L8124A circulator output dead on heat-only boiler — replacement/control options?

Hi all,

I have an S-Series Thermodynamics oil boiler running hydronic heat only (no tankless coil / no domestic hot water).

Control is a Honeywell L8124A triple aquastat. I believe the circulator relay/output has failed:

-Boiler fires and heats normally

-Burner cuts out at high limit as expected

I can hear/feel the control “click” as if the circulator relay is engaging

-But I measure no 120V at the circulator feed, and the circulator does not run

- Circulator pump has been replaced and is known good

I’m looking for replacement/control options. Since this is heat-only, I’m also open to a setup where the boiler doesn’t maintain temperature year-round and the circulator runs only on a thermostat call (while keeping proper high-limit safety).

Thermostat is a Nest (single zone).

What’s the best way to replace/modernize this control? (Direct replacement vs alternative control strategy/parts.)

Thanks in advance,

Chris

Comments

-

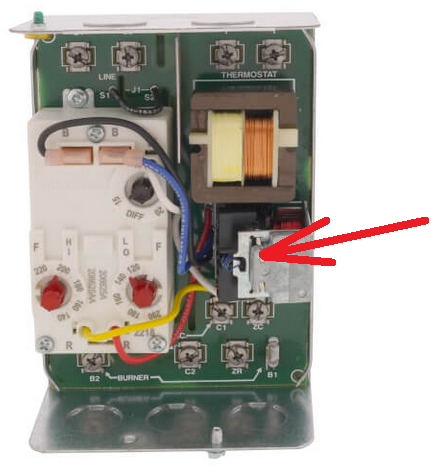

Most likely the solder joints that connect the relay (Red arrow) to the circuit board have failed. They can be repaired and even improved if you have those skills, secondly the contacts in the relay have failed.

Typically a pro will just change the whole Aquastat. Hydrolevel makes a model that some folks claim lasts longer and less expensive.

You probably don't need a triple Aquastat if you replace the whole unit.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

-

Thanks for the reply! I was wondering how repairable the relay was.

I'll look at it closer tomorrow morning.

Haven't considered running the pump continuously. Is that typical?

0 -

" I was wondering how repairable the relay was. "

All depends on what failed, the relay itself is not repairable and not sure if there is an exact replacement available, the bad solder joints are quite common IMO and are repairable. As simple as re-flowing the solder joint with new solder or in this case I remove the old solder, bend the relay's pins perpendicular to the board and bridge the gap from the pin to the circuit board trace by adding wire wrapped around the pin (maybe 18 or 20 Ga.) then extending both ends of the wire at least 1/2 inch onto the circuit board and re-soldering the whole joint. Makes the joint(s) more mechanically robust than just the soft solder.

For me removing the aquastat and dealing with the capillarity tube and the bulb and making sure the capillarity tube does not short against anything when reinstalled is the hard part, the solder joint repair is the easy part.

" Haven't considered running the pump continuously. Is that typical? "

Typical ? If you don't need heat than don't bother. It you need heat, IMO running the circulator continually for just a few days until a proper repair can be made is better than no heat. You can always, at your leisure just shut the whole system down to give is a break if you want (circulator not running and no high limit burner shut down activity).

Typical is only running the circulator when needed, but that means is presently broken, right ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Actually if it a single zone system continuous circulation has some nice advantages.

Less noise from expansion/ contraction room temperatures are more consistent, less on/ off cycle on the relay and motor.

The thermostat wires to the boiler TT, pump has a summer winter on/ off switch

Using an ECM circulator would cut down on electrical costs

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

If the relay is activating, (lower right) component but power not passing through. Most likely the point contacts are pitted on it. For interim, we have taken like 400 grit sand paper, turned off all power to boiler. Cut small like 1/2” strip of sand paper maybe 1.5 “ long and slipped it between points of contacts, slide paper back and forth to smooth points out. It’s tedious and you have to be gentle doing it. It can get you by as long as that is the issue. Other problem may be the wires in pump are loose where they connect in terminal box on pump. You did mention pump was replaced.

0 -

Actually if it a single zone system continuous circulation has some nice advantages.

Less noise from expansion/ contraction room temperatures are more consistent, less on/ off cycle on the relay and motor.

The thermostat wires to the boiler TT, pump has a summer winter on/ off switch

Using an ECM circulator would cut down on electrical costs

If I end up just wiring it direct to the switch, wouldn't that mean that the triple aquastat would trigger even when there was no call for heat, because we'd be pumping hot water out of the boiler and through the system, dropping the temperature to the lower set limit?

Continuous run does have its appeal, I just want to make sure I'm not boiling my family and burning extra gallons of fuel oil 😂

0 -

If the relay is activating, (lower right) component but power not passing through. Most likely the point contacts are pitted on it. For interim, we have taken like 400 grit sand paper, turned off all power to boiler. Cut small like 1/2” strip of sand paper maybe 1.5 “ long and slipped it between points of contacts, slide paper back and forth to smooth points out. It’s tedious and you have to be gentle doing it. It can get you by as long as that is the issue. Other problem may be the wires in pump are loose where they connect in terminal box on pump. You did mention pump was replaced.

I will give this a try. Thanks! Connections are good to the circulator. No voltage detected on the cables coming in. I had gotten the circulator to run one time by manually manipulating the relay. I feel pretty confident the issue lies there.

0 -

If you want to run the circulator constantly for a temporary fix until you get the proper part, you must turn the L8124 into a cold start control. If you don't use the boiler for DHW, that should have been done long ago. Here is how you do it.

If the Aquastat part is the problem, then this may be all the fix you need. But it is more likely the relay portion that is defective.

The replacement for the L8124A on your oil heater is the L7224U because it is less expensive and has more features that will make your boiler operate more efficiently.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

" Continuous run does have its appeal, I just want to make sure I'm not boiling my family and burning extra gallons of fuel oil 😂 "

Well you are not (or should not be) bypassing the thermostat control of the burner, just set it a bit lower if needed. And the warm start can be reduced or disabled as @EdTheHeaterMan explained.

Personally I rather be a few degrees warmer than normal than no heat at all.

My money is still on dilapidated solder joints to the relay.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I have had this control do the same thing numerous times. Like others have said, the solder joints under the relay are usually just barely soldered on, and with the force of the relay opening and closing, the solder joint cracks and separates. As 109A_5 said, repair it and it will work fine. In the meantime, try taking your neutral wire from the pump and connect it with the burner neutral and see if the pump then runs. I had at least one where the neutral foil on the board burned off, but just the one going to the pump.

Rick

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements