DHW mode rapid cycling of boiler

i have a munchkin modcon boiler with vision 1 control which gives priority to DHW when it’s needed. So when the DHW tank drops in temp the main boiler loop circulator stops and the dhw circ starts to circulate supply towards its circuit. This appears to be working but I’m often getting a fault for supply temp exceeding 230 that requires me to reset the boiler. Doesn’t happen all the time.

I ran some tests and when the dhw calls the boiler rapidly gets to 190-200 and then the ignition shuts down as it should since 180 is the target temp. Then within 10-30 seconds the supply drops to 150 and ignition happens again and very quickly I’m back to 190-200. So my boiler is cycling a lot during dhw calls.

is this how the boiler should work during dhw mode? Seems the dhw loop is too small for the boiler and causing this rapid cycling. The boiler is 20 years old and it’s always been this way so maybe leave it alone?

Comments

-

Is there an indirect tank or just a heat exchanger? 20 years of this probably doesn't make sense to change it now, but with a properly sized and piped piped tank, it should not be short cycling. Maybe there is a blockage or air bubble in the line, maybe the pump is going bad, maybe the exchanger is scaled up, 20 years is a long time for things to degrade.

0 -

it’s an indirect tank and I just replaced the pump with an IFC pump so don’t think it’s a bad pump. I replaced a taco 007 with same 007 ifc version. Looking at the manual from 2008 i believe they wanted the next pump size up which is the 010. But like I said it was always setup this way and no idea if it always short cycled it this is a new thing I’m chasing.

So I guess you answered my question which is - No the DHW circuit should not short cycle the way I’m describing and indicates some sort of problem….

0 -

Munchkins are high pressure drop boilers. So the indirect needs a high head circ if it is piped parallel. I doubt even the smallest Munchkin gets along well with an 007. The manual tells you what pump you need.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

is there a way to determine if the heat exchanger is the problem and therefore I need to replace the tank?

0 -

What brand indirect? The fined coil brands scale up and prevent heat transfer that you are experiencing. Smooth coils do better. Assuming the pump is working and the loop is air free.

If you have hard water, and 20 years of use, it is undoubtedly scaled on the coils or HX surfaces.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

i got a Burnham AL40A, 39-gallon indirect fired water heat

time For a new one?

0 -

I wouldn’t change it until it leaks, it can be cleaned

Save your money for the boiler replacement, that is the critical component and long in the tooth

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

flush it with some kind of mineral solvent? I can isolate that loop and run some kind of CLR through it I guess. And looking at manual it seems they want a 011 on it - larger than what’s on the primary loop…

0 -

-

I service a lot of Munchkins 'long in the tooth' including mine. I wouldn't change it unless the HX failed.

You don't want a variable speed pump on the DHW circuit. It's a waste. We use variable speed pump where there is a variation in flow. An indirect and boiler flow is going to be consistent, so, a fixed pump is cheaper and perfectly fine. The indirect piping from the boiler to the indirect should be 1" copper piping. I assume the Burnham tank has 1" HX ports. I don't know what the pressure loss thru the Burnham HX is or the size of your Munchkin in BTUs. Assuming it's a 140 BTU/Hr and assuming the piping between the two is short, you need 14 gpm thru the HX of the Burnham. That flow is well within the capabilities of 1" copper pipe. That said.

You go into the programing thru the key pad, the code is 925 and reset the programing for a lower DHW supply water temperature. You will be able to see the current SWT to the indirect tank. You can lower this temp. This is all in your manual.

Reaching high limit on the Munchkin indicates that you are not subtracting the heat energy from the boiler flow because your SWT setting it too high, a plugged HX, or a bad or improperly sized pump.

I don't know what your boiler-indirect configuration, piping, or a lot of other things about your sys. Pics help.

the only gripe I have about the manual is there are piping diagrams that are not piped primary/secondary. The Manual has pump recommendations for both the boiler and the indirect. I hope you are not using one pump for space heating and the indirect. You need at least two pumps and in some installations three pumps.

0 -

i know i’m late to respond but i’ve been doing tests and replacing pumps. I have a taco 015 on high running and used purge valve to confirm i’m getting at least 8 gpm through dhw circuit. I also reduced the dhw supply setting (19) to 160. so now on dhw mode the boiler fires rapidly to 180ish and then shuts off. then the supply temp drops within 20 seconds back down to 140ish before firing up again. so i’m short cycling but at least it’s not triggering the high temp fault. i’ve also replaced my indirect tank to a weil-mcclain 45 which expects a 8gpm with 1.5” head.

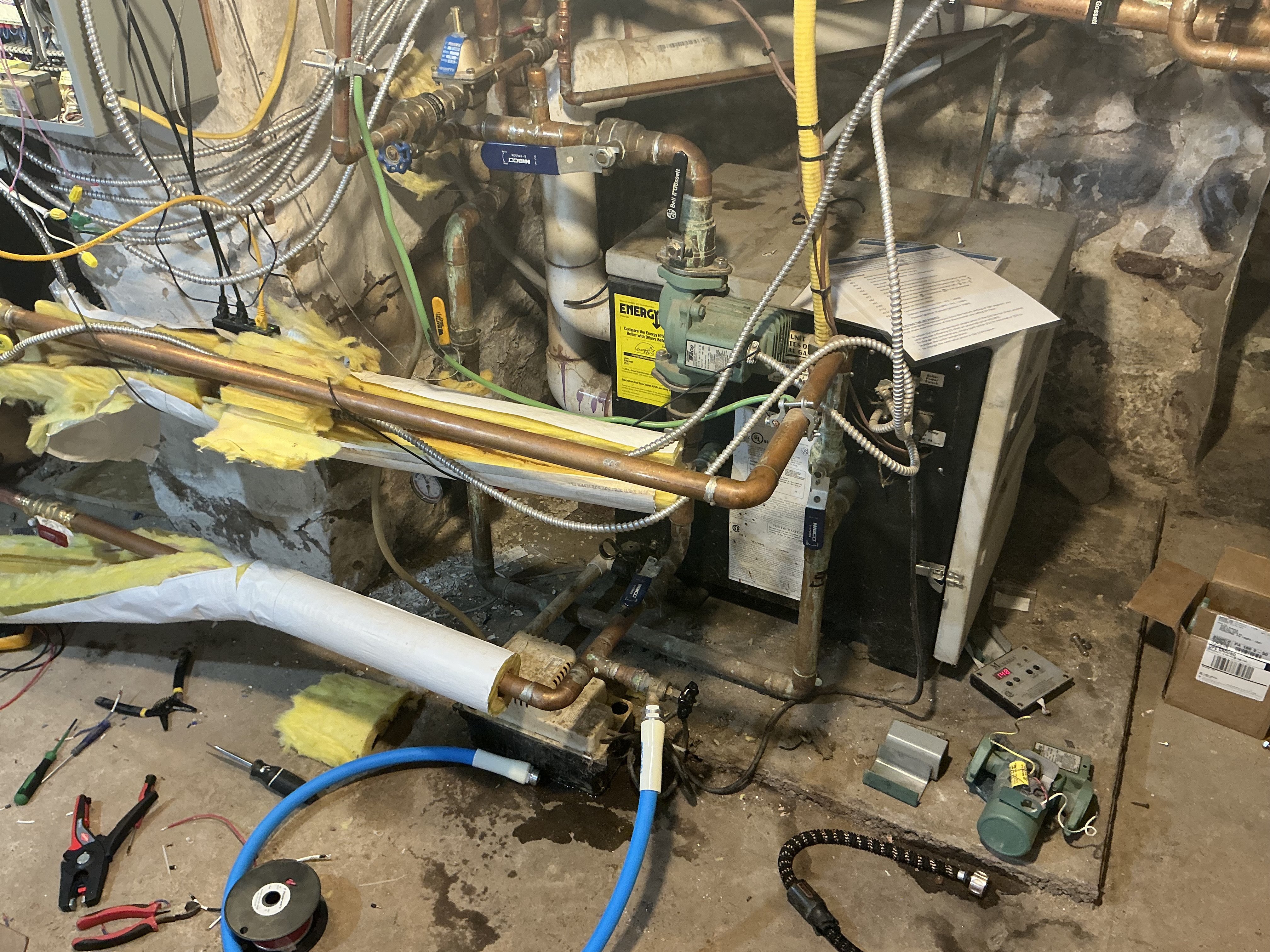

here’s a picture of my piping which seems to follow the munchkin manual as spec’ed. it’s using 1” pipe and yes I have a separate pump for dhw and primary loop. dhw is T’ed off the primary loop near boiler.

maybe munchkins just short cycle or perhaps I have a control board issue? I did replace the board recently…

0 -

If the mfg want's an 0011 and you have an 007 that is a big issue. It could be scaled up as well. One way or the other you are not transferring heat.

You already know you have low flow. Clean it and change the circulator. Determining whether the cause is lo flow or scale is difficult

I find 007 to be a weak circ but they are the standard and work on a lot of systems. I also think a lot of systems are under pumped and people don't notice it unless the problem is severe.

It has become the standard. If its residential put an oo7 on it and it may not be right.

0 -

yea I replaced the water heater since it’s been 20 years and figured it was time. then I put a 011 on it and it’s still cycling. i’m working on other zones and needed 011 for a radiant zone so put a 015 on high flow on this. measured 8+ gpm using a bucket and time coming off the dhw return so i’m getting good flow.

it’s the supply that spikes quickly to 200 and then collapses to 150ish but the return temp on the boiler holds pretty steady around 150-160. both supply and return pipes of dhw feel hot so seems something else is happening. if boiler return is 150-160 then im dumping heat no?

0 -

-

but my 7 heating zones behave just fine? i’m seeing good heat transfer, deltas around 20, etc?

if the hx was scaled up wouldn’t I be seeing symptoms outside the dhw zone?

that said this munchkin is from 2008 and I have very hard water. can I descale the hx?

0 -

You know, that the Munchkin should be piped primary/secondary even tho one diagram on the installation booklet shows a direct piping method. A mistake. A 0015 one speed is too big a pump and a steep curve. A 0010 has a flatter curve and is the recommended boiler pump for P/S piping. A mod/con requires three pumps, a boiler, distribution, and indirect pump. The problem I come across with the Munchkin is the direct piping, having the boiler pump do distribution, too. With zone valves, the chance of boiler cycling and pipe erosion is enhanced with high head pump doing boiler and distribution.

One picture doesn't make it easy in understanding your setup.

Water quality is really important and should be mineral free.

0 -

Thanks Homer….thats not a great picture but I have a primary loop with closely spaced tees powered by a 010 on the return side. I then have a secondary loop with the zone supply and return with 007s per zone. The indirect is T’ed off the boiler supply and return and has the 015 on the supply side. I’m pretty sure this is how the munchkin manuals i’ve seen for the 140m specifies.

i moved in 10 years ago and have done lots of renovations and extensions in my house including adding zones. between this and other boiler stuff Ive done and burst pipe in an old section I’ve added lots of new well water which I know is very hard on the scale.

I used the purge on the return of the dhw to measure time to fill 5g bucket and it was around 45 seconds so I believe I’m getting good flow. i’ve also tried the low setting of the 015 and didn’t see less cycling.

i’m thinking it’s scaled HX and i’ve got a project this weekend to descale….but welcome other ideas….

0 -

Scale is probably thru your whole sys, not just the Munchkin HX. The domestic water side of the indirect HX has probably scaling, too. You might want to descale inside the tank. Stop using well water in the heating sys. Distilled water buffered to about 8 PH would be more preferable in the heating sys. The only thing that may help the domestic water supply is a water softener or maybe one of those electronic descaler. Hard water is hard on everything.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements