Tuning ODR on ModCon boiler

Hi everyone,

I posted a thread a while back as I was preparing to install a new boiler in my home. I ended up with a Weil Mclain Ecotec 2 80,000 btu model which is working well.

I have been experimenting with the output water temperature at differing outdoor temperatures to determine how I want to tune the outdoor reset.

I hooked up to the boiler via the Modbus connection which gives me a great deal of logged data and flexibility in how I control the unit.

That all being said, are there any guidelines for how long an ideal furnace cycle should be? I know that short cycling is the enemy of heating equipment, and long cycles are desirable, but is there a point where it becomes excessive or a problem?

For example, last night I was able to get a 3 1/2 hour cycle during the coldest part of the night. Outdoor temp was around 15degF, Thermostat is set to a 2 deg swing (kicks on at 69.5 and off at 71.5). I had the water temperature set to 140degF. In one cycle the furnace kicked on at 3:45AM, and didnt finish its heating cycle till 7:15AM. The house then takes about an hour to drop 2 degrees to where the boiler kicks back on which repeats the cycle.

During the long cycle, return water temp was ~130 which should have been very close to, if not in condensing range. The indoor temperature in all rooms stayed within range and were constantly increasing, though obviously very slowly. The modulation was sitting right around 48% during this whole time.

Does this sound like an optimal point for the reset curve, and a good cycle length to target? Am I missing any downsides if I tune the system to run like this?

The only downside I can think is if you need to change the setpoint, or for some reason would be trying to recover from a lower temperature (i.e. furnace is off, house is 60deg and you want to start up). With my current controls however, I could make a "boost mode" and run the cycle at a higher water temp to get the house to temp, then fall back to the lower temperature.

Thoughts? Other things I should try?

Comments

-

Sounds reasoable. On a design day with everything designed exactly one could expect the boiler to run non stop. The boiler exactly matching what the build load is.

ODR can get you close to that constant firing/ constant circulation depending on modulation and small load match up.

The type of heat emitters are pert of rapid changes or adjustments. Low mass copper fin tube compared to high mass in-slab radiant. With radiant I find a comfort spot and leave my system there without any setback schedule to complicate things.

You mention furnace and boiler, do you have both?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks for the insight.

I only have the boiler, no furnace. Sorry, I sometimes incorrectly use those terms interchangeably.

Almost everything is copper fin tube, with a small section of the Ultra Fin convection plates in the bathrooms to warm the floors.

0 -

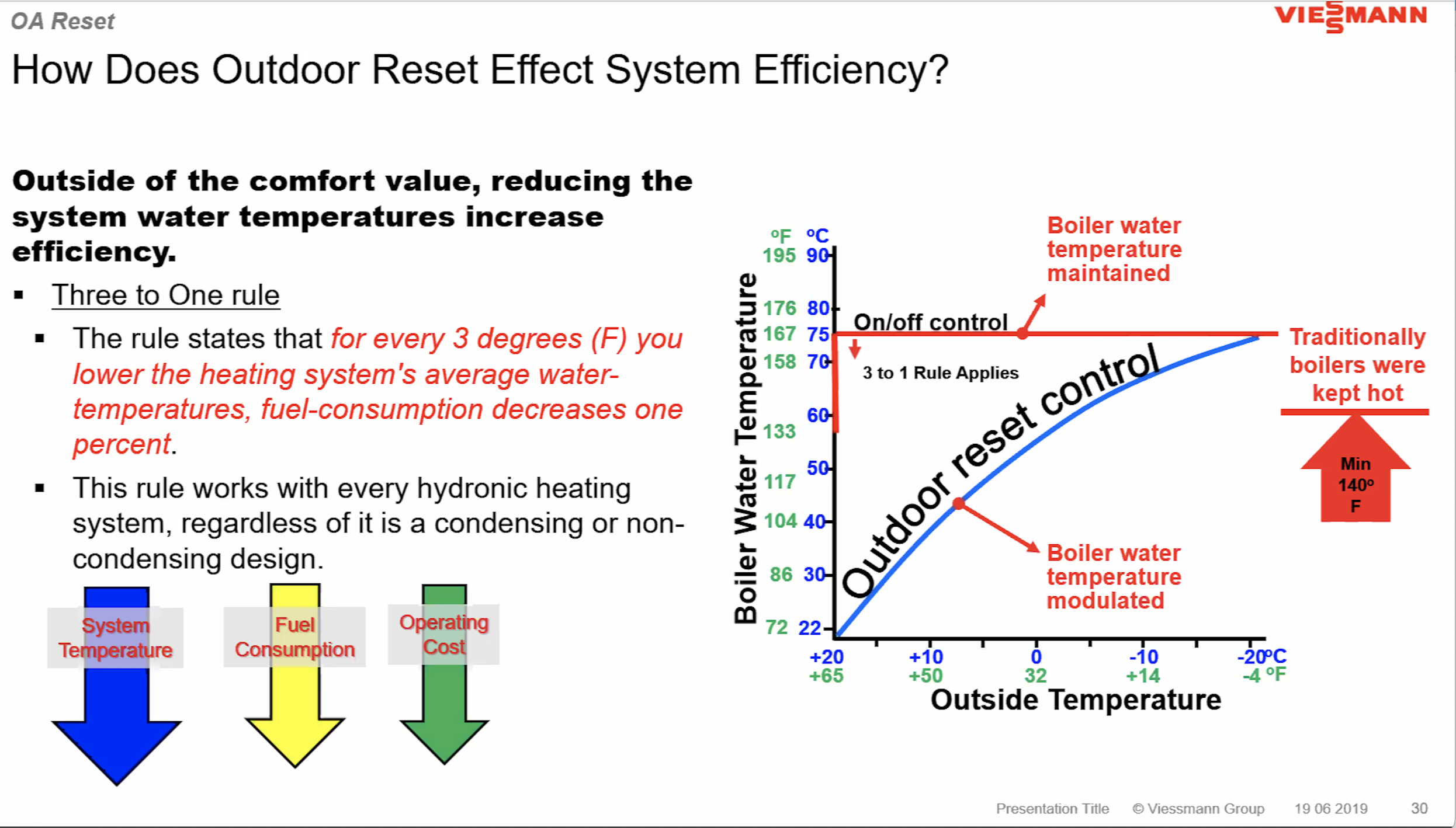

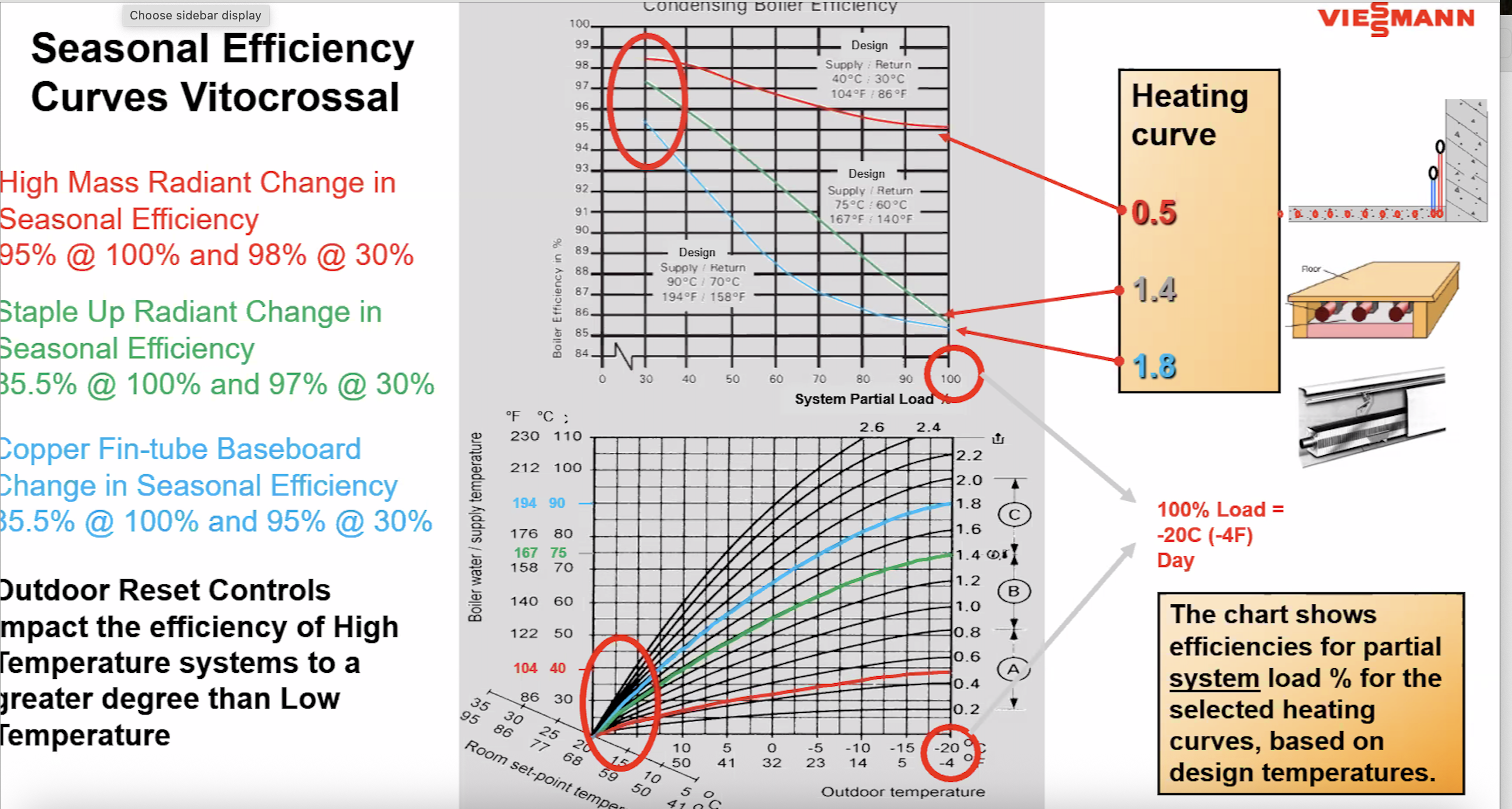

The lower the boiler operating temperature the more efficiently it runs. So comfort and fuel efficiency are what you can chase with the tuning of ODR.

Some training slides from Viessmann.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements