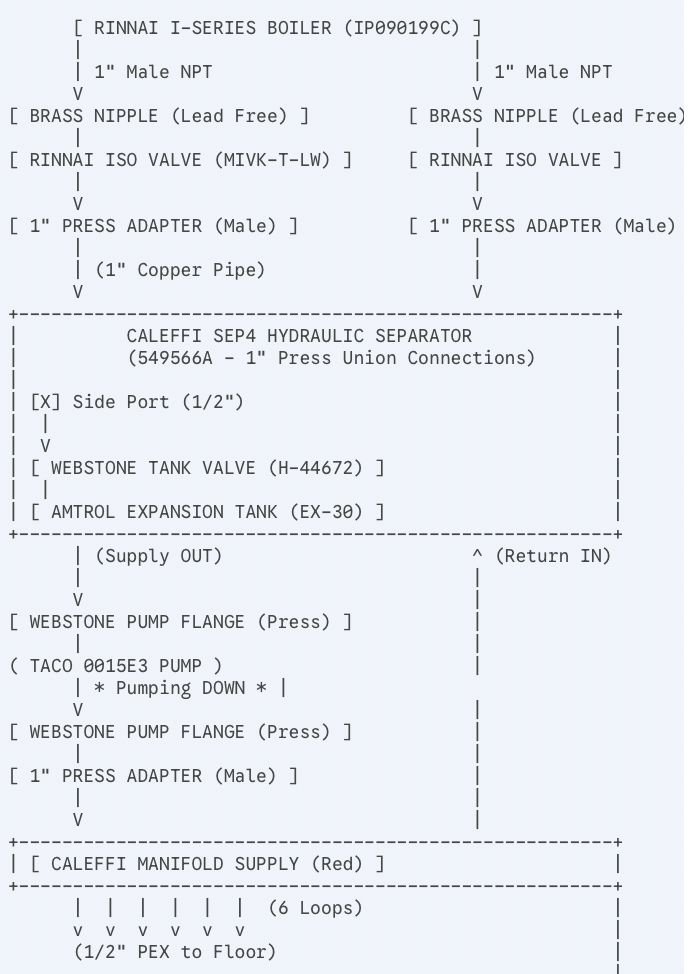

Near-Boiler Piping & Layout for Rinnai Combi + Caleffi Sep4 (Seattle)

Hello! I am a homeowner in Seattle planning a hydronic radiant floor project with my contractor for a basement renovation and would appreciate a "sanity check" on my near-boiler piping and loop calculations.

We are remodeling a 1933 house with a ~900 sq ft basement and installing a hydronic radiant system in a new basement slab. We will install over a 2” foam and given the location in Seattle is quite temperate, we’re estimating heat loss at ~18,000 BTU/hr. The finished floors will be concrete. There will be three bathrooms in the finished house, and we designed to run two at a time.

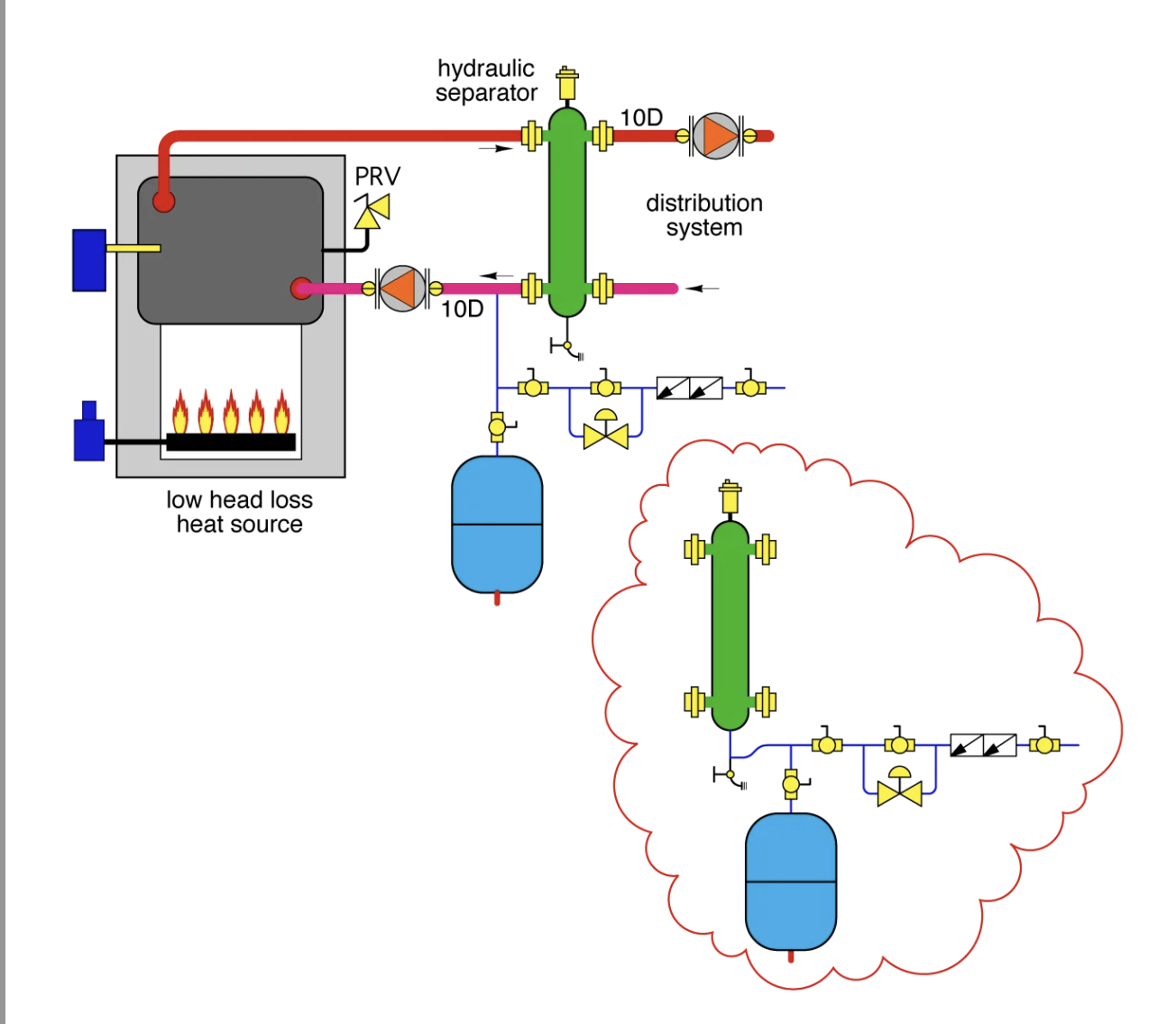

The hardware stack is modeled around an Idronics-style Primary/Secondary approach using a hydraulic separator.

- Boiler: Rinnai I-Series Combi (IP090199C).

- Hydraulic Separation: Caleffi SEP4 (549566A) - 1" Press Magnetic/Hydraulic/Air/Dirt separator.

- Pump: Taco 0015E3 (Variable Speed / Delta-T) situated on the system side, pumping away from the separator.

- Manifold: Caleffi TwistFlow 6-Loop (6686F5S1A) with standard "tubing down" orientation.

- Controls: Tekmar 564 WiFi Thermostat + Taco SR501-5 Switching Relay.

We only need one zone in the basement, and are planning on using 6 loops to keep lengths at ~180 ft/loop. Max spacing is 12” with 6” along exterior walls and in the bathroom.

- Near-Boiler Piping: Does the Rinnai I-Series require any specific flow rates on the primary side that the SEP4 might interfere with, or is this standard Primary/Secondary setup safe?

- Pump Sizing: Is the Taco 0015E3 sufficient for this ~900 sq ft / 6-loop load (High Mass Concrete), or should I be looking at a different curve?

- Expansion Tank Location: I have the tank hanging off the SEP4 body. Is this acceptable for "pumping away" physics, or should it be on a tee before the pump suction?

I have attached a schematic of the piping plan below.

Thank you in advance for your time and expertise!

Comments

-

The piping looks fine, and the circulator will work well there, but you do not want to hang an expansion tank from the drain port of the Sep4 as any crud in the system will fall out of suspension within the sep and accumulate in the top of the expansion tank. Perhaps add a tee somewhere on the inlet side of the system circulator, unless you were referring to the upper port in the Sep4 in which case you'd be alright.

1 -

GroundUp, thank you for your review. I was originally planning on using the 1/2” side port on the SEP4 body, but based on your comment we looked back at the specs and it appears to be a thermowell tap for a sensor rather than a port for piping.

Given that and based on your advice we will add a tee between the SEP4 and the pump to hang the tack there. Would that do the trick?

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements