Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Pex

Options

Comments

-

Yes. This is one of the reasons why we can't discuss specific pricing here. And discussing what one contractor charges vs. another can also lead to price fixing, which is illegal.Solid_Fuel_Man said:I believe wages are also dictated by local demographics. In some areas a hundred dollars an hour would be considered a bargain while as other areas the same man for the same hundred dollars an hour would be considered robbery. So one size doesn't necessarily fit all.

Let's get back on topic. Thanks!President

HeatingHelp.com0 -

I agree @Stephen Minnich , and @Solid_Fuel_Man . Sometimes that cost differential isn't many miles apart.0

-

We recently moved from a heavily populated, fairly affluent area, to a much more rural, and sparsely populated area. Because of the difference in rental costs, local utility rates, etc... we were able to lower our labor rates by almost 40%. We are now in the middle of the market for pricing, and are doing just fine. Just a good example or how pricing is very geographical. We only moved about 3.5 hrs away too.....

Anyways.....I was thinking about this thread yesterday, somewhere I have a picture of a system (DIY install and design) that I was asked to come assess and repair after they just bought the house. Just looked for 20 minutes, can't find the pic, but it was a solar/open wood boiler system with cast iron radiators for emitters, and shell and tube HE serving a 100 gallon tank for the DHW. This whole thing was installed with pex and sharkbite fittings. There were 4 pieces of bailing wire strategically placed to offer some kind of support for the pumps, but that was the extent of the piping support. The glycol was probably 15 years old at least (nice muddy brown color) and every single joint was leaking. EVERY ONE! I gave my bid for complete replacement, heard a couple months later, they installed forced air. Actually okay with that, I wasn't looking forward to that job.

Wish I could find the pics, it was a sight to behold....0 -

-

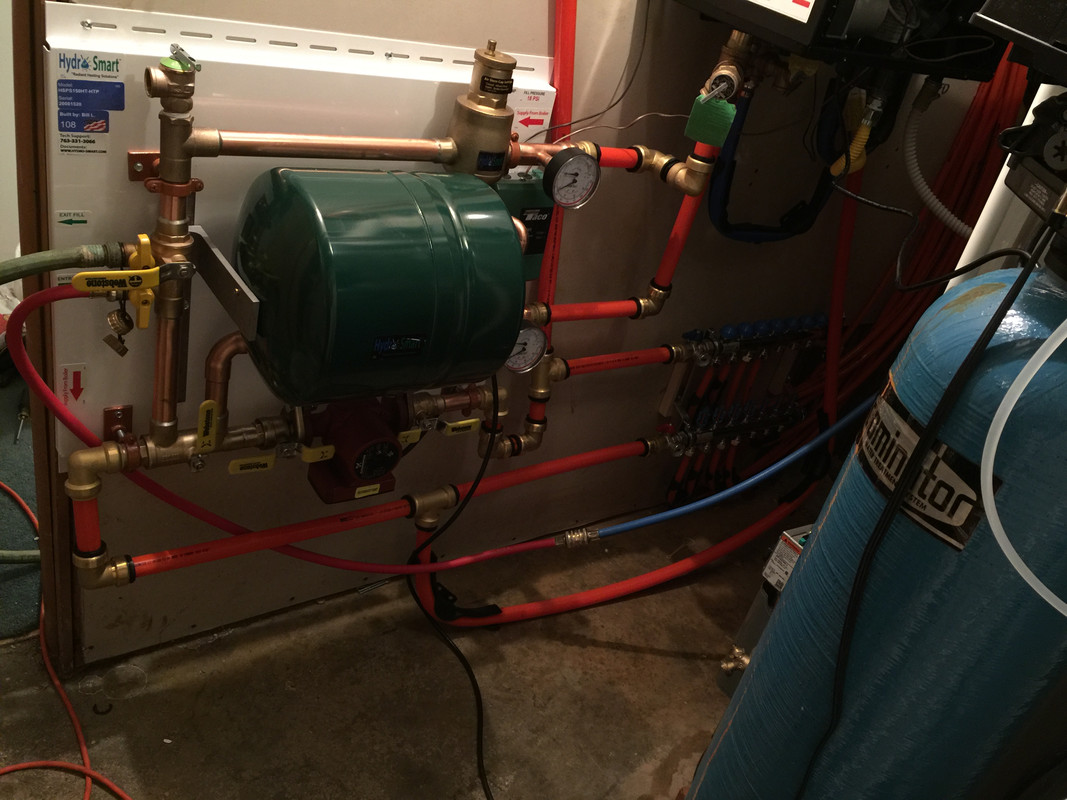

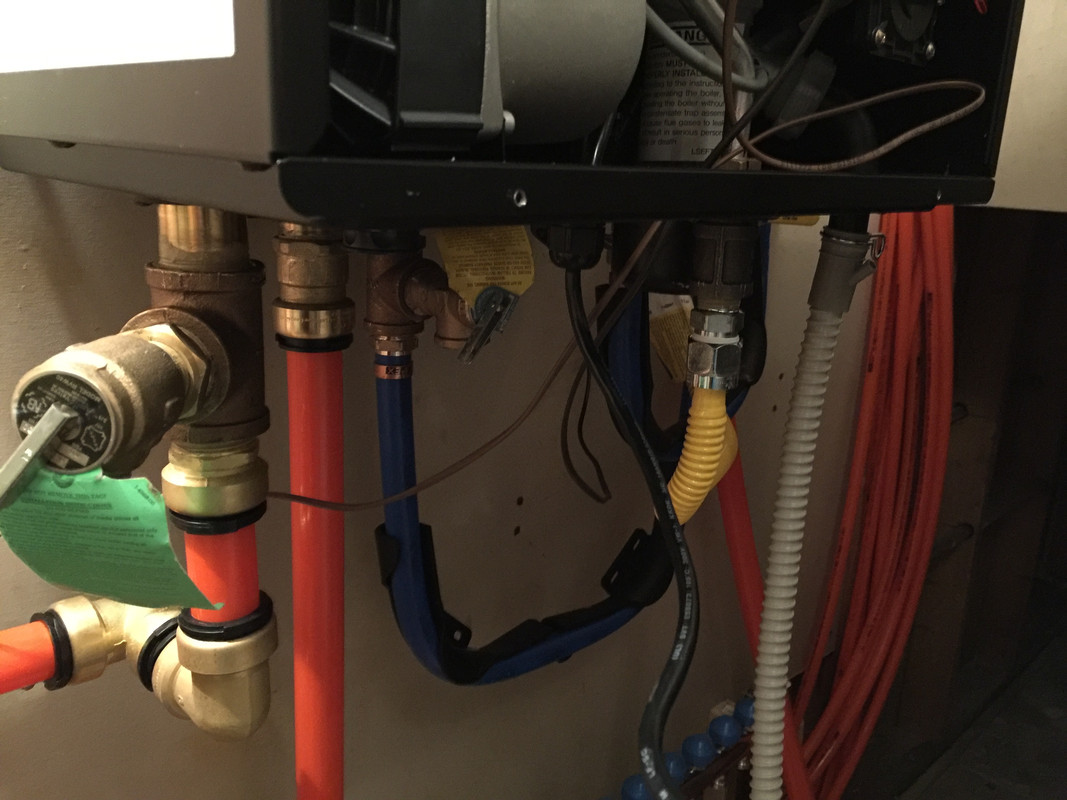

Those look like quick connect fittings too, not something I would use permanently, especially that close to the boiler.

Also looks like the prefab expansion tank setup is being supported by the air valve stem.

And no downpipe on either of the PRVs.

Ironically with those sharkbite fittings, copper wouldn't really have been much more expensive or more difficult than the PEX.1 -

^ IIRC, the poster was having issues with the setup as laid out in the photos.

No way would I use Shark Bite fittings near the boiler, cast iron and copper for me. I have some (very limited) OB PEX after my zone valves, but I've been swapping that out for copper on a piecemeal basis. I'm not a big PEX fan.

When you compare the cost of a 3/4" copper elbow to a 3/4" Shark bite elbow copper wins every time, but with no soldering required... PEX is perfect for the Lego generation.1 -

I respectfully disagree with @NY_Rob "pex is perfect for the Lego generation". Please dont try to pegeon hole, not all of the under 40 guys are the same. I've seen plenty of old guys use sharkbites and PEX....

I'm still I the category of pro-press is really a glorified sharkbite, still just an O-ring providing 100% of the seal, just a crimp vs stainless "teeth" provide the mechanical holding power.

Flame suit on for that last paragraph......Serving Northern Maine HVAC & Controls. I burn wood, it smells good!2 -

^ well, I just looked up Lego... seems the "Lego Generation" started way back in 1949... so anyone under 69 yo is part of it.

Maybe that's why you see "old guys" using Sharkbite and PEX?

PEX and crimp rings/fittings is one thing, but I would be very uncomfortable using Sharkbite on PEX for anything other than temporary use.

1 -

-

@NY_Rob At least that pex jumble is supported lol. Those premade panels are such an overpriced mess, but they sell a LOT of them! I bet I get 5-6 calls a year asking to come hook those up, and although I disagree with they way they're set up and what they cost, the hookup is easy money. The "D'oh!" factor when you tell the HO you could've built the same thing properly for half the price can be comical sometimes, and of course there are no returns as they are special order.

The push fittings and pro-press are of similar distaste in my mind, I have used both but I don't like either. The whole o-ring thing just doesn't sit well with me, but time will tell. I ran across a job last summer where someone had used MegaPress for rooftop galvanized gas lines across a large commercial building. It was very surprisingly straight, unlike how copper gets all wobbly when you crimp it but the fact that I could spin one of the crimped fittings around in a circle by hand was less than flattering. The owner of my company was out to ask what I thought of it, as he was considering purchasing a MegaPress setup. I showed him the joints I cut out to be replaced with threaded and he was no longer considering it.0 -

I waited 20 years before pulling the trigger on ProPress. I have friends who've been using it all that time and they swear by it. In my limited experience with it I couldn't be happier, especially on service repairs. Its so quick and easy it ought to be illegal.

I still solder but its mostly on prefab stuff in the shop.Steve Minnich4 -

-

Pex shouldn't be used within 5-6 ft of the boiler. It's not designed for the high temps found at the boiler. It also doesn't support well and as the pic shows, is not representative of a craftsman who knows how to assemble a system properly. As to charging enough to make a living, that's been discussed thousands of times here and there will always be those who struggle with the real costs of doing business.0

-

-

Why do we so often blame the lack of craftsmanship on the material choice? It's a poor Craftsman that blames his tools or his materials. Is somebody that has repaired 100 year old hack jobs on Steam heating systems this is not a new subject or a new complaint. And you can look back through my old posts and I ranted multiple times about how bad ProPress was. Now I have 2 ProPress tools. And a small MAPP gas cylinder last me 6 months.Cost is what you spend , value is what you get.

cell # 413-841-6726

https://heatinghelp.com/find-a-contractor/detail/charles-garrity-plumbing-and-heating3 -

I believe there can be and often is a correlation between skill set and material used.

Siding contractor A does only aluminum and vinyl siding.

Siding contractor B does does aluminum and vinyl siding PLUS Hardi cement board siding and cedar shake siding.

Roofing contractor A does asphalt shingles only.

Roofing contractor B does asphalt shingles PLUS copper tin roofs, clay tile roofs, and cedar shake roofs.

Heating contractor A installs only radiant systems using water heaters and pex tubing for all piping.

Heating contractor B refuses to use contractor A's methods and material, opting for a well designed system using math, proven and trusted mod con boilers, controls, piping, pumps, wire management, and piping methods that guarantee comfort and maximize energy savings.Steve Minnich2 -

-

lol I can do cedar shakes well. heck my father even owns a shingle mill I can run. I see no issue with properly applied vinyl as it holds up much better than poorly installed Cedar.Cost is what you spend , value is what you get.

cell # 413-841-6726

https://heatinghelp.com/find-a-contractor/detail/charles-garrity-plumbing-and-heating1 -

-

Meh, we are getting into other construction materials. I’ll disagree on vinyls longevity as siding in the aspect it looks the same color as the day it was installed. Especially darker colors. Most don’t realize the fading until they hold a new piece up to it. Durability is subjective to wood, or stone. Maintenance is the biggest pro.Charlie from wmass said:lol I can do cedar shakes well. heck my father even owns a shingle mill I can run. I see no issue with properly applied vinyl as it holds up much better than poorly installed Cedar.

My point is a copper, or black piped near boiler pipe job just looks more professional strictly my opinion. Yes pex well done looks professional too, not to be used in the near boiler piping.

If you like wood the right style home looks far more majestic in cedar, redwood, stone, bricks, or logs than any vinyl could possibly convey.

Then we could even go down the road of cast stone, stacked stone, and brick. The like of which eliminates the mason......kinda like how pex tends to eliminate the true pipe fitter, or hydronisist. Dumbing down the installation process of which seems to make it as to which anyone can do it.

I would compare the pex hard pipe debate to conduit verses Romex wiring. Both do the job, and romex can look good in the hands of the ocd electrician, but it never hardly does. I’ll take conduit any day over romex baring cost.

4 -

Lest we forget Contractor C: only installs cast iron boilers with fin tube as a "water solution" or prefers forced hot air as the "air solution". Installed with only the finest of materials!Serving Northern Maine HVAC & Controls. I burn wood, it smells good!0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 427 Carbon Monoxide Awareness

- 119 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 165 Indoor-Air Quality

- 3.7K Oil Heating

- 76 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.6K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements