Surging?

Should the sight glass fill up completely?

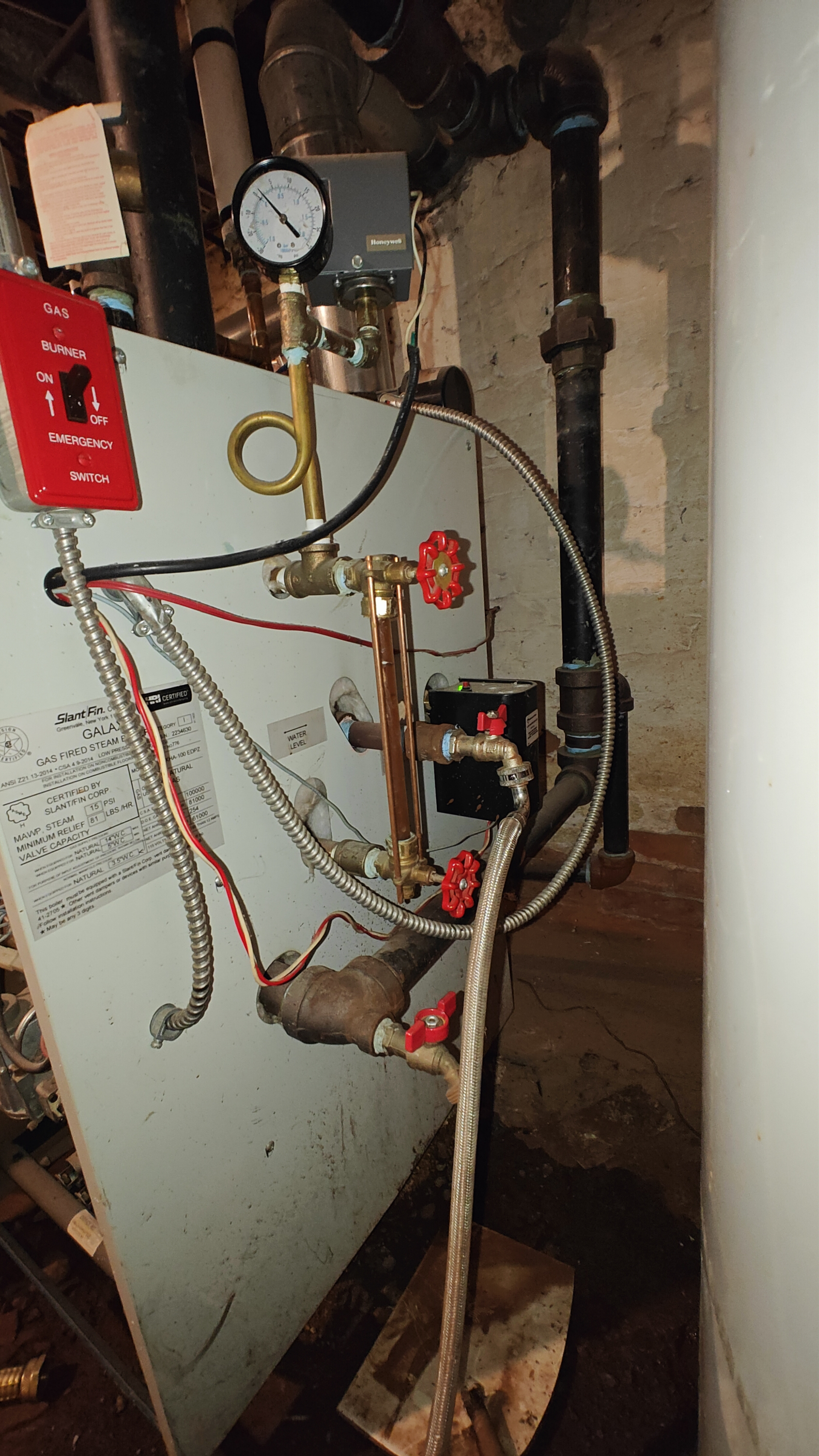

I drained the boiler down to the level of the lowest drain in the pic and slowly filled it back up to where the screwdriver is pointing in the pic.

I fire it up and 8 min later the sight glass is full and the water is much dirtier.

I understand it needs a proper skimming and flush but it never used to surge so high before. I'm thinking the top valve on the sight glass may be partially clogged and giving a false level due to the steam pressure

? Idk. Nothing bangs or anything.

Any help is appreciated. Strapped for cash at the moment but ive read Dan's books so I'm fairly well versed in this and I'm very mechanically inclined.

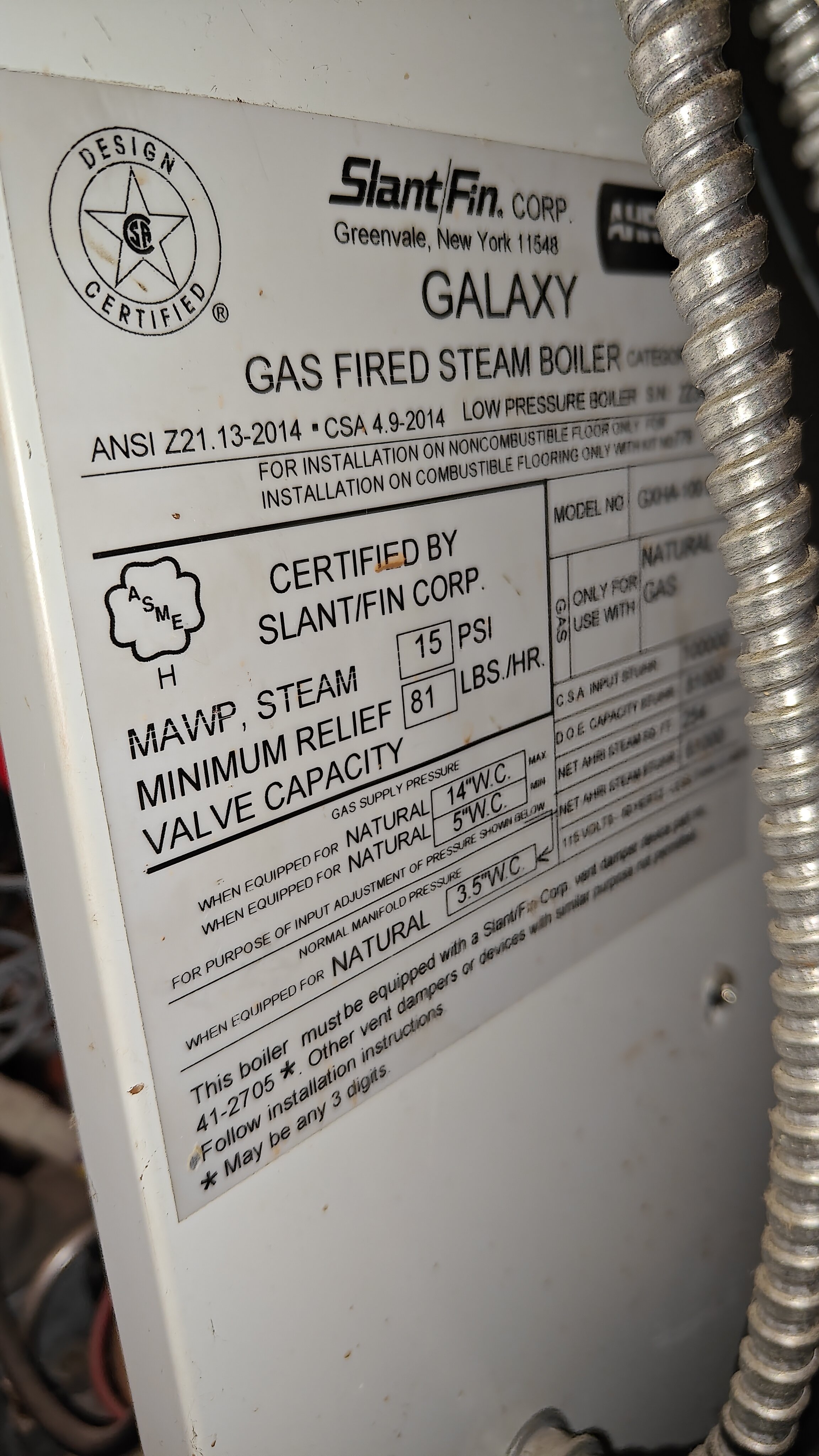

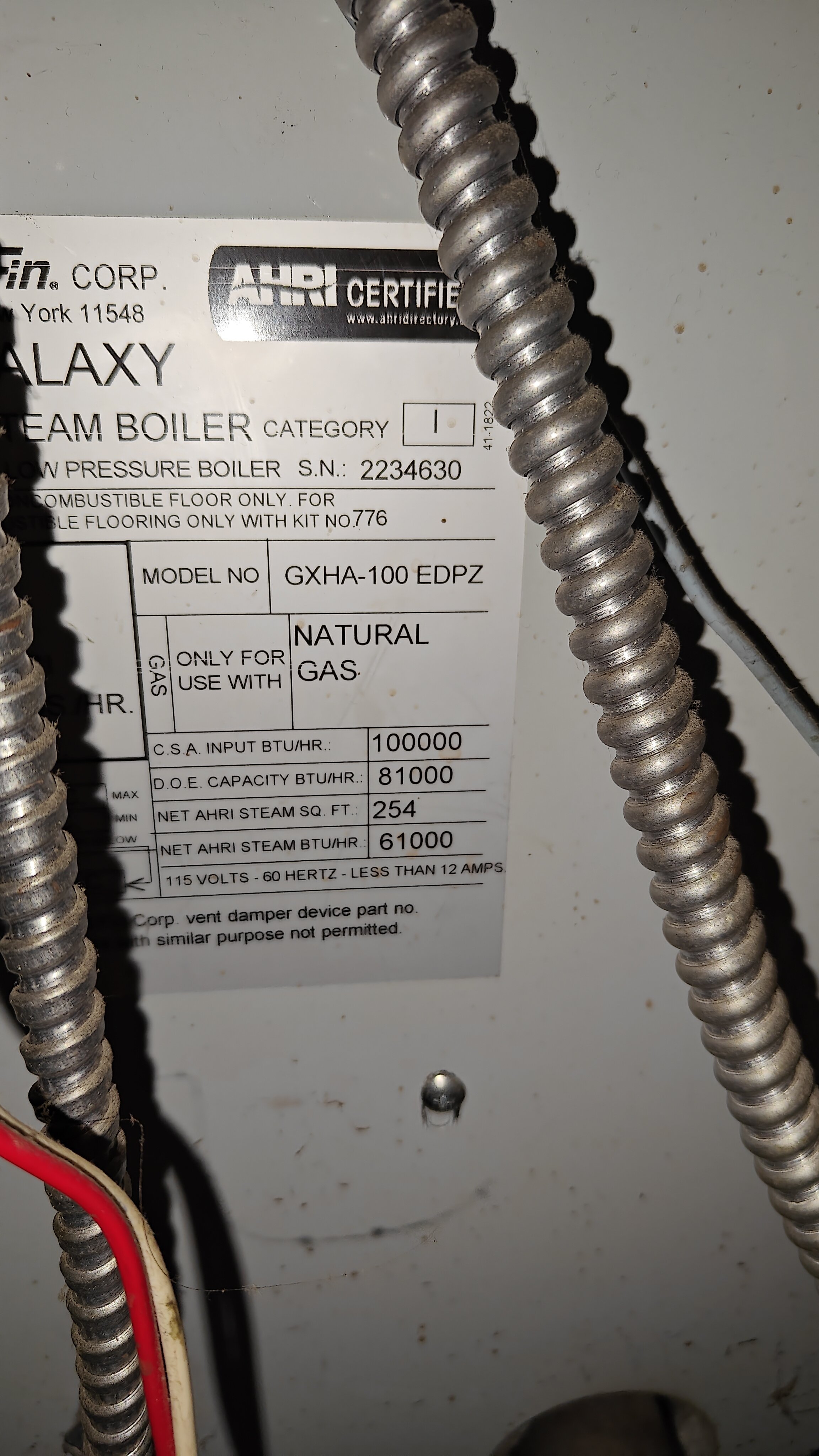

Thoughts? Boiler was installed by a licensed plumber about 6-7 years ago.

Boiler ran for 28 minutes then kicked off on pressure apparently since i have the Tstat wires jumped out. Gauge said 5psi.

I have some Big Mouths i haven't installed yet on the mains.

Any help appreciated.

Thanks in advance.

Happy Festivus

"The toes you step on today are connected to the butt you'll have to kiss tomorrow". ---Vincent "Buddy" Cianci

Comments

-

check that the pigtail for the pressuretrol is clear and you can remove the valve stems from the sight glass and use something like the guards for the sight glass to poke in to the boiler to make sure the ports are clear.

I don't see the skim port on that boiler, it might be on the other side. check the manual.

it doesn't seem like it is surging, just that it was overfilled because the sight glass is partly clogged. have a spare piece of sight glass tubing if you try to remove that, it is easy to break it, but you don't really need to remove the tube right now.

0 -

I suppose it is possible. I would verify the water level. Shut the boiler down and close the top gauge glass valve and open the bottom one. Then open the bottom pet cock to drain the sight glass. You need like a 3/8 or 7/16 box wrench, I think. Let it run to see if you have good flow.

Then reverse both gauge glass valves close bottom and open top and start the boiler until steam goes out the drain cock.

Once you have proven they are clear shut the drain and open both valves and adjust the water level and see how it goes.

1 -

Once the boiler shuts down for a little while The sight glass gets clear from the water level up and it goes back to the correct water level…so I'm not sure.

I j Just got a big mouth installed on one of the mains for now. That should help with The venting quite a bit.

Homeowner, Entrepreneur, Mechanic, Electrician,

"The toes you step on today are connected to the butt you'll have to kiss tomorrow". ---Vincent "Buddy" Cianci0 -

-

does this connect back to the boiler somehow? it looks like a drip but it doesn't look like it connects to a return.

0 -

Just did that so now I know they're clear but the water level still goes high when the boiler starts producing steam.

The water level sticker on the boiler is for the minimum operating level? Or is it where the LWC cuts off at?

I'm noticing It's still cuts off on high pressure not on thermostat being satisfied. Not sure if that's normal or not.

But that could just mean I need to do the other main vent?

Homeowner, Entrepreneur, Mechanic, Electrician,

"The toes you step on today are connected to the butt you'll have to kiss tomorrow". ---Vincent "Buddy" Cianci0 -

No that other pipe is the return for the other boiler. It's a two family house.

Homeowner, Entrepreneur, Mechanic, Electrician,

"The toes you step on today are connected to the butt you'll have to kiss tomorrow". ---Vincent "Buddy" Cianci0 -

One pipe steam and all the rads get hot.

Homeowner, Entrepreneur, Mechanic, Electrician,

"The toes you step on today are connected to the butt you'll have to kiss tomorrow". ---Vincent "Buddy" Cianci0 -

if it changes dynamically it isn't the gauge glass. if it goes back down again something is actually pushing water in to the boiler.

or something is sucking it out when it cools. try unscrewing various vents and see if a bunch of ait comes in, especially the 2 main vents above the returns on the boiler.

also make sure all the radiator valves are either all the way open or all the way closed.

if the systems were split at some point a lot of things could have been screwed up when they separated them, including not actually fully separating everything.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements