In FPHE separated water/glycol system, what is advantage of circulator on glycol "cold"/return side?

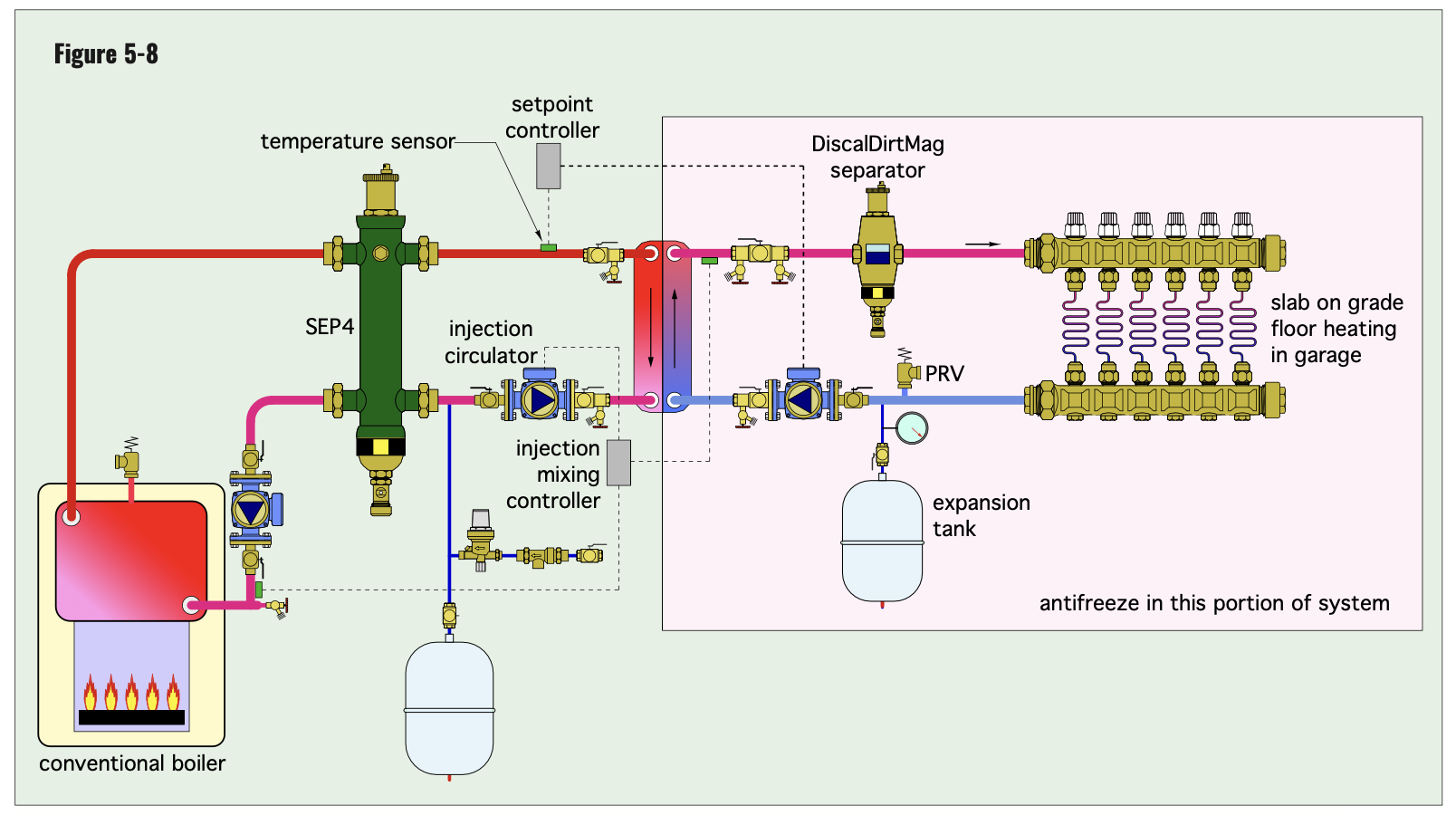

In Idronics 29's Figure 5-8 (first picture below), shown is an example of a FPHE separated system and on the glycol sidee, the circulator pumping away on the cold side/return piping. Certainly this allows a single combined dirt-mag-high performance air separator on the hot side, correctly pumps away from a low hanging expansion tank, which is also conveniently positioned, but is there any problem for the circulator pumping cold glycol, which could for example be below freezing at least briefly in initial start up (or for some time in a snowmelt application?) The usual criculators all have water temperatures above 36 degrees in their specifications (i.e. Grundfos alpha).

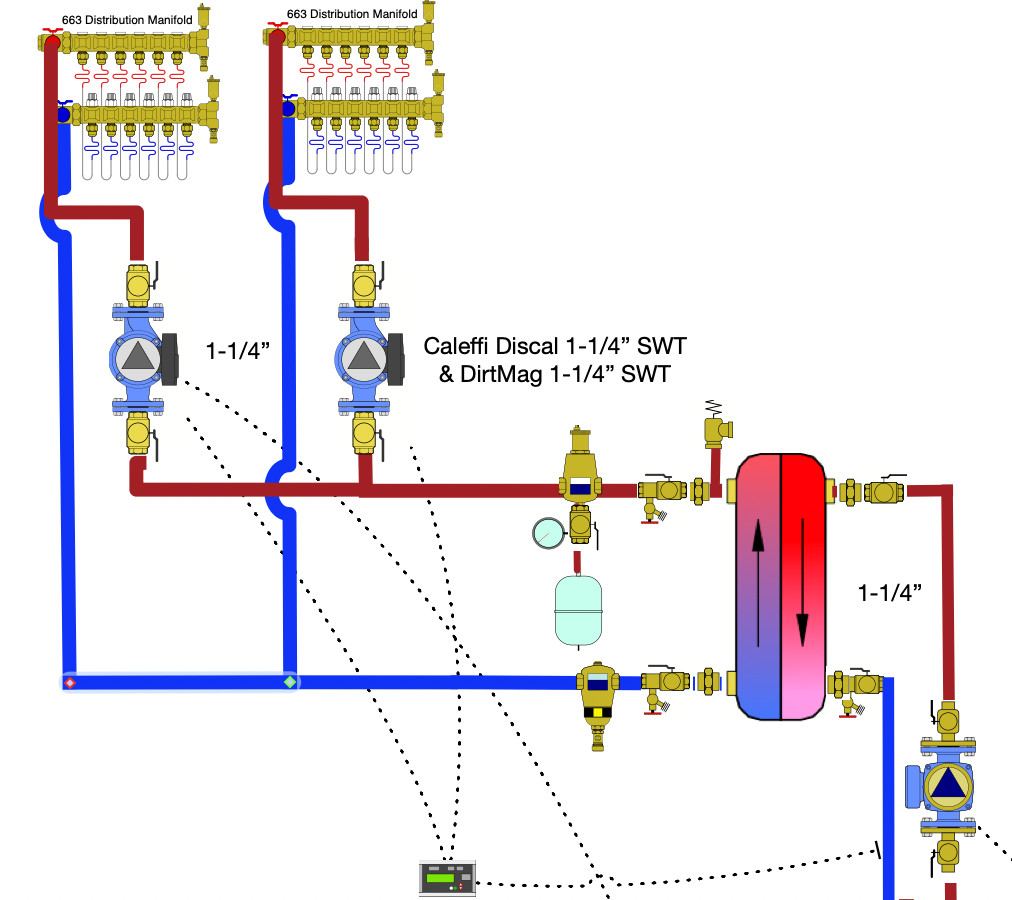

Obviously, the alternative (2nd picture) is to move all of those components to the hot side and get separate air and dirt separators if protecting the heat exchanger is desired, and deal with awkward location of expansion tank on hot side which I suppose is also suboptimal? Or is the application everything and this would be a bad idea on snowmelt for example.

(Lastly, for the PRV on the glycol side, is there any code requirement that there be no valves between the heat exchanger and the PRV? My particular code seems to require a PRV on the glycol side for a single walled heat exchanger for occupant protection ("(b) The pressure of the heat-transfer medium shall be limited to a maximum of 30 psig (207 kPa) by an approved safety or relief valve." from 603.5.4.1, Ch. 4717 Mn. Plumbing code), but otherwise isn't very specific about its location. Adding flush valves or circulator isolation valves could defeat them but it doesn't seem particularly pertinent or the intent here since if the goal is to avoid fouling of domestic side water, closed valves would make it a moot point, and a functioning system would drain tap water through the relief valve if the FPHE failed and a autofill was on on the water side. )

Thanks!

Comments

-

yes the HX could get a slug of even 0 degree glycol. So starting the boiler first may prevent freezing the A side. No issue with the glycol side pump on the supply side, either

This piping keeps the relief valve “seeing” both the heat source, and the expansion tank, it cannot be valved off.

The lower purge ball valve isolates the DirtMag, and one side of the pump.

Use the Webstone purge ball valves that allow you to purge from either side of the ball valve

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1

Categories

- All Categories

- 87.4K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 115 Geothermal

- 168 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.8K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements