TT Prestige w/ MCBA control

Customer of mine has a fairly old (Pushing 20 yrs) heat only TT prestige 175. Its been a champ until as of late.

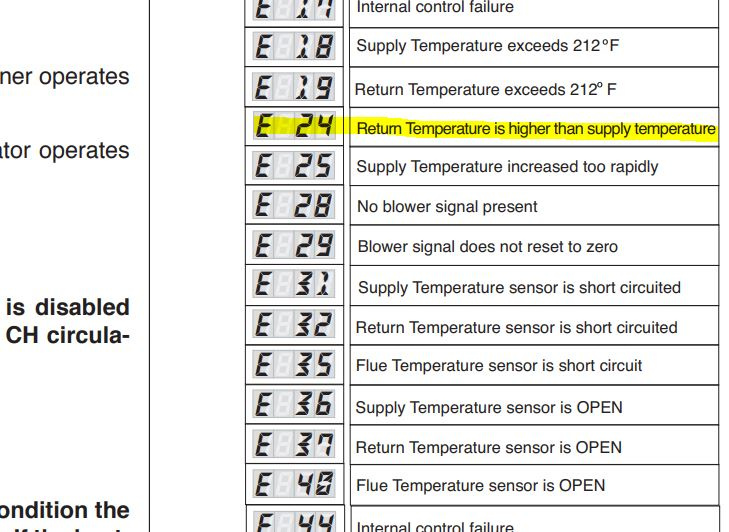

It has locked out 3 times in the last couple months. E24.

A simple reset does not work. Only shorting the 2 pins allows it to fire back up.

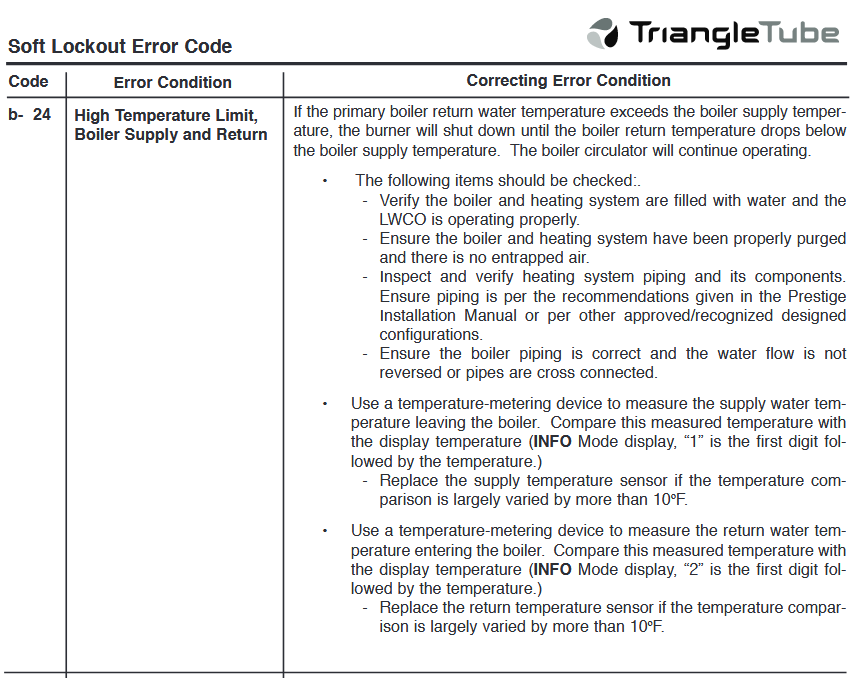

This code does not show up in any of the manuals… including the "Trouble shotting guide " that i have.

Any ideas from experience?

tia… kcopp

Comments

-

Looking at the error listings, it seems often an "E" error is a more severe or happens more often than a "b" error criteria, so the "E" version gets locked out. Since there is a b24 error, I would use the b24 information as a possible clue.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Been here done this. I found a build up in the base of the heat exchanger insulating the return sensor. Causing water to bypass flowing over the return sensor and up to supply. So if it had been running prior and sat in off cycle, when boiler fired up again, the return water was not being sensed by return sensor and cooling down the supply sensor. Supply sensor would say cool down to 110 from cooler return water while return sensor may have still be sensing retained heat from being insulated and no flow over it. This took a while to validate, Then endend up pulling return pipe and return sensor, Made up a valve with small copper spray tup to be able to get in and around the base of the heat exchanger and blew out with city water pressure, flushing out the sand/sediment that was present. Put back together, filled flushed and then operation good.

We did not do original install but they had been using well water from a sanpoint well, looked like that may have been the debris we found. Good luck Kevin, Tim

2

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements