Splitting existing forced hot water gas boiler into more zones

I have a house with a main zone (all living space) and a basement zone. I would like to split the main house zone into two zones, one zone being the original house, and the other zone being an addition that was added a long time ago. I think I have an idea for doing this that will work, but I'd like to know if I'm missing something, or if there is a simpler way.

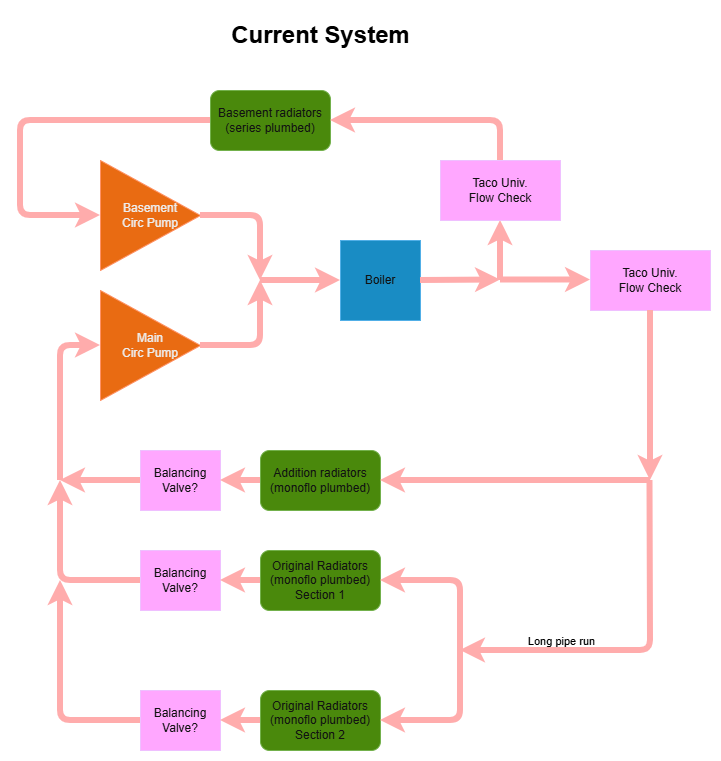

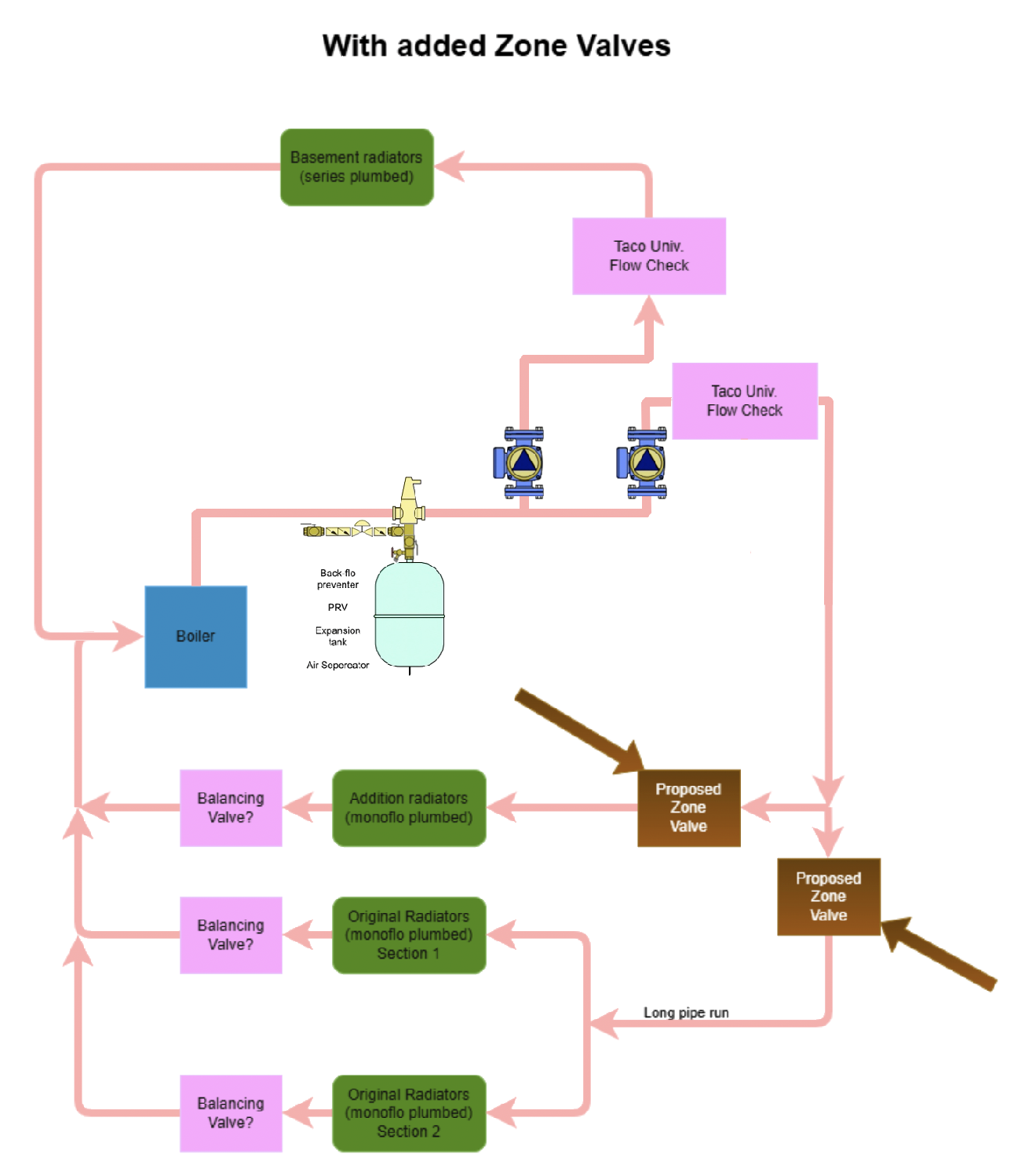

Here is the current setup:

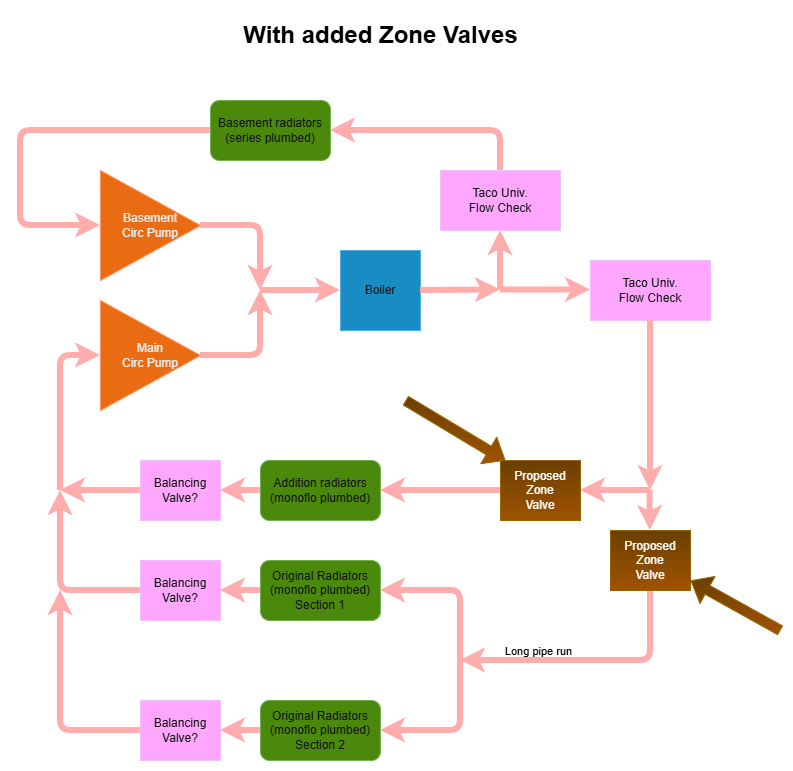

I think that I could add a high Cv zone valve ahead of the addition radiators (White Rodgers 1361-102) and ahead of the "long pipe run" (White Rodgers 1361-104) to the original radiators in order to make the plumbing work for splitting the addition radiators on their own zone.

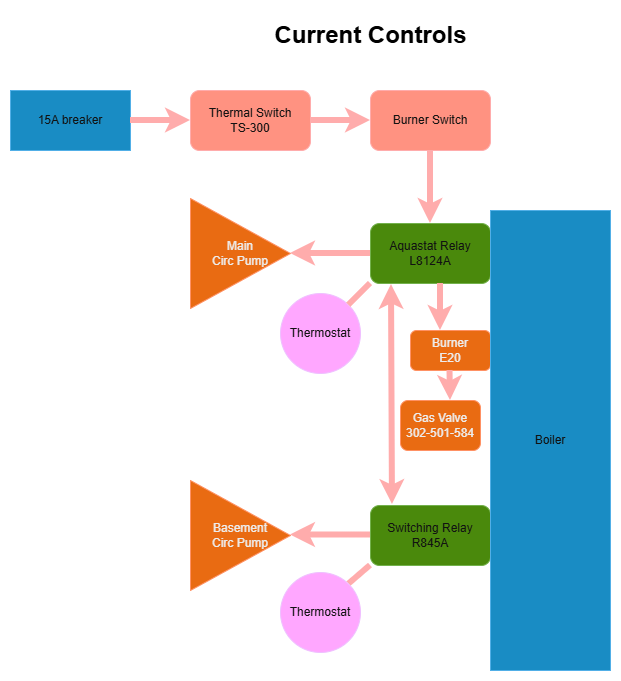

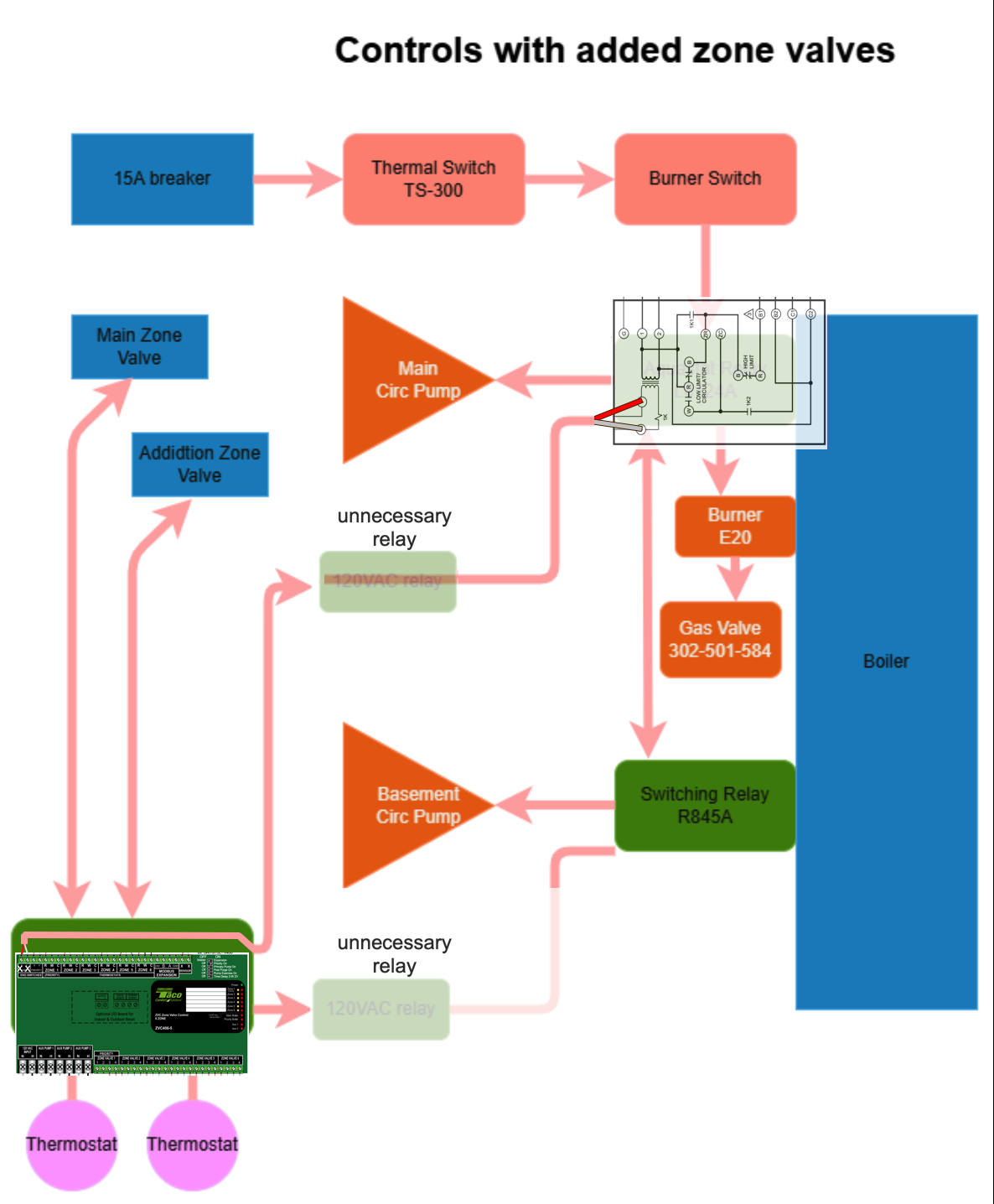

Currently the boiler is controlled by a Honeywell L8124A aquastat. The basement zone is controlled by a Honeywell R845A relay. I'm not quite sure how to connect everything. Is there a zone control that easily allows for control of zones that are not all on the same circulator pump?

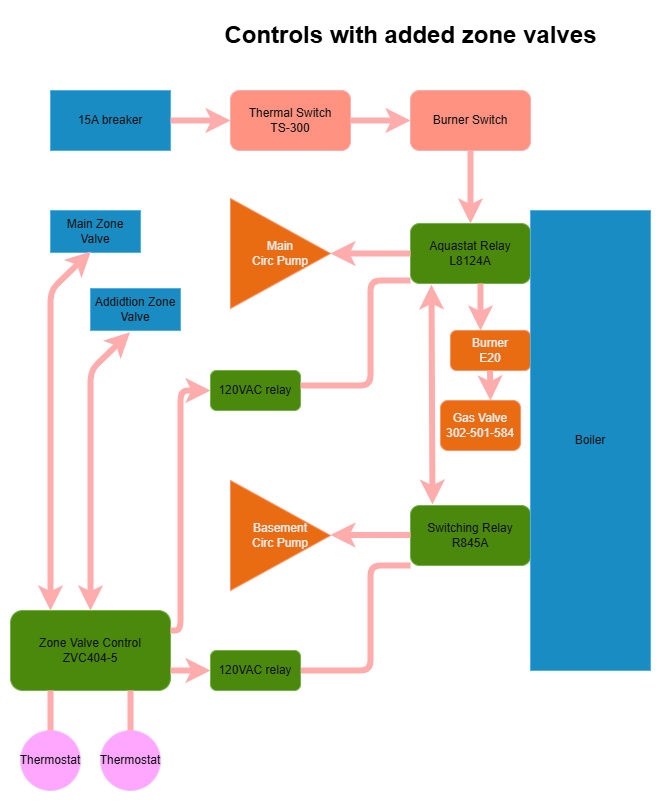

Since the basement zone basically never calls for heat, I think that I could do it like this, with a Taco Next Generation Zone Valve Control with Priority. I could put the basement on the priority zone, since it has one thermostat input and one output. I could install the two thermostats for the main house and addition, and send those outputs to the zone valves. Then I could put the circulator pump outputs (priority and zone) to relays which would act the same way as the thermostats do in the current system.

What I think this achieves is:

- The aquastat still controls the boiler temperature, and can disable the circulators if the boiler temperature falls.

- The zone valve control only calls for heat to the old aquastat relay once the zone valve(s) are open, so the pump won't be pumping dead-headed.

Current parts:

Boiler: Blue Circle 813 N, originally an oil fired burner, I think with a tankless DHW coil. Hot water is now on its own tank separate from the heating system.

Burner: Economite E 20 gas fired conversion burner

Aquastat: Honeywell L8124A

Switching relay for basement zone: Honeywell R845A

Comments

-

-

OK, you have a good idea there to separate the zones the way you want. Be careful with MonoFlo® tee systems. The pressure drop of the zone valve may or may not disrupt the balance. When the MonoFlo® was added to the addition, the installer must have done their homework in order to be sure the single zone was balanced with the rest of the house. (Unless that is the reason you want a separate zone because it is not balanced).

So zone valves are a good way to make zones happen and I see no reason zone valves will not work for you. Since you no longer heat your water with a tankless coil, your aquastat should be rewired to make your boiler a cold start boiler to reduce fuel usage. Is that done? OR Do you need to shut the switch off in the summer so the boiler does not maintain a minimum temperature all summer for DHW you will never use.

Next, while you are doing the repiping, the boiler will be drained of water. This would be an ideal time to redesign the system to eliminate any air problems that may occur based on the location of your circulator pumps. Read the book Pumping Away for reasons to make that change.

I might think that this design would be a better design.

Diagram to follow

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

You also need to replace the main circ pump with a delta P unit. What you want is the flow to each zone not be effected when the zone valve is closed, the simplest way to do that is a delta P circ. Monoflows tend to be high pressure loss, so make sure you match the new pump to existing.

You might want to also add an off delay timer the main floor zone driven by the burner signal and use the as a thermal purge. Buys a couple % efficiency for not much cost.

0 -

Here is the diagram with the pumps pumping away from the Expansion tank and air separator like the Califee Discal or Spirovent or any other microbubble air remover.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

@Kaos mentioned Thermal Purge. The thermal purge timer is a great idea, but with zone valves, that presents a problem. If the call for heat to the main zone ends the zone valve closes and the circulator pump has no place to pump the leftover heat to. Thermal purge works when you use circulators for zoning. There are no valves closing so the pump can push heated water out of the boiler without finding a way to open a random zone valve somewhere. Thermal purge can work on your basement zone… but you mentioned that the basement zone never calls for heat so using it for thermal purge will most likely over heat the basement.

There are no commercially available thermal purge controls that are made for your setup with 3 zones that use 2 circulators and 2 zone valves. Kind of a unique setup. Also your existing circulator will most likely work on the zone valve zones. The ECM ∆P pump is a nice idea, but they are pricey. It will save on operating costs over the life of the circulator pump but not enough top warrant replacing a perfectly good PSC pump.

So basically you can stick with your idea and go with your existing pump until you have a problem that needs to be addressed. If there is no problem, then it didn't need fixing.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

with the monoflo you have to be really careful that your high cv valves really are high enough. it would be a better idea to do zoning by circulator here.

0 -

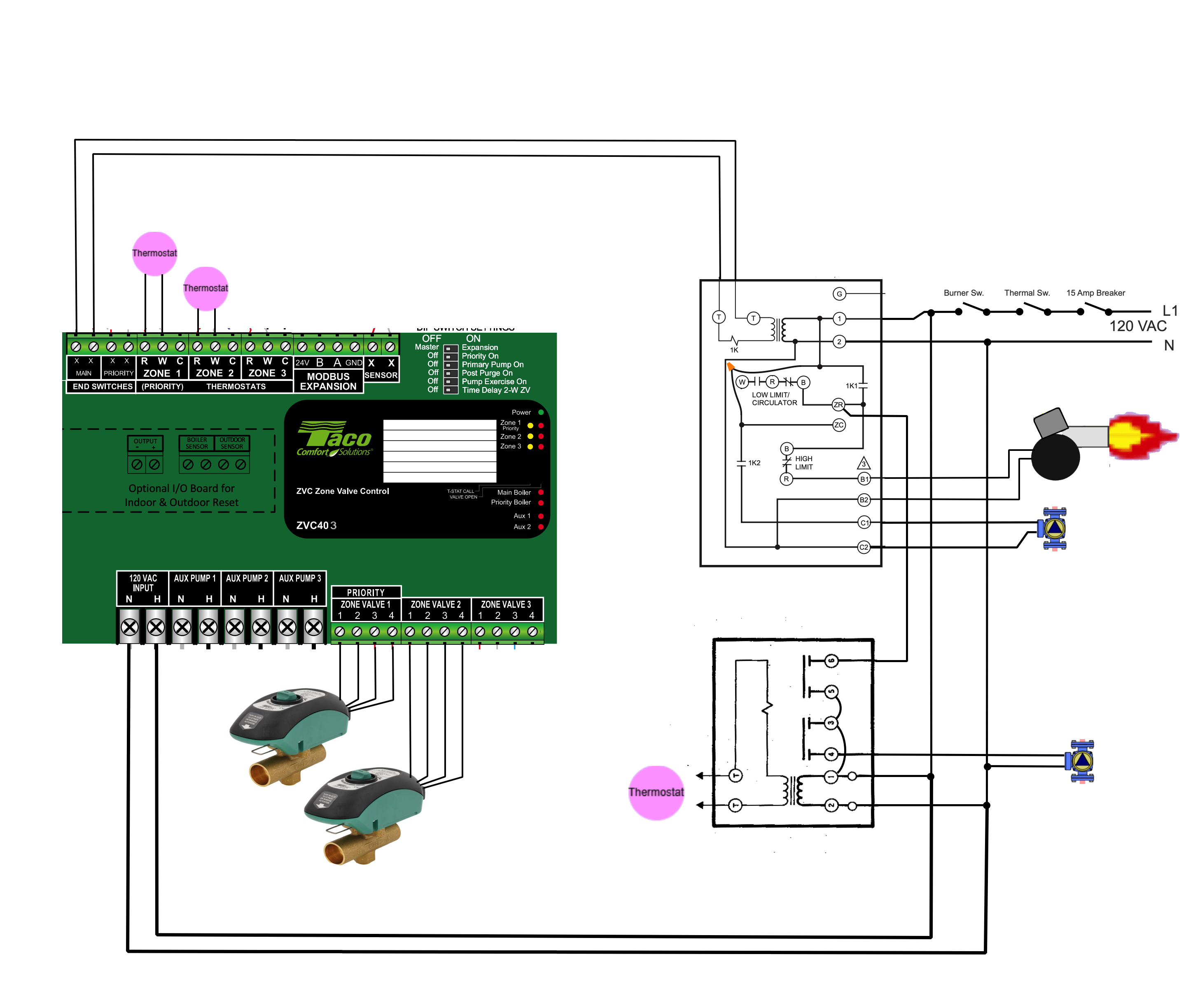

You need not use the 120V realy to operate the L8124A when you are using the ZVC404. Just use the X X from the ZVC 404 directly to the L8124 T T terminals. Don't use the Priority zone for anything, That zone shuts off all the other zones in favor of making DHW. You are not making DHW so there is no reason to shut off any circulators or zone valves to heat one space over another space. Let the zones heat as needed without priority.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

@EdTheHeaterMan Thermal purge can work with zone valves. What you need is a double pole delay timer (interval switch off mode) say:

One normally open pole goes in parallel with the thermostat of the zone you want to purge into, the other the normally closed pole in series with the XX signal out of the ZVC.

This way when the burner shuts off and the timer is triggered, it closes the thermostat input triggering the zone valve to open an pump to turn on but the XX signal is interrupted so the boiler won't fire.

I think in the case of the OP, @mattmia2 is right. An extra pump instead of zone valves is simpler. That also makes thermal purge trivial to add.

0 -

@Kaos I looked at the Taco ZVC404-5 and that has a thermal purge feature built in to it. And since the thermal purge is built into it there is no need to make it more complicated with additional relays. Just flip the DIP switch

Here is the wiring diagram for the system as I might do it.

The Priority DIP switch is OFF so zone 1 is the same as the other zones. I have also substituted the ZVC403-5 to save some money on the control system. Unless there is a need to add 2 more zone valves in the future, the 3 zone control is all you need.

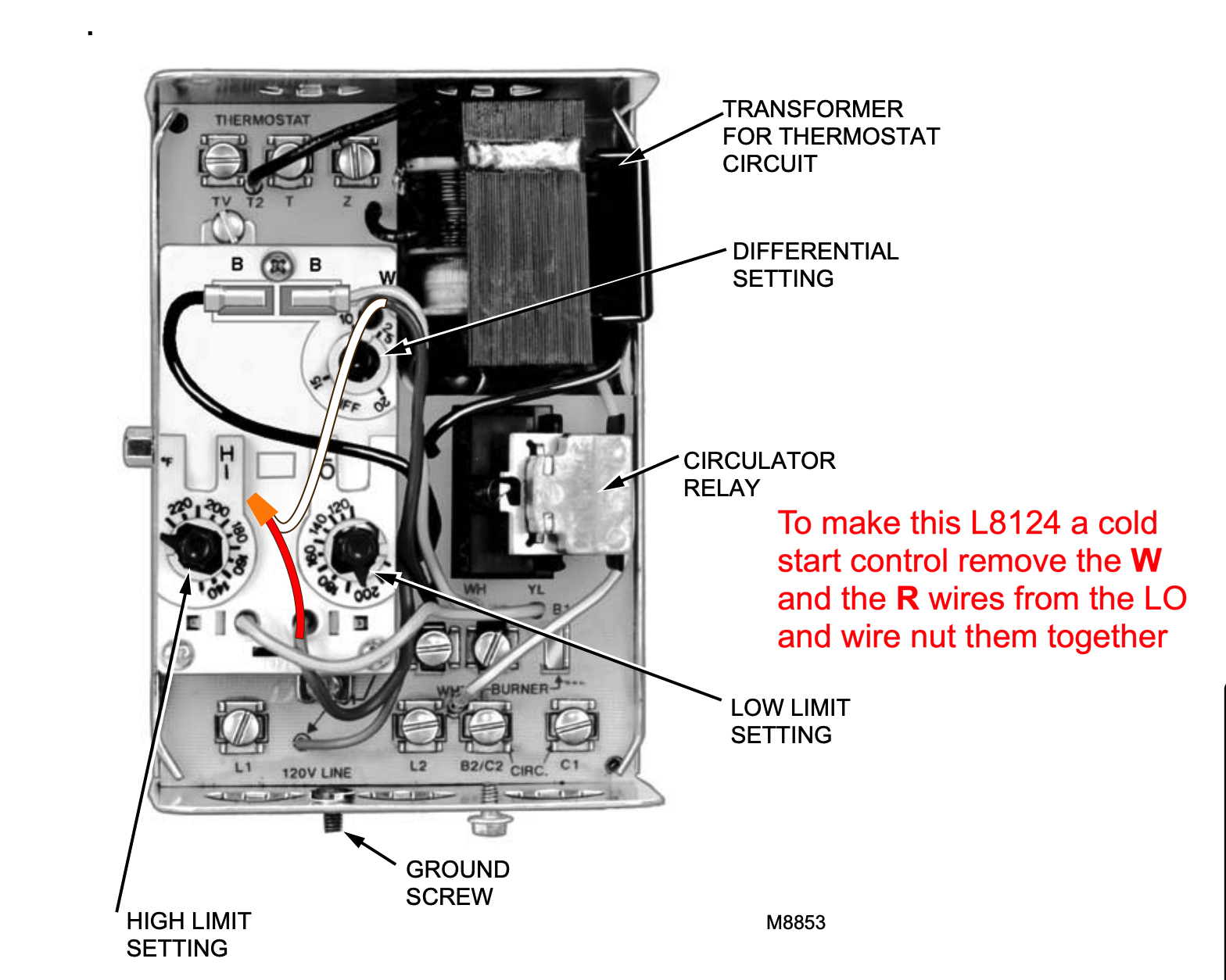

Look close at the L8124 triple aquastat… I have rewired the DHW priority so it is now a cold start control.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Hi Ed,

- I was thinking of using this 1-1/4" valve on the main loop and this 3/4" valve on the addition loop (matching the piping on those runs). Those have very high Cvs (42.2 and 23.5) equivalent to 6.5' and 2.5' of straight tubing, so I thought that would probably maintain the balance reasonably well.

- The reason I want to split the addition off is because a piano is going to go there, and I want to be able to keep that room at as constant a temperature as possible, while I'm okay with the rest of the house being colder in the winter. I didn't spend much time in that room last winter (when the house was bought) but I don't think there are any particular problems with the system as it is.

- The aquastat currently maintains the boiler temperature constantly, and I shut it off in the summer. I don't think it's a huge issue fuel wise, and a big part of why the basement zone doesn't kick on much when I keep it set to 50degF. My understanding is that converting it to cold start would be harder on the seals in the boiler, and also more corrosive with condensation at every startup. Is that correct? Do you think it's worth changing the wiring with these factors?

- I ordered the book, and also read this article. I can see the value in relocating the pumps, but if I were to go through the effort of changing a bunch of the iron pipe I would probably just add another zone pump for the addition, which would make the system more conventional. I haven't drained the boiler yet, and haven't noticed any symptoms of air problems so far. All the radiators have air valves on them. Right now there is an American Air Purger (equivalent to Amtrol 444-1) and expansion tank in the same location as your modified diagram indicates. However the boiler fill goes into the bottom of the boiler.

- I can see how X X would work for the L8124 T T terminals. And then I wouldn't connect the basement thermostat to the ZVC 404 at all, just keep it on a conventional 2-wire thermostat.

- Part of the reasoning of putting it on the priority zone was to get it on a smart thermostat (there is no C wire available on the R845A switching relay according to some internet research). I thought that even though it would have priority it would have minimal impact on the rest of the house since I keep it set low. But it would probably be more elegant to supply a thermostat with a transformer, and use a 24VAC relay directly on the output of the thermostat to avoid any ground level issues (I read something about the transformer in the Honeywell units being center-tapped).

- Keeping the basement off the priority would also be good if I go to a cold-start boiler, in which case the basement zone will probably have to run more often.

Thank you so much for these diagrams (and your experience)! This is very helpful.

0 -

- A delta P circ was also part of my initial idea, but I heard elsewhere (and from Ed here) that it probably doesn't make a huge difference. If the circulator goes bad I would replace with an ECM delta P model.

- Ed has found a clever way to do this. Thanks for the insight.

0 -

I just mentioned it in my reply to Ed, but I was thinking of using this 1-1/4" valve on the main loop and this 3/4" valve on the addition loop (matching the piping on those runs). Those have very high Cvs (42.2 and 23.5) equivalent to 6.5' and 2.5' of straight tubing, so I thought that would probably maintain the balance reasonably well. Do you agree?

0 -

What type and size boiler?

If you have a cast boiler or any non modulating type, splitting zones may lead to short cycling.Especially with a small low load basement zone. You might swap one problem for another

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Boiler: Blue Circle 813 N, originally an oil fired burner, think with a tankless DHW coil. Hot water is now on its own tank separate from the heating system.

Burner: Economite E 20 gas fired conversion burner

Aquastat: Honeywell L8124A

Is short-cycling a concern if the aquastat is not modified? It is currently set up to constantly maintain the boiler temperature, but there has been some discussion here to change it to a cold-start configuration.

0 -

@sre92 said: "I was thinking of using this 1-1/4" valve on the main loop and this 3/4" valve on the addition loop (matching the piping on those runs). Those have very high Cvs (42.2 and 23.5) equivalent to 6.5' and 2.5' of straight tubing, so I thought that would probably maintain the balance reasonably well.

Not a fan of that valve actuator but it is a great choice for the Cv. I never realized that valve had such a high Cv. Now, after all these years, it finally makes sense to use those WR valves

@sre92 said: "The reason I want to split the addition off is because a piano is going to go there, and I want to be able to keep that room at as constant a temperature as possible, while I'm okay with the rest of the house being colder in the winter. I didn't spend much time in that room last winter (when the house was bought) but I don't think there are any particular problems with the system as it is."

We must keep out pianos comfortable. @hot_rod brings up a good point about zoning and short cycling the burner. Since you are using the Taco ZVC series -5 with the thermal purge feature, I would recommend using that feature to reduce burner short cycling.

@sre92 said: "My understanding is that converting it to cold start would be harder on the seals in the boiler, and also more corrosive with condensation at every startup. Is that correct? Do you think it's worth changing the wiring with these factors?"

Rarely is there a problem with converting a tankless coil boiler to a cold start boiler. If you are shutting off the switch in the summer. you are making it a cold start boiler for the whole summer. Does it leak over the summer? If not then you won't have a problem making it a cold start boiler. I like to think of it this way:

- One day in September or October you will feel a little chill. Then you go to boiler and switch it on to warm up the house. From that point on, the boiler will maintain a minimum temperature set by the L8124A low limit dial. Even if the next day the outdoor temperature rises, and stays higher for the rest of the week or so. During the time when the thermostat never calls for heat, you are burning fuel for no reason.

- When that boiler was manufactured there was an identical boiler without a tankless coil that came with the L8148A cold start control. The company made thousands of them. Way back then, the boiler gaskets and seals were able to withstand that cold start design, and the condensation of fuel gasses from the cold start were quickly evaporated away once the boiler reached temperature. Ususlly within 3 minutes of operation.

If you have a boiler that has a leaking gasket and keeping the burner operating to stop the leak, that is not an efficient use of your money. Get the gasket leak fixed and use the savings in fuel to pay for the repair.

@sre92 said: "I ordered the book…"

👍️

I might add that you may want to add a third zone valve for the basement and use the thermal purge on all three zones. Just a thought to reduce short cycling from that basement zone on its own pump. If you do that, then the ZCV404-5 makes a little more sense for the extra ~$30.00 to have an extra zone to use if one zone relay on the control fails for some reason.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

Thanks for all your input Ed!

I read the book.

I've decided that for this heating season I'll close down the dampers on the radiators in the main house, and run the zone off a sensor in the piano room.

Next season I plan on doing it the right way. Changing the setup to pump away, and adding a zone circulator for the piano room. That way future changes (hopefully radiant floor heat in the kitchen once a renovation happens) will be to a much more conventional system, without an oddball combination of zone valves and zone circulators.

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements