Hydronic closed loop question

hello all- I have a steam boiler with a heat coil. I have 3 zones-

zone 1 - hot water zone in the the basement with hydronic baseboard. It only has a circulator pump.

zone 2 - steam baseboard radiators

zone 3 - hot water zone with circulator pump and newly installed air separator/ expansion tank.

should zone 1 have anything additional? When I replaced the circulator pump on zone 1 it was filthy- I’m wondering if it should have an dirt mag or something else?

I’m also curious if it needs a dedicated expansion tank or air separator.

thanks in advance

Comments

-

Sounds like you have at least one zone that is using the tankless coil inside the steam boiler. That zone is operating under pressure as a closed loop system. I can see the combination Pressure relief/water feed valve that goes to that system. I think that is #3

#2 is just the regular team system that appears to be properly installed. 👍️👍️👍️

The #1 zone may just be an open loop system since all the radiators are below the water line. That means that the water from the boiler is open to the atmosphere and can be circulated without the need for added pressure relief valves since there is already a pressure relief valve on the steam side of the boiler. That is the water you are using for the basement zone. There are some things that you need to be aware of when using that type of system.

- Iron body circulator pumps may not last as long in that zone. If you need to replace that pump in the future you may want to consider a bronze or stainless steel pump so it will last longer.

- The circulator pump should be on the coldest part of the loop, that is the return pipe and pump into the boiler

- The circulator should be as close to the floor as possible. there is very little static pressure on that open system, so the pump differential pressure should be pushing into the steam boiler and the lower pressure inlet of the pump should be in the coldest water on that loop.

In order to be sure that is an open system loop off of your steam boiler, can you take some photos of the other circulator pump and where those two pipes get connected behind the front door of the boilerNever mind, I see the other pump near the floor

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

can yo take a picture with the front cover off the boiler?

0 -

the circulator for the direct loop can be on the supply side but it has to have a bypass so it tempers the water from the boiler with some return water to keep the pump from cavitating. it can work on the return as @EdTheHeaterMan said if all of that loop is below the water line.

depending on the capacity of the tankless coil in the boiler you might be able to move that loop to the closed system with zone 3 to get rid of the various problems of an open loop.

2 -

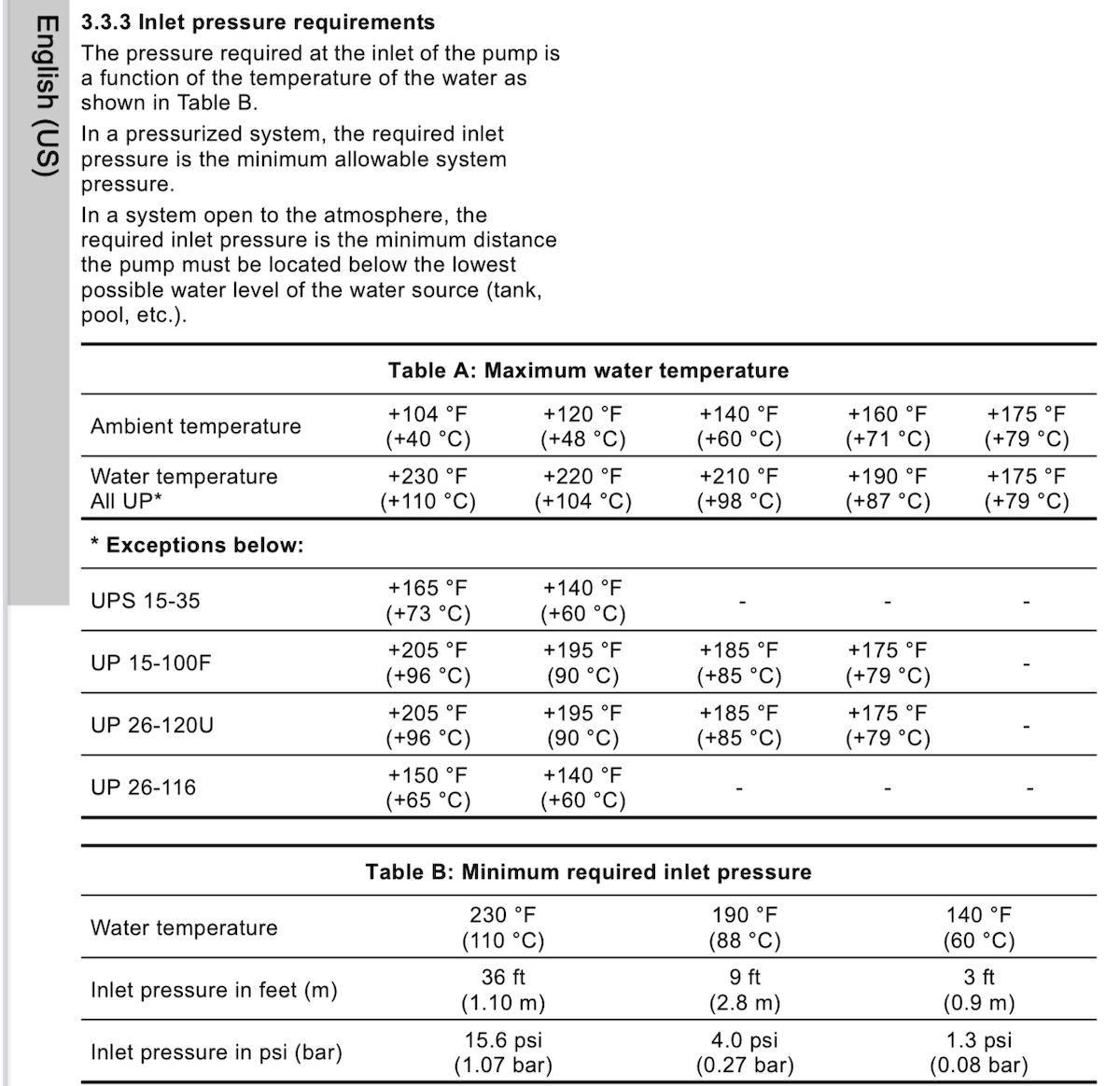

A similar condition happens on unpressurized wood boilers OWF. The circs depend on a temperature pressure relationship to prevent cavitation. Here are Grundfos recommendations.

So with 190°F water you would want 4 psi. Higher temperatures require higher pressure. Notice the big jump at 230° water, 15.6 psi!

To get 4 psi you would need a water lever about 9' above the circ intake.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements