Best way to clean a stainless steel heat exchanger (without removing)

Hi. Need to descale a combi boiler with a stainless steel heat exchanger (experiencing decreased efficency with space heating).

Finding the proper product has proven difficult. Not removing the physical heat exchanger and instead utilizing isolation service valves. Any suggestions? Hoping 'hotrod' will comment here, too!

Thank you!

Comments

-

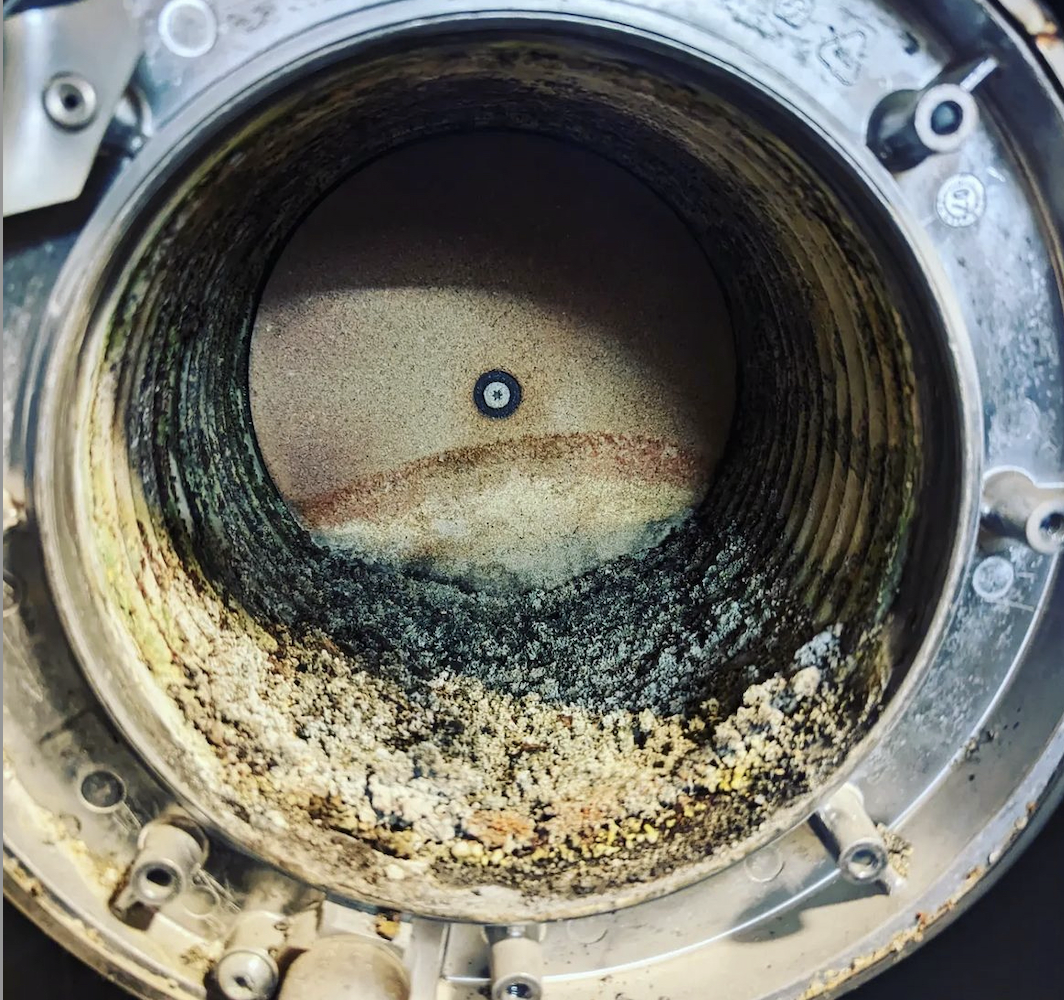

Inside or out? Here is a pic of a scaled inside and a scaled outside.

Inside cleaning involves running a hydronic cleaner for a day or so at high temperature if possible.

To clean the outside is more involved. Pull the burner use cleaners, brushes, @HomerJSmith feeler gauge trick if it is a water tube design.

Axiom has cleaners and tools available.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Hi. Hope all is well.

It's the inside of a Bosch singular 5200. It's almost 3 years old, but we have heavily treated water here from the water district.

I've noticed axiom - any particular one you suggest running through the service valves?

Considering your skillset, anything else I should be considering since my baseboards are not pumping out btu as much as it was last season (pressure levels are normal at 24psi for a 3200 sqft ranch)?

0 -

I'm ordering Axiom AXTH-CFSTEEL-1L.

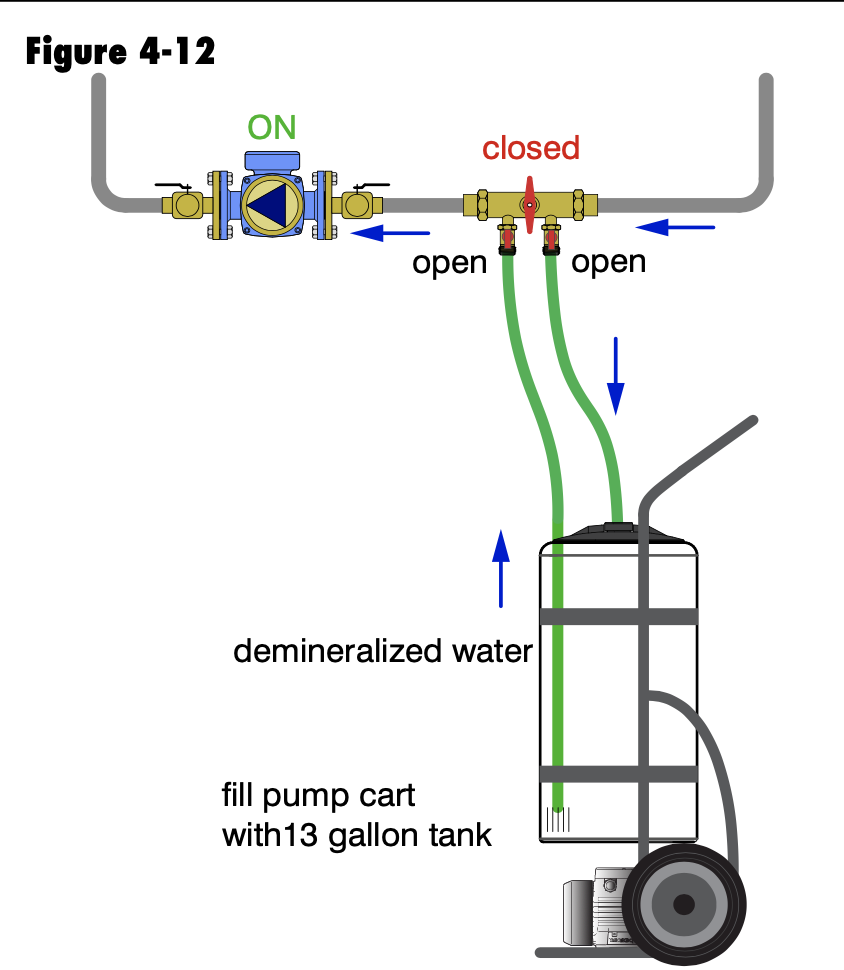

Can I simply throw this into a bucket and run it through with a pump accordingly into the service valves (after isolating the boiler, of course)?

0 -

Yes, if you can circulate just through the boiler that is ideal, the cleaner will have more strength without the system fluid volume diluting it..After running just the boiler, let the cleaner go through the entire system to descale heat emitters.

\

Actually those tankless water heater cleaner kits work great for boiler only cleaning. The pump included has enough umph for the boiler flow.

A 5 gallon plastic bucket and the cheapest plastic sump pump Home Depot has is an option. If you drain and refill, I would get a DI cartridge fill the entire system with pure water, to prevent putting hard scale back into the system.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

what were they burning in that? gassified coal?

0 -

Thank you gentlemen for your input. Will implement every letter. I'll likely skip the part of filling the system with pure water only because I don't want to invest in that rig - plus, my whole house filter is supposed to reduce scale and sediment found in my water.

Hot rod, I closely follow your input on various topics - please never stop, I've personally come a long way with your posts alone.

Have a great holiday and happy new year

0 -

it is good to know how hard your water is and the TDS, total dissolved solids.

The boiler manufacturer typically tell you the acceptable numbers.

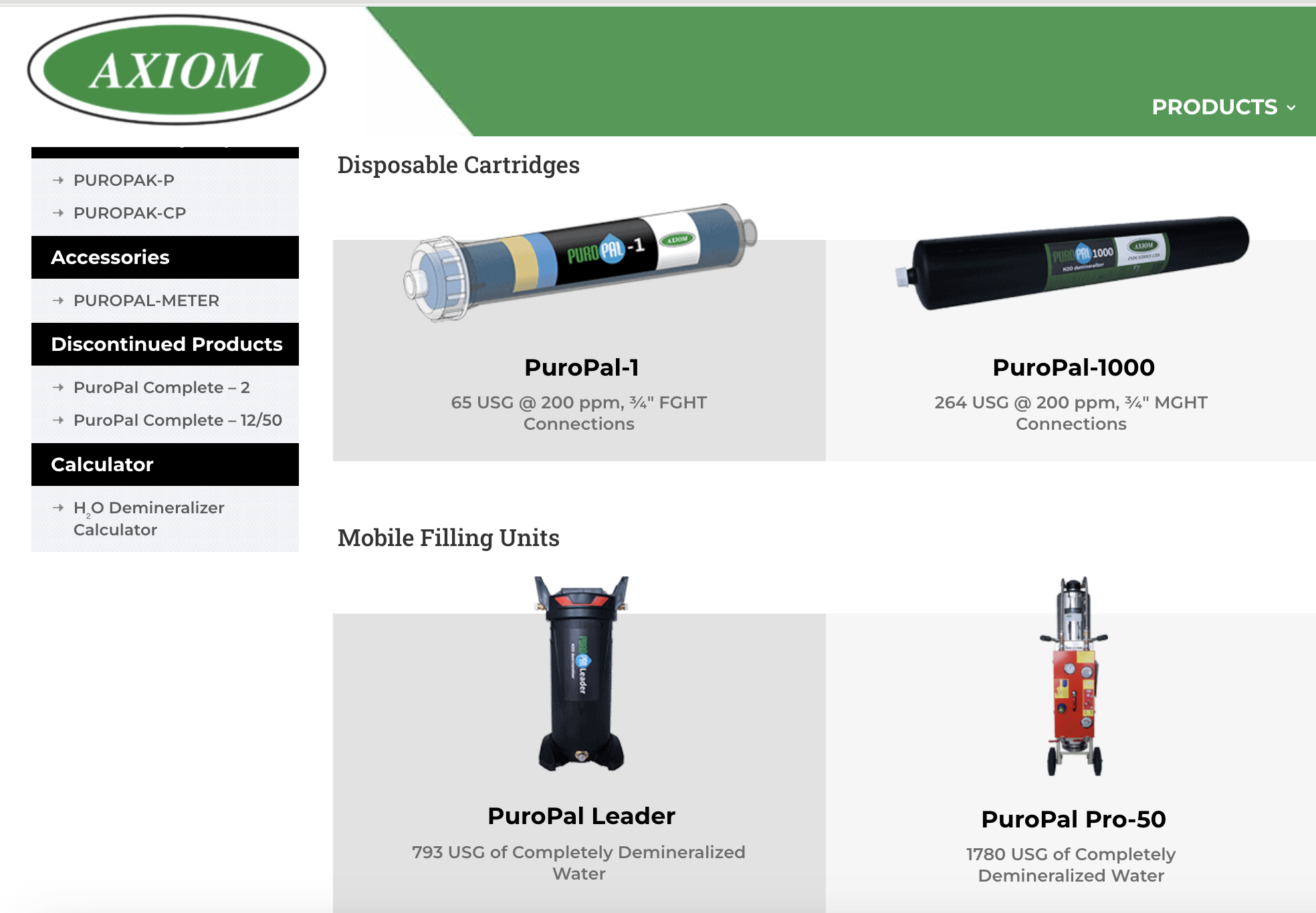

I have seen these small cartridges for around 150 bucks. It shows 65 gallon capacity but it depends on how hard your water is to begin with. It has connections to adapt to hose thread

Typical cartridge filters can handle dirt, smell, but will not remove hardness, that takes an ion exchange, or RO membrane

you can also buy deionized water at water treatment companies. I had a 55 gallon plastic barrel that they would fill for me.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

I utilize a 'Polyphosphate Anti-Scale' based filter system. I'd love to go with one of these cartridge systems for the closed loop, but I actually have a small leak somewhere - which translates to my fill valve being constantly active. As in, nearly discernable, but not that serious of a leak where the cutoff switch kicks in. But if I close my fill valve, the boiler will display the error code after a few weeks. So, I'm always introducing - though, small amounts - water (and air) as a result.

Thanks hot rod - as always, you're a rockstar. Will clean boiler tomorrow once cleaning solution arrives.

0 -

-

I certainly agree - but my home is 80 years old and is an extension on top of an extension, followed by 3 additional rounds of extensions. And then I moved in. I've nearly replaced all the baseboards, but have yet to find this leak. I'm throwing what I can at it in terms of treating the water in the mean time. I do love the idea of filling the system with pure water - but, need to find that leak first

0 -

did yo check that something like the relief valve isn't dripping because of an issue with the expansion tank?

0 -

Hi. No dripping at the relief valve.

0 -

Any idea of how much water is leaking out? Per day or week.

If there is not tubing buried in a slab for example, at some point the leak should appear?

Maybe come summer you isolate the boiler, pump the pressure up in the system to find the leak.

I've used Leak Busters in the past to find rouge leaks.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

I doubt it’s weeping into a slab and disappearing. The tubing isn’t embedded very far down and concrete attracts moisture and stays damp. Even a very small leak would become obvious when the system doesn’t run during warm weather.

A completely invisible leak is all too often weeping in the firebox and disappearing up the chimney. It’s common at the beginning for a crack not to leak without the heat of the fire to expand it. If it was going to extend on its own it would do it very quickly. Air in the fill water eventually causes the crack to corrode increasing the leak rate. Eventually the leak is large enough to disrupt combustion and the fire becomes sooty. At some point it leaks cold and a puddle of water emerges from underneath.

You don’t want to wait for that to happen. Unlike an automobile radiator a hydronic heating system doesn’t rely on corrosion inhibitors, it relies on exhausting the dissolved oxygen and the water becoming saturated with dissolved iron and copper. Even things like the expansion tank’s steel internal wall and the rubber in the bladder assume the oxygen in both the water and in the air cushion have been depleted.

If you want to know where the leak is you attach gauges and isolate parts of the system. It’s difficult to do when it’s still hot. Airless water cooling from 190F/90C to room temperature drops the system pressure around 30%. Be sure to turn off the autofill and isolate the expansion tank first. Don’t let anything reach a negative gauge pressure, Many component have seals that aren’t restrained in the direction of being drawn into the system.The most likely result for a warn system is that within a few hours the peripheral pressures fall to 2/3 or 1/2 of the auto-fill pressure and levels off and the boiler pressure falls to less than 1/4 or 1/3 of the auto-fill pressure and continues to fall. It would be nice if of the peripheral zone loops is where it leaks instead of the boiler.

0 -

-

Was just about to clean the combi boiler and when I pulled out the drain plug, not much water came out. Bizzare. Hoping the heat exchanger isn't super clogged where I'll have to take it out.

0 -

what temp is it running at? if your return water temp is above 140 f or so there will be very little condensing.

0 -

180 out and around 155 coming back - not even remotely condensing.

Even the drain plug had scale on it. Going to take hot rods advice and get clean water into system and also take advice of polychrome and find that blasted leak, though I'll likely end up cutting it out and decomission in place the original copper

God bless you all gentlemen

0 -

Hi. Want to give an update -

Ran through the cleaning process.

However, not much of an improvement. Except now my boiler psi is at 29 instead of normally 23/24.

Temp is stagnant at thermostat.

Internal pump rpm started off very high at 5700 firing after cleaning, but reduced to 2800 (though gradually). But now climbing again - likes to stay around high 3k. All my baseboards are certainly warm, but some are lacking compared to others. My exhaust temp has been climbing from 139 to 147 degrees and my return temp is now at 152 degrees (from 180 out). System not tripping any error codes as of yet, but I can see previous codes were 'AA - overheating' and 'E2 - exhaust temp overheating' from before the cleaning.

Lol not in a good mood. What am I missing? Please and thank you

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements