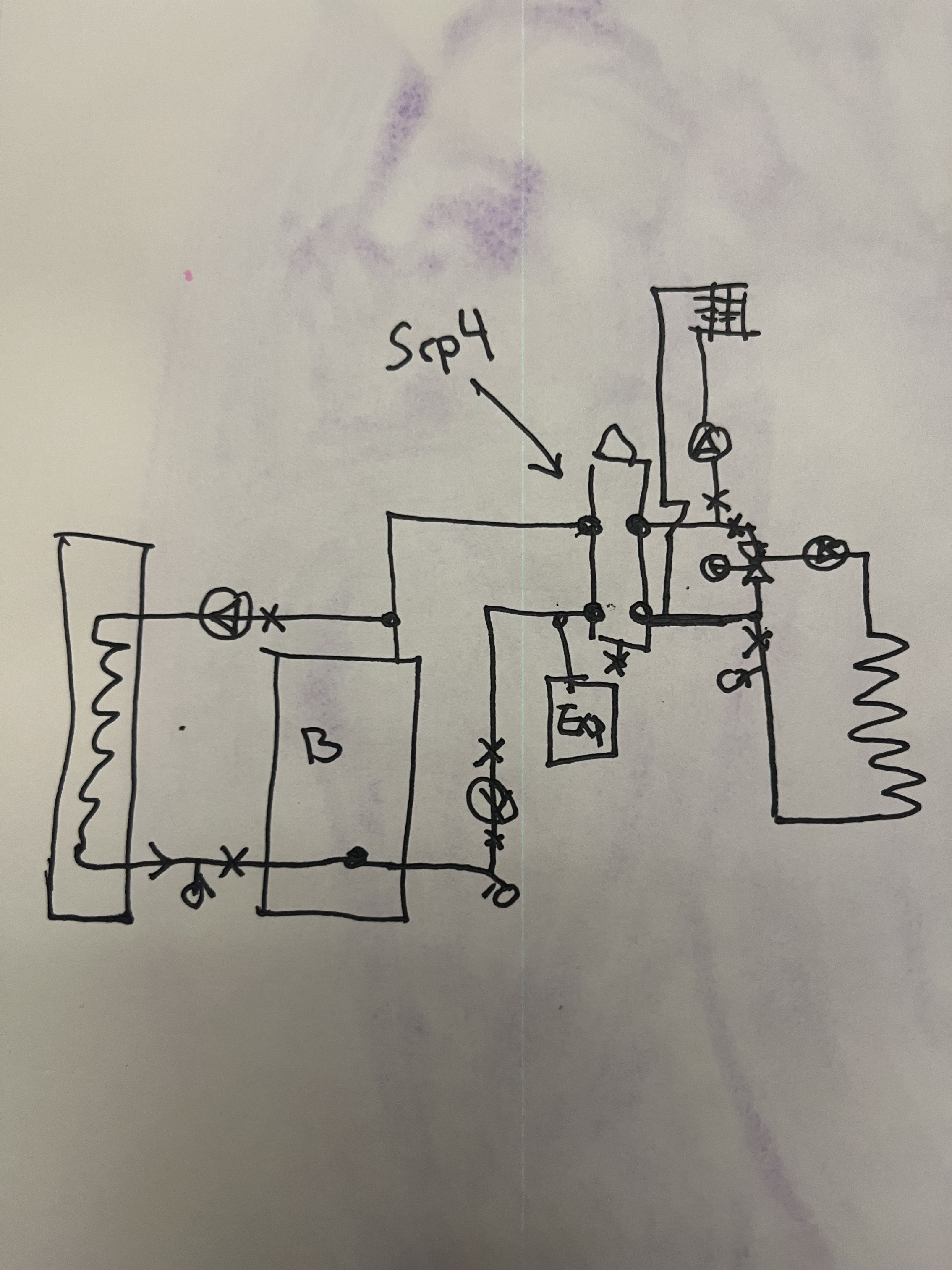

Critique of this design?

Guys just wanted to check whether this design is good as I’m adding to an existing single zone oil burner baseboard system

Anything glaring that you’d change?

Comments

-

The circulator on the feed rather than the return. Pipe the boiler using the point of no pressure change, pumping away from the boiler.

Add service valves for future use.

Use a micro bubble air separator rather than an air scoop. [Spirovent].

0 -

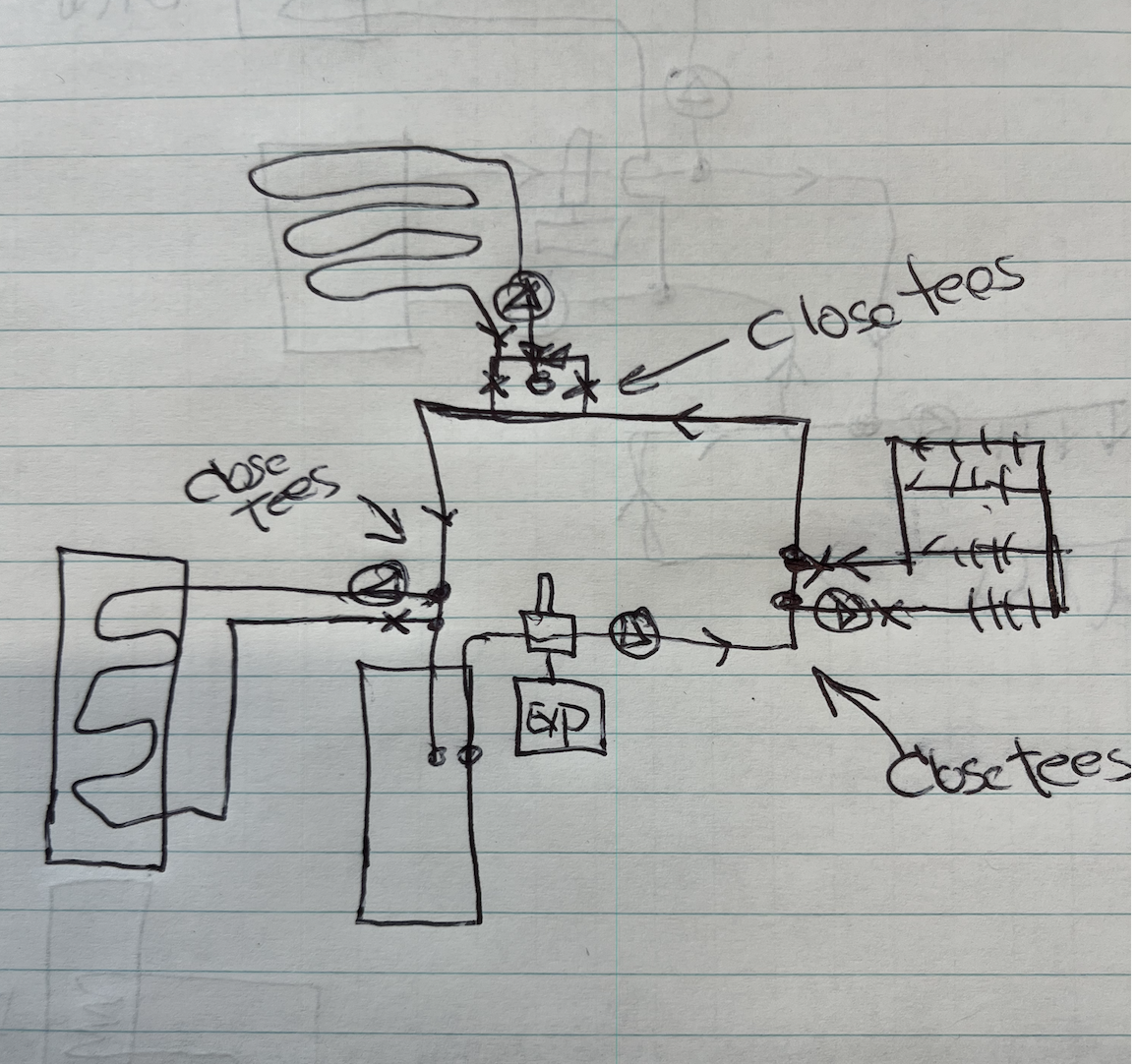

You're likely to have some ghost flow through both zones due to lack of hydraulic separation, and your indirect will be receiving pretty cool water under full load rather than priority as it should be. Personally, I'd keep the boiler loop but then add in one pair of closely spaced tees with 3 branches on each leg so that each load gets the same supply temp. I'd also recommend moving the boiler loop circ to the supply, downstream of the expansion tank as was mentioned.

1 -

what type of boiler? Are there zones for the high or low temperature circuits?

A hydraulic separator adds air, dirt, magnetic and hydraulic separation in one device. If you use ECM circs you need magnetic separation.

Indirect is parallel receiving the hottest water from the boiler

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

non condensing boiler with single high temp circuit currently

0 -

when you say one set of closely spaced tees, each having a 3 way branch isn’t that basically a 3 circuit manifold?

0 -

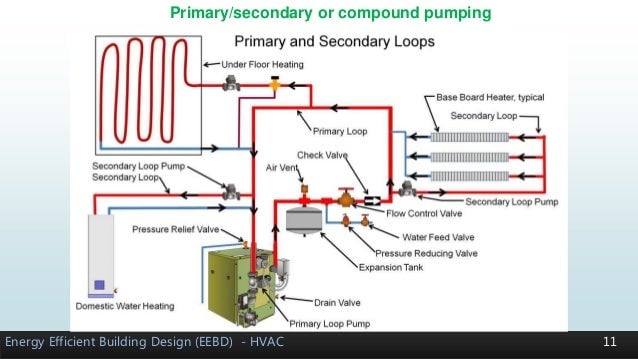

Your piping is not too far off. This shows the boiler as the primary loop, pump away from the expansion tank. Main loop,is 1" for up to 80,000 boiler size. 1-1/4" if it is up to 150,000 btu/hr.

Then any connection into that loop is done with two tees about 6" apart.

Each set of tees needs it's own pump. A 3 way mix valve for the radiant.

Isolation valves at each tee. Purge valve at each return tee.

There are numerous ways to pipe this, many different options depending on the installer.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

If those manifolds are piped directly to the branches of both tees, yes.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements