Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

thermostatic valves and air

Options

mschlee

Member Posts: 4

i'm having some problems with air in my system and cant figure out a solution no matter how much i search and read. hoping someone can help.

i have a dual temp system - 2 sperate manifolds, one running radiators and the other running radiant floor at much lower temp. the system essentially goes like this:

fill valve

boiler

spirovent with expansion tank

t'd to 2 thermostatic valves

each valve then goes to it's own manifold

the return on the manifold is t'd to the thermostatic valve and the return to boiler

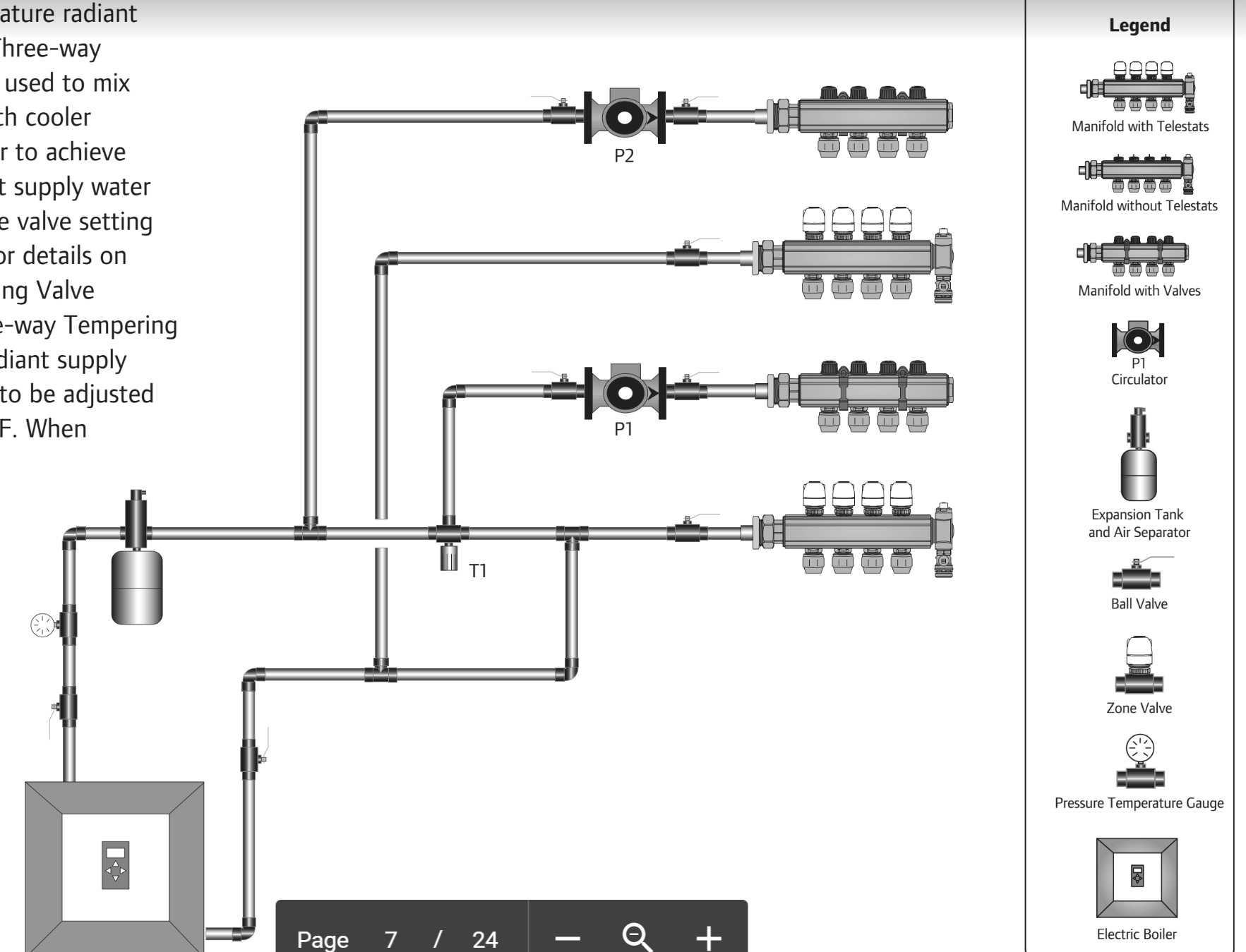

i found the attached piping diagram from uponor manual that is pretty much identical to what i have (except i am not using an electric boiler).

problem is that when i adjust the thermostatic valve for the lower temp radiant loop, i hear a swirl of air which i worry will not make it back through the boiler to the spirotherm becuase it will either sit up high somewhere or just keep going around and around since the low temp loop only sips a little bit from the boiler and gets most water supply from it's own return since it only looses about 15 degrees.

normally it runs silent with good flow at each pump and i dont hear any air anywhere. my guess is that there is a low pressure effect being caused when the thermostatic valve opens to let more return water in (say when i turn the temp down). whatever the cause, what is the best way to eliminate any air caused by adjusting the valve? or better yet, avoid it from happening in the first place. i was thinking about placing another air eliminator between the pump and manifold, but i know from reading that it should not be placed there.

any thoughts would be helpful, thanks in advance.

i have a dual temp system - 2 sperate manifolds, one running radiators and the other running radiant floor at much lower temp. the system essentially goes like this:

fill valve

boiler

spirovent with expansion tank

t'd to 2 thermostatic valves

each valve then goes to it's own manifold

the return on the manifold is t'd to the thermostatic valve and the return to boiler

i found the attached piping diagram from uponor manual that is pretty much identical to what i have (except i am not using an electric boiler).

problem is that when i adjust the thermostatic valve for the lower temp radiant loop, i hear a swirl of air which i worry will not make it back through the boiler to the spirotherm becuase it will either sit up high somewhere or just keep going around and around since the low temp loop only sips a little bit from the boiler and gets most water supply from it's own return since it only looses about 15 degrees.

normally it runs silent with good flow at each pump and i dont hear any air anywhere. my guess is that there is a low pressure effect being caused when the thermostatic valve opens to let more return water in (say when i turn the temp down). whatever the cause, what is the best way to eliminate any air caused by adjusting the valve? or better yet, avoid it from happening in the first place. i was thinking about placing another air eliminator between the pump and manifold, but i know from reading that it should not be placed there.

any thoughts would be helpful, thanks in advance.

0

Comments

-

It's not that the valve is "causing" the air. The air has just found a place to come out of solution, somewhere around your mixing valve. My initial thoughts here are to not let it drive you crazy since you said the system works well and quietly. What I would do if it were my system is I would open the mixing valve fully and let it run full temp for a cycle or two and make sure all the water in loop is cycled through at least one time. And don't worry about the tempered water not making it back to the air eliminator. Eventually all the water gets there.mschlee said:whatever the cause, what is the best way to eliminate any air caused by adjusting the valve? or better yet, avoid it from happening in the first place.

Contact John "JohnNY" Cataneo, NYC Master Plumber, Lic 1784

Consulting & Troubleshooting

Heating in NYC or NJ.

Classes0 -

good idea. i'll shut all but 1 zone valve and crank the thermostatic valve up to try and flush any air out through the main loop which has the spirovent. i actually have a shut off valve on the return side going to the therostatic valve that i shut when i'm filling the system to force water through the loops rather than spill out the cold side of the thermostatic valve. i can shut that too and only use the main loop.

thanks for the idea0 -

Do you have manual or automatic bleeders on the radiators? Those will release any trapped air that does not get into the flow. If those are cast iron radiators usually there is low velocity in those wide spaces, hard to entrain the air and move it to the Spiro.

Is the pump located downstream of the expansion tank? Doing so add the pumps pressure differential to the system and eases air removal. It's called pumping away and many air removal problems are directly linked to the concept.

Raise the temperature when bleeding also, the hotter the water the easier it gives up air.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

thanks bob. i do manually bleed the radiators so i'm less worried about them. i'm more focused on the radiant floor loops.

the spirovent is before the pump but right after the boiler so the water is pretty hot and pumping away (i believe that is right). i just looked back and doesnt look like my pic made it . i'll try again which shows pretty much the same setup as i have.with the first manifold supplying the radiators and the other supplying the floor radiant loops.

0 -

if you have it piped like that drawing you have a perfect purge setup for the mixed, radiant zone.

Shut off that ball valve downstream of the return manifold and connect a hose to the purge cock on the return manifold.

I like to do a loop by loop purge, turn all but one off, purge to clear, shut off, move to the next, continue until all run free.

If you remove an actuator from the manifold, that loop port will be full open. It is easier then trying to power up each actuator for purging loop by loop.

Crank the thermostatic valve to full hot when purging.

Any small bubbles left behind will eventually make it to the Spiro.

Are you sure the Spiro is working properly? Sometimes the vent on top gets plugged or the float inside hangs up on some crud and it is not expelling air.

You may need to disassemble the Spiro and check or replace the top end.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

thanks. the spiro is brand new so pretty sure it is working.

yah the piping is set up for good purge options. there are some small differences from the pic like temp gauges on the manifold supply and returns to check delta t, etc. but the main differences are that i have a thermostatic valve on both manifold supplies rather than just one, i have shut off valves on the return side of each loop between the t and the t-valve so i can shut off flow from the return side, and i also have a couple of 3 way valves on the return line before the boiler that allows me to run hoses into a bucket so that the water on the return dumps to a bucket, and then is sucked back into the system through a separate hose so that all the air just floats to the top and the supply hose picks up air free water from the bottom of the bucket (i do also have purge valves on the supply and return sides of each manifold).

one other point, i usually close off the spirovent when i'm purging to make sure it doesn't suck in any air. i re-open it once the purge is completed.

thanks for the help, i'll try to purge with the temp turned up and thermostatic valve all the way open.0 -

Are you sure it's air and not just velocity (flow) noise.steve0

Categories

- All Categories

- 85.2K THE MAIN WALL

- 3.1K A-C, Heat Pumps & Refrigeration

- 55 Biomass

- 424 Carbon Monoxide Awareness

- 73 Chimneys & Flues

- 1.9K Domestic Hot Water

- 5.2K Gas Heating

- 129 Geothermal

- 160 Indoor-Air Quality

- 3.3K Oil Heating

- 61 Pipe Deterioration

- 884 Plumbing

- 5.9K Radiant Heating

- 376 Solar

- 14.7K Strictly Steam

- 3.2K Thermostats and Controls

- 58 Water Quality

- 49 Industry Classes

- 89 Job Opportunities

- 28 Recall Announcements