Circulator on Cold Fill: Boiler Protection or System Instability?

I’m looking for experienced input on a hydronic system configuration I’ve inherited.

There is a circulator piped off the boiler return that ties directly into the cold fill and the expansion tank connection. The pump runs without any temperature sensor, thermostatic valve, bypass piping, or control logic.

One vendor stated that the intent of this circulator is boiler protection, specifically to prevent thermal shock by mixing warmer return water with incoming cold make-up water. However, there is no defined minimum return temperature or any means of controlling that mixing.

The system serves convectors and currently lacks a proper air eliminator installed on the supply. There are two #79 air vents installed on the supply, and auto vents at the farthest and highest convectors. We plan to install a Spirovent SR on the boiler supply.

In operation, the system experiences pressure instability and recurring air issues, including air-bound convectors and inconsistent heat distribution. I am also trying to determine whether this circulator, being tied into the expansion tank and fill connection, could be contributing to pressure instability or interfering with system performance.

My question is whether a circulator alone, in this location, is ever considered a valid method of boiler protection, or whether true thermal shock prevention requires controlled mixing through bypass piping, a thermostatic protection valve, or a proper primary/secondary arrangement, and whether this configuration could also be adversely affecting system pressure.

I’d appreciate hearing how others would interpret this setup and how they would correct it.

Comments

-

do you have a pic of the near boiler piping? Yes some boilers include a bypass pump.

A bypass pipe or sometimes a bypass pump can be helpful for protecting the boiler from cold return. The type of heat emitters has a part also. Low mass fin tube or convectors that heat quickly. Observe the boiler temperature if you kick all the zones on. Rule of thumb is within 10 minutes the boiler return should be within the temperature the manufacturer suggests in the manual, 130 typically.

A good air purger goes a long way towards solving air issues, even with the pump on the return.

Boiler pressure should be 12-15 on a typical 1or 2 story home. Inadequate pressure can make air removal harder.

Be sure the pressure gauge is accurate, the needle should move some from cold start to operating temperature

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

During sustained calls, supply runs ~180–186°F and return is consistently ~155–162°F

Return temp rises quickly and stays well above 130°F.

Given that, I’m questioning whether the return-side circulator tied into the cold fill/expansion tank is providing any real boiler protection, or if it’s instead contributing to the pressure instability and air-bound convectors we’re seeing.

0 -

-

Ideally the pump would be on the supply with the expansion tank and fill valve before the pump, on the intake.

BUT many systems have pumps on the return, and work fine.

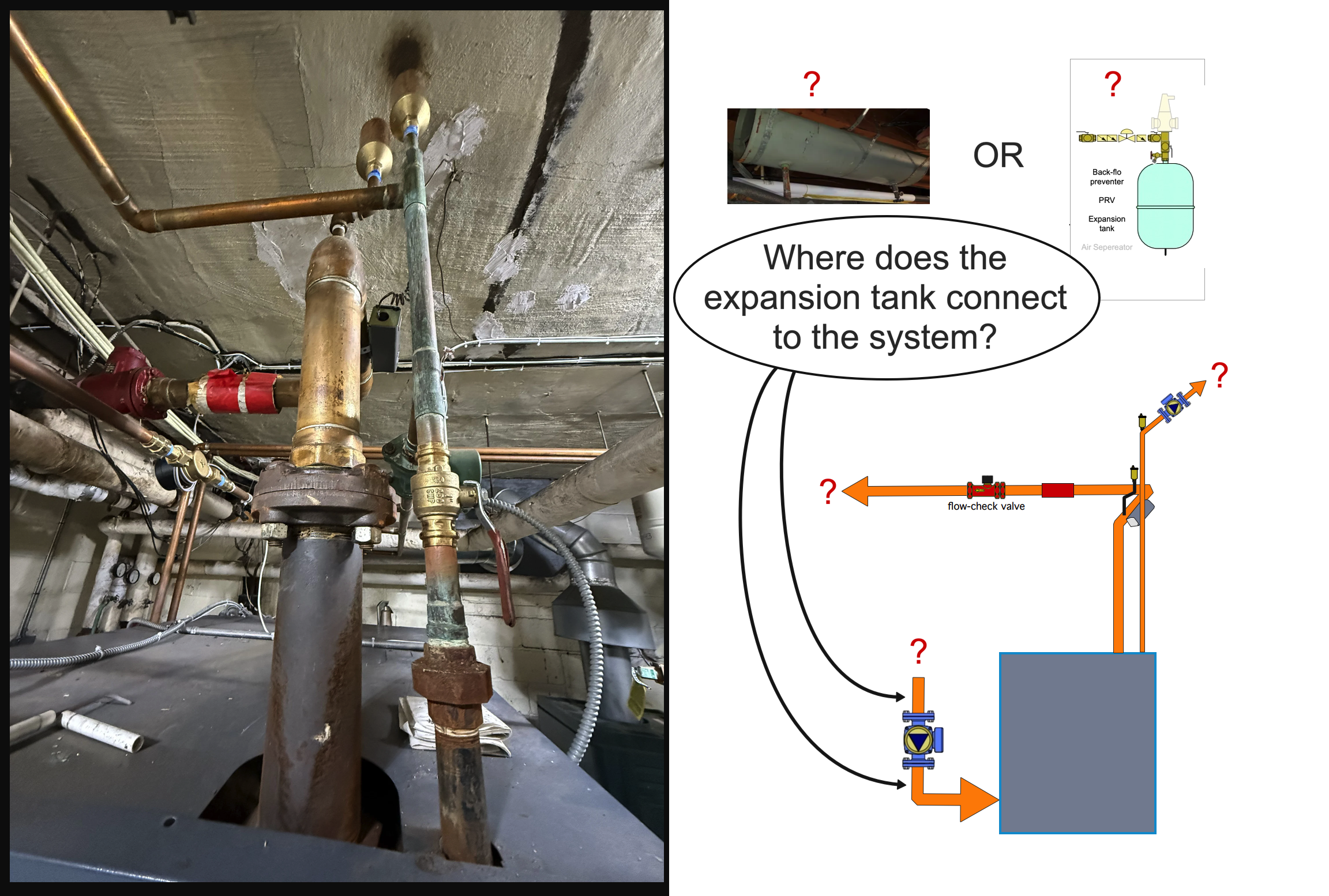

The fill valve is typically at the expansion tank connection, is yours, where is the tank in the piping?

As for the fill valve, it should not be adding cold water on a regular basis, or ever if the system is air and leak free.

So you should not be adding cold water "makeup"to the boiler, which could shock it. If that is the question?

If the question about "protection" refers to the expansion tank providing thermal expansion protection, it should work on supply or return piping, assuming it was pre-charged properly and is not waterlogged.

Now the system could be taking on fill water if the relief valve is discharging? That could indicate a failed exp tank, regardless of where it is connected.

A pic of the boiler piping tells us more.

Your handle @SteamHeatCantBBeat hopefully doesn't refer to this boiler. This is a hydronic boiler correct?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I will take a few overhead photos of the near-boiler piping for review. As I understand it, the pump is effectively mixing supply/return water without any temperature control. That same loop contains the auto fill, bypass, expansion tanks, and a single #79 air vent. My concern is that this configuration interferes with the point of no pressure change.

Yes, this is a hydronic system. I would prefer a two pipe steam system.0 -

Have you ever looked at this book?

This has some information that explains how some systems that have chronic air bound radiator problems can be corrected by rearranging the components in a way that actually eliminates air from the system. The way your system is currently piped, you are creating air problems. The pump on the return is a prime example of how to create air problems by design, along with other design flaws.

Your one photograph shows a Taco 007 attached to the vent tapping on the boiler after passing by an air vent on the vertical pipe from that tapping. Probably not the best design

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

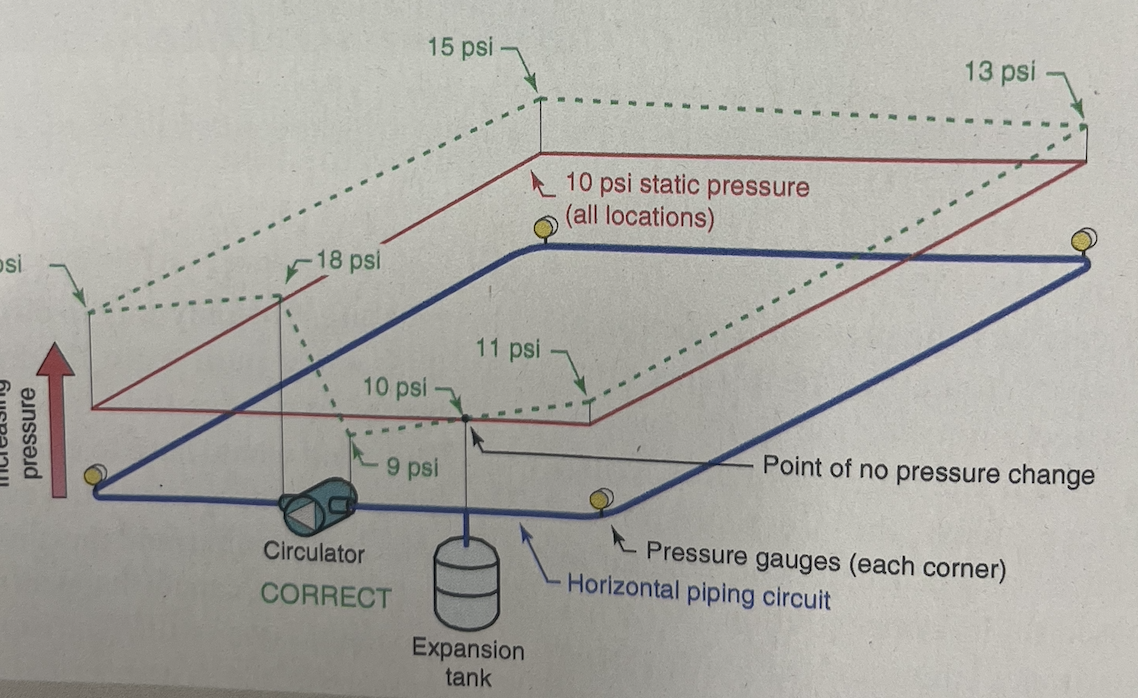

This whatb happens in a system where you are pumping away from the tank PONPC.

The energy added by the circulator, head, which is mechanical energy"

This shows up as a pressure icrease at the discharge of the circulator pump.

As flow goes around the loop that added energy gets used or scrubbed away.

Important is that the pressure at the tank, and inlet of the circ never drops below the static fill pressure in this case 10 psi. There is a small pressure drop shown between tank and pump as even 1" of piping has some pressure drop. So that short section shows a 1 psi drop.

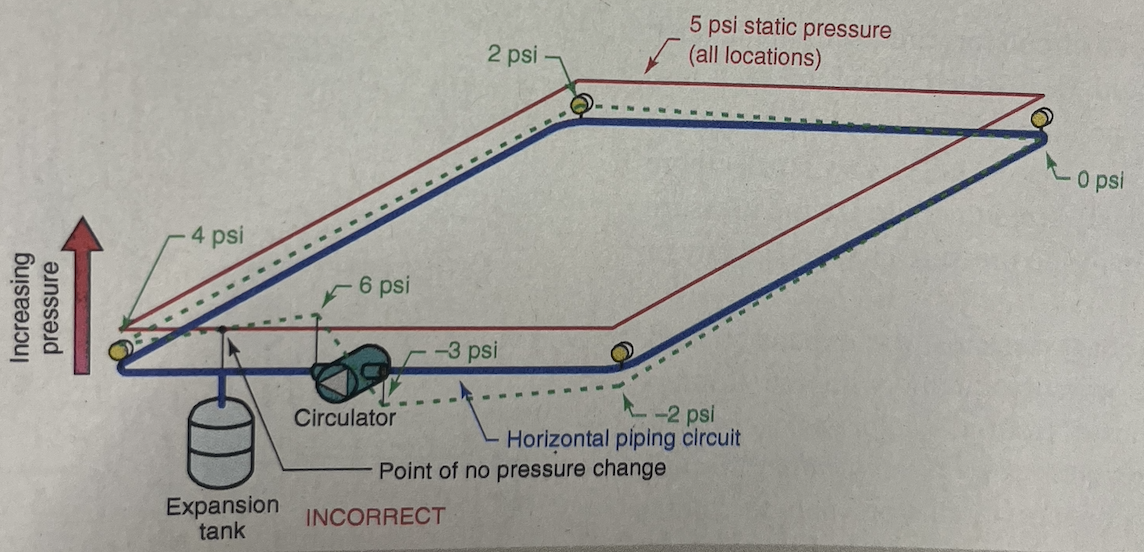

When you pump at the expansion tank this is what it looks like.

Note that we just use a 5 psi fill pressure to show how the system drops below atmospheric condition, see the -3 psi at the circulator intake.

If the static was 10psi in this example it would not go negative.It would be 2 psi.

If an auto air vent was installed anywhere in the piping fro 0- -3 psi portion, it could suck air in!

Circulators need to have some positive pressure at the intake, it's based on temperature of the fluid. Grundfos shows something like 1.5 psi at 140. At 200° F you need about 4 psi to prevent cavitation, which is dropping below the vapor point of the fluid.

These are conceptual drawings the actual pressures depend on the circulator and the circuit it is connected into. Longer piping circuits, higher pressure drop piping and fittings needs to be calculated or measured with a gauge connected to intake and discharge side of the circ. Higher head, even higher rpm circs are more prone to cavitation conditions.r

The the question about pumping at the PONPC causing issues really depends on YOUR system. Actual accurate pressure measurements are the best way to know.

Cavitation sounds a lot like an air problem, however you will never purge or bleed your way out of that condition :( Raise static fill pressure or drop operating temperature to stop cavitation.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

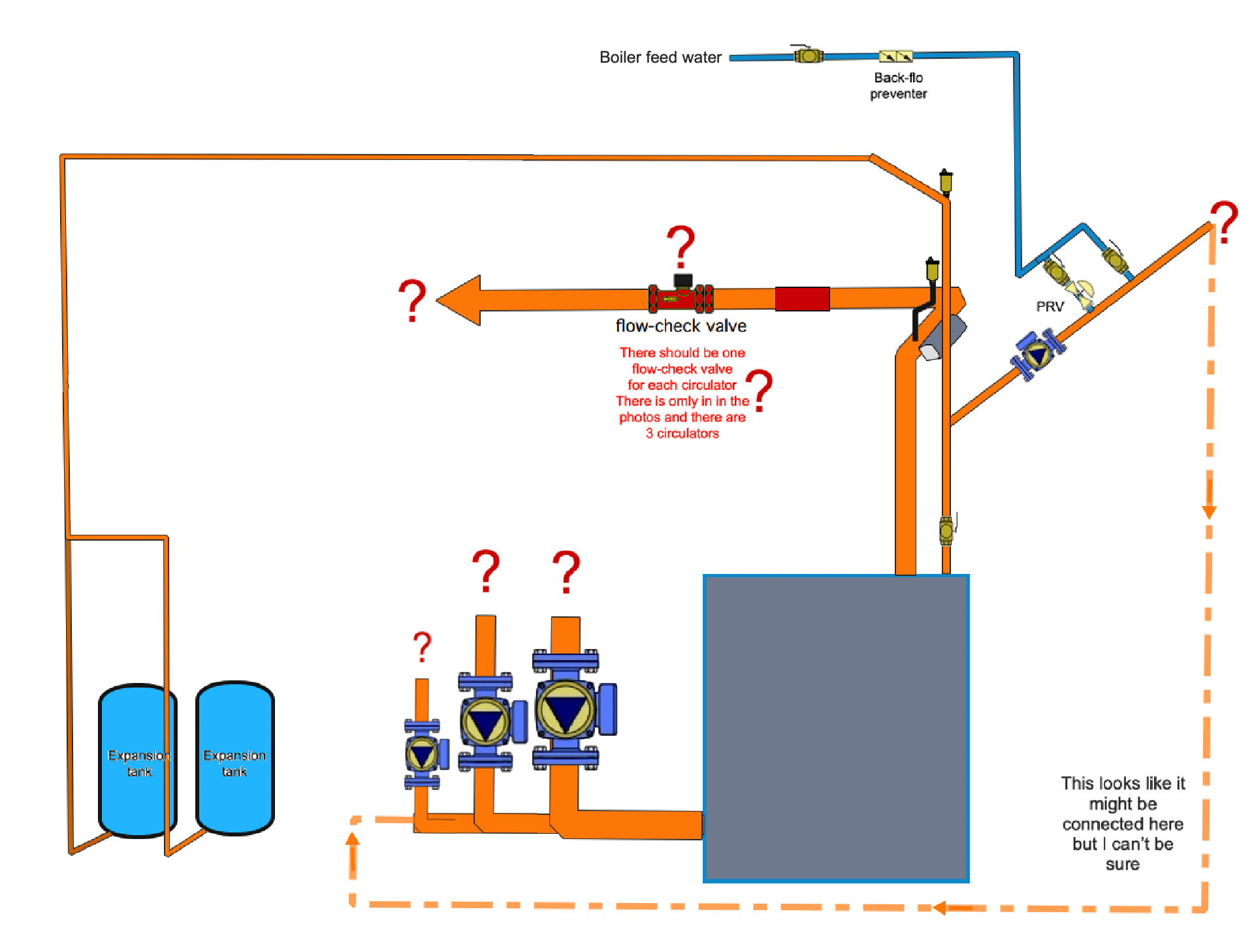

Based on your photo and "There is a circulator piped off the boiler return that ties directly into the cold fill and the expansion tank connection." this is all I can get for your system. there is probably more since there is a second boiler in the photo.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I’ve attached a few additional photos showing the expansion tanks, circulator, and return piping. The second boiler shown in earlier photos is for domestic hot water only.

From what I can see, the circulator is tied into the same loop as the expansion tanks and the auto fill. I’ve temporarily closed the auto fill because it was overfeeding the system and causing pressure to climb; we are replacing it with a new auto fill this week. The expansion tanks are currently set to 20 psi and are holding charge. One of the two was installed in 1997 and we will be replacing both this week. Our intent is to set the new cold fill to 18 psi, which should adequately serve the loop.

At present, pressure climbs to roughly 27 psi when the control calls for heat. That pressure feels excessive, yet it’s the only way all units on the loop reliably get heat.

I’ve ordered Dan Holohan’s book and came here to confirm my understanding. My goal is to have our master plumber correct this properly by Tuesday, and the guidance here has been very helpful. Please let me know if there’s anything else you’d recommend looking at.

Thank you all for the continued input.

0 -

I know we replaced a Burnham with the same boiler a couple of years ago. We suspected that the old one failed from thermal shock. The heating load was several large air handlers.

Burnham recommended (in there install manual) a "blend pump" You simply tee into the supply and return near the boiler and install the pump they spec for that boiler. No control on the pump it runs all the time

Page 34.

0 -

it looks like the circulators are pumping down toward the expansion tank connection? Based on the shape of the volute on the far left.

Should be arrows on the pump bodies.Pumping at the tank could cause the fill valve to kick on, it tries to maintain 12 psi, but as the drawings above show, pressure will be lowered at the connection when pumping at the PONPC

I would also suggest a boiler protection valve or device. Check how long it takes for return temperature to get around 130 when all zones are turned on. Should be 10 minutes or less

I don’t see an air purger, just a couple float style auto vents?

Burnham and other brands are acknowledging that blend pumps may not provide adequate return temperature protection. Note D

They have no way of knowing what the return temperature is.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Each picture shows more information but I still have missing pieces.

Obviously a large boiler for a large building with three different pumps on the return. Not Ideal may have air problems built into the design but it has worked for years so we can make it work for more years.

There are three pumps on the return and each pump should have a Flow-Check of some design to prevent reverse flow thru a loop that is not operating. (unless all three pumps are always operating, then that is not a problem. Not a great design, but eliminates the reverse flow issue.)

The Taco 007 pump appears to be taking water from the air vent tapping at the top of the boiler, and pumping it directly to the return where the three circulators are connected to the return. This looks like an after thought that was added to reduce flue gas condensation from return water from the radiators that may be too cold for extended time periods of operation. The manufacturer requires a minimum return temperature of 135° (or there about) within the first 10 minutes of burner operation. This might be someone's design to resolve that problem.

Thermal shock is not the reason for the Taco 007. I would consider what problems you are trying to resolve and take the proper action to resolve all the issues.

- Is there any signs of flue gas condensation damage on the cast iron sections?

- That would show up as rust dripping from the flue pipe conncetor from the boiler to the chimney.

- you can look at the cast iron near the rear of the boiler to see if any of the pins look like that are missing any metal. Removing some vent pipe or metal panels might be necessary for that inspection.

- Do you need the remove air from convectors on a regular basis?

- If you open the convector vent and air comes out, then you have an air problem

- If you open the convector vent and no water comes out, you don't have an air problem.

- Are there places that are not heating evenly? Some rooms too hot and some rooms too cold?

- Are there any other problems that need to be addressed? Banging, noise, odor are a few that come to mind.

If you are going to drain the system to make repairs this spring or summer, then you may as well solve ALL the problems and not just the Spirovent SR air vent. Especially if you don't have an air problem.

You have several weeks to identify those other problems and address them too. Sometimes fixing the least of problem will correct other problems that you are trying to fix with the wrong parts. Ask me how I know this?

Read Tag Line I would ask my mechanics all the time!

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 - Is there any signs of flue gas condensation damage on the cast iron sections?

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements