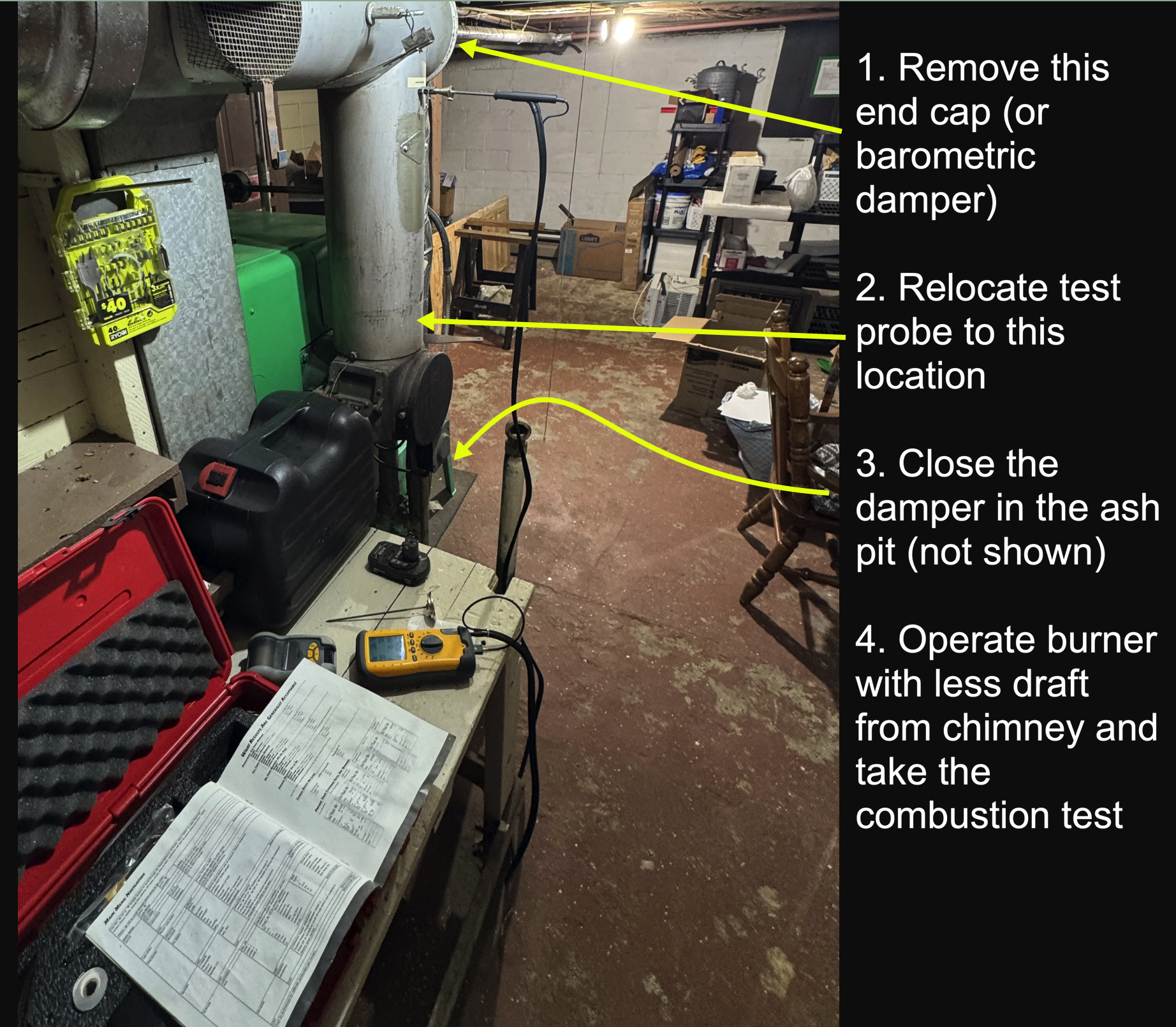

I will give that all a try this weekend when I have some time to play around with things."To get the draft thru the boiler to the minimum for a new combustion test take these 4 steps:

After taking a closer look, I can't tell if #1 is a cap or a barometric installed incorrectly, but removing it so most of the chimney draft will come from the basement will reduce the air movement thru the boiler heat exchanger and any leaks will become neutral or may even push combustion byproducts out any leaks in the seams. You will not want to do this for hours, just enough time to get the combustion test completed. If you start to get a headache, you have operated the burner this way too long. Ask me how I know?

EDIT: keep an eye on the flame and the analyzer. if the flame turns yellow ot the analyzer shows the CO getting above 100 PPM shut the burner down right away. Your draft thru the boiler adjustments have gone too far. You need to put some things back as they were. Maybe starting with the ash-pit damper being opened a little.

What ever the case, you will want put everything back as you found it once you have made the test. The leaking air infiltrating into the flue gas does not make your flame any less efficient. It only makes the test results incorrect.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

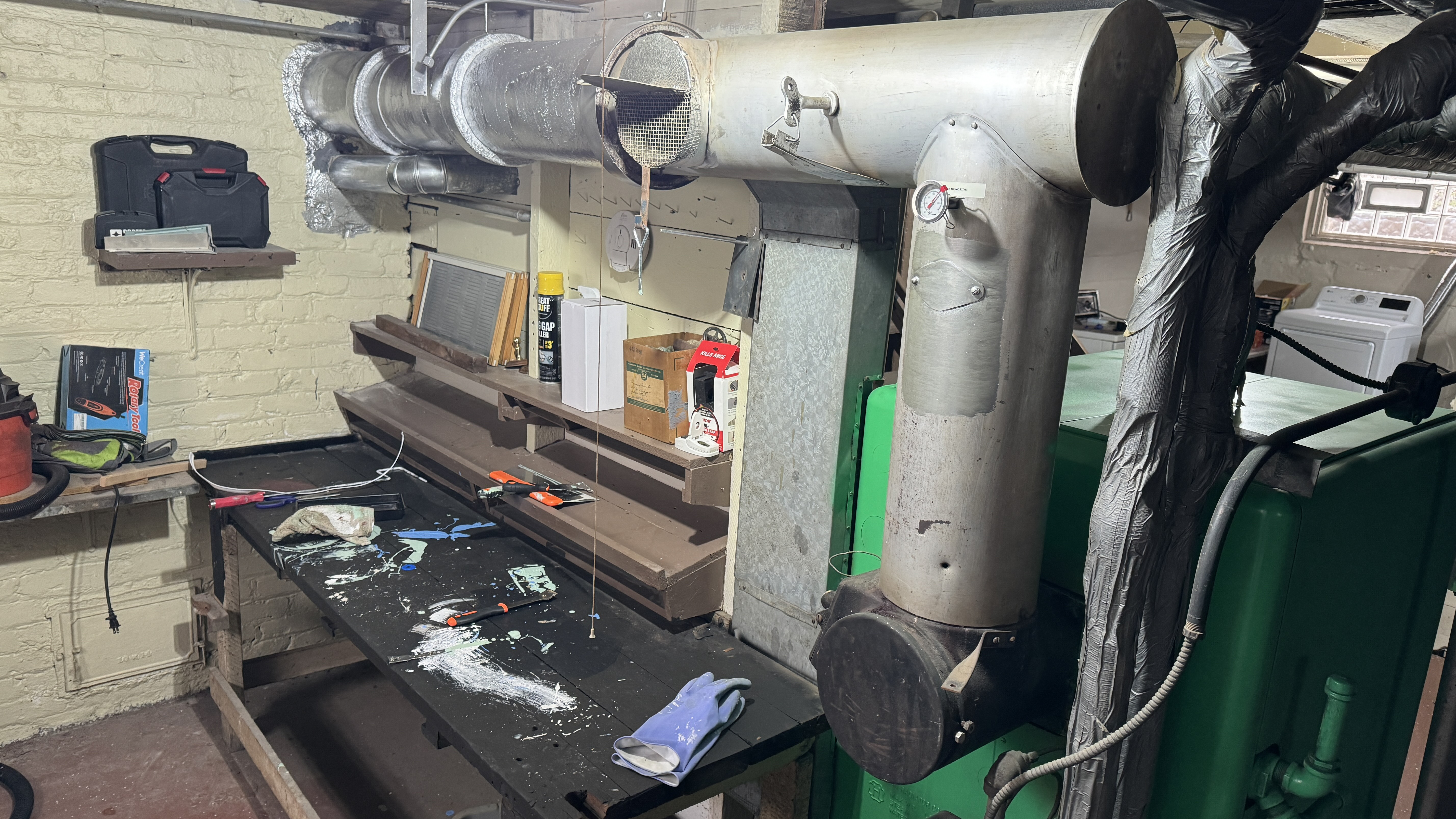

See view from other side. Looks like someone already drilled a hole lower down too looking at these older pics. As for end cap, you want me to remove that and operate the boiler for a short period of time just to get the new CA reading with this fully open ? I have a sensitive CO detector plugged in right in behind the boiler. I will also have both my basement vent windows fully open.

The flue pipe is half clay pipe and the rest aluminum as seen. The clay portion is just painted with radiator paint.

Lifelong Michigander

-Willie

0 -

OK so I see that is an end cap and not a barometric. That looks like it might be difficult to remove but that is the best place to do it. The manual damper between the draft diverter and the Tee with end cap looks like it is 80 to 90% closed. That may help to reduce the draft thru the boiler and removing the draft diverter completely may allow more basement air into the chimney

Here is a post I wrote on the subject of combustion efficiency and how it is only telling you what is happening in the boiler and not the complete thermal efficiency of the system.

You can read more on the subject in the link at the bottom of the post.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

-

Very nice boiler. It will probably outlast us all.

I noticed your boiler also has a Honeywell Heat Generator installed. These are pretty uncommon today, and need to be handled carefully if you ever remove it due to the mercury contained inside.

https://www.heatinghelp.com/systems-help-center/honeywells-heat-generator/

1 -

What is your draft? You do not need to take off anything. Your barometric damper controls draft. It's not an oil burner. It should draft -.02 to -.04. Which I don't think you are over drafting your oxygen is not low (recommended 6 to 9 %) for max. efficiency. And yes don't worry about excess air. Just oxygen 6 to 9% maybe a little lower on boilers ( If you keep your CO under 100 ppm). Its done by adjusting gas pressure. But it's a good idea to be trained what to do and know exactly what the numbers mean. But I would not worry about it those numbers are okay and your fine with your heating bills. no offense intended just my opinion.

1 -

-

I don't understand what he will gain by fooling with the draft. His net stack temp is only 309 so he is not pulling a lot of excess heat up the stack. He could have excessive air leaking into the boiler as you mentioned but we don't know what they did inside the boiler when gas was installed. Is the air leaking in through the opening in the ashpit door or does the air come in through the burners? Did they seal off the ashpit door with refractory and all the air comes through the burner? Can't tell without seeing it. Primary air through the burners and secondary air from below?

The way I look at it the burner is not mixing the air and gas as well as it should maybe due to xcess air at the burner. I am thinking the air adjustment on the burners is the round disks mounted on the T section of the burners. Looks like a gap there that could be adjusted.

The damper in the stack looks pretty well closed already

1 -

@EdTheHeaterMan (and everyone else)

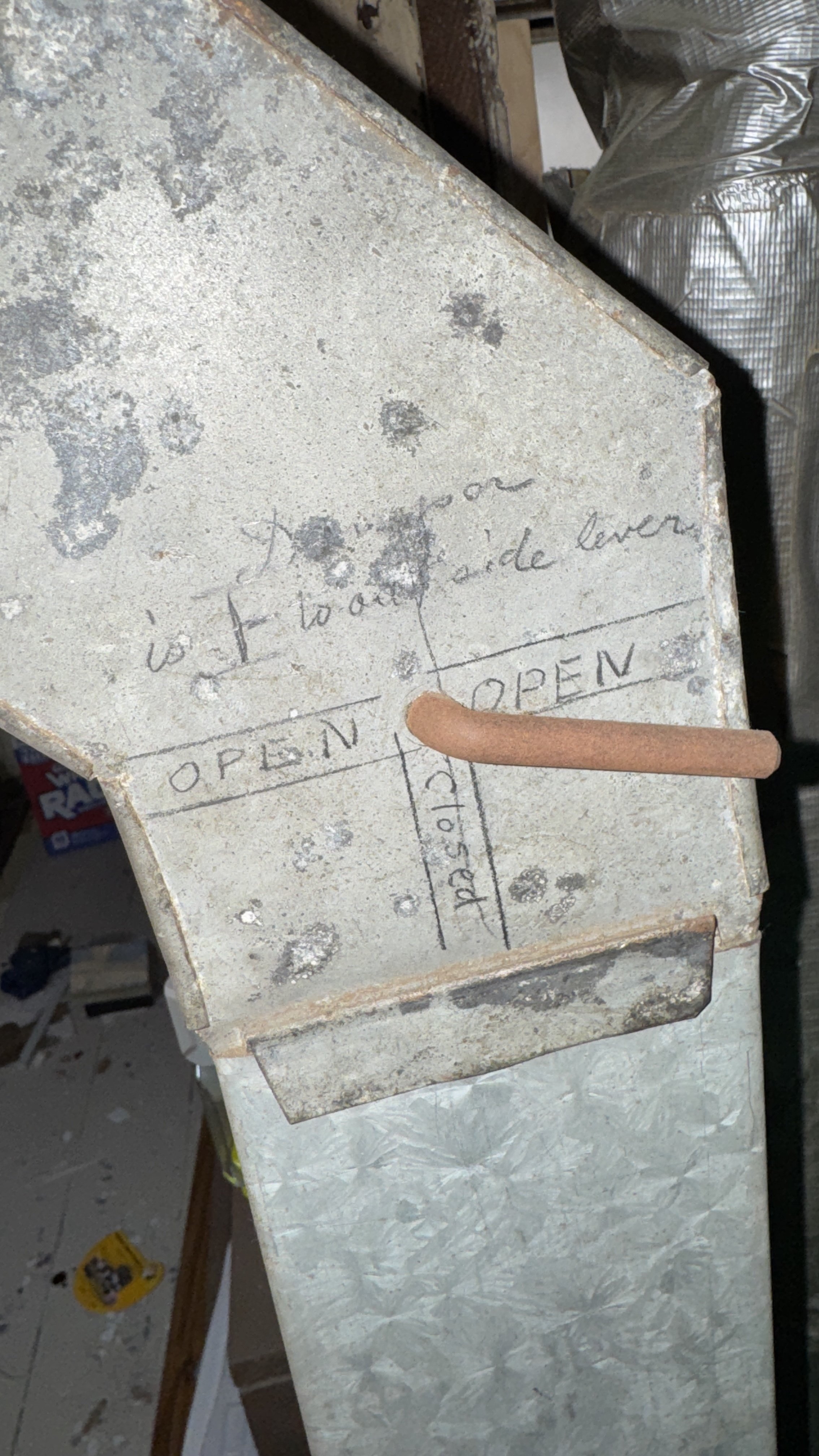

My apologies, but I forgot to include pics of the second damper seen in the other pics. Looks like a forced air vent but it’s a second damper that pulls air from the floor area. Just wanted to add that detail as the deadmen saw fit for this second one too. This might modify your previous instructions. I included a pic of the deadmen handwriting (instructions). They were craftsmen for sure. Even the custom notch to fit it around the boiler (pic 3). Precision at its finest.At the floor level. Definitely could use some vacuuming this weekend. Air flow is definitely restricted by all that dust caked on. Yikes! 😬😅

Lifelong Michigander

-Willie

0 -

There is no benefit. There is only knowledge to be gained. There is actually no need to do the experiment, because I have already completed that same procedure in the past. Sometimes seeing it with your own eyes is better that taking someone else's word for it. And for some reason I believe that @TheUpNorthState88 is the kind of guy that would like to tinker to gain realtime knowledge.

As I said in my previous instruction, after the test is completed, put everything back the way you found it!

You don't want insufficient draft from leaving the exhaust vent partially disconnected, to be a problem.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements