Maintaining Manifolds on IPEX/Warmrite/Kitec Radiant Floor System

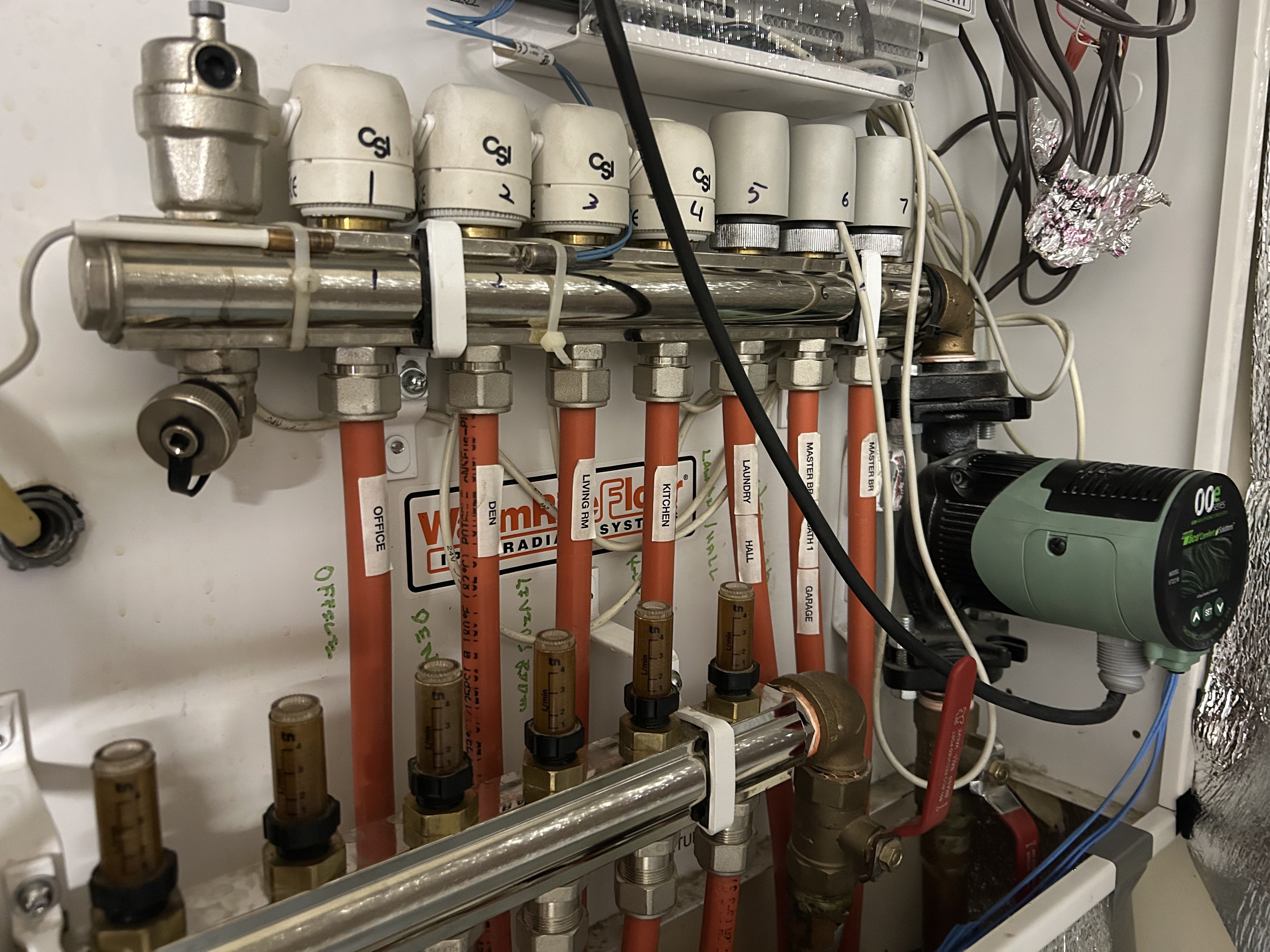

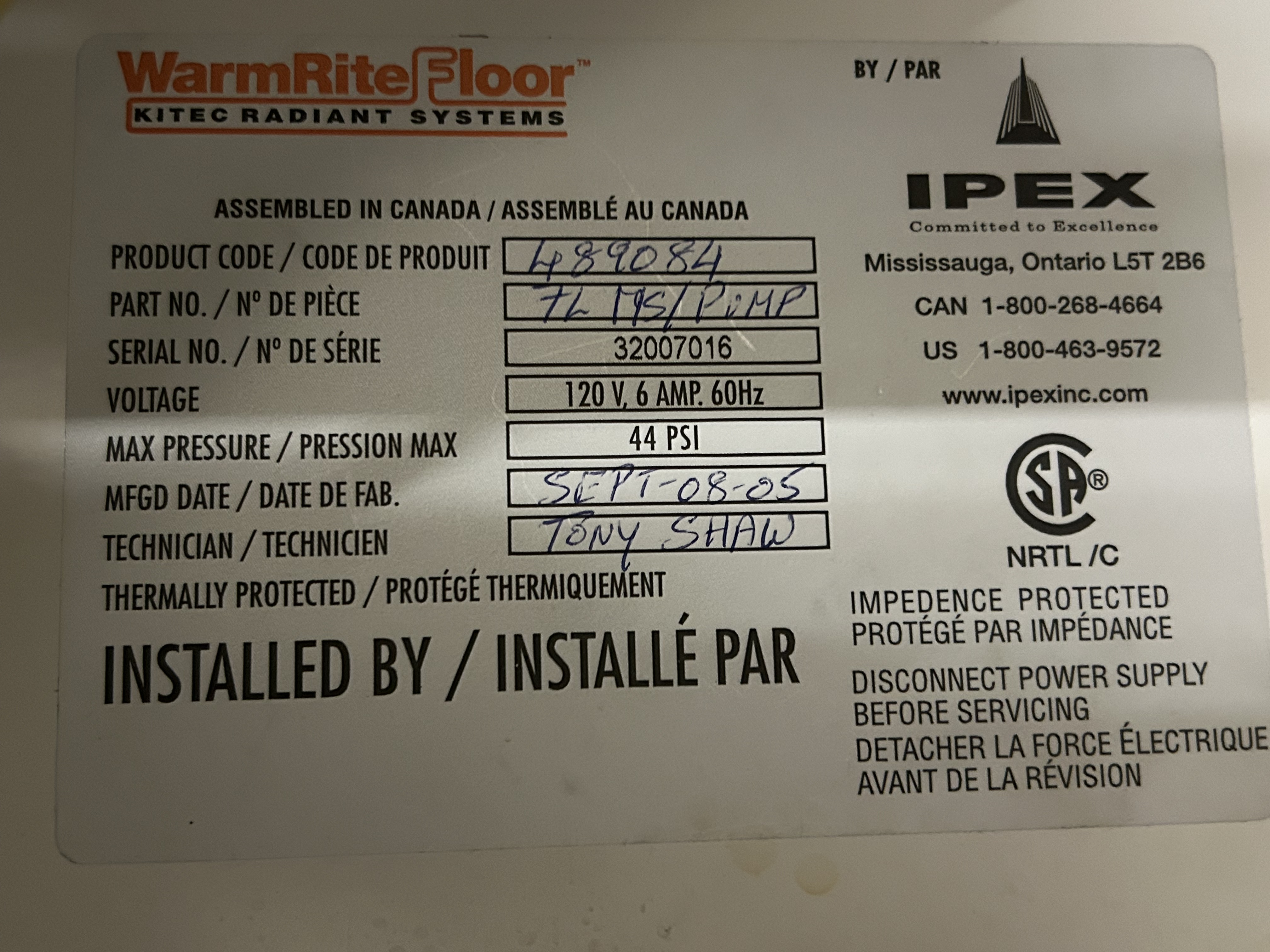

I purchased a home in 2019 that has a Munchkin boiler tied to an indirect water heater, and an in-floor radiant heating system in tile floors. I have two manifolds, one in the garage that handles the main floor of the house (approximately 3,700 sq ft) with 7 circuits on 5 zones controlled by actuators, and another in the boiler room with 5 circuits on 3 zones controlled by actuators that services the walkout basement area (about 700 sq ft). The in-floor radiant system was unused by the previous owner for 7 years to the best of my knowledge. All manifold valves were in the off position when we purchased the home.

Long story short, I started using the radiant system and have been successfully to date. It seems to be working well, and I have had some other issues with vent leaks and manifold leaks over the years that have been addressed to some degree of satisfaction by a vendor or two that sort of worked on these systems.

As you can see in the pictures below, the fluid in my system is contaminated by something. When I brought things back online, the fluid in the flow meter glass was not clear, but it was not this color either. I am on a well and our mountain water does have high levels of iron in it.

So my question is should I/ can I clean out those flow meters by taking the IPEX manifold apart? I did have one vendor offer to do that for $$$$. I thought that was insane so I passed.

Seeing how the water/glycol mix (I think) is discolored should I flush the system and then replace the fluid with a new mixture? I have one run of pipe that goes up against a wall in our shower and the other side of that wall is the garage so I guess that is why they have glycol in the system. I have used this system continuously during winter for the past 6 years.

What else should I do for maintenance? Is it DIY friendly tasks? Thanks for any advice.

Comments

-

First you should test the concentration of the fluid with a refractometer. And the quality. And if you don't know which type of glycol.

I cant for sure rule out oxygen ingress.

If you don't have to open it up to change the fluid, I wouldn't worry about it. If you do open it up check for oxygen corrosion.

With system off and all the heads closed, you could remove the circulator and see what that looks like inside.1 -

Definitely not a Caleffi manifold.

5,6 & 7 look like Caleffi actuators, they would be labeled on the top.

It's possible those flow indicators will disassemble at the black nut.

CLR available at the grocery store works well with a cotton swab. Although I wouldn't bother knowing they will get colored within days of a cleaning. If they all indicate or bounce a bit, you have flow. Let the sleeping dog lie :)

I don't see signs of leaks or dezincification anywhere, I think you are in good shape.

A small piece of foam insulation zip tied over that sensor on the left end would help it read more accurately and quickly. Not a dealbreaker, however.

Ipex is still around, growing in fact. Probably the last thing they want to hear are the words Kitec or WarmRite.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

can you make out anywhere on the tubing that it has an oxygen barrier? I can just make out the word "potable" on a piece of pipe, which doesn't necessarily mean it has no O2 barrier but just a little suspect considering how dirty the water is.

0 -

I cannot make out anything specific about it having an oxygen barrier. I know it is Kitec and that there was a class action lawsuit about it reacting with zinc fittings or something?

Does anyone else know if Kitec had an oxygen barrier in it? It was installed in 2006.

0 -

kitec and Warmrite is, was a PAP. The aluminum is the O 2 barrier

I don’t recall them ever making a plain pex, under those names

It is a different OD than pex so it takes a specific PAP fitting

On alleged cause of failures was the aluminum touching the brass fittings, causing electrolysis, breaking diwn the aluminum

The better fittings had a fiber isolation washer in the fitting. And a double o-ring on the insert part.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements