Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

Purger fixture on AOSmith burkay heater - What's in it?

Options

rlaggren

Member Posts: 162

This is on a 1980 AOSmith HW225P burkay which has been heating a 3 story 110 yr old house ever since. The hx outlet connects directly into a 10" sq x 3" casting I have seen called a "purger". Gravity conversion. Not much maintenance . Four years ago I opened the boiler and cleaned the hx mechanically, straightened a lot of fins, gave it and the coils a wash and scrub w/CLR. Helped a lot.

Opened it again for cleaning and started brushing the hx of light deposits. Found some seepage near the outlet manifold (left side in pic), apparently from a pinhole at/near the braze between the outlet manifold and the hx, but haven't found it precisely - just enough for a hint of moisture over 5 days. During heating season the last 10 years or so there has been dampness or something appearing from under the boiler on the pump side. This is the first smoking gun I found. Since I was planning on flushing the boiler w/a phosphoric acid or Nu-Calgon's Eco-Lyme (phosphoric acid descalers seem a little hard to find locally) it occurred to me that maybe I'd best do that first before I spent any more time on the outside. Might turn out I have a sprinkler system after I run the chemicals.

https://c1.staticflickr.com/9/8218/28512531944_2369ec2c1f_z.jpg

I read AO Smith's descaling manual and the concepts seem pretty clear. Isolate, back flush from tees (close bypass), when it runs clear and fast, you're done. However, the manual appears written for very simple water heater applications and does not mention (that I noticed) the purger fixture where the bypass and controls are mounted. So I can do the descale run easy if I run it through the purger fixture - but I don't know whether descaler will cause problems inside there.

Also, I'm curious whether there is a thermostatic valve in that purger controlling bypass or whether is just a fat place in the pipe. I assume the left and right outlets are symmetrical, ie w/respect to the L & R outlets and ignoring the bypass, the purger is just a big tee fitting. The front connection gets the compression tank, the makeup water and a temp sensor.

https://c6.staticflickr.com/5/4128/5020300901_f0dcc45a96_z.jpg

https://c4.staticflickr.com/5/4147/5020290491_3584b10814_z.jpg

The top has an air release (left), a gauge (ctr), and a PRV (right). Left and right outlets feed two single pipe systems (3"); the two system returns join above the pump, drop through the bypass tee and into the pump inlet. One pump does it all.

I plan on trying a flush w/water first and if I get good flow I might just skip the descaler in favor ot letting it soldier undisturbed as long as possible. This is in Evanston, just north of Chicago, and all the galvanized water pipe I've pulled has been clean inside ..(!) Amazing, 70+ years and clean galvanized pipe. So the water appears pretty benign. But my decision would also be informed by whether it appears that purger fixture is OK w/descaling chemical.

So, can anybody say what's in the purger fixture? Is it OK to run descalers through it? I haven't tested the compression tank but I guess my question applies there, too. Is the tank OK w/descalers?

Appreciate any/all info.

Thanks

Rufus

Opened it again for cleaning and started brushing the hx of light deposits. Found some seepage near the outlet manifold (left side in pic), apparently from a pinhole at/near the braze between the outlet manifold and the hx, but haven't found it precisely - just enough for a hint of moisture over 5 days. During heating season the last 10 years or so there has been dampness or something appearing from under the boiler on the pump side. This is the first smoking gun I found. Since I was planning on flushing the boiler w/a phosphoric acid or Nu-Calgon's Eco-Lyme (phosphoric acid descalers seem a little hard to find locally) it occurred to me that maybe I'd best do that first before I spent any more time on the outside. Might turn out I have a sprinkler system after I run the chemicals.

https://c1.staticflickr.com/9/8218/28512531944_2369ec2c1f_z.jpg

I read AO Smith's descaling manual and the concepts seem pretty clear. Isolate, back flush from tees (close bypass), when it runs clear and fast, you're done. However, the manual appears written for very simple water heater applications and does not mention (that I noticed) the purger fixture where the bypass and controls are mounted. So I can do the descale run easy if I run it through the purger fixture - but I don't know whether descaler will cause problems inside there.

Also, I'm curious whether there is a thermostatic valve in that purger controlling bypass or whether is just a fat place in the pipe. I assume the left and right outlets are symmetrical, ie w/respect to the L & R outlets and ignoring the bypass, the purger is just a big tee fitting. The front connection gets the compression tank, the makeup water and a temp sensor.

https://c6.staticflickr.com/5/4128/5020300901_f0dcc45a96_z.jpg

https://c4.staticflickr.com/5/4147/5020290491_3584b10814_z.jpg

The top has an air release (left), a gauge (ctr), and a PRV (right). Left and right outlets feed two single pipe systems (3"); the two system returns join above the pump, drop through the bypass tee and into the pump inlet. One pump does it all.

I plan on trying a flush w/water first and if I get good flow I might just skip the descaler in favor ot letting it soldier undisturbed as long as possible. This is in Evanston, just north of Chicago, and all the galvanized water pipe I've pulled has been clean inside ..(!) Amazing, 70+ years and clean galvanized pipe. So the water appears pretty benign. But my decision would also be informed by whether it appears that purger fixture is OK w/descaling chemical.

So, can anybody say what's in the purger fixture? Is it OK to run descalers through it? I haven't tested the compression tank but I guess my question applies there, too. Is the tank OK w/descalers?

Appreciate any/all info.

Thanks

Rufus

disclaimer - I'm a plumber, not a heating pro.

0

Comments

-

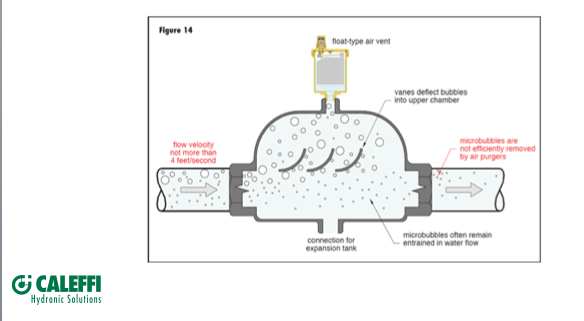

My guess it is just a "wide" spot air purger with some nice connivence ports? Usually if their is a thermostatic element there would be signs of where it mounts into the block.

I see smaller versions of that still used on some of the German iron boilers.

By descaled are you considering an acid product?

Rhomar tells me their Hydro Solv 9100 will descale boilers like that and it is non acid, non TSP based. It might be safer and less stress to that 38 year old boiler! It is compatible with all the components in the system and will not leave you with a low ph.

If you use an acid based cleaner, check ph, some brands send a second "ph down" treatment to flush through after the acid is used, and a ph test strip.

Be sure to wear a respirator when you disturb and vacuum that outside. Nasty stuff in those white deposits.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

HR, I think you're right- a combination air separator and gauge/control manifold. Wonder how well it works?All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Depending on flow rate, and what is inside it could work similar to a scoop type air purger. Fingers or a ramp inside would help get the air to the upper part, like scoop vents.

Assume it is about a 3" pipe dimension, at 23 gpm velocity would be about 1fps, so it would be an ideal low velocity zone, at the hottest point in the system.

If that is a 225,000 boiler I think it would require good flow, certainly not a boiler that could work with a gravity system, without any pump.

It will make a good paper weight or small boat anchor someday.

Here are some versions we still offer in Europe.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

> acid

Yes, was considering phosphoric acid. AO Smith spec'd their product "Un-Lime" which some have said is mostly phosphoric acid; the MSDS says phosphoric acid but AOS is coy about the concentration, claims a trade secret. Moot because "Un-Lime" seems not available. A Nu-Calgon graph showed phosphoric acid as being one of the most benign vv. copper but so far I haven't found any likely phosphoric cleaners from an easy local source. The Nu-Calgon Eco-Lyme looked interesting and that I can get easily. Rhomar 9100 looks like a slightly different usage format, eg. much longer "run times" but that might be good. I'll look more at that; so far I haven't seen explicit mix instructions for isolated boiler use. At this point I don't seem to have any reason to attack the pipes or radiators, plus don't want to buy into that pretty large job. Each radiator holds about 10 gal if I calculated right - 17 of them I count off hand - then there's 80-100' of 3" mains and the 1" risers. So maybe 250 gallons in the system. Rather just deal w/the boiler for the moment.

> [t-stat valve would show on casting]

Ah. Yes, that seems right. There would be an installable element of some type which would show. Thank you. Less worry now about causing unnecessary damage.

Thanks for you thoughts. Greatly appreciate you help.

Rufusdisclaimer - I'm a plumber, not a heating pro.0 -

Phosphoric is sold under the Naval Jelly trade name. Concentration is 10-30% (another "trade secret")

We buy powdered sulfamic acid from a local chemical supplier and mix (very carefully) to desired strength.0

Categories

- All Categories

- 87K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 57 Biomass

- 425 Carbon Monoxide Awareness

- 112 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.7K Gas Heating

- 106 Geothermal

- 160 Indoor-Air Quality

- 3.6K Oil Heating

- 70 Pipe Deterioration

- 980 Plumbing

- 6.3K Radiant Heating

- 388 Solar

- 15.4K Strictly Steam

- 3.4K Thermostats and Controls

- 54 Water Quality

- 44 Industry Classes

- 48 Job Opportunities

- 18 Recall Announcements