Draft inducer motor for gas boiler

Looking to get a backup motor for my gas boiler’s draft inducer unit. My unit is a Jakel with a 3000 RPM motor. I have located replacement motors rated at 3000/2500 RPM. Would this motor provide the necessary CF/ m ? Why would a motor be rated at two different RPMs? Thanks for any advice.

Comments

-

I can't see and you don't say what kind of boiler you have. If it is a high efficiency boiler you generally have to but the OEM blower assembly from the boiler MFG. As far as I know you can't just replace the motor on those. Need more info on what you have

0 -

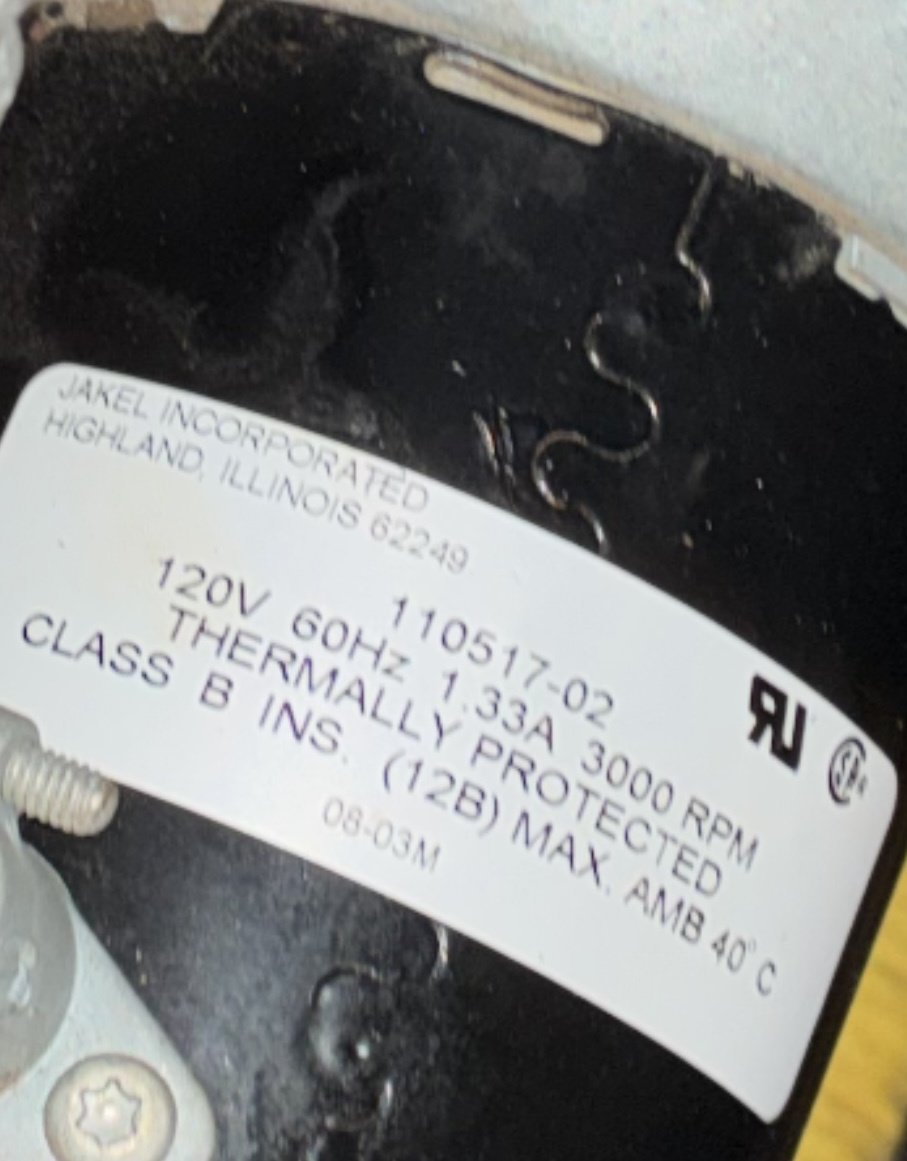

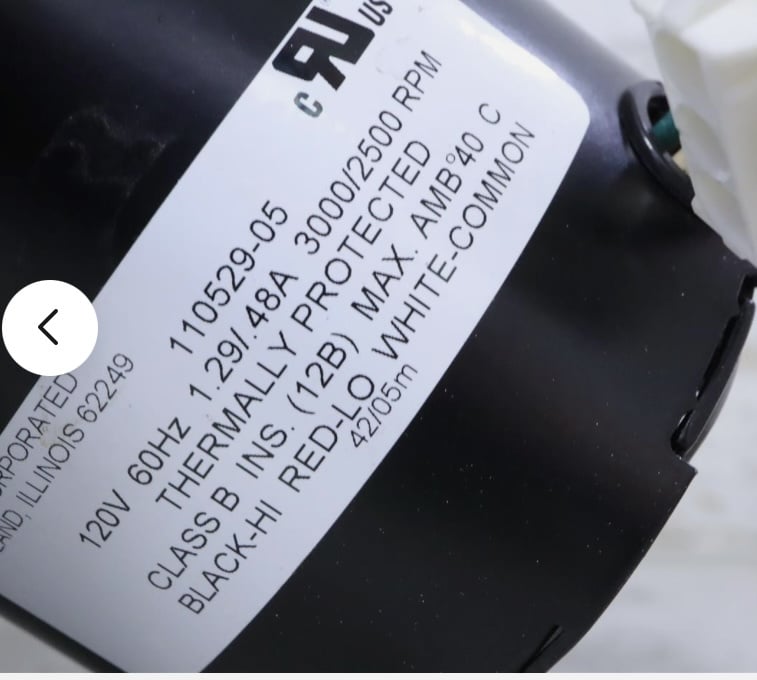

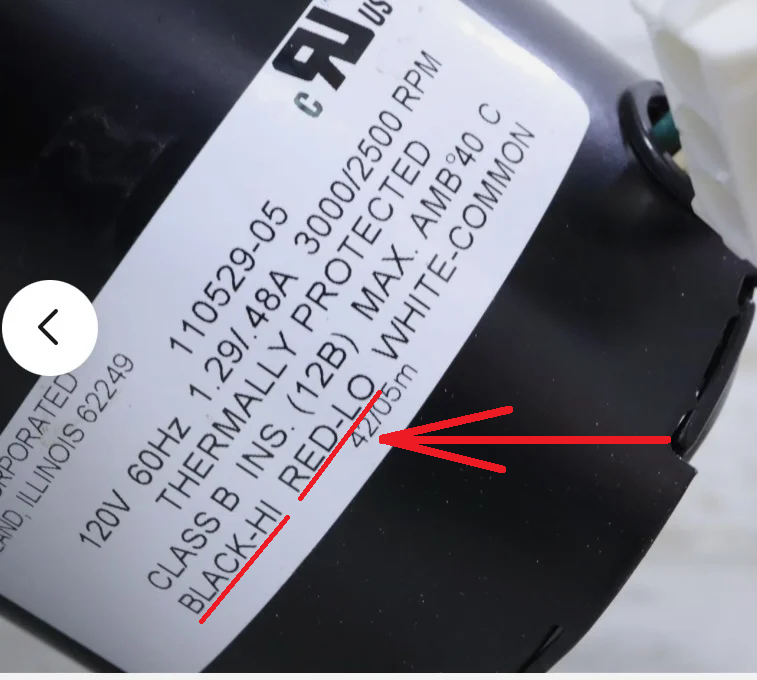

Some motors are two speed. However Line frequency, I bet the 2500 RPM is the 50 Hz speed (3000 RPM is the 60 Hz speed). Post pictures of the stickers on the motor.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

The boiler is a Buderus G 124-X-32 . Attached is a photo of the existing motor tag, and another of the potential replacement ( with two RPM ). It seems likely the two RPM are for 50 and 60 Hz applications. I notice the different serial numbers. Thanks for your input!

0 -

-

-

I agree that you do not want to get "just the motor". That motor only is not a repairable part. otherwise Buderus would have that motor only as a one of its available parts. There are seals that allow the motor shaft to penetrate the blower housing that are factory installed and provide protection form carbon monoxide or the fuel gas from leaking past the shaft seal. There are no DIY or in the field repair parts that can be easily installed without the fan manufacturer's factory equipment.

I'm not sure that combustion inducer fan is from a Buderus G 124-X-32. That model number appears to be a natural draft boiler with an automatic vent damper. Are you sure you have the correct model number form the boiler and not from a piece of literature that someone left there with the boiler? That looks lime it might be from a GA244 or some other Sealed Combustion boiler

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

-

-

-

-

EdTheHeaterMan:

Interesting to consider that the draft inducer may not be the intended vent. The vent seems to function satisfactorily (we have used it for two winters), though I would prefer the simplicity of a natural draft. I appreciate the information that I should look for a complete unit with the same motor specs. Thanks!

0 -

Is this unit inside the boiler or used as an external power vent ? Better pictures of the situation may help.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

The unit is external.

0 -

As @EdTheHeaterMan suspected, I don't think that inducer is approved for that application. No draft proofing for one thing. Does it vent through the wall or into a chimney ?

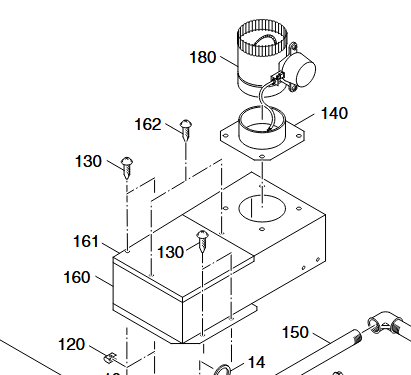

180 is a Damper.

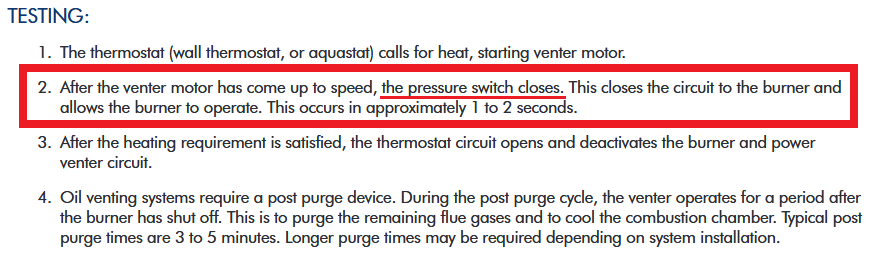

I don't see any provision for a pressure switch in your situation.

From a true Power Vent document.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

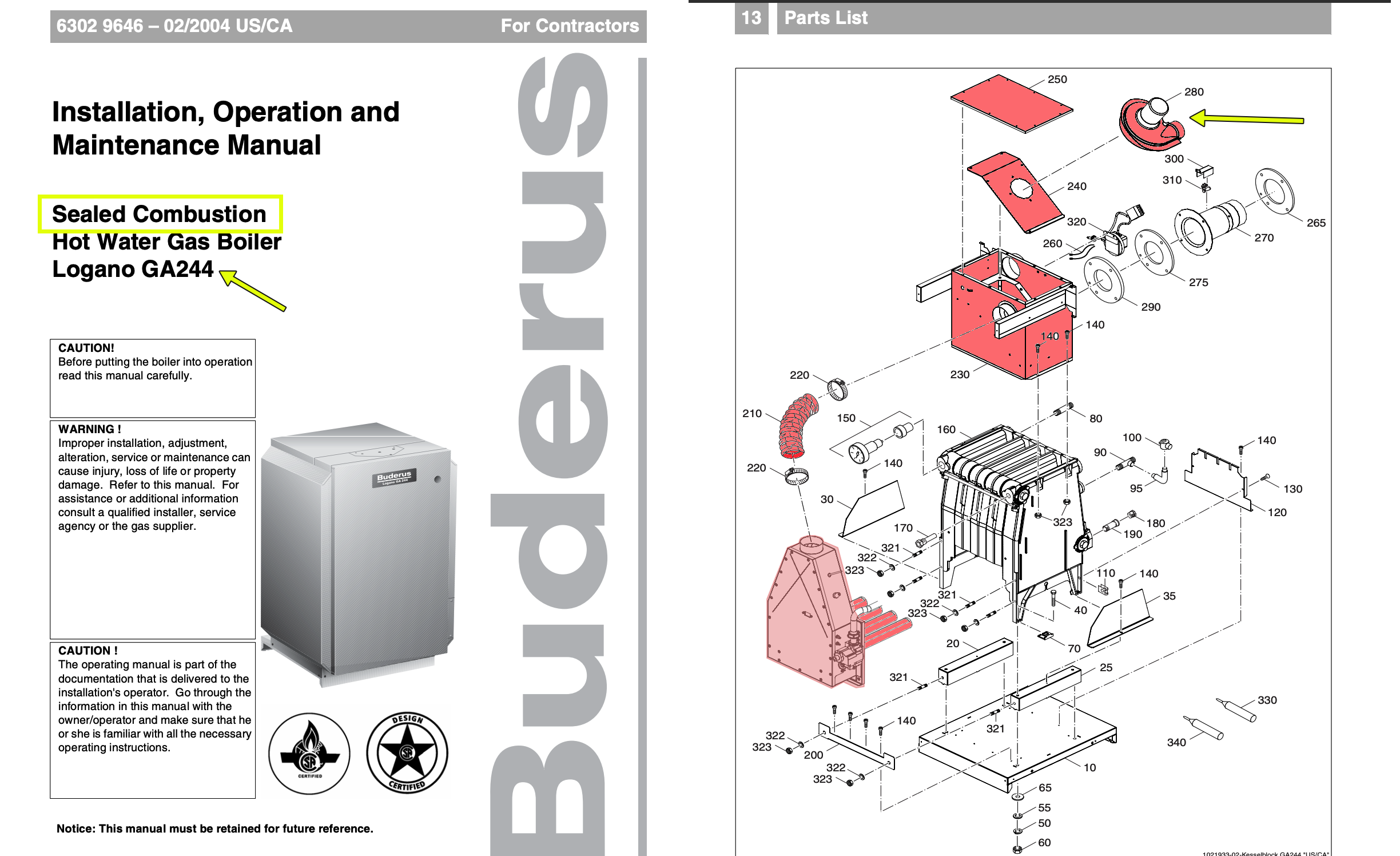

Someone made a mistake here. That venter motor is for a sealed combustion boiler or furnace like the Buderus GA244. Here is the cover page and the parts page of a Buderus GA244.

See how the red shaded areas are sealed against the boiler with gaskets and sealant (not shown) so the combustion air is metered in at the burner and out at the combustion fan. This is considered a Category III vent system that must be properly sealed, starting from the combustion air inlet, from outside the boiler room, all the way through the boiler heat exchanger and out the exhaust pipe, until it reaches the outdoor termination.

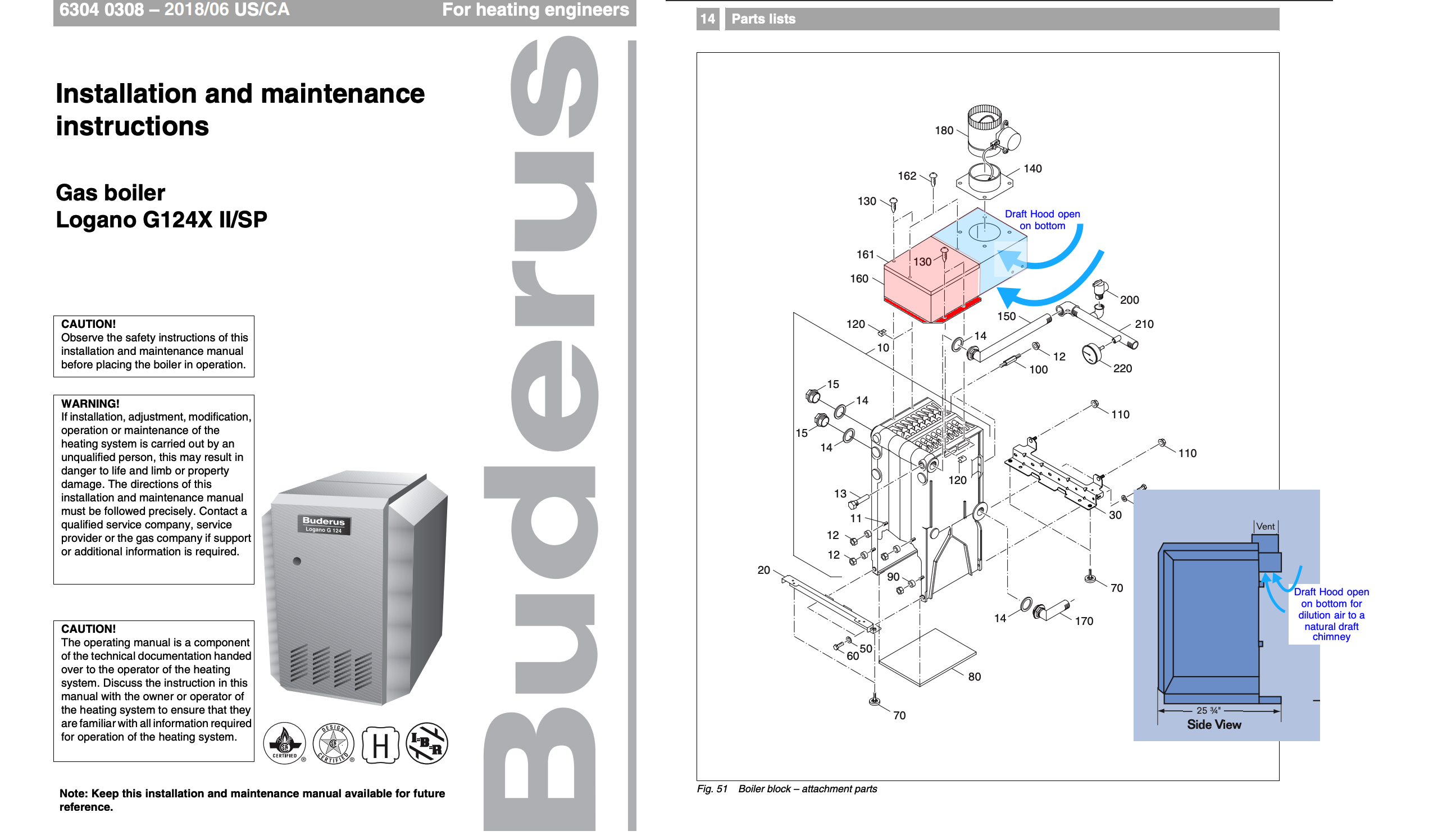

Here is the cover page and the parts page for the G124X boiler it is a category I vented boiler

I added a side view from the dimension page to illustrate that the G124x is not a sealed combustion Category III vented boiler. Look closely at the bottom of the cast iron portion of the boiler on the parts page. It is wide open for the atmosphere to provide combustion air to the burner (burners not shown). The red shaded area of the flue gas collector box is sealed to the top of the boiler and the blue area of the same box is open to the atmosphere. There is no bottom to that portion of the box. This is clearly not a sealed combustion boiler and ahould not have a combustion fan assembly as shown in the photo.

I would stop using that boiler with that non-authorized venting system at once. You need to get the correct boiler, or you need to add a Cat I vent system to continue to use that boiler. There are a couple of options like B-vent manufactured gas vent system, or a Power vent by Field Controls or Therndlund

EDIT:

There are some other observations about the photo:

- The inducer assembly appears to have a plastic housing.

- That particular inducer assembly is intended for a Rheem/Rudd condensing furnace.

- That is a category IV furnace with lower exhaust temperatures than the Buderus G124X.

- As @109A_5 mentioned there are no provisions in the Buderus G124X factory wiring to prove the fan is operating .

- There are safety pressure switches on the Rheem furnace it is intended for.

- I feel that the parts will fail as a result of overheating and will cause a dangerous condition where the boiler fire will continue to operate after the fan housing fails.

- Without proper exhaust because the fan will fail and there are no safety switches that prove the fan is operating, the exhaust will be vented into the home without anyone realizing there is a problem.

- You may not have time to wake up from your carbon monoxide poisoning to fix the failure if it happens when you are sleeping.

- Recommend you get the correct venting, or correct boiler, or don't sleep there when you operate the boiler.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements