How to bleed the Radiant Floor Heating System

I have a 3-zone radiant floor heating system with 3 zone valves that control the floor heating to my basement, my garage and the master bedroom. Lately, I have noticed a lot of noise in each of these rooms and the floors haven't been heating. In the past I had an HVAC technician come out and bleed the lines and this has resolved the issue. I would like to do this myself and not have to call them every time. Based on these pictures, can someone walk me through exactly what needs to be done to get rid of the air in these lines.

Comments

-

concrete infloor heating?

Looks like that boiler is piped direct to the radiant without any mixing device? What temperatures does it run? What pressure is it filled to, the fill valve should maintain around 12 psi.

The silver air vent should remove air over time, maybe it is stuck or plugged, remove the black cap ad push down the pin air or water should come out. If neither, it is time to replace it.

That black soot indicates it needs some TLC, the boiler could be running much too cold.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Simply keeping adequate pressure in the system would eliminate the possibility of air being introduced, but it does appear that you could close that ball valve above the circulator and hook a hose to that boiler drain on the end of the return header, using the fast fill feature to purge. As Hot Rod stated, if this is a low temp radiant floor system, the boiler is piped wrong and your auto vent may very well be plugged which would not allow air to escape after makeup water is added.

0 -

Unfortunately the near boiler piping was completed by someone that is not aware of the best practice for air removal in hydronic heating systems. Several mistakes are obvious to me from the limited near boiler piping you have pictured.

- Is there any temperature reducing designs near the point where the radiant floor tubes enter the floor? If not, the floor water temperature may be too hot and/or the return temperature to the boiler may be too cold.

- The circulator location is not ideal air removal.

- The Air Scoop location is not ideal for air removal.

Just to name 3.

Air removal can be accomplished by purging the air from the loops. This involves getting the boiler water pressure to about 25 PSI. Anything over that may cause the relief valve to operate and leak water all over the floor. Then opening the purge valve to expel the air from the system. The problem with this procedure is that it will add additional fresh water to the system which can cause premature boiler failure. You want to design the system to expel air by design and not need human intervention on a regular basis

If you are constantly adding fresh water to purge air from the system You should plan of replacing that boiler more often that necessary.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Pics of the boiler gauge when the boiler has been running. Pics from farther away would be helpful.

The black tire cap on top of the silverTaco air vent which is on top of the black air scoop should be loose or off as @hot_rod has stated.

0 -

Here are some additional pictures

0 -

It's not normal to have to regularly add water and purge air. It's a sign your system is leaking. You need to find and fix the leak before it becomes a bigger problem.

0 -

assuming the gauge is working,pressure is fine. You have an excellent fill valve, it should maintain pressure

You could get another screw on pressure gauge to confirm pressure is correct

I do not see a reason chronic air problems

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I've only had to purge air one other time last year when i had to replace my circulator pump. I've been at this home for at least 8 years and this boiler is about 23 years old. I don't know if the previous owner had purged air in the past.

0 -

I'm curious where you hear air? Tube in concrete tends to muffle air noise, it must be coming from the copper tube running to and from the slab?

Temperature drives air out, I don't know what that system runs at? If you can increase it 10° or more for a few hours you may drive some rouge air out.

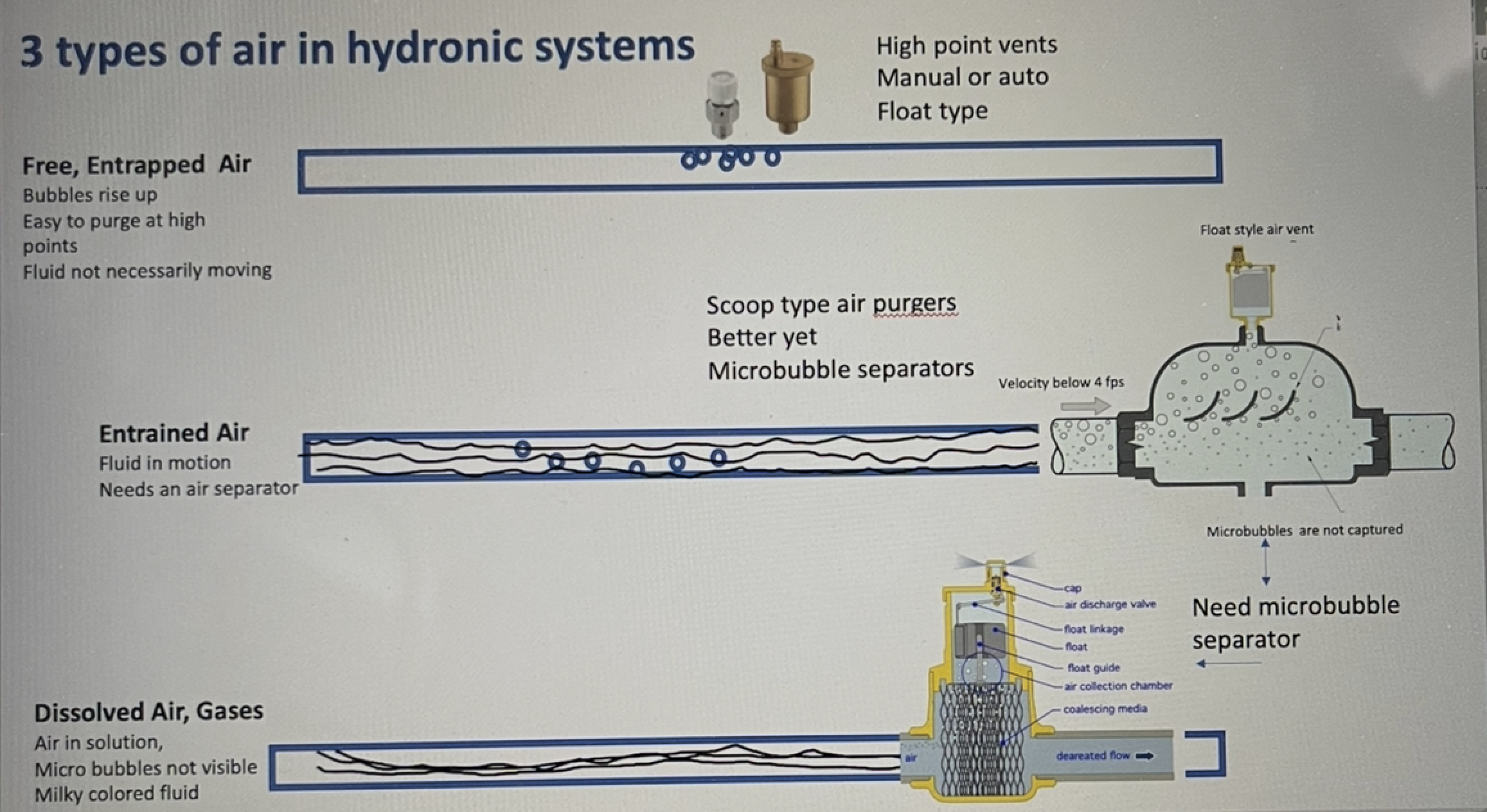

Also slow flow velocity, below 2 fps feet per second, does not carry the air bubbles along with the fluid very well. The same happens with excessive velocity over 4 fps, air rushes across a ramp type purger and does not rise up to the vent. But with that circulator and tube size I would not suspect excessively low velocity. If it is a multi speed circ, put it on the various speeds to see if that changes anything.

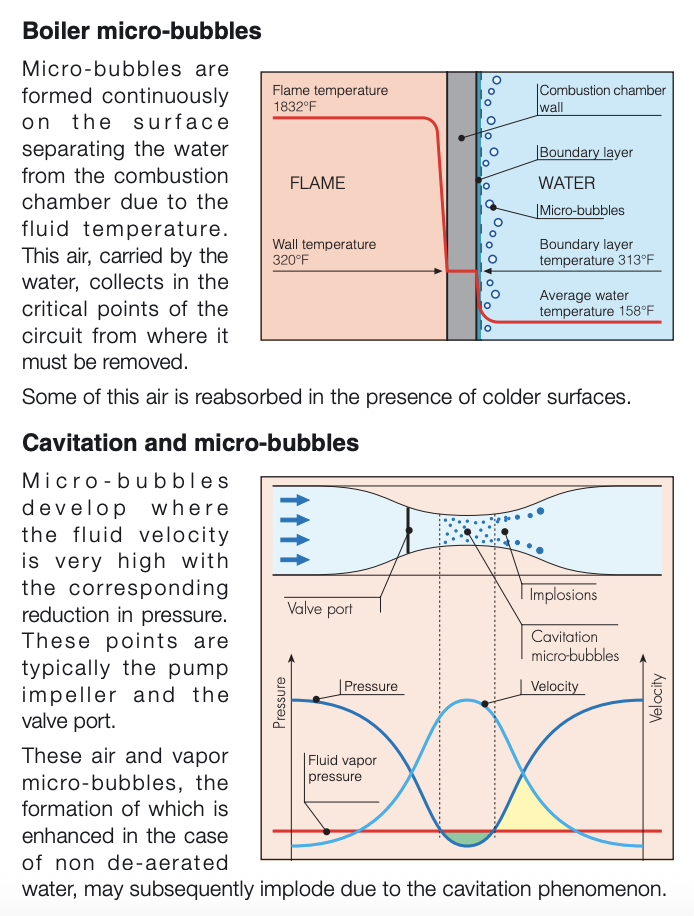

Air that is not removed goes in and out of suspension as the fluid heats and cools back down. Air forms at the hottest point in the system where the flame touches the metal surfaces in the boiler. It should flush through to the purger.

So I come back to that air purger not working properly, or at all?

I always promote the microbubble type air purgers, they all work in the high 90% range, and do their job quickly. You rarely hear of noise or air issues with a properly working microbubble type purger. Should you choose to upgrade.

A system without leaks or additional water (air) being added should get to a point of air and noise free, as long as the air has a means to get from the inside, out.

One last thought is cavitation, this is created anywhere flow is reduced to a small opening, a pinched tube, a partially opened valve, debris plugging flow, a zone valve stuck is a partial open condition, etc. I've seen those WR zone valve spools lock in partially open positions, that could induce a cavitation condition. Turn the thumb wheel to see if they all rotate.

Cavitation sounds like air. This could be happening in one section and the copper tube being a good conductor transmits the noise.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I assume there is air in the piping under my master bathroom because it has a loud gurgling sound that i hear all day and night and the master bathroom floors don't get warm. I'm sure I'm not explaining this correctly as I am not really familiar with this system.

Last year when I had an HVAC technician come out, he stated if I hear that noise then there is air in the lines and I would need to purge the air. And that is what he ended up doing which fixed the issue with the noise and also fixed the issue with the floors heating up correctly.

0 -

The pic of your gauge shows the pressure high for the temperature reading. These gauges do go bad so you should probably verify the accuracy with another screw on gauge on the boiler drain as stated. 12PSI for one story house and 15PSI for two story house when the boiler is cold. That's what I do.

If the technician bled the air out of the sys and that solved the problem, why would you need to do it again? Where is the new air getting into the sys? That's the question. I have never had to extract air repeatedly.

I can think of 3 ways that air is getting into the sys. 1) fresh city water entering the sys, 2) a failure of the Expansion tank, 3) air being sucked into the sys thru the air vent because of improper piping and pump placement.

1 & 2 would be most probable, I would think. You could shut off the fresh water supply to the boiler and see if the pressure gauge falls to zero, indicating a leak somewhere in the sys. You can shake the E-Tank and see if it is sluggish, indicating that water has leaked into the air side of the bladder. You can push the tire valve on the bottom of the E-Tank, quickly, and see if water comes out.

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements