Troubleshooted to bad aquastat

I have a Burnham PV84WC-GBWN oil-fired, hot water boiler (2006) heating a single story house in upstate NY. It uses a Residio L7224U aquastat.

I've been troubleshooting short cycling (runs for 5-7 minutes and shuts down even when it's getting a call for heat and the water temp is 130 to 140) for days and finally got around to putting a jumper across TT at the L7224U. After a power-on, it ran for 9 minutes and then shut down. Water temp at shutdown was 135*F. Pressure is 19psi.

So, I think that means the L7224U is failing. I read about it "learning" to do limit runtime after extended periods of calling for heat. I've been playing with home automation that controls the tstats controlling this, so if it can learn, it would make sense.

I tried to edit the programming but I've been unable — I think it might not be one of the programmable versions.

I am concerned about replacing it with the same model and having it get stuck in the same crippled mode — run for 5-7 minutes and shut down. So, I was considering replacing it with an L8124A. Does this make sense?

I'm not a pro or an expert.

Thank you!

Comments

-

I haven't looked at that aquastat, however, that may be the problem, but, there are other things that can create that situation. Possibly, a high limit sensor failing or other part of the burner circuit that is temperature sensitive not functioning properly.

Look at the other possibilities. I'm not an expert. X in mathematics is an unknown and a spurt is a drip under pressure, so, maybe I qualify.

0 -

What is your high limit setting?

0 -

the only safety cutoffs on the boiler are incorporated into the aquastat.

High limit is 180.

0 -

The L8124A is more expensive and has less energy saving features.

Is there any other control attached to the L7224U? like is there an outdoor reset accessory wired in the that control. % minutes of on time for some oil burners is normal as long as the return temperature to the boiler is above 135° you should be just fine.

To be sure that the control is actually defective and not the sensing probe you can try to replace just the sensing probe. 12" sensor This is the one that comes with the control and if you order the replacement control, you can try the one from the replacement control. If that solves the problem then you can purchase the replacement part and put it in the new control and you will have a good unused working L7224U that you can return, or keep in stock for future use.

I have a feeling that you don't have a problem but more information is required to determine that.

- What type of radiators do you have

- How many zones so you have

- What size is the main pipe leaving the boiler and returning to the boiler.

- There are more questions but I can't think of them right now

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

If you put a jumper across TT, what is the thermostat wired to? Or is there more than one thermostat?

If nothing is connected to TT, the aquastat will only maintain Low limit.

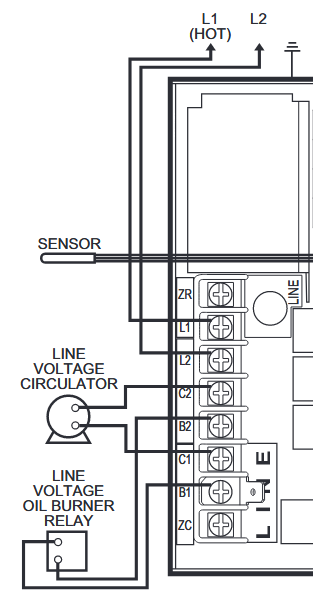

If there's a zone panel, and the boiler has a tankless coil, they should be wired using ZR/ZC. That's the only way the circulators will stop if boiler temperature drops below the Low limit.

0 -

Thank you all very much!

The house is 2 floors (plus basement where the boiler lives). First floor is approx 1100 sq-ft, second floor is approx 800 sq ft.

Two zones: 1st floor and 2nd floor, each controlled by an Ecobee tstat.

Radiators are not old cast iron — they are new baseboard types.

There is no outdoor reset.

Hot water is made separately.

Two, 1/2" copper pipes leaving the boiler carrying heating hot water to each zone.

One Grundfos circulator pump.

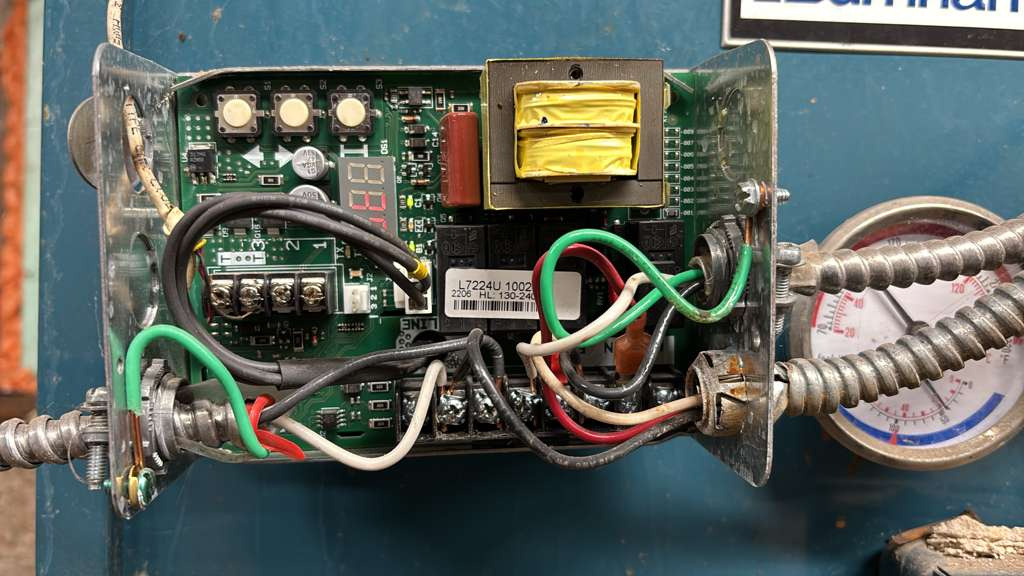

Pump and both zone valves (V8043E1012) and tstats are wired into the L7224U-1002 aquastat.

The oil burner is a Becket with a Resideo R7284 controller. The controller's TT are shorted permanently.

My test included temporarily shorting TT on the aquastat to determine if the short cycling was being caused by the boiler (and its attached controls which I think include nothing more than aquastat) or the external controls (valves, tstats, wiring).

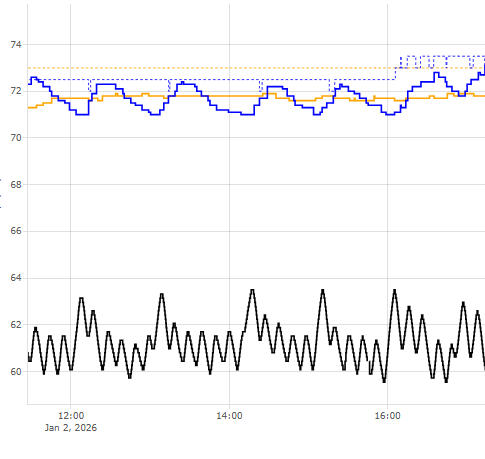

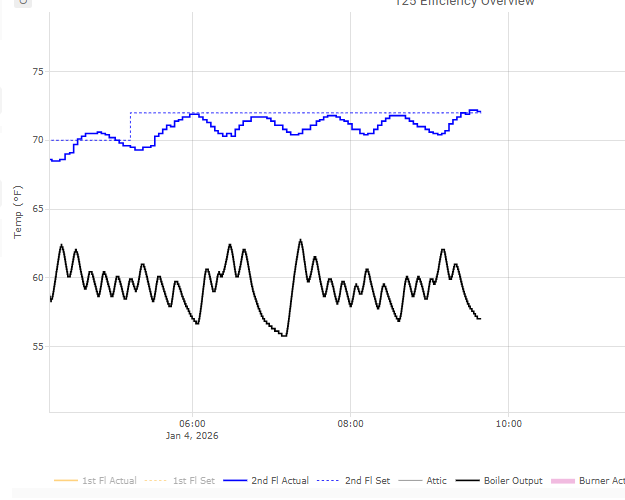

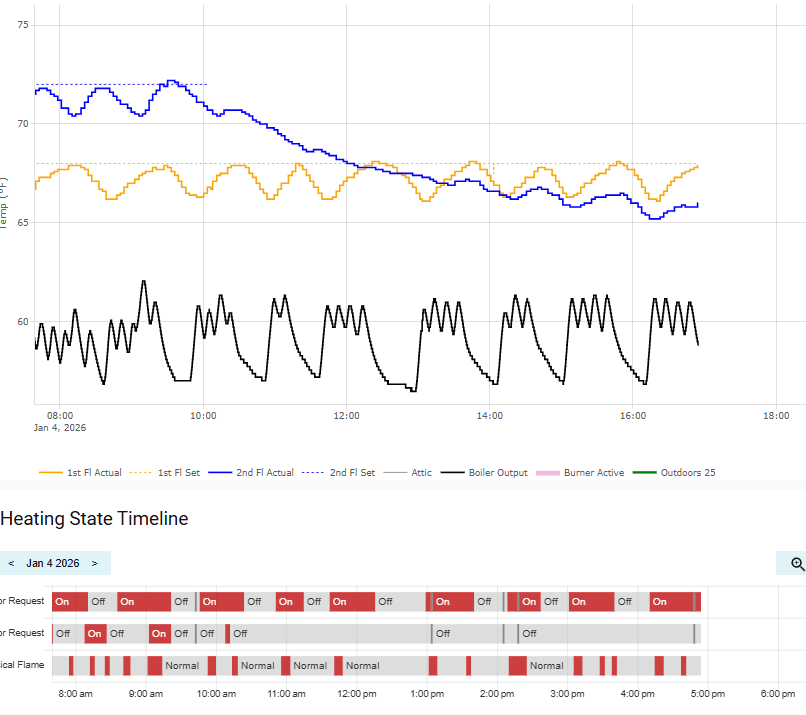

This graphs is characteristic of what I am working with. Black line is the temp from a gauge hanging in the air a couple inches from the exhaust pipe of the boiler (the absolute valves are worthless, but the relative valves and the rate of change indicate whether the boiler is firing). Orange solid is the temp in 1st fl zone. Orange dash is 1st fl setpoint. Blue solid is temp in 2nd fl zone. Blue dash is 2nd fl setpoint.

Two thing I note is that the 1st fl is never reaching the setpoint and the frequent firing/not-firing of the boiler. A week ago the boiler had no trouble getting the temp in the 1st fl zone to hit the setpoint.

Anything else I can share that would help diagnose?

0 -

Pics here.

https://ibb.co/nM0nvhY5

https://ibb.co/RkBfQW6C

https://ibb.co/3927c7V0

https://ibb.co/bRgbqk7W

https://ibb.co/xq3hjsWg

https://ibb.co/60H7XQHm

https://ibb.co/MxNm0bMy

https://ibb.co/2YCfp7ts

https://ibb.co/NgtXtZpZ

https://ibb.co/kgccmfNM

https://ibb.co/prRWrqtV

https://ibb.co/7xJgZsX6

https://ibb.co/wrNfSR3X

https://ibb.co/HTbb4PR3

https://ibb.co/p6MZDrtg

https://ibb.co/7JzvVZxJ0 -

0

-

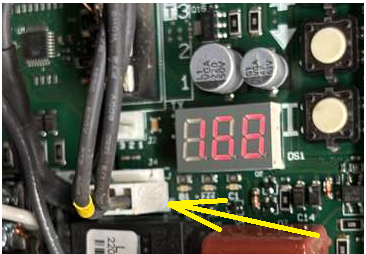

Looks to me like the boiler temp is around 130 and the aquastat thinks it is about 168. Assuming the 168 is the ' bt ' value. So either the aquastat is defective the sensor is defective or the sensor connection (yellow arrow) is poor. Shut the system power off, then I'd try unplugging and reconnecting the sensor connection (at the yellow arrow), since that is quick, easy and free. The power to the aquastat Hot and Neutral being reversed does not thrill me, but probably not the problem and may be the colors are revered at the other end. L1, Hot is usually Black.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

those various types of plastic foam right up against the vent are a big problem

0 -

-

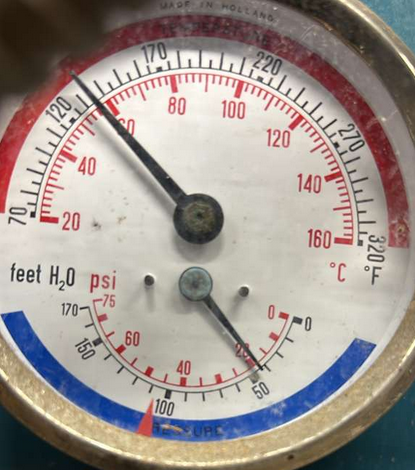

It’s also the wrong gauge.

0 -

I'll remove, spray a little contact cleaner inside, and reinsert the sensor connector.

If that doesn't solve it, it is safe to say the problem is either the sensor or the aquastat?

Is there any truth the L7224U learning (i.e., reconfiguring itself) to shut down at a lower temp and/or preventing longer burn times? I am concerned that if I have to replace the aquastat it might happen again -- that's why I was considering the non-smart version.

L1 is supposed to be hot -- got it.

The smoke pipe going through the foam has been like that for several seasons. I think it might be fire block (rated to 240*) spray foam. I see mention of leaving a gap and filling in with rockwool instead.

I have no idea of the gauge issue with the heat pipe.

0 -

I am wondering what temperature gauge is more accurate and what temperature measuring device you are using to make you measurements, adjustments and diagnosis. I have a feeling that you do not have a problem that needs to be fixed (except the combustible insulation material being within 18” of the bent pipe connector (incorrectly called smoke pipe)

According to the clearance to combustibles information that comes with your boiler, you need to have anything that is possibly combustible farther away from the vent pipe, that can reach over 1000° in a burner malfunction situation, than it currently is .

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

@josephny said: "I'll remove, spray a little contact cleaner inside, and reinsert the sensor connector."

that's probably not a good idea. the contact cleaner chemical is basically carbontetrachloride and may not play well with the polymer coating of that sensor.

You can add NeverSeez which is a graphite paste that will assist in heat transfer from the well adaptor to the sensor. They usually include a small packet of that heat transfer compound with a replacement control. Since no one actually stocks and sells that packet over the counter I have used the NeverSeez for that function

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

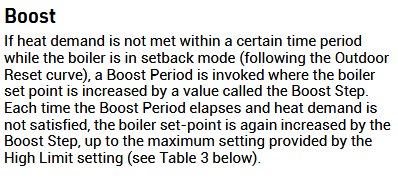

I think the " reconfiguring itself " works this way not the way you think. Also you stated and it appears you don't even have the outdoor reset features hooked up.

Does the system heat the house sufficiently ?

You need to determine which temperature indication is actually accurate. Until you do that guessing is useless.

Some documents to read.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I will take care of the foam problem after getting the heating problem fixed.

I am not using any temperating measuring device other than the gauge attached to the boiler.

That "Boost" feature is interesting. From my basic and initial read, it sounds like the controller is in Setback mode. But, I don't know if that is possible without an outdoor reset.

The house is heated sufficiently but with a permanent call for heat on the 1st floor (i.e., the setpoint is never reached).

I read those docs and they are indeed very informative. For example, I now know that bt is boiler temp (duh), and I see that the aquastat is showing 179. So there is a discrepancy between the analog gauge and the reading that the aquastat has.

I'm at a loss for what to do now.

Here is a link to a video showing bt 179.

0 -

" I am not using any temperating measuring device other than the gauge attached to the boiler. "

OK, I was, since I saw the 168 in one of the pictures.

But kind of forgot the 1st floor thermostat was never satisfied. So the mechanical gauge may be more accurate. Since maybe the aquastat shuts the boiler down at what it thinks as 180 yet the boiler is actually only at 140 ish and that is the problem. The two temperature measurements should agree much more closely.

So you can get a third opinion maybe (with some other thermometer) where the hot water supply pipe comes out of the top of the boiler.

You could assume the aquastat sensor has failed and is reporting the wrong temperature. Or the sensor is OK and the aquastat is defective, interpreting the sensor's correct data incorrectly.

That sensor being a three wire sensor I believe it is a chip that actually sends analog or digital data to the micro-controller in the aquastat, so it may be difficult to independently test. Some thermistor based temperature sensors (two wire) can be tested with an inexpensive multimeter.

As I stated before I would shut the system power off, then I'd try unplugging and reconnecting the sensor connection, since that is quick, easy and free. Also being a microprocessor based device maybe it just got glitched and a power down reset may heal it.

A replacement sensor is the next most inexpensive option, but it is a gamble.

Some folks like the Hydrolevel product line, they claim they are better and less expensive, maybe look into the Model 3150 HydroStat for Oil Boilers or similar.

Going with a different aquastat the external wiring may need to be changed, since it may no longer reach correctly and the sensor well may have to be changed too take advantage of all the features (Hydrolevel product).

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I don't know that the aquastat has a 'Setback Mode'. I think what it is referring to is when recovering from a thermostat setback, the limited boiler water temperature due to the outdoor reset function will extend the recovery time so the Boost period is invoked.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Does it make sense to think that maybe the 1st floor zone valve is not fully opening, thereby limiting how much hot water gets to that zone and gets out of the boiler, thereby making the aquastat's probe accurately read ~170 when the analog gauge reads ~140 because of lack of water flow through the boiler?

0 -

Since the aquastat with its sensor well and the old gauge are inches from each other in the same boiler water I would think they would read the same temperature within a few degrees of each other, especially with reduced water flow (if that is true).

If you had a pot of water on the stove would you expect a 30 degree difference in two different spots only inches apart ? If one is close to the casting where the burner is or the flew gasses are moving through that may be a hot spot. Shut the burner down for a few minutes and see if the temperature readings equalize.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I'm not on site, but the logic makes perfect sense.

I assume that means my thinking about a malfunctioning zone valve is not correct. And, therefore, we are back to either the analog gauge is bad, the aqustat sensor is bad, or the the aquastat is bad. Do I understand correctly?

0 -

Sure there could be something wrong with the first floor zone. But the different temperature readings bother me and I would think the aquastat's well position may be cooler not a lot hotter (supply pipe location). And the different temperature readings may explain the behavior of the first floor zone. And the 2nd floor zone may aided by the first floor's heat.

Do you think the 2nd floor would keep up if it was a lot colder out ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Very interesting analysis.

It's mighty cold out (23*F) and the 2nd floor is keeping up nicely.

0 -

If you were to disable the 2nd floor for a while would the 1st floor catch up ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I will do that now.

0 -

Hello JosephNY,

I live south of you in the Finger Lakes.

I may be speaking out of turn here,

but the first thing that I saw when I looked at your pictures is the front view of the boiler and it is not good. The flue piping is leaking at the joints and should be replaced too.

Does your chimney have a chimney cap?

I agree with Ed in saying the thermocouple should be immersed in Never Sieze paste to increase its conductance to allow more accurate sensing of temperature. I used the 3M supplied conductance paste in my immersion well and it has helped my L8124L triple aquastat perform flawlessly for the last 10 heating seasons.

The piping as installed DOES NOT allow for cleaning of the boilers firebox and that is not good.

If as you say the boiler has been burning since 2006, it has not been cleaned since it was installed due to the location of the circulator feeding water into the boiler sump.

The fire box access door swings outward and to the left to allow for the cleaning and inspection of the firebox and flue breech.

The other major issue is the sloppy oil burner plumbing. The soft copper oil delivery line does not and would not allow for the boilers access door to be opened safely to clean the fire box, change the burner nozzle, replace the electrodes or adjust the electrodes for that matter. You need the woven wire mesh oil delivery hose. The filter screen in the oil burner is long overdue for cleaning as well.

The oil burners missing cover is another issue as you probably have a great deal of dirt in the combustion fan as well and the dust bunnies are loving it.

The wiring to the boiler is also sloppy.

The BX cable feed in power to the boiler should be routed from the ceiling joists downward to the sheet metal skin of the boiler and then held in place with BX clamps to allow an upward sweep to reach the triple aquastat and connect the BX cable to the triple aquastat with a 90 degree BX clamp and a 90 degree BX clamp to allow an upward sweep loop of the BX cable downward to the burnhan supplied junction box for the grounded outlet for the Beckett oil burner.

A BX 90 degree clamp should be used for the BX cable leaving the triple aquastat to allow a an upward to downward sweep of the BX cable to the circulator as well.

Allowing the BX cables to sweep upward allows for an unobstructed view of the pressure gauge for the boiler as well and eliminate excess strain on the conductors and ground wires.

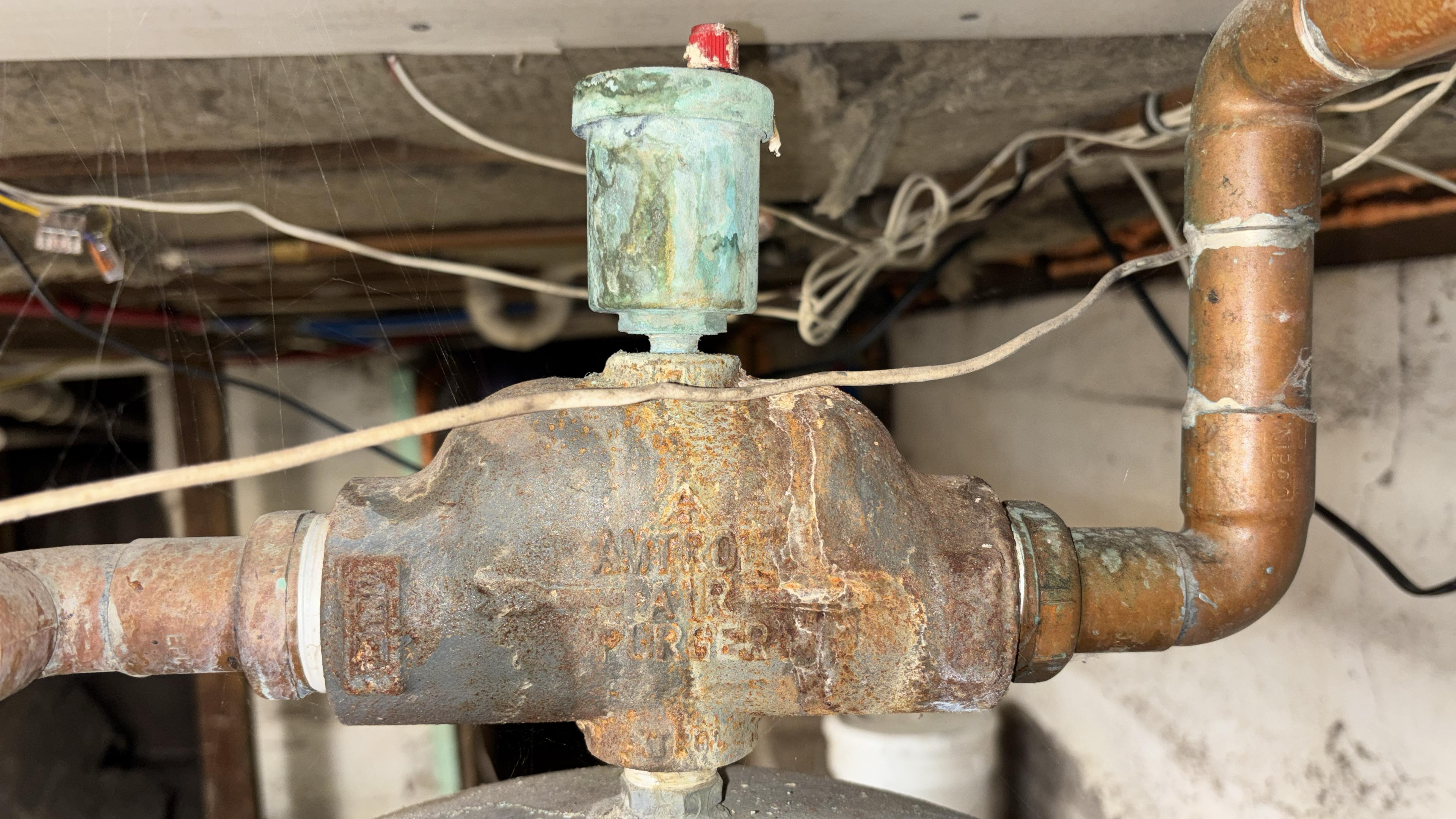

The automatic air vent that is mounted on the air scoop needs to be replaced as it is leaking.

Ideally an automatic air vent should be mounted so that a ball valve is located between the air scoop and the automatic air vent to allow the removal of a leaking automatic air vent without draining the boiler.

You also lack a low water cut off control that should be the first boiler control before the triple aquastat which will kill the power to the boiler in the event of a water loss condition.

The Low Water Cut Off sensor can be installed in a Tee located in the piping to the boiler sump or the feed pipe coming from the boiler riser to the zones. I have a Bell & Gossett RB-112-E Low Water Cut Off Switch that is self cleaning by spinning the immersed probe and it has worked flawlessly for 10 years in my boiler.0 -

As long as the sensor is fully inserted in the well, I'd say the tridicator is off.

Set the High to 180°.

Set the High diff. to 30°.

Set the Low to OFF since the boiler isn't making domestic hot water.

Does the Ecobee ask what type of equipment during setup? Does it ask type of emitters? That matters for cycles per hour.

0 -

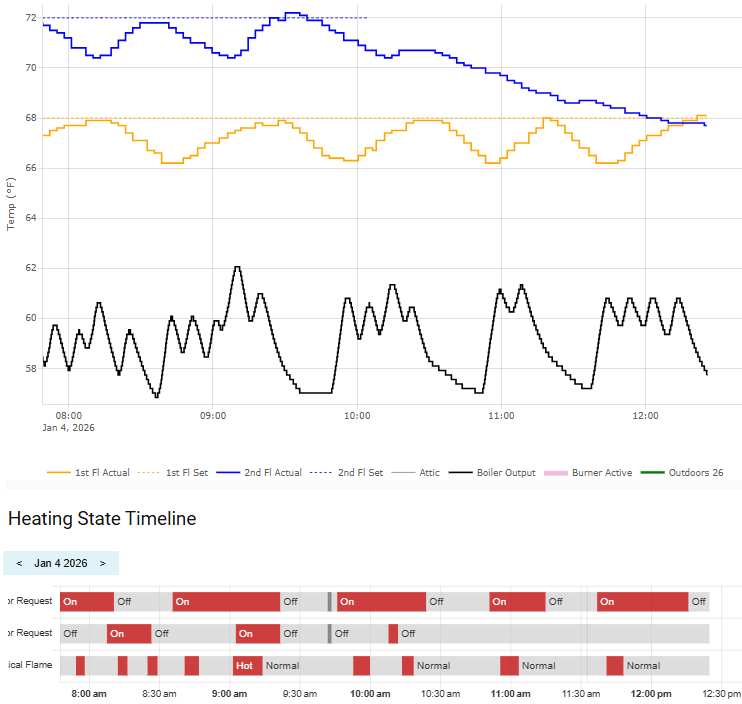

Here is a graph of the results. I shut off 2nd fl zone at 10:11am. Looks like the 1st floor performed fine (right?). (Boiler output is just for relative temps — I don't think their absolute valves have any usefulness.)

0 -

Wow! That's a lot of stuff to do. I'm actually substantially South of you, near the Ulster-Sullivan counties border. Are you a pro? I wish I had a pro that knew what you know near me. I'd pay him to do this and a little extra to watch (I know, I know, but really truly no-joke, my watching is because I'm curious about everything and want to learn (not to compete, or take away someone's work).

You must have zoomed it so carefully to see the leaking automaic air vent. My (very) basic understanding is that if it is malfunctioning, that alone could cause air to be in the system and result in short cycling.

BTW, behind that 4" foam board is a big opening that goes to an uninsulated crawl space. The exhaust pipe goes another 8-10 feet before it hits the chimney. I haven't seen it that area in years.

I don't believe there is an external (canister-style) oil filter on the system. I don't know if there is a screen (or other) type filter in the burner, but I do know nothing's been cleaned in a long time.

While I normally dive right in, I also normally break something, so I'm loath to stick my fingers in the heating system mid-Winter.

0 -

I think that is how it's set up.

Not sure about the Ecobee setup, but I know that the Ecobee continues to call for heat while the boiler is not firing. My understanding is that we can conclude from that that the cause of the non-firing state is not the ecobee.

0 -

Follow up. 2nd fl zone still off and 1st fl is okay.

0 -

To me it looks like it was OK before you shut off the 2nd floor. But the set point was lower 68 instead of 73.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Never Sieze makes a lot of products. I use a heat transfer paste on the sensor tube which is the same compound that I use in computer heat sinks to transfer heat from the chip to the heat sink. It used to be a silver compound, but because of the silver price has changed to a cheaper ingredient.

If you use a heat transfer compound, clean the sensor and the well really well. ha! I use lacquer thinner as the the final cleaning.

0 -

Can I replace only the vent or do I need to replace the purger also?

0 -

No, you don't have to replace the air scoop. But air scoops aren't as efficient as a micro bubble air purger. But, it does the job.

That looks like a Taco Hi-vent air eliminator .

0 -

That's great — thank you.

I went on supplyhouse and (shouldn't be a surprise), there are several different Taco Hy-Vent models.

Any suggestions on which one to get?

Thread is 1/4"

Looks like a 426?

0 -

They are all going to leak on you eventually so it is a case of being prepared to change a bad one.

So for a shopping list:

two 1/8" by 2" inch pipe nipples

one 1/8" inch female/female ball valve

one 1/8" pipe coupler

Pick one air vent and buy two or three of them and either change that bad one now or wait.

Shutting the boiler off for a few hours to let it cool will allow you to change it now.

It is faster to assemble the pipe nipple, ball valve, pipe nipple, pipe coupler and then the air vent before you remove the bad one as you will have water coming out of the elbow piping.

Please use only 2 pair of pump pliers and an open end wrench to do it. You need the open end wrench for the flats on the new air vent. Use a little pipe dope on the threads with a Q tip starting at the second thread of the male threads to seal them.

I am glad I removed all of my air vents when I had the steel compression tank installed, no more bleeding baseboard or dealing with slugs of air blocking water flow.

If you have a step ladder great you will have a safe work surface to work from to remove the old air vent with the open end wrench, remember to push away from you with the open end wrench to loosen the leaking air vent.

0 -

Thank you. I'll take the less pro way at this time and just order one of the ($65) vents and do a direct swap.

I'm pretty sure it's a 1/4" thread — does that make sense?

I sure hope this helps — and that all that corrossion and evidence of leaking means there is air trapped inside, causing problems that I won't have when this is replaced.

0 -

Amtrol air scoop vent tapping's are 1/8" on air scoops 1 1/2" IPS and smaller. The 2" scoop has a 1/2" vent tapping and the 2 1/2" & 3" scoops are 3/4" vent tapping

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements