Will this hydronic layout work?

Hello everyone. I am building my own home and will be installing radiant heating in my basement and garage. I am a gas fitter but dont deal with hydronics often but I have designed this system for my home. The system is using IBC HPX 5 air/water heat pumps and other IBC components. My question is about the heat exchanger in the diagram. Would this be better as a buffer tank? Originally I had designed it with a 50gal buffer but IBC tech support recommended against it saying the thermal mass in my concrete is enough to provent short cycling. I agree with this at colder temps when I actually need the system design btu but when its warmer out and the heat pumps are even more efficient, I feel like it will short cycle. They also recommended not to use the heat exchanger and just run glycol in the entire system; but thats a huge amount of glycol. I would use the buffer tank regardless if it werent for the fact I will be using the heat pump for cooling as well through the AHUs. I have read the buffer tanks dont fair as well in cooling mode. It also presents a problem in the shoulder season where you might need cooling one day and heating the next. What do you guys think about the design? Thank you.

Comments

-

What is your outdoor design temp? How much summer cooling and dehumidification do you need in your climate?

You are showing about 100k of emitters. If old construction in cold climate, is that house about 5000sqft? Extra capacity with heat pumps is expensive, you want to get an accurate handle on load.

I'm living with it can can tell you in cold climate making DHW with and AWHP is not worth it. Once it gets near single digits, recovery is forever and COP is close to 1. A regular HPWH is cheaper and gets you better combined COP.

Not seeing any radiant for bath/kitchen. You definitely want these. I run these as always on as outdoor rest takes care of the thermostat work plus it keeps it a bit warmer than the rest of the house which is a good thing.

The IBC rep is correct about a buffer tank. As long as you have enough always on emitters you don't need it.

You never want to mix down water with a heat pump, there is bit difference in COP between making 120F and 90F water. I would figure out a layout that lets you skip it. I run my low temp emitters downstream of the high temp ones, they are essentially using the return water from the high temp zones.

Cooling with water is generally not worth it unless you want to micro zone. If you are running ducts, get a standard air to air heat pump. Cheaper BOM, higher efficiency and you don't have to deal with condensation on your water lines (harder than it sounds as EVERY little thing exposed will sweat).

I run plain water in the monoblock on the north edge of zone 5. You have to take some precautions but possible.

1 -

The design SWT for the air handlers will be the number that the HP needs to run. Get that as low as possible. Perhaps the radiant runs that same temperature? There may be times the radiant runs and the AH are not, so the one temperature system needs to work for all heat emitters.

Glycol does cost you some heat transfer and pumping penalty. I would not glycol the entire system$$ and leak prone. The HX is easy enough to pipe in. Size it generously.

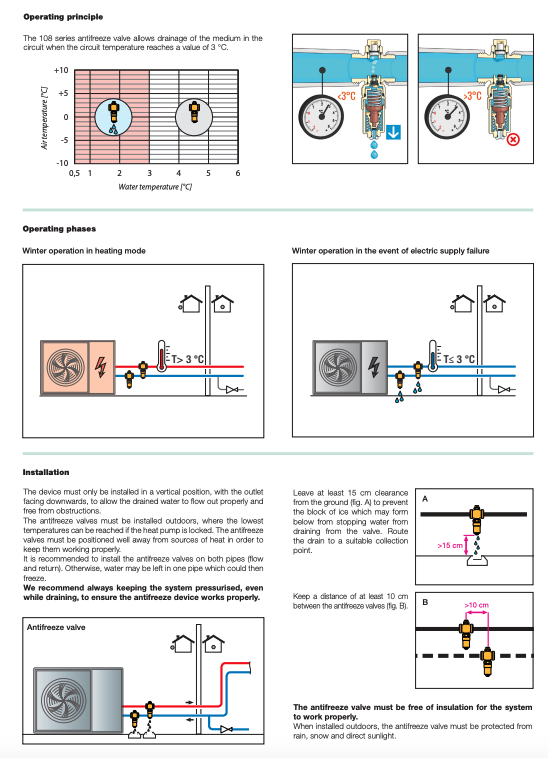

In moderate climates the I-stop valve protects plain water systems. SUNY Morrisville has been testing the drain valves this winter on a system in a freezing climate. The I-stops are very common in the UK systems.

Beware that the drain valves are at the low spot, in some cases the HX in the outdoor unit is lower than the piping connections and would not be protected.

Buffer tanks when used are getting much smaller 10- 20 gallons seem to be the common sizes now with better compressor modulation. If you use a buffer go withn a 3 pipe arrangement as on the cover of this tech journal.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

My design temp is 1F. Also Zone 5 near Toronto ON. We may have hit that temp about 10 days this year. House is 4600sqft plus 1400sqft garage/shop. New construction, triple glaze windows and spray foam insulated. I figured with 10 tons of heating, those heap pumps will put out only 26mbtu each at -13F at a cop of about 2. There is a 115Mbtu boiler in the system for supplemental/backup heat on cold days and for dhw via indirect tank.

It sounds very risky to me not to run glycol out to the HP. Im glad you agree on the buffer tank but I wil keep the heat exchanger to to separate the glycol system which is also in my garage.

That is a good point about the sweating. I would obviously be insulating everything but still good to consider.

Perhaps a more simplified system would be to run a single AWHP for my radiant loads and then AAHP on my forced air systems. But those AAHP would also require gas backup for super cold nights. Seems we are just getting into a lot of stuff.

0 -

No doubt it gets to be an expensive system with HX, back up, DHW, multiple systems, etc. Plus hours and hours of labor to get it all installed correctly.

Design in my area is 0-5°F and I went with glycol. The HP, piping and HX holds less than 5 gallons. The SWEP people helped me with a proper HX sizing.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

50% glycol seems a bit extreme though doesn't it? Even if you mix half and half with a standard boiler antifreeze like noburst -100 you won't quite have 50% glycol

0 -

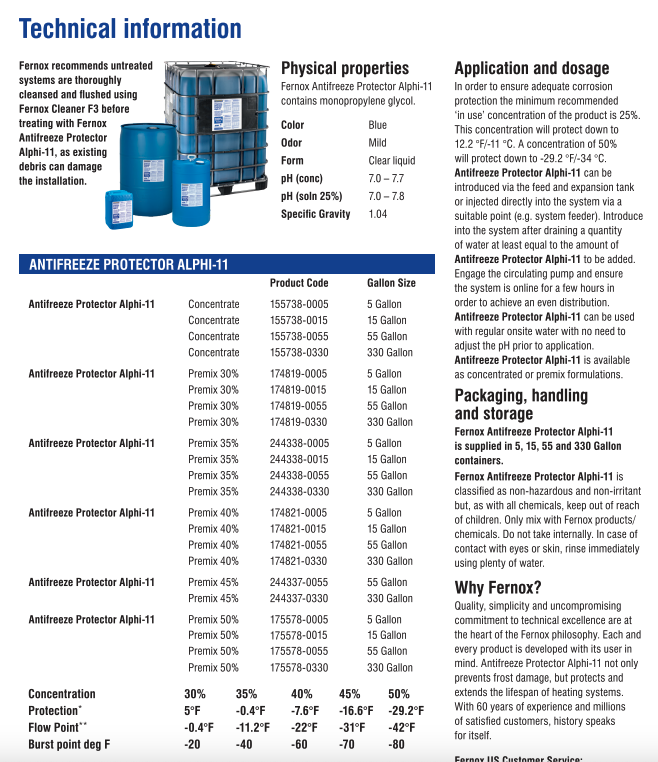

There are three temperatures to look at with glycol, here is an example of the 1'st column 30% Fernox Alphi product.

The first number is where ice crystals start to form, but the fluid is still pumpable.

The second is the slush point, no longer pumpable

The third is the frozen solid temperature.

It is rare to need more than a 35% mixture which is a -40°F burst.

These protection numbers vary from brand to brand, so check the spec sheets.

Many of the A2WHP run the pump constantly, so more protection for plain water use.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

With a heat pump, you always have to be conscious of the temperature difference between outdoors and the output. The greater that difference, the lower the efficiency and the lower the output of the heat pump. With an air-to-water heat pump you always want to have the coolest water that will do the job. The complication is that your emitters — the things that emit heat, radiators, air handlers and heated floors — will always put out more heat with hotter water, so you have to balance trying to keep the water temperature down with getting enough heat. Most heat pumps have outdoor reset which automates that balancing.

The problem with heat exchangers is that in order to get the same temperature drop on both sides you have to have exactly the same flow on both sides, and with a heat pump it's hard to guarantee that the flow is the same. The heat pump has a variable speed circulator, it's trying to modulate the compressor output to match the load and modulate the circulator flow to match the compressor output. So unless you have some way of modulating flow on the heat exchanger output you're not going to be able to get the same temperature change on both sides. This is going to mean that you output water is not going to be as hot as the input water, so you're giving away both efficiency and capacity.

To the question of using your floor as a stand-in for the buffer tank: you can do that, but you can't have any zone valves, and you have to be willing to accept fluctuation in the room temperature. The purpose of a buffer tank is to keep the compressor from short-cycling when all the zones shut off. If you have zone valves you have to have a buffer tank. If you don't have zone valves you don't have any way of thermostatically controlling the heat output.

The buffer tank is also used to provide heat when the heat pump goes through a defrost cycle. Zone valves will interfere with that as well.

I agree with @Kaos that providing domestic hot water is a poor fit for air-to-water heat pumps. In addition to the reasons he cites it doesn't save any money on the initial install cost, nor on the operating cost, nor does it save any space in the mechanical room.

0 -

A mix of AWHP and ASHP is much better value, in your case I would guess it would reduce the BOM cost by about 1/2 and about the same, maybe a bit less, install work.

1F design is well within the range of vapor injection units. Since you would have multiple units, they are their own backup, no need for extra. The ASHP deliver more heat at low temp, many units provide their name plate output at 5F, some even at 0F, they don't loose as much output as monoblocks. If you are in an area with frequent power outage, I would look at something non powered for backup like a pilot operated fireplace or through the wall vented heater. Even if you have a generator, they might still not start and you want something that will keep your place from freezing. If you want some backup, I would look at either a strip heater for the ducted units or an immersion heater for the monoblock.

With air source heat pumps, zoning gets expensive, so I would look at reduce it to around 2 zones. You can still zone smaller zones with a damper on the supply driven by a local thermostat as long as they are small fraction of the overall output with any fancy zoning controllers. You mention loft, the key to multi story comfort is to have a large return near the ceiling on the top floor.

I would still get a better handle on your actual load. Code min construction with reasonable glazing size especially if triple pane at 1F design should be around 10btu/sqft. Spray foam is still just insulation so if standard 2x6 construction you have an R20 assembly. Not bad but also not a lot of R value.

With the garage heat in there, you will need glycol and a plate HX anyways, so it makes sense to have the monoblock and garage on the glycol loop. The key for efficiency with air to water is to oversize the plate HX, you want very low approach temperature. You also want the house side loop to run at a lower flow rate than the glycol side, make sure not to overpump. If you set up a good portion of the house zones as always on, you can skip the buffer tank. I would set any high traffic areas as always on and only zone areas where you want to turn down the heat when not in use. Even better, skip any zoning and just use the outdoor reset, it works supprizingly well and free.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements