3 Q's: PexA - Heat removal from attached MA and Pex2Copper Press fittings | Swing arm still needed?

I have some Uponor HePex to replace before I close up some areas, where I it was exposed to some light for several years. Yeah, it was a mistake not covering it. Three questions… sorry for the tall order!

1. I have a couple stainless manfolds with brass male uponor pex adapters. On one I used blue monster teflon tape + megaloc sealant. The other T+2 only.

Given I have to heat up the tubing quite a bit to remove it, and the fitting will also get hot, do I need to remove the MA fitting, or it's fine if the tape/sealants get hot?

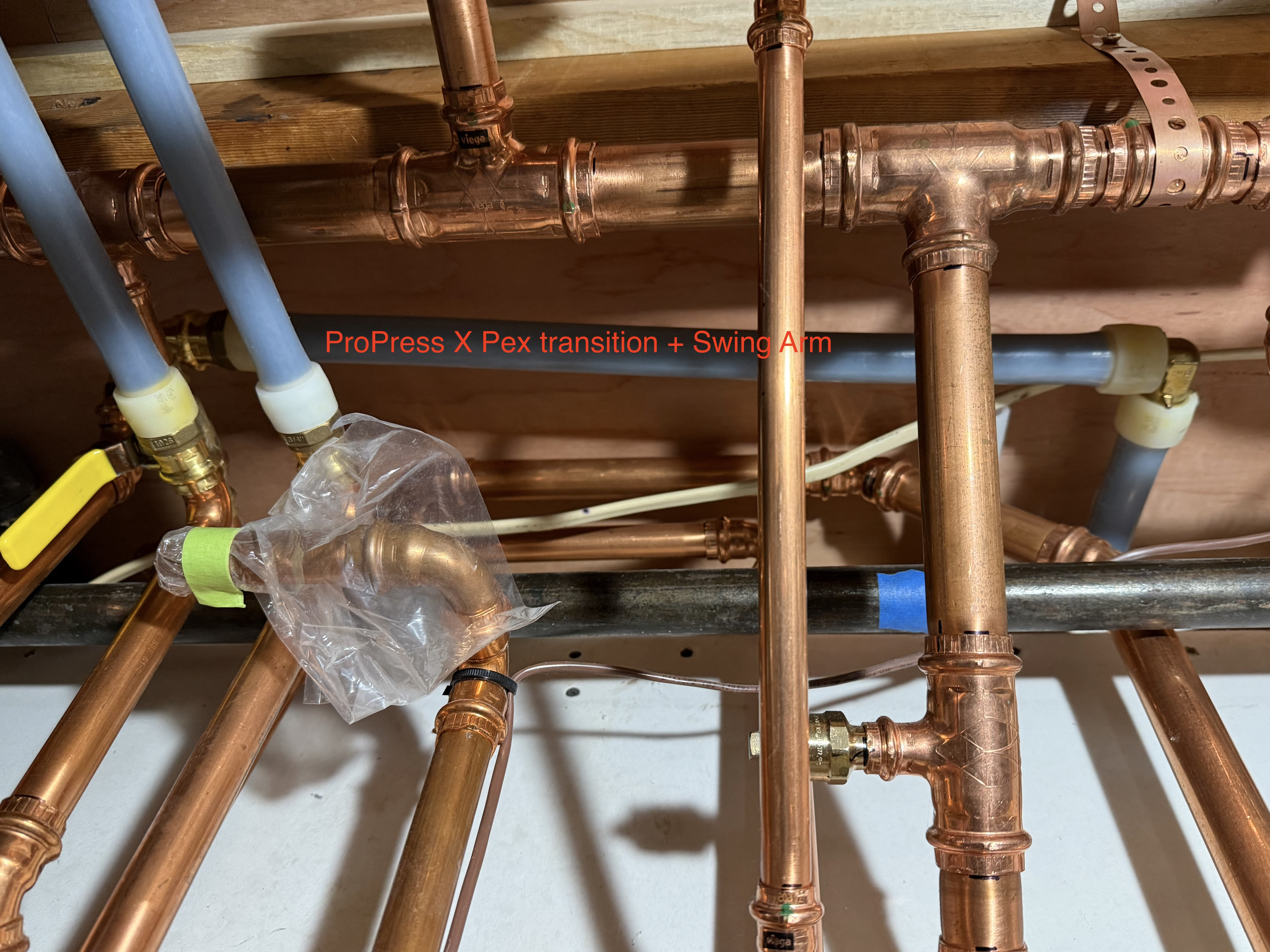

2. I have some Uponor adapter fittings for Copper Press x Pex. I called Uponor tech support to see how hot the fitting could get during PEX A removal, given the sealing o-ring… they couldn't tell me! I see Viega's ProPress fittings are rated at 250F. I will certainly try to shield the fitting and put a cool rag on one end, so may not be a real issue.

Do I have to worry about overheating the sealing element in the press portion of the fitting?

3. HePex thermal expansion question. When I initially installed the main supply and return HePex 1" lines (about 40' long through joists), I put a swing arm on one end and the other end (once it transitioned from 1" to 3/4"), I made a long u-shape. I was later told that if I used the mickey mouse clamps on it at every joist, I didn't need to worry about expansion(?). This distribution line will be mid temp - about 135F.

Since I am now replacing the tubing… should I keep the 3/4" long U to account for thermal expansion, or is it truly not needed with the clamps? If not needed, how tight should the clamps be?

Thank you all. Always appreciate the great insights received here.

Comments

-

can you split the pex rings with a hack saw blade and pull the pex off? No heat required,

That is how I remove pex that has had copper crimp ring connections

I did recently buy a crimp ring splitter pliers. It works faster than sawing

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Bob, probably so for the ring. Maybe even an oscillating tool with a narrow blade and great care. However, since it's PEX A, I am thinking I'll still need heat to get the actual tubing off? I'm all ears for ideas without heat.

My guess is if I shield and use a cold rag, it will probably be fine, but certainly don't want an issue years down the road.

0 -

Re: #1: Seems the megalock is good to 400F and the blue monster to 500F, so I should be good on that. Tplus2 spec sheet only lists some standards temps that go up to 140F, yet their other docs say good for steam applications, so I'll call them tomorrow to confirm. I think I'm probably good on #1.

0 -

you can whittle the pex away slowly until you get almost to the brass to get it off the fitting. be careful because there is a ridge in the fitting that sort of sticks out. I wouldn't be super worried about how hot the other end of the fitting gets if you concentrate on the tubing, since the tubing is nonconductive the heat won't transfer much to the fitting if you concentrate on the tubing and just get it hot enough to slip off.

btw, painting the tubing would have shielded it from uv.

2 -

Matt, thanks for the great tip on the paint - that's helpful. I did check what types of paint they allow on the HePex, due to the sensitive O2 barrier (water/latex based), and they did share with me to check with the paint mfg to ensure it blocks UV, as he mentioned some do and some do not.

For posterity, I checked with rectorseal about Tplus2, given they list 'flash point above 300F' and only mention 140F in the spec sheet. they confirmed a working temp up to 350F.

Now, just need to figure out if I keep that U for thermal expansion reasons. I've gotta think the pipe will actually move when varying between 60F and 140F, regardless of the mickey mouse clamps.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements