manifolds vs Trunk-and-Branch on 100-Year-Old Brooklyn Hydronic System

Hello all,

I’m working on a 100-year-old, two-family hydronic hot-water system (not steam) in Brooklyn. The house is about 1,800 sq ft, with 10′ ceilings on the living floors and a basement just under 8′, which will be finished as living space.

Originally, the system had large cast-iron gravity mains, which were removed years ago to gain basement headroom. About three years ago, during a partial update, the distribution was converted to a ½″ Viega PEX manifolds system with manifolds.

Since that change, I’ve been dealing with:

- Lukewarm radiators

- Uneven heat distribution

- Ongoing balancing issues

The basement is currently open, and before the ceiling is closed, I want to correct the piping properly.

Current system

- 10 cast-iron radiators

- Two pipes at each radiator (½″ supply + ½″ return)

- Single zone / single thermostat

- Boiler: New Yorker CG50DNI-G2 (94,000 BTU)

- Circulator: Grundfos UPS 15-58

Proposed change

Since the radiators are already two-pipe, I’m considering removing the monoflow/diverter tees entirely and repiping as a true two-pipe trunk-and-branch system:

- 1″ supply main

- 1″ return main

- ¾″ branches to each radiator (currently ½″)

- Radiator-level control using TRVs or manual supply valves, with lockshield valves on the returns

- Ability to shut off individual radiators

Both mains would be run along the floor joists.

Questions

From a hydronic design standpoint:

- Is there any real advantage to keeping a monoflow/diverter-tee system here, given that the radiators are already two-pipe and the mains are being rebuilt?

- Does a trunk-and-branch layout make more sense for cast-iron radiators on a single-zone system?

- Any guidance on where to originate the 1″ supply and return mains once the monoflow piping is removed?

- Any layout or sizing concerns you see with this approach?

I’ll be doing the work myself, but it will be reviewed before final tie-in and before the ceiling is closed.

I appreciate any guidance, I want to do this once and do it right.

Thank you.

Comments

-

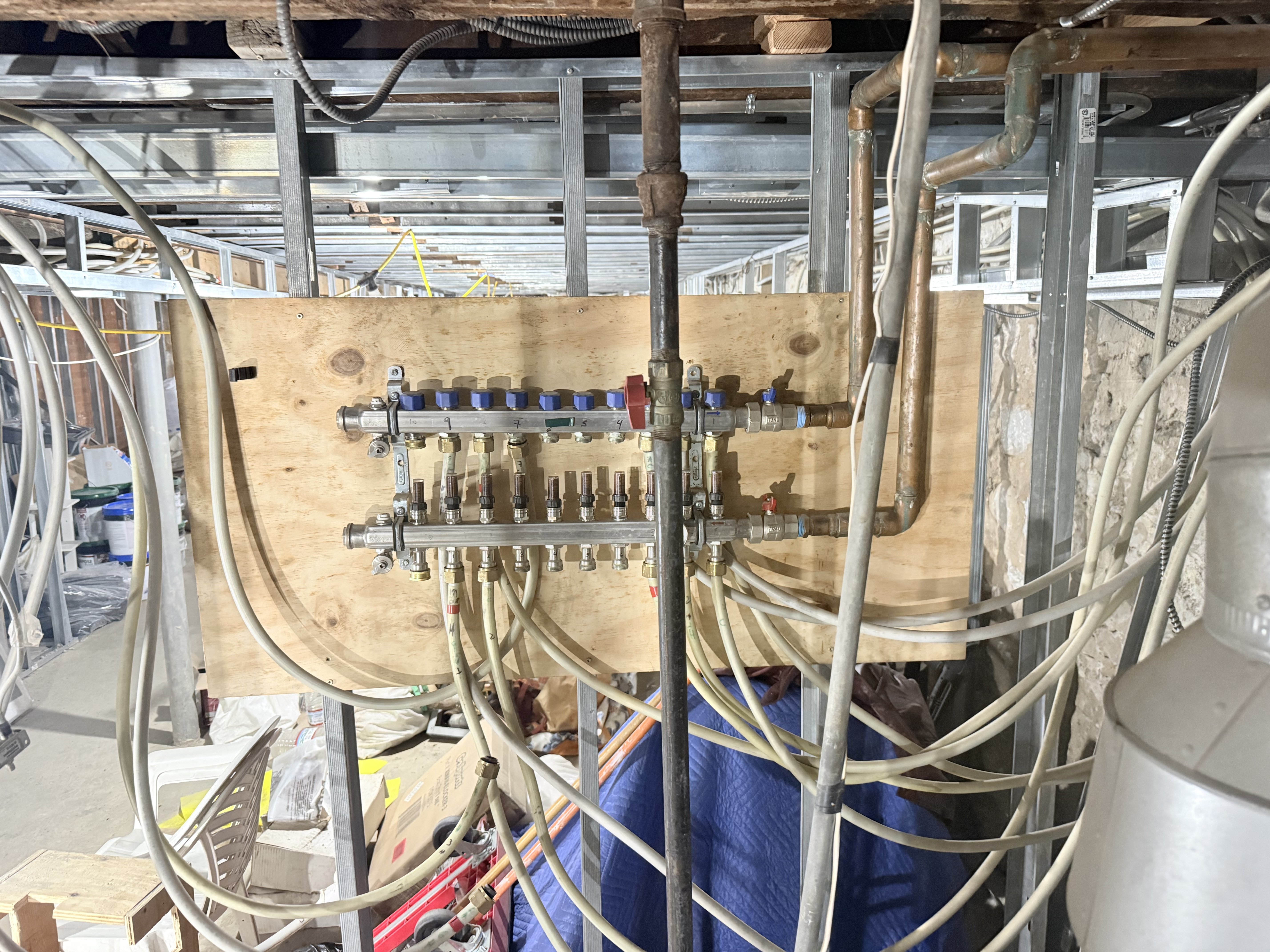

what is that picture with the manifolds?

your picture isn't of a monflo(diverter tee) system.

home run to manifolds, which i think your pictures are of will work well (although that installation is abysmal) if it is designed correctly.

you need to start with a heat loss, from there you get the flow you need, from there you get what size pipe and boiler you need.

0 -

I don't see monoflow in the pictures but if its there get riid of it. You gone this far with it start from scratch and do it right. You have to go through all the design steps to get it right. And the steps need to be done in the right sequence.

- heat loss

- select radiation based on the SWT you use. The lower the temp the more fuel you save but the lower the temp the more radiation you need. Trade offs.

- Determine the flow rate of water to be moved based on the radiation and supply temp

- size pipe and pumps

- select boiler

With a two family I would have at least two zones and if the basement is a living space I would probably make it 3 zones

1 -

I think you have a homerun system, I have not heard of 1/2 monoflo tees?

10 radiators on 1/2” should move 100,000 btu/hr, all that the boiler can produce?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements