Buffer Tank Port Selection

I'm redoing my mechanical room and managed to acquire a AO Smith TJV-120M at a very reasonable price. Hoping to use it as a buffer tank, but I'm a little conflicted about how to pipe it.

My first thought was to pipe it as a 3-pipe using a cross fitting from the top port (boiler in, heating out, and air vent). However, having the boiler input coming in through the top is probably going to disrupt the stratification in the tank.

The topmost side-wall port is located further down than I'd like (42" on a 62" tall tank) so it's not going to be getting the warmest water even if the tank is well stratified.

Alternatively, I could pipe it as a 4 pipe with the boiler coming in the side-wall port and the system piped from the top port, but then I'd lose the direct to load advantage of the 3 pipe.

Any thoughts on what might be preferable?

Comments

-

What type of boiler?

If you have a conventional non condensing boiler you could run the tank up to the highest temperature the system requires

Is it a single temperature system? Multiple zones? Zone valves or zone pumps?

For high temperature fin tube or radiators perhaps the tank goes to 160-180

Then you could pull loads off via an ODR control. This maximizes the tank drawdown.

Or the tank temperature could be controlled off the boiler ODR temperature, the tank just charges to whatever the ODR controller determines

The is a great tank to score! It has nice connection options.

with that large top connection you could drop a sparge tube in, a capped nipple with slots cut around.

A double tapped bushing supply house.com or RW Beckett has them.

I think the 4 pipe is best for wood boiler systems, it acts as an over temperature dump as much as a buffer.

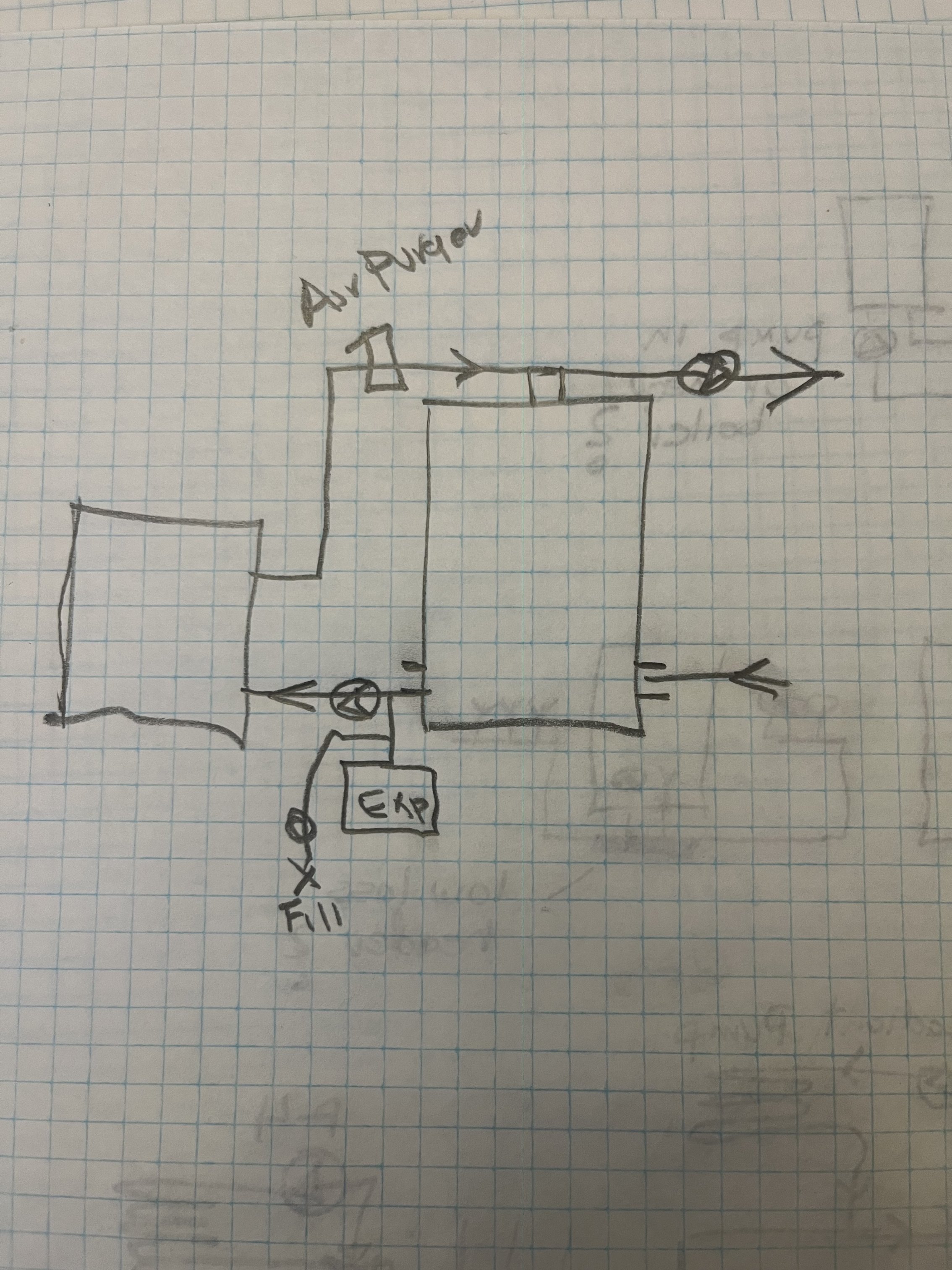

2 or 3 pipe direct to load has a few advantages as you mentioned. Here is a simplified sketch.Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks @hot_rod for your suggestions.

Boiler is an IBC mod-con. Majority of the house is fin-tube baseboard with zone valves, then a bit of radiant in the basement. My plan is to have the tank controlled by ODR from the boiler with the reset curve tuned at the higher temp for the baseboards. The radiant zone will be mixed down from the tank temp.

Sparging tube is an interesting idea I hadn't considered before. I'm in Canada (BC) and locating a double tapped bushing is proving a little tricky. Might be able to improvise something by skimming off the end stop on a reducing bushing with the lathe effectively turning it into a slip fitting. Stackup would be 1-1/4" copper from boiler → 1-1/4" x 1-1/2" bushing (converted to slip) → 1-1/2" sweat x MIP adapter → 2" x 1-1/2" reducing bushing → 2" tee → buffer tank with the 1-1/4" continuing through the center of the whole stack and into the tank as the sparging tube.

Another question I had is where to put the thermowell. Usually I see them around mid-height so the 2" sidewall port might be my only option?

0 -

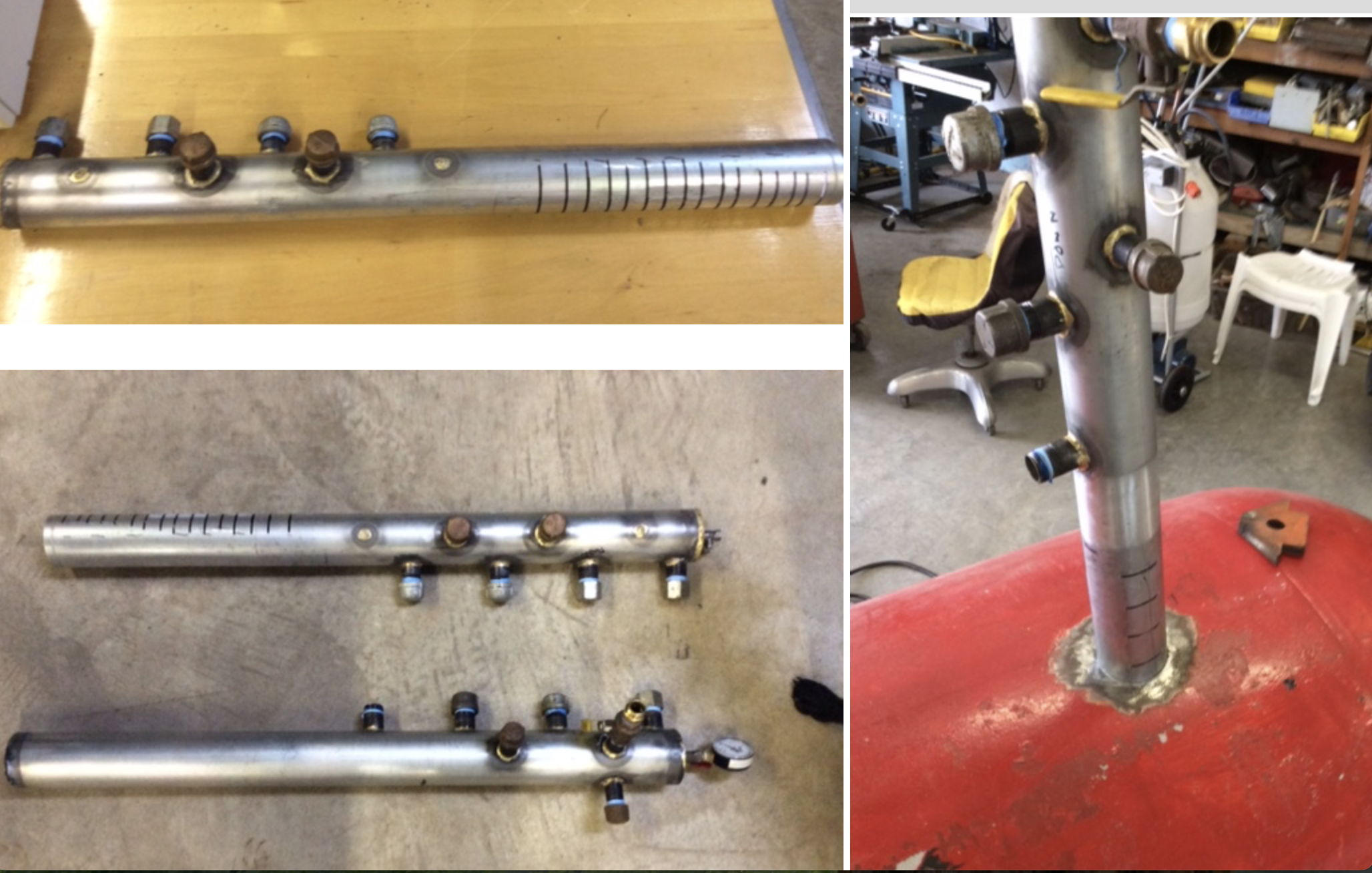

Its pretty easy to build a dip tube nipple

copper tube fits closely inside a steel nipple, you may need to machine out a few thousands. Then a spot or two of braze

You can build the header pipe with threaded or sweat fittings

Yes mid tank for a temperature well

You can also slide a sensor under the foam tank insulation, so the end is tight against the steel tank

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

This is what I used for a tank to avoid flow downward. NPT fitting with a pex elbow soldered in. If you wan to get fancy (and you have room to turn inside the tank), you can add a length of perforated copper pipe.

There is no good locaiton for temp sensing. You can try the 2" upper first, probably your best for a thermowell. You won't need an anode, so you could drop a length of of 1/2" copper pipe down the anode port to near mid tank. If that doesn't work, you can set your boiler to constant circulation which doesn't need a sensor on the tank.

Even with a free tank, unless you have major micro zones, not sure if this is worth the effort though.

0 -

Last time I built a sensor well, I just brazed a section of 1/2" copper pipe inside a brass bushing and screwed that into the anode rod hole. Same could theoretically be done for a sparge tube

0 -

Some homemade sensor wells and sparge tube with double taped bushing

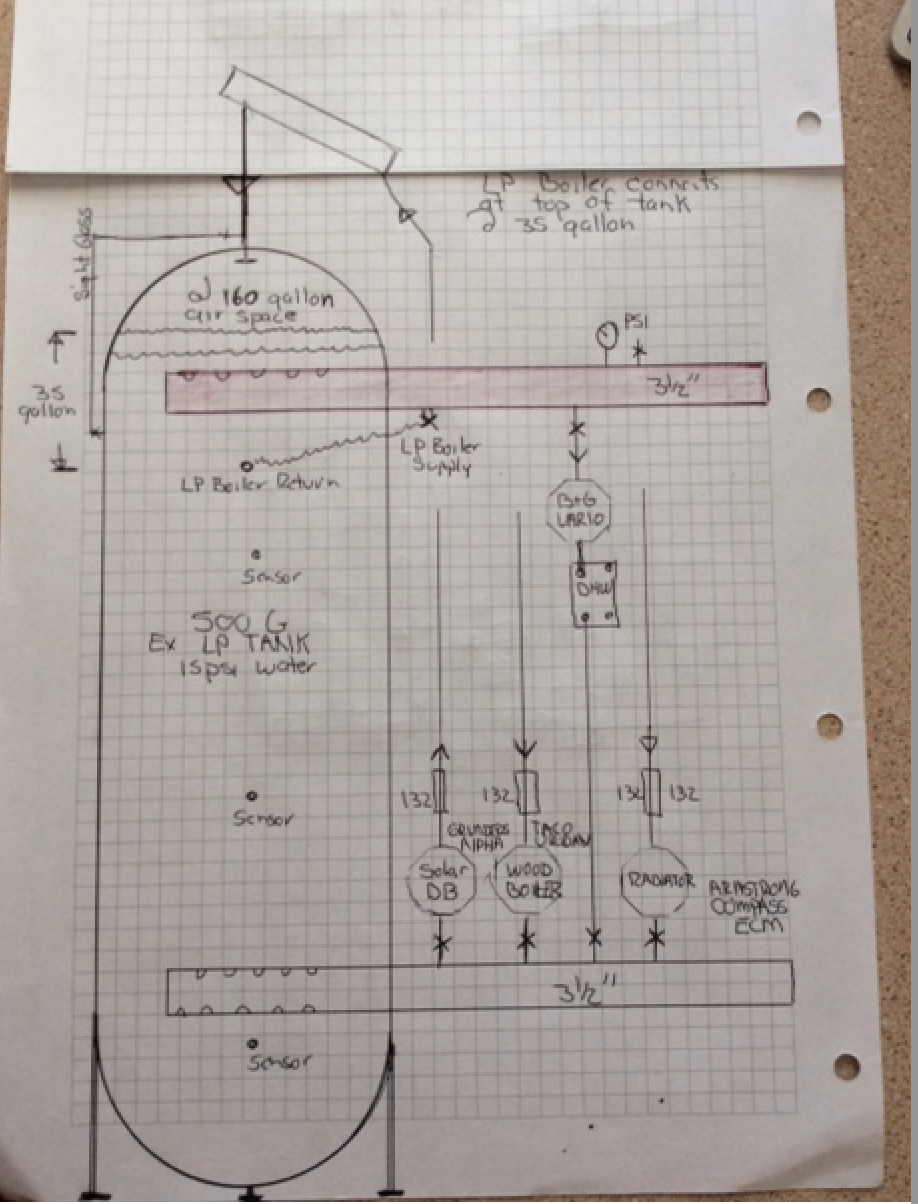

Sparge tube welded into side of 500 gallon LP tank.

With a copper to male adapter, run a hole saw through it the size of the tube. Then slide the copper tube through for the well. Brass tube from K&S metals to fit 6 mm sensorsr

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

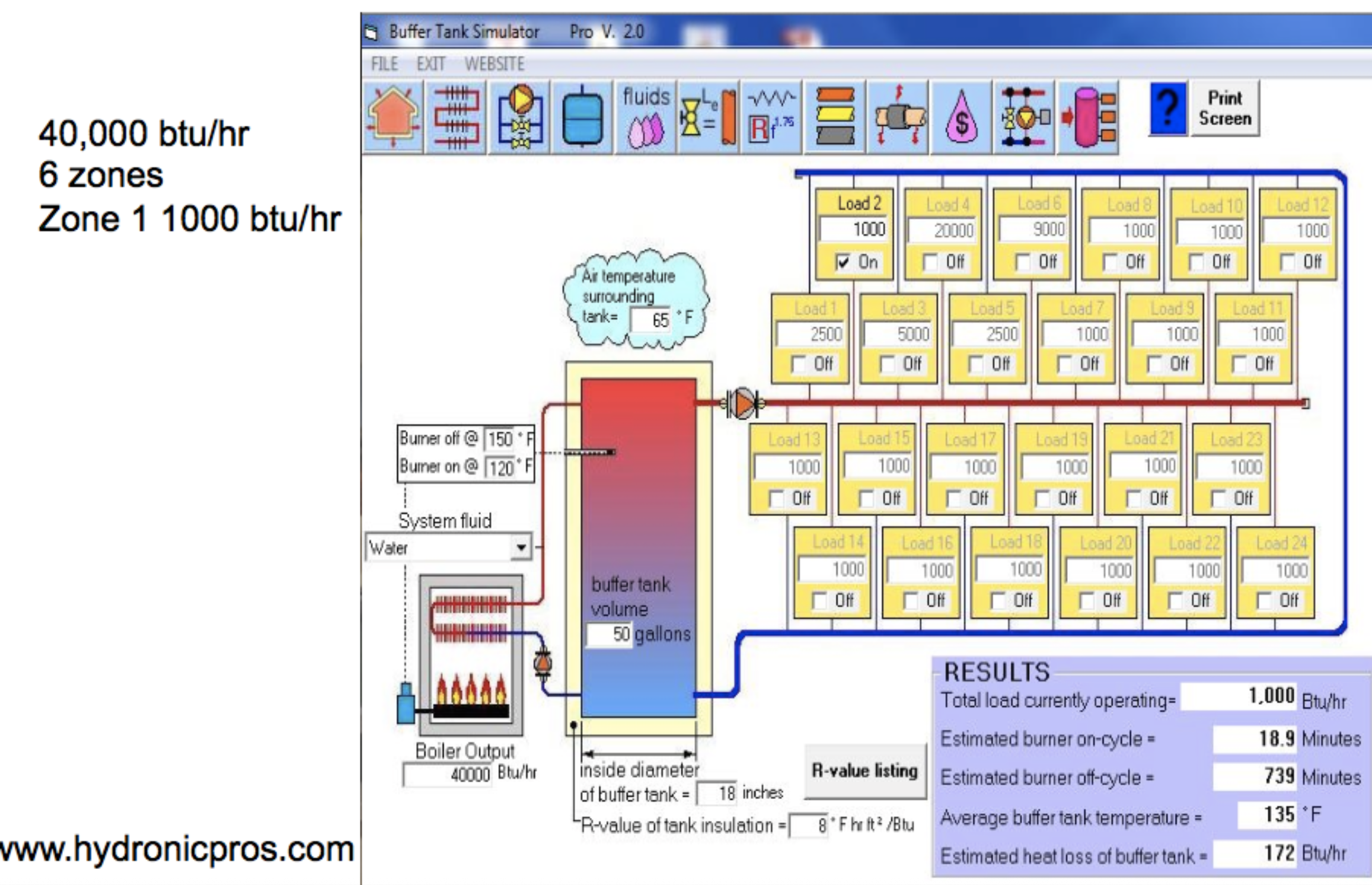

A buffer on a mod con makes the most sense with multiple and micro zones. Zones that operate consistently and at below low turn down BTU output number.

The HDS software has a nice buffer simulator to try before you buy :)

My all time favorite radiant heater was the HTP Solar Phoenix. 60 gallon tank, solar coil in bottom, 5-1 burner above the coil. Simple, single footprint, well insulated, stainless tank. A buffer with a burner.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements