Homeowner and plumber disagreement

Comments

-

" That “high flow” fixture also has at thermostatic valve built into it. "

Well to me that thermostatic valve, anti-scald valve is highly suspect of leaking through with the assistance of the circulator. Since that would provide a path for the hot water to heat the cold water pipe towards the street

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

If I was the Plumber and I actually understood the 'Big Picture' and you did not want to replace the shower fixture, I would install two check valves in the correct strategic place so that water could only flow to the shower valve and not through it in an undesired direction.

One check valve on the hot 3/4 pipe leaving the the storage tank to the shower and the other check valve between the Tee at the main pipe from the street and the shower fixture.

The third check valve on the cold side of the hot water heating system and the expansion tank were probably not actually needed to solve the issue.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

the shower valve, if it is the source of the problem, likely just needs a new cartridge.

0 -

it also would heat up every cold pipe in the house. Every cold tap all throughout the house would get hot. “Very hot”.

The multiple check valves have solved that problem. How could they not???If I move the expansion tank(K) to above the cold feed from the street, I mean above the red ball valve(C)

do you think that would quiet that spring check(H) down.

That is what I plan to doBut I’m not going to start cutting and moving pipes until I get a professional opinion

I have already handed the plumber a lot of money. And ended up with this mess.

I think he should correct the mess without having for me to buy another box of expensive parts and also paying him his hourly rate to install it

When I questioned his approach to the problem he said “good luck”

I took that to mean.” My way or the highway.

I think that is a bad way to do business. Why would he talk to me like that???

I don’t feel good about his attitude.

He has not been in touch with me since that comment. I feel like I just wasted a lot of money. I am not a wealthy man.

I can’t pour more money into a band aid

behind the washing machine.73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

any chance you paid with a credit card?

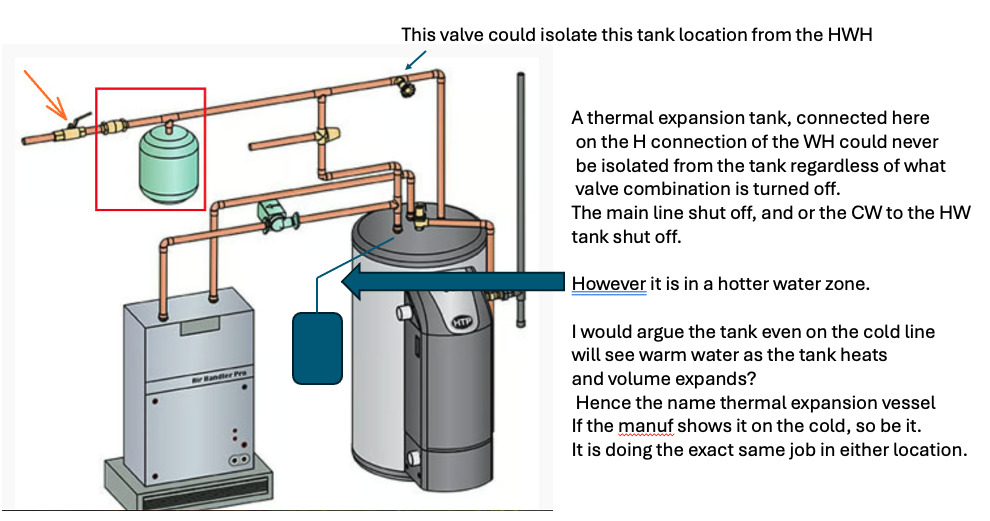

if the tank is before the ball valve the relief valve on the hot water storage tank will blow off because the expanding water will have no place to go.

0 -

Your plumber issue is why I do 99% of my own work, I buy the tools needed, which I can keep forever or sell after the project is done.

Just to be clear you can't have a check valve in-between the expansion tank and the hot water storage tank.

If your 30 feet of cold water pipe from the street fills up with hot water you would have hot water on the cold side until it purged out or if the undesired leak was significant the hot and cold may always blend a bit. Also if the circulator happens to be running at the time you are drawing cold water that also may aggravate the issue.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

this system in my basement has never had an expansion tank. It has operated perfectly fine for the past 40+ years.

The initial problem was with the hot water mixing with the cold water.

the plumber did not perform the test that Larry Weingarten suggested.

the plumber also did not check or adjust the pressure on the tank(K).

All he did was add a whole **** load of check valves to solve that problem.

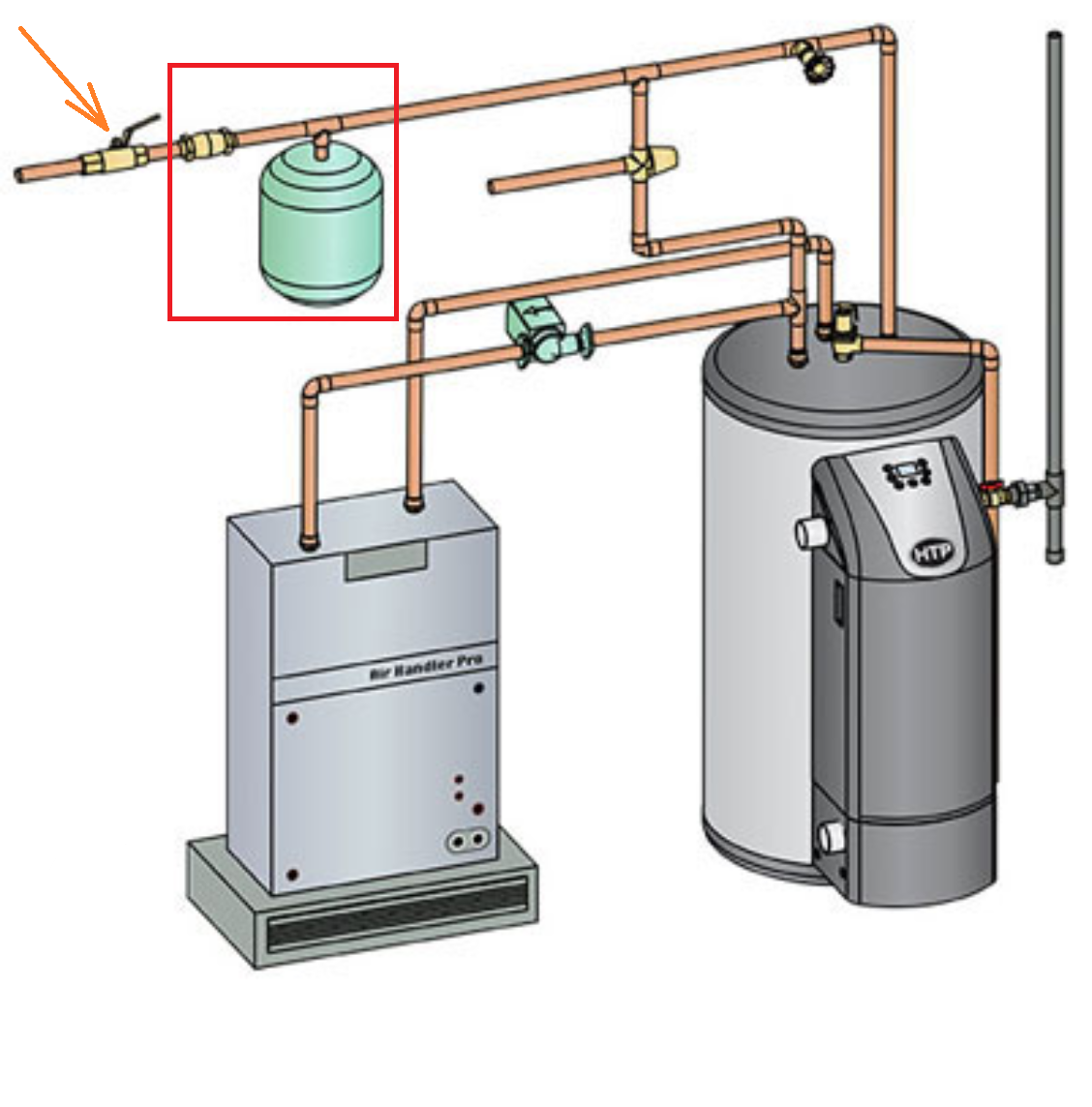

maybe this is a controversial issue. But nine opinions out of 10 say that the pressure tank(K) should not be laying on its side on top of the water heater.

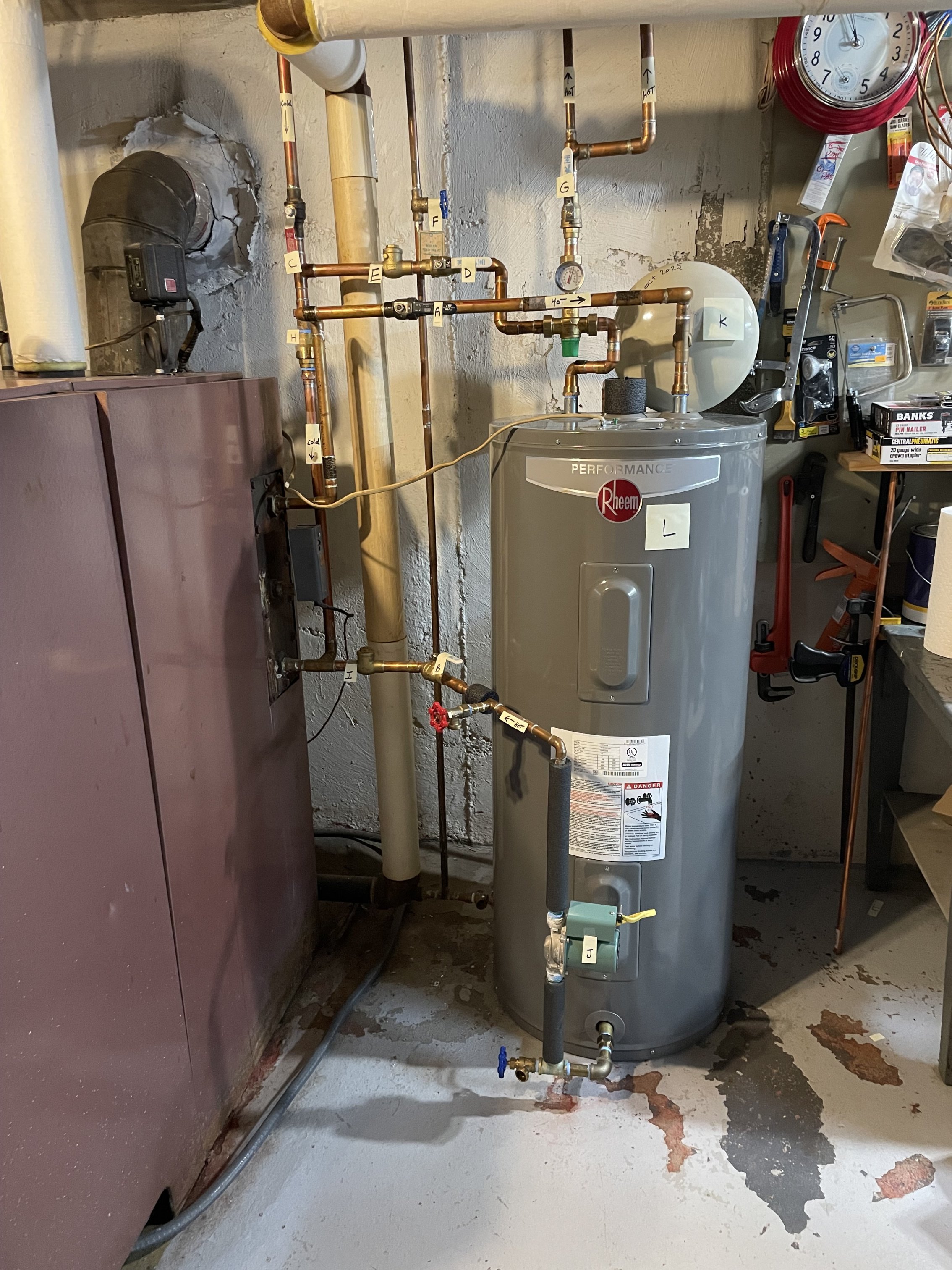

The same nine out of 10 opinions say that the pressure tank(K) should be on the cold side of the system.A. Ball valve

B. Ball valve

C. Ball valve

D. Ball valve

E. Swing check

F. Hot boiler fill valve

G. Ball valve

H. Spring check valve

I. Swing check

J. Taco pump

K. THERM-X-TROL ST-12

Expansion tank

L. Rheem modified holding tank

so, given the fact that this holding tank((L) has never had a pressure tank(K) on it before. Why would installing it on the cold feed) ( C ) cause such a dramatic situation that you described??73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

old Photo of my system before any work by the plumber was done

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

If E and H are check valves and the expansion tank is placed at C… How is the expansion tank going to mitigate the expansion of heating the water ??? The expanding water can't get back to the expansion tank through the check valves.

Previously the expanding water simply went back to the street.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

so, looking at the labeled photo.

what should I do73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

I uploaded the photo with the labels to AI. (artificial intelligence.)The AI analyzed the photo and the attached Legend.

This is what it said after analyzing my system:

Given that the cold supply from the street feeds only into the boiler coil loop, not into your domestic plumbing, here’s the correct reasoning and placement for your expansion tank (K):

⸻

🔧 Correct Location for the Expansion Tank

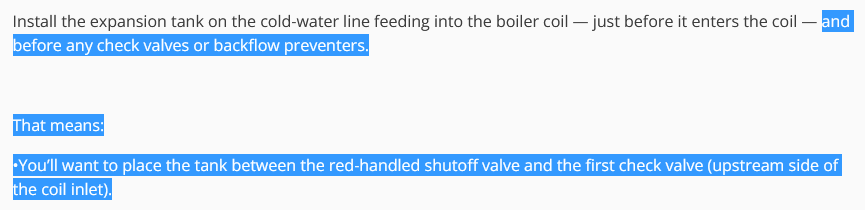

Install the expansion tank on the cold-water line feeding into the boiler coil — just before it enters the coil — and before any check valves or backflow preventers.

That means:

•You’ll want to place the tank between the red-handled shutoff valve and the first check valve (upstream side of the coil inlet).

•Mount it vertically (bladder up).

•This allows the tank to absorb pressure changes within that closed heating/coil circuit.

⸻

⚙️ Why That’s the Right Spot

•The cold-water line feeding your boiler coil is a closed loop once the check valve closes. When the water in that loop expands (as it’s heated in the coil and stored in the Rheem tank), it has nowhere to go — which is exactly what causes the banging and pressure spikes.

•Placing the expansion tank before the check valve and on the coil feed gives the expanding water a compressible space to move into.

•Mounting it anywhere downstream (like near the mixing valve or tank outlet) won’t help because those check valves isolate that section from the source pressure.

⸻

✅ Summary

Your expansion tank (K) should go:

•On the cold supply pipe that feeds the boiler coil,

•Above the red-handled shutoff valve, and

•Before the spring check valve or backflow device on that line.

That’s the “pressure reference” point for your entire heating/coil loop — and it will stop the water hammer you’re hearing at every cold fixture.

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

so, that’s what I have been saying all along. It would seem that the artificial intelligence agrees with me that the pressure tank should be installed above the Red handled shut off valve( C) on the cold feed to the coil.

I would like to hear what you guys think about that

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

Put the expansion tank anywhere you want as long as it has access to the water tank with no closed valves or check valve between it and the tank it will work.

If you think moving the tank will solve your issue it will not. If you think the expansion tank move will solve your check valve issue it will not.

Could the tank have been installed in a better position Yes. Should it be on the CW pipe yes

Will moving it solve the problem.NO

0 -

EBEBRATT-Ed

Thank you very much for taking the time to reply to my post.

“Could the tank have been installed in a better position Yes. Should it be on the CW pipe yes”

I do not like where the tank was installed. I very much would like to put it on the cold supply. Just above the red handled shut off labeled ( C )

“Will moving it solve the problem.NO”

I have been on this heating help website for a long time, and I respect your opinion very much.

By you looking at the photo with all of the parts marked with a letter. And the corresponding legend.

Moving the tank,(like I want to do, above the red handled shut off labeled ( C ).

Assuming that this does not work like you have said.

Would you be able to take the time by looking at that photo and tell me what would work?

Please keep in mind that in the process of moving the tank I will also be checking the pressure in the tank and matching it to the house pressure.

Your help, and everyone else’s help, is very much appreciated

Steam Rookie

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

" I do not like where the tank was installed. I very much would like to put it on the cold supply. Just above the red handled shut off labeled ( C ) "

And that may be fine, its just you should not have any check valves between the expansion tank and the part of the system that heats and/or stores heated water. So you would have to remove or disable at least (H) and maybe (E) also.

I think your AI assessment missed this point. The highlighted part seems wrong to me

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

If your issue is still water hammer then it is probably a check valve issue.

0 -

EBEBRATT-Ed

Yes. You are definitely correct.

The banging that I can hear outside of the house is coming from the spring check, and probably one or both of the swing checks. I would like to leave one check valve in. I would like to leave it where (I) is. There always used to be one in that location when we moved into the house. That was almost 40 years ago. Years later, when we bought the new front load washing machine. That’s when the water hammer first began. So I removed it, and the water hammer went away. At that point there were no check valves at all. After that, I could start to feel the Hot Water migrating up into the cold feed pipe. I guess, over the years, the Hot Water began to move higher and higher in that cold feed pipe.(C) Eventually, just recently, like I said. The Hot Water moved up that cold feed pipe all the way back to the street. I did try putting the check valve back on. But the water hammer returned. So I took it off again.

With the new hot water holding tank (L) and the new pump, and no check valves everything was working fine.

But like I said, the hot water gradually began working its way up that cold pipe, resulting in the mixing that I was experiencing.

The new pump was the same size as the old one. It was almost as if the new pump grew new muscles, and was pushing that hot water all the way up that cold pipe, and then all the way to the street, and every cold pipe in the house. This is what I called mixing. Because whenever we put a cold tap on, no matter ware in the house it was, it would run hot. Very hot. For quite some time, before it would turn cold

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

If this was my situation, I would remove check valve (H), install a Tee where check valve (H) was, then move the expansion tank with proper orientation to the new Tee, as @Larry Weingarten suggested add a service valve between the expansion tank and the Tee.

Then reassess, knowing that there may be a shower valve that may need repair or replacement.

Now this may not be consistent with present plumbing code. Personally I don't understand and have done zero research as to why a check valve (or back flow preventer valve) on new water heater install is typically required. It seems we survived for decades without them.

Typically once the check valve (or back flow preventer valve) is installed you need the expansion tank to mitigate the expansion of heating water since it can no longer go back towards the street. I suspect there was one incident of some kind of backflow contamination so the code folks went nuts.

To me if you want (or need or should have) the backflow preventer valve and you want to the 'Dual Duty' of the expansion tank (hot water heating expansion mitigation and whole house water hammer prevention) the back flow preventer valve needs to be right after the water meter coming from the street before any other cold water branches off, like for your shower.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

There is no BFD requirements for WH installations. But WH manufacturers install the heat trapper nipples as part of the energy standard, they are a "weak" check valve, they are not a 100% bubble free stop like a spring check. I have never heard hammer noise from the trapper nipples. Just a reduced flow :)

Soft seat spring checks, used where needed, generally do not cause water hammer. Or else ever circulator would be hammering.

Dual check BFDs on you main incoming line do not cause water hammer, there are millions installed. They all use a soft seat spring check of some sort.

A fast stop of flowing water starts a hammer. Solenoid type valves in washers, dishwashers, icemakers, some lawn sprinkler valves.

The check valves in a DHW are not stopping a fast moving stream, they merely close to prevent flow in the opposite direction when flow stops.

It is the long travel length and typical brass on brass seal in a swing check that may start elastic shock aka water hammer. Not all swing checks can be installed in vertical or horizontal orientation.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Curious @hot_rod "There is no BFD requirements for WH installations. "

Maybe an incorrect assumption on my part, but then why do I keep seeing it ? And not a part of a space heat hot water hydronic heating system ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

109A_5

Artificial intelligence (AI) is not always right. It makes a lot of mistakes.

I want to move that tank. I do not like where it is.

But I am not a plumber

I watched the plumber as he heated soldered joints and separated them. That takes a lot of heat.

Most likely, I am going to break something.

So my only option, as an amateur plumber is to cut things off.

Most likely, I will have to throw away the tank, and everything else I cut off.

I have not made my list yet. But it looks like I will be needing a new pressure tank, a bunch of connectors, probably a new brass tee, and most likely a whole bunch of other stuff. Not to mention at least two or three trips back-and-forth to the plumbing store.

My best bet is to hire a new plumber. But I just don’t want to.

I don’t understand why the plumber I hired the first time is so unreasonable? I don’t understand how you cannot address a customer’s concerns with an open mind. I don’t understand why he said basically it’s my way or the highway.

But I do not want to pay to install a big box of expensive parts behind my washing machine. I want him to come back here and put the pressure tank on the cold side where it belongs with the nipple facing in the right direction. I do not want it just laying on top of my hot water heater. Is that a lot to ask?

I wish the plumber would come back and move the tank for me and fix the water hammer. And I think he should do it with no cost to me. I don’t mind buying parts. But I don’t wanna pay any more labor for a problem that he created. But he already said if he comes back, he’s going to charge me his hourly rate. There was no water hammer when he came. And now I’m starting to get the neighbors complaining about the banging noise. And of course, my wife thinks I’m an idiot for hiring this guy. I’m not an idiot. I felt this Plumber and I had a friendship. He has done work in my house before. And it was very beautiful work. I truly felt like he and I were friends.

But as soon as I questioned the way, he’s going to fix this problem he became mean. Why did I have to hire such a mean plumber. I don’t think it was anything I said, I was very nice to him. Even got him a cup of coffee. What did I do to deserve this, Mr. Plumber?

Sorry for the rant.

I am just so angry for the way he treated me.

I like very much your idea of changing out the spring check(H). For the compression tank. That looks like an easy job. Something that I can do myself. But what about the other two check valves. Are you saying I should remove them both . It sounds like that. I would say definitely take off (E). But I might leave (I). And then see how that goes/works. Either way, the position that you suggested to put the expansion tank sounds like a very good idea.

Steam Rookie

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

You shouldn't need a new expansion tank that should just unthread from the fitting. I would take the swing checks out and maybe put a spring check in its place.

Soldering fittings isn't hard just takes some practice.

Scrounge around and find some copper scrap tubing and get a few fittings, A vise helps if you have one. Practice soldering the fittings on and taking them off and soldering them back on and you will get the hang of it after a few tries. You will screw it up but just stay with it.

0 -

I do not have a PhD in human nature. Folks do like to be paid for their time. Apparently in his view he repaired what he was tasked to do, and any resolution of any side effects to that original task that incurred should be at your expense, since it is your system. I agree it don't seem fair when you expect an expert repair, although I have said for decades that 'professional' and 'expert' are two different things.

That is why (I think I stated before) is one reason I do my own work, then I only have to fight with myself. Doing your work also has its perils.

Anyway I would JUST do this;

I would remove check valve (H) from the system, install a Tee where check valve (H) was, then move the expansion tank with proper orientation and support to the new Tee, as @Larry Weingarten suggested add a service valve between the expansion tank and the Tee.

Then reassess, knowing that there may be a shower valve that may need repair or replacement.

doesn't the expansion tank just unscrew, just a pipe thread ? Look closely.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

With soldering copper pipes the joint (both pieces) have to be super clean and well fluxed. Many YouTube videos on the subject.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

BFD back flow devices are to protect a potable water system or source from water of a higher hazard.

Basically on the main line to a home or building a RPZ type BFD is the most common. Some water meter yokes have a BFD built in, but non testable.

The public water supplier doesn't want water back once it has entered a building or piping system off the main, ever. They have no control over what cross-connections or hazards are in your building. Even a garden hose in a mud puddle could contaminate the public water, in a back flow or back siphonage condition.

Once the water is in your building additional BFDs may be required to keep YOUR water safe, boilers, lawn sprinks, fire protection various faucets, etc.

As such the plumbing codes identify typical hazards that need protection, and usually the ASME listing number.

Hose bibs

Kitchen faucets with spray hoses

Tub fillers with spray hose

Hand held hose type showers

Old style tube spouts below the flood rim of the tub itself

Hydronic systems

Drink dispensers

Lawn sprinkler

Fire sprinkler system

etc, etc

Different levels of hazards require different ASME listed BFDs. A boiler with EG is a high hazard, needs a testable RPZ

A boiler with tap water is a low or medium hazard, a vented dual check is acceptable, some ADUs allow unvented style dual checks.

AHJs identify boiler water hazard differently. We sell 3 different boiler BFD devices. In NY state alone 3 different types are accepted depending on the area.

A swing or spring check is not a listed ASME BFD, unless it specifically has an ASME listing number permanently affixed on the device.

I read through the UPC, don't see a requirement for BFDs on tank water heater supply? Check valves yes, for backflow within the recirc, but not a listed BFD. Unless you know of another?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0

-

Why did my plumber he leave me with a mess

and wants to waste more time and more of my money by solving the symptom but not the issueI don’t want to order another big box of expensive parts. Including three more ball valves with air vents on them and an industrial size water hammer arrester And have them all installed behind my washing machine.

I don’t want hammer arresters under every cold tap in my house. Like I said before. Even the toilets are banging when their tanks finish filling

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

@steam-rookie, you've gotten a lot of helpful advice here. You keep returning to your frustrations with your plumber and it does not seem like venting about him online is going to solve the problem or get him to return to this job. That is also not what our site is here for. The two of you are at an impasse and you either need to work through it offline or you need to move forward with someone else. Thanks.

Forum Moderator

0 -

Understood.

I would like to add that the first, three pages of this thread there was no mention of my plumber, other than “my plumber”.

The first 100+ comments on this thread were extremely helpful. I appreciate each and every one of them. I appreciate the time it took for all of those Heating Help members to write them.

I have been a member of this website since 2009. Over those past 25+ years I have learned and I have received loads/tons/a lot, of invaluable information. I believe this information could not have been found anywhere else.

I do not believe in trash talk on website like this. On Sunday my patience ran thin. When my phone calls and messages went unanswered. That is what lit my fuse.

I hired the best plumber in New York and all of its surrounding areas. I thought, how could I go wrong. I strongly believe that being the best plumber in New York is only half of the job. The other half would be excellent customer service. That’s the that half that was lacking on this job.

Out of respect for my plumber, and everyone else on this website. I will be deleting that last post.

I would like everyone to please forgive me for losing my temper.

With all sincerity,

Steam rookie73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.1

Categories

- All Categories

- 87.2K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 59 Biomass

- 427 Carbon Monoxide Awareness

- 118 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.7K Gas Heating

- 113 Geothermal

- 164 Indoor-Air Quality

- 3.7K Oil Heating

- 73 Pipe Deterioration

- 1K Plumbing

- 6.4K Radiant Heating

- 393 Solar

- 15.5K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 49 Job Opportunities

- 18 Recall Announcements