Calculating head in primary loop and recommended replacement circulator

Hi, I'm new to this forum so please excuse my mistakes.

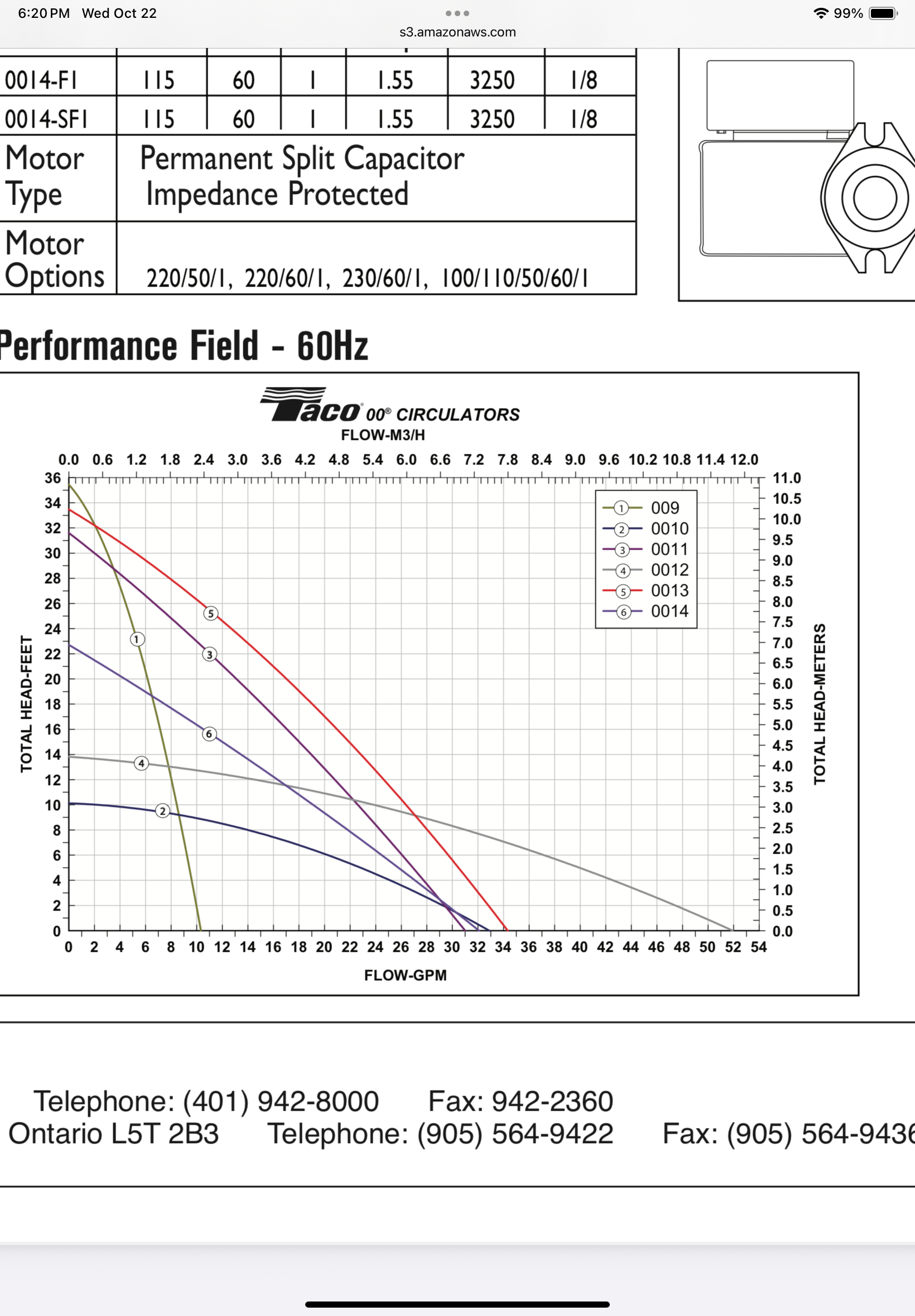

My 24 year old radiant system is showing its age. I suspect the Taco 0014- F1 is oversized and I am looking to replace it soonish. Details of the primary loop:

16 feet of 1.25" copper (6) T's (6) 90 degree bends 1 ball valve 1 Taco air scoop with expansion tank and air vent

Boiler is Laars Minitherm 2 JVS 160, deregulated for high altitude 133,000 BTU/hr Laars says at a flow rate of 12.8 gpm head loss is 1.8 feet. This is at an outlet temp of 180 degrees, Delta T of 20 degrees.

My current max on the boiler is set to 160 degrees. Other system notes: The there are five radiant zones, all Honeywell zone valves, circulated with Taco 0010 F-3. The system is controlled with a Tekmar 356 variable injection (Taco 007-F5) DHW is a separate loop using SuperStor indirect, Taco 007-F5 circ.

I calculated 5 feet of head at 12.8 gpm. Is that even close? And what Taco circ would be a good replacement? Thank you in advance.

Comments

-

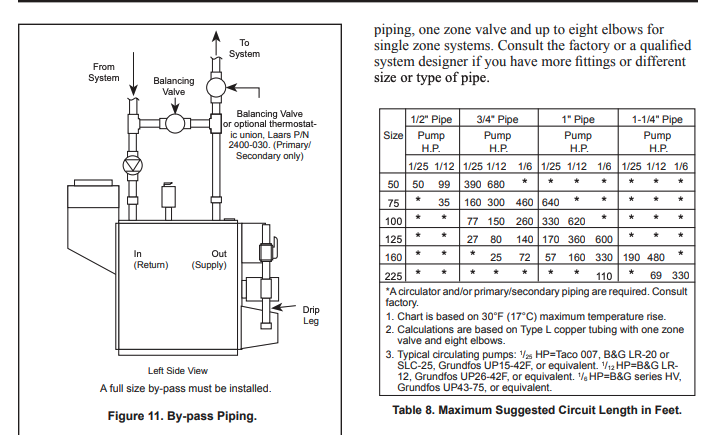

Laars has a pump selection table 8

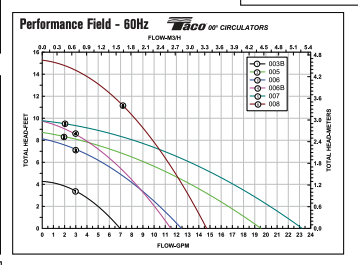

It shows a 1/25 hp circ for the 160, that would be more like an 007. 13 gpm 6'

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Dose the system not work well or is noisy? Why would you go with a smaller pump and risk it not working. need more info to convince me.

0 -

I come up with 13.3 gpm & 4.02 ft of head

0 -

Yes it is noisy. Always has sounded like bubbling water once the primary loop is heated up. But I agree, prob does not need to be replaced just on that premise. I'm just thinking ahead at this point. And trying to get other peoples opinions.

0 -

I suspect there are many over pumped systems out there.

If you trust the numbers from the man and @HydronicMike 13 gpm range, less than 5’, then a 0014 is way off curve for the job

Over pumping leads to high flow velocity, which often presents as noise. Does the boiler short cycle, on and off a lot during a load?

Check the delta across the boiler S&R to get an idea of actual run conditions.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

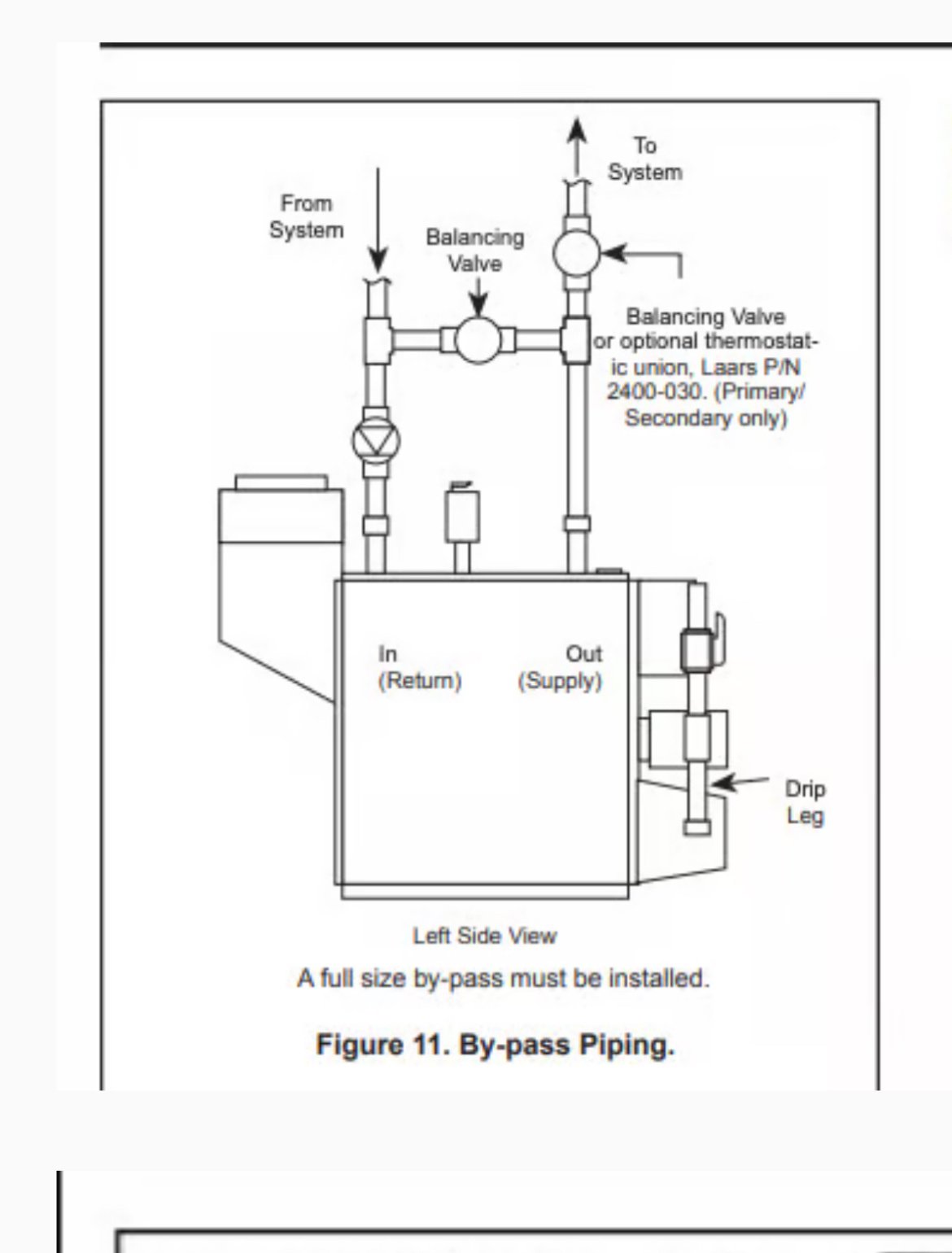

I don't have much of a reference for what short cycling is. But if I had to guess, I would say yes. My house is mostly heated with a gas fireplace. Two zones (the bedrooms) get heat during the cold months. The other zones not so much. I'll get a IR heat gun on the S&R to see what the Delta T is. As a side note, I live in the high rockies. Similar aged boilers here have a modification where a pipe has been soldered between the S&R close to the boiler and the ball valve just closed slightly. I was told this is to help stop short cycling. I kinda thought this is what my primary loop is doing.

0 -

That is a pretty good sized boiler for a residence, what size home is it heating ?

A couple ways to install that bypass crossover. Either an adjustable valve, like a globe valve , or Laars has a thermostatic valve to put in the piping

It keeps the boiler from seeing cold return, mostly used on slab radiant systems. It aslso assures the boiler gets some flow as zones close off

If it has run 24 years without it….

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

if your pump was acting like an oversized pump, you would experience velocity noises, where you would hear the water racing through the system piping. The noise you’re referring to, sounds more like air?

Check your system pressure make sure it didn’t drop, and if that noise persists you can try purging the system, one zone at a time isolation of others while forcing air out using city water pressure. Hopefully this helps. Also, Taco has a very knowledgeable Tech support team that can provide further assistance at 401-942-8000

Joe Mattiello

N. E. Regional Manger, Commercial Products

Taco Comfort Solutions0 -

@hot_rod "Does the boiler short cycle, on and off a lot during a load?"

my thought also. because that boiler has no turn down, with an injection system that often uses part of its capacity, i.e. couple bedrooms reported as principle regular load, I would say its overpumped and underutilized. but even way wide of specs it has worked fine for 20 years.

the bypass would not be to stop short cycles but, as @hot_rod notes prevent cold return to boiler although I can't quite tell from pics because i'm not sure i'm seeing your secondary pumps, but a primary loop essentially performs that function already unless secondary pumps against their head are are crazy oversized.

now, the 356 should do some cycle flattening and depending where the sensor is located can be set to seek a minimum return temperature to boiler irrespective of the radiant curve target temp. i'm not precisely sure how it balances those when trying to limit short cycling. But a real world way of looking at this, besides checking the delta T is to hang by the boiler and time your cycles.

while that stuff looks very neat that was done before the era of isolation flanges for circulators and i'm not sure bleeding was really well thought out. inter alia, i don't see an isolation valve on the return (labeled "IN" on the boiler I think) and that comes from what I assume is the primary circulator high up next to the wall on the return so you can't cut the boiler off from bleeding water that is higher than the relief valve. and you can't limit the air to the pump change. and the location while efficient in keeping the mechanicals to small corner looks like a real PIA to get up there. without those constraints, after checking delta T and cycles, I'd just through an 007 or maybe a grundfos or Taco 3 speed and then you can try 3 different curves without changing the pump, if you are into empiricism which has, i admit, generally been my methodology.

This setup is kind of one of the best cases for a modulating boiler or what i've always done is just used a domestic hot water storage tank as a thermal flywheel and water separation for floors (many of mine were put in before anyone thought about oxygen barrier and honestly, I like the flywheel effect anyway and you get a used domestic storage tank cheap because people take them out either in favor of combi boilers (which I hate) or stand alone on deman (which I love). I just needed a very specific unit , triangle tube smart40 or the weil mclain equivalent because of the tapping locations, and it took me a month of waiting on facebook and I got one for $50. that will extend cycles and cut starts. starts are not as much of an issue for an atmospheric. it does take up a little room, but I would really want to give some room to the system so the pumps could be installed where taking them off doesn't drip the contents onto other components, esp. electrics. and where they are just plain easy to access.

But if your system worked for 24 years with it sounds like limited maintenance and NO (editted to add, i always leave out the important word) need to open the system, you could leave it and maybe it will work for another 24, seriously. It is good to think ahead about what to have on the shelf if something breaks, but honestly, if anything broke apump is the least of your worries because they are everywhere accessible. if something does need replacement, or if you are getting the 25 years time to prophylactically replace some stuff itch, I'd buy a propress and change the piping around to improve circulator isolation and physical accessiblity, bleeding (i also jump out a tee after the backflow preventer with a ball valve that bypasses the pressure reducing valve for bleeding purposes because those PRVs are one of the weakest links in the system. These valves generally don't get a lot of exercise and when they are need the most, e.g. when I hit the 'quick fill' mode after they have been sitting, half the time it won't shut off, sometimes it doesn't go on. Caleffi's are great, not blowing smoke @hot_rod, but I still pipe around and I like to have bleeding tees with ball valve to pex to an open drain, e.g. laundry or set tub often available, instead of having to hook up a hose to bleed when I give a system I will have to maintain a going over.)

there's my novel, fear and loathing in the boiler room (well i get to make a head to head comparison with fear and loathing in las vegas at AHRExpo this year.)0 -

-

PS in the NFN department, this system is not configured to pump away from point of no pressure change. i hadn't stopped to think if that is as important with a short low head primary loop. its a little bit of a thread jack but I do mean it in service of larslars, if he ever has to open the system, is that a relevant consideration with any reconfig or given the low loss it doesn't represent that same potential issue as pumping toward the fill and expansion in a non primary secondard approach with a much higher head loss in the heating loops?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements