was this old boiler gas or oil fueled?

I have a boiler museum in the basement. I'd like to smash or cut this one up and cart it away but I'm hesitant to make any sparks around it. if its full of oil, it could be dangerous . This thing is beyond heavy.

Comments

-

How about a pic of the other end?

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting2 -

i'm not even sure that is a boiler. the box looks like the flue collector

0 -

Looks like a horizontal steel tube.

0 -

there was a wood fired boiler made in California, Missouri that was shaped like that,

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

i found the nameplate

american standard model 319

steel boiler.

max WP 30lb

net edr 850.

----

And very large threaded fitting top and centre front.

small flare fitting front lower left.

there are no fittings on the back. just a hole (no threads or anything about 1 inch diameter. maybe air intake?

0 -

It was oil. that tube in the middle is where the burner went in and that flared tubing on the left is the oil line in the floor.

That round port you cut off is the inspection and observation door for the combustion chamber.

or maybe the burner tube went in to that box. it is hard to tell the scale. that line out of the floor very much looks like a copper oil line for an oil burner

0 -

What's at the upper edge of this picture?

Looks like a hole.

Trying to squeeze the best out of a Weil-McLain JB-5 running a 1912 1 pipe system.0 -

the big hole (the core). some sheet metal venturi spirali/fusilli down in those bores.

the small hole in the back. the one in the lower left is capped off.

Home Depot pails and 2x4 studs for size reference.

my plan is to chop it up with a large hilti cutting disc. possibly smash the core with hammers. I'm worried about fire risk if there is still some oil in there somewhere. I didnt find an oil tank in the basement so not sure about this one.

0 -

@Rickam , can you re-check the rating plate? I can't find this boiler in any of the usual references. The only 319 I could find was an aboriginal round coal-fired cast-iron boiler…………..

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

-

Oil needs to be atomized to a fine mist to ignite. I was taught that an open flame won't burn #2 fuel oil. I'd be surprised if there was any danger in cutting up the boiler.

0 -

thank you for all the advice and input. The boiler model is 319.

I'll be using a cutting wheel, hammers for the core, and a reciprocating saw. (not a cutting torch) so all I have to worry about now is asbestos.

0 -

I dont see any asbestos there. All the insulation is gone by the looks of that pic. As far as where the fire box used to be, and any asbestos insulation near that chamber… that part is also gone. the side with the flue collector is the front or back and the side with plate bolted on it might have some gasket or furnace cement between that plate and the boiler. The top is the part where the rag is stuffed inside the supply pipe tapping.

The actual heating unit's bottom was a box that was the length and width of the blue steel boiler that held the water and about 18" tall. That part that is missing is what held the fire box, or combustion chamber. The oil burner or gas burner would be mounted in an opening designed for it. Since that part is missing, There is no asbestos to worry about.

The brown "Fire Box" at the bottom is where you might find the most asbestos insulation. But since you done seem to have that part, …

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

-

I think you're right, Ed. Looks like A-S did make a residential dry-base steel boiler that was oil-fired, the AP

series. I wonder if the 319 in the pic is an internal code or part number for that tube section, which was then sat on a base and the burner and jacket mounted to form the final assembly?@Rickam , if you don't see any insulating material, you should be OK cutting that thing up.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

@EdTheHeaterMan is right with his description of what that boiler looked like before the burner base was removed. That boiler is a typical horizontal fire tube, dry base boiler that could have been fired with your choice of almost any liquid or gaseous fuels. ( You can see the welded "stay bolts" in the sides of the steel boiler).

1 -

Very nice illustration Ed.

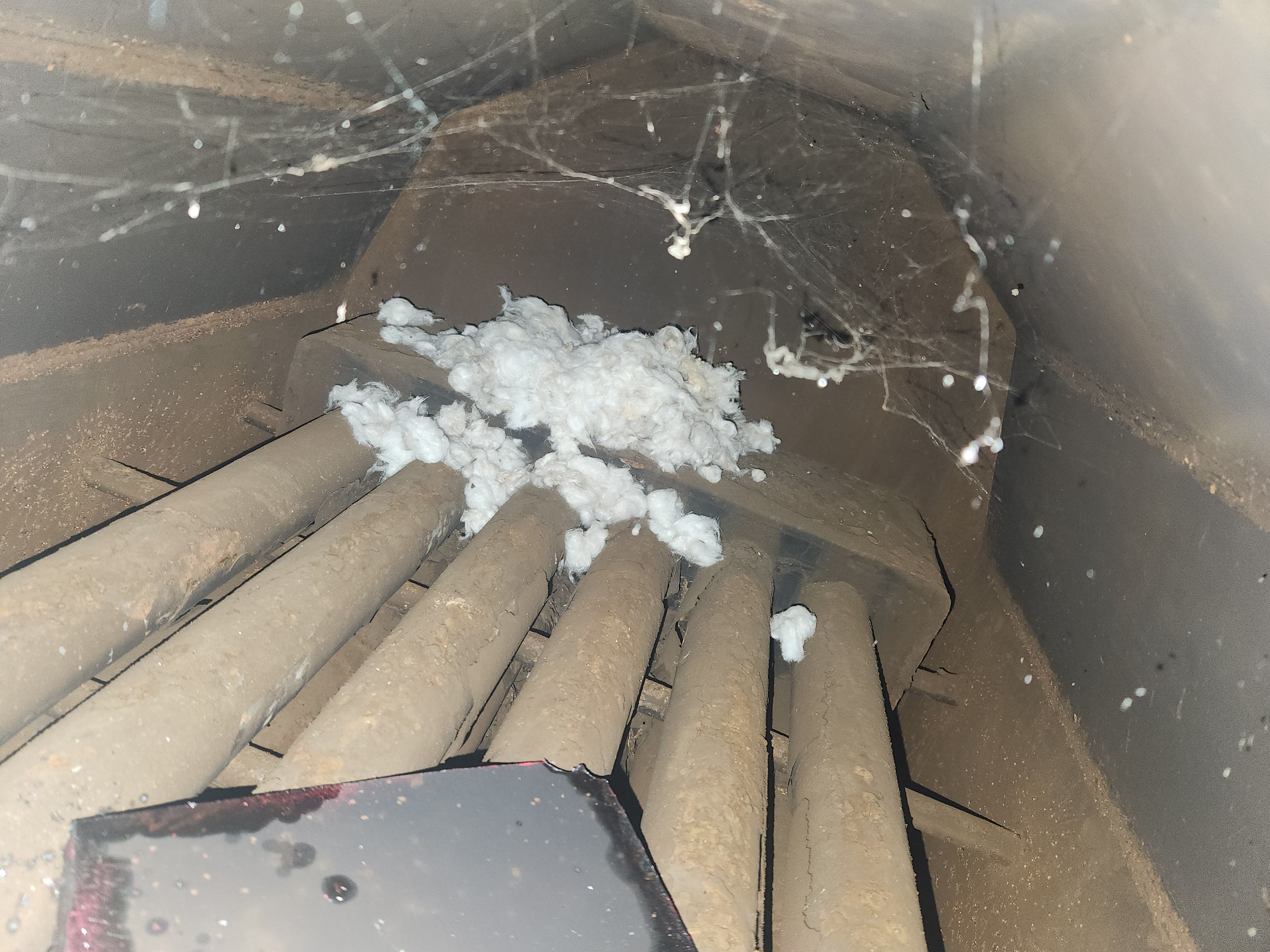

I've started chopping. Here are some photos.

I'm guessing a chipmunk stole some fibreglass insulation from the nearby Slant-Fin and tried to buld a nest inside.

Vortex generators in the tubes for better heat transfer. The tubes are press fit and not welded. There was a lot of soot in these tubes.

0 -

I've chopped enough material out of it to be able to tip it over (the bottom is open). Prior to this it was just way too heavy to move at all. It is just as you have described Ed. Its just the top of a larger assembly. This thing was so well made, I began to feel pretty bad about destroying it, but there was just no other way to get it out of here.

Side cover removed. It was held on with steel studs and what looked to be copper or bronze nuts.

I didnt use any cutting discs. I used 8tpi and 10tpi carbide blades (6 and 9 inch length) on a recip saw, and one 1/2 drill to stitch an opening for the blade. It was really hard on the tendons in my forearms - and is taking 5x longer than I thought it would to cut up. When the dust settles I'm going to weigh the pieces and figure out the original weight of this thing.

0 -

maybe a cutoff disc in a circular saw would be easier to control

0 -

A true artifact of a once-functioning, highly-skilled, heavily industrialized America. Now…obsolete and "in-the-way." Must be broken down and replaced…with…?? (fill in the LARGE blank).

0 -

The cutting disc was a great way to change direction of the recip blade to make a 90 degree turn, just cut a slot. The problem was that cutting away just 1" of material ruined the air quality in the entire house. Stitching 2 1/2 holes together was better.

This boiler would have had asbestos jacket and gaskets, so I was mindful of that too. My p100 mask cant stop smoke. So I only used water as a lubricant/coolant for the blades. I wet everyrhing down with a glue/water mixture.

I have very large 12" a 4.5" and a mid 230mm disc cutter. It would have been unsafe to use them even with complete body armor because of the double skin on the boiler (internal tension) and the weight of the thing would have caused the discs to pinch and potentially shatter. I had many recip blades bind into certain cuts, and had to rescue them with spare blades by chopping out a different section.

The Ergonomics of the recipricating saw was only a problem early on when i had to work in awkward positions and run the saw sideways near the ground. I could not use my body weight to put pressure on the blade. The boiler was to heavy to move at that stage.

Early on I dreamt of having a plasma cutter. But the recipricating blades started to shine later on. 10x quicker than a cutting disc on this thickness of steel. It can go through both skins in one pass.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements