DIY questions tuning up my furnace

Hello,

I have a Thermo Pride OL6 oil furnace about 6 years old. The burner is a Beckett AFG. I'm mechanically inclined and have done a lot of remodeling and automotive work, but have never worked on a furnace. For various reasons I ended up attempting the maintenance on this unit this year. I feel as though it was a mixed bag trying to install the oil filter, pump strainer and nozzle.

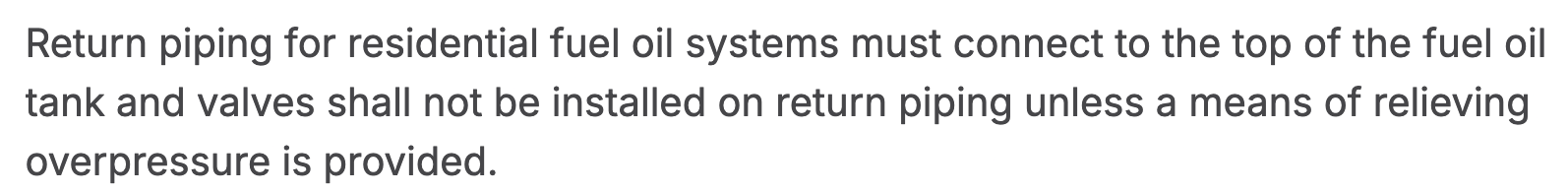

1)The oil filter was a replacement for an RF4 that was in there. I'm not sure if that's correct for the Ful Flo canister, but it's what the last tech put in there. The main issue I had with this part of the project is the mounting bolt would leak a bit. I've done it over a couple of times and I've improved the leak by cleaning everything real well and aligning as best I can where the bolt goes through the canister. I've tightened the bolt down but am concerned about over tightening. All gaskets were replaced. I thought I could possibly use some diesel resistant sealant in this area but haven't done that yet. Any thoughts on this tendancy to leak at the bolt gasket on a ful flow canister cap?

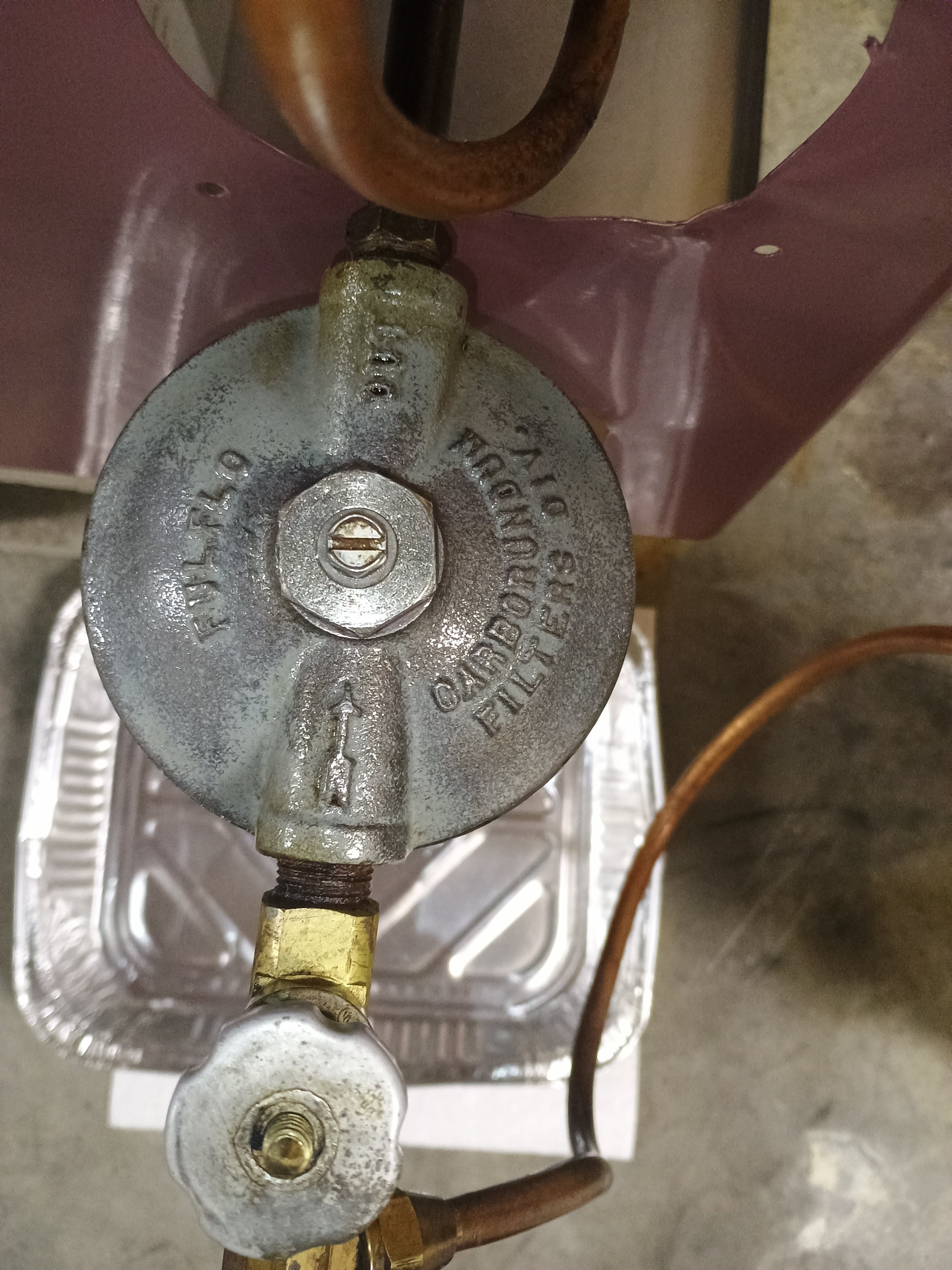

2) The pump strainer cover shows Beckett Cleancut A2EA-6527 on the cover. This strainer looked almost new when I finally got the cover off but the problem I had was oil was spurting out into my pan so I had to put the cover back on in short order. I turned the incoming line valve off and also turned the return line off (I have a two line system). I'm not sure if the return line should have been kept open or if the oil spurting is typical when trying to change the strainer. Any thoughts are appreciated.

3) Changing the nozzle did not go as I had planned either. I got the gun out OK but for the life of me I could not remove the old nozzle. I was using two wrenches the proper way but it would not budge. I tried to put it in my vice to get more leverage but that didn't work either as I was afraid of damaging the housing and electrodes. All the videos I've seen people quickly unscrew the old nozzle fairly easily with the two wrench method. Mine wouldn't budge haha. I cleaned what was already in there and reinstalled. Anyone struggle with a stuck nozzle in their experience?

Thank you for any help

Comments

-

-

-

I have an air impact at my other place but didn't think such force was necessary as video after video shows people just removing the nozzle with a wrench.

0 -

If you have issues with the filter leaking , replace it .. Install a spin-on with a vacuum gauge , it will show if you need to change it ..

Two pipe system with a good syphon oil would flow back to the pump when you service the pump .. A valve on the return is dangerous if left closed with burner running ..

I never had that much of a problem breaking off a nozzle .. Working two wrenches can get confusing .

There was an error rendering this rich post.

1 -

A 3/4" and 5/8" box wrenches should get the nozzle off easily. It is a machined surface so it doesn't have to be cranked hard just snug.

There is a gasket under the top of the ful flow filter bolt did you replace that? If it still leaks I would put in a General Filter 1A-25A or its equivalent.

If you shut the return and supply to the pump you should be able to change the strainer. The oil should stop running. be sure to open both valves before starting up.

1 -

Its NOT necessary. Call a professional.

0 -

If the nozzle is frozen/stripped in the adapter just buy a new adapter.

0 -

1)The oil filter was a replacement for an RF4 that was in there. I'm not sure if that's correct for the Ful Flo

canister, but it's what the last tech put in there. The main issue I had with this part of the project is the mounting bolt would leak a bit. I've done it over a couple of times and I've improved the leak by cleaning everything real well and aligning as best I can where the bolt goes through the canister. I've tightened the bolt down but am concerned about over tightening. All gaskets were replaced. I thought I could possibly use some diesel resistant sealant in this area but haven't done that yet. Any thoughts on this tendency to leak at the bolt gasket on a ful flow canister cap?

Are you sure you replaced the fiber gaskets at the top ?

This is from the Massachusetts mechanical code: The most comprehensive oil burner code in the country in many respects.

Most of the other state codes and the uniform building code adopted by many states use this same instruction

2) The pump strainer cover shows Beckett Cleancut A2EA-6527 on the cover. This strainer looked almost new when I finally got the cover off but the problem I had was oil was spurting out into my pan so I had to put the cover back on in short order. I turned the incoming line valve off and also turned the return line off (I have a two line system). I'm not sure if the return line should have been kept open or if the oil spurting is typical when trying to change the strainer. Any thoughts are appreciated.

Based on the information you provide, you do not need a two pipe system from the tank to the fuel pump. Basically two pipe systems are used when there is lift condition when the fuel tank is below the oil burner. You have indicated that there is gravity flow from the tank to the fuel pump. I would not install a valve on a return pipe from the pump to the tank in any case. You are asking for trouble leaving that valve in there for 30+ years. A lot of dummies can come across that valve in 30 years, and all you need is one dummy to cause you a problem.

3) Changing the nozzle did not go as I had planned either. I got the gun out OK but for the life of me I could not remove the old nozzle. I was using two wrenches the proper way but it would not budge. I tried to put it in my vice to get more leverage but that didn't work either as I was afraid of damaging the housing and electrodes. All the videos I've seen people quickly unscrew the old nozzle fairly easily with the two wrench method. Mine wouldn't budge haha. I cleaned what was already in there and reinstalled. Anyone struggle with a stuck nozzle in their experience?

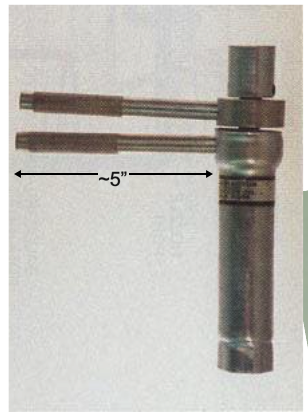

This is a nozzle wrench. the handles are only 5" long and to use this wrench properly you place the wrench over the nozzle and the nozzle adaptor so the nozzle is hand snug with the two handles at about a 30° angle. Then squeeze the handles together. This will exert about 25 inch pounds of pressure on the machined surfaces that will create a leak proof mechanical seal

If you can not remove the nozzle from the nozzle adaptor with two 8" long box end wrenches, then you are probably going the wrong direction, or the previous nozzle installer has used some sort of high strength glue to install that nozzle.

You may need some new parts if you can't get the nozzle apart from the adaptor.

Finally, after you get all the mechanical stuff completed… you need to use a combustion analyzer to make the final adjustments.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Thank you for the thorough replies. This is not a house I'm at full time, and this time of year it's been difficult getting an HVAC tech to return calls, show up when they say, etc. I finally did talk to someone who said they would be willing to come out in the event of an emergency, but they are booked solid for regular maintenance for a bit. I'm hoping at this point to get through to the spring and get someone out to evaluate this system, upgrade oil filter canister, look at the return shut off and maybe add a main shut off at the tank, which there currently is none. As far as the combustion analyzer, I've actually inquired with different techs whether they use a Testo or something similar and a lot of them don't. The person who installed my Thermo Pride 6 years ago did use one but he is too far away for regular maintenance. I will continue my search in this regard.

The system appears to be running fine at this point so I'm going to leave well enough alone, with the exception of the oil filter canister. I've improved the leak there but still getting a couple drips per day. Yes I've replaced all three gaskets that come in the kit. The top bolt gasket is where the main issue is. I'm concerned about upgrading this canister at the present time as the main shut off valve is connected to it and I don't want to cause any harm to it. I also don't know how much I can wrench this bolt tight without stripping it. I wonder if I can use some diesel resistant sealant under the main bolt gasket.

FulFlo Canister with leak between main bolt gasket and mounting surface.

Return Shut Off under pump

Both lines going in/out of tank top with no shut off

0 -

-

That's ok. There's already a Firomatic valve on the return at the fuel pump waiting to fail and blow the pump seal.

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements