waste oil and condensing boiler

Hey all!

So I have been bothering poor Hot rod with this and he as always has been very helpful. I am putting this out here in case others have been through this or have good ideas.

I am finally getting to the point where I can start building the boilers for the 50x100 building. It's got all 5/8 tubing in the slab. The customer has a lot of waste oil so they would like to heat the building with it. So it will be a energylogic waste oil boiler and a condensing boiler as back up. The ignition control on the burner of the waste oil has and alarm so I was going to tap into that to bring the gas on when the waste oil locks out. The waste oil is primary and will do the majority of the work, but when or if it goes down the gas will back it up.

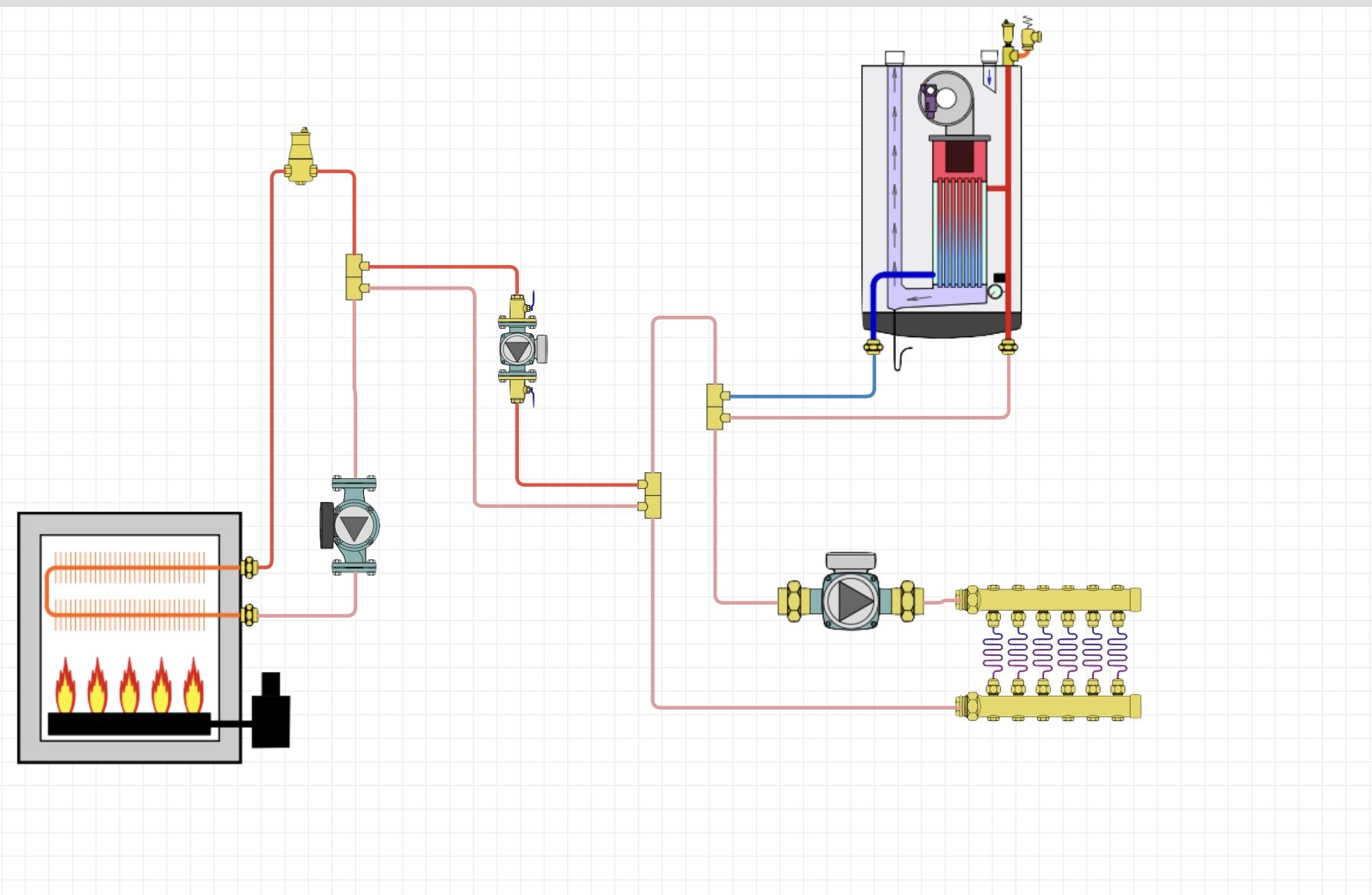

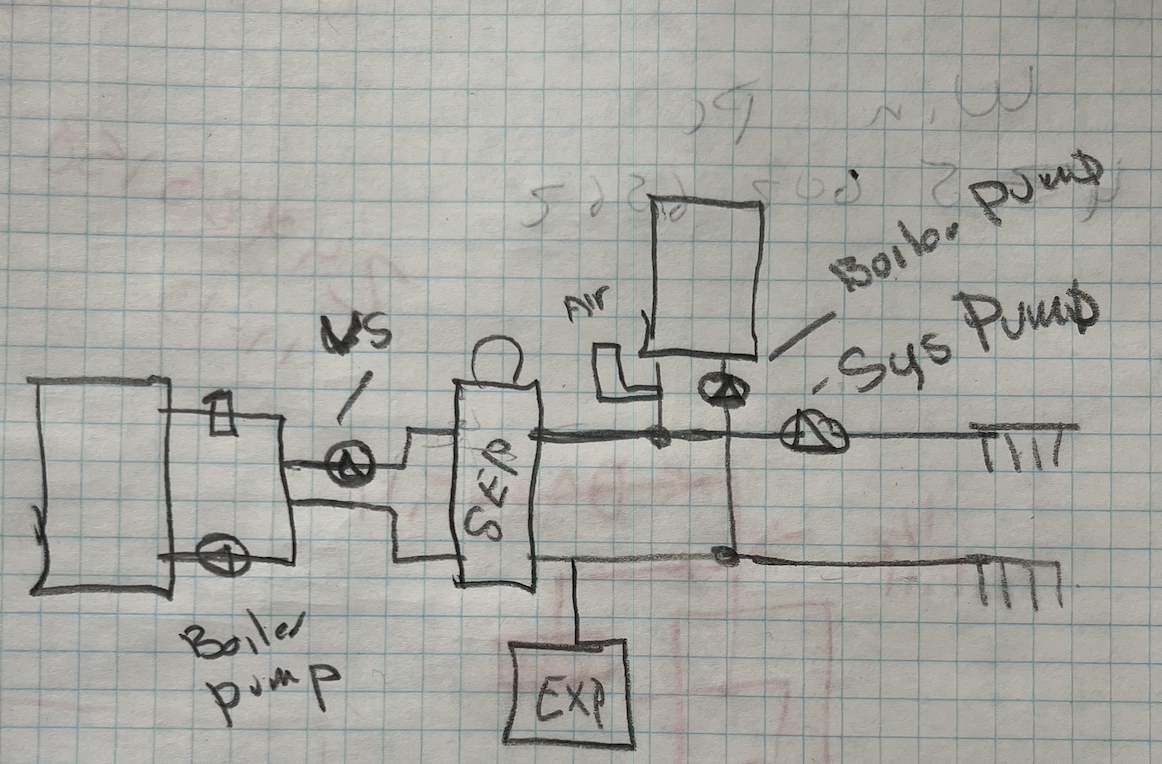

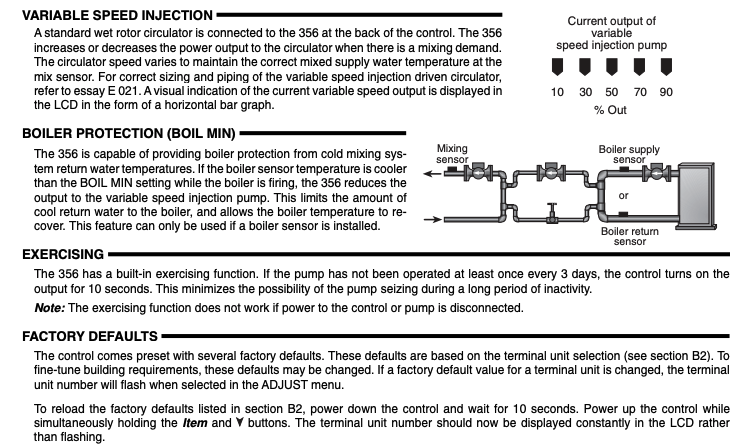

I am thinking I would like to do an injection style setup and use a tekmar 356 I attached my idea, so let me know any issues you see. The mix control is not on the pic but it will be there, the feeder and expansion are also not there, as well as the multitude of misc, just a rough draft.

Montpelier Vt

Comments

-

That works.

Or use a sep to get air, dirt, magnetic and hydraulic separation. It gets you a couple more gallons of buffer for the waste boiler.

Maybe an additional air sep under the mod con.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Hot rod,

Thats doable as well! I kind of like the Condensing boiler on closely spaced tees, I guess Im just a little nervous of flowing through that boiler when i dont want it to? Probably not a real problem.

I also assume by doing this I dont have to worry about a thermostatic 3 way on the waste oil? The tekmar should keep the temp going back to the boiler from getting too cool.

Since this will be a big COLD slab, would a reverse injection be better to try to keep the water coming back to the waste oil warmer?

Tom

Montpelier Vt0 -

A check in the mod con pump, a second on the supply side would give you 100% flow stop through the mod con.

Close tees always has some blending, piping the boiler direct to the floor assures the lowest possible return temperature for highest condensing efficiency. It should run high 90% with radiant return temperatures.

Yes tekmar does show how to use the sensor location and programming for boiler return protection

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

That's a great to use waste oil for heating the building. An even better idea to have the gas backup. Those waste oil burners can be a mess to work on. and no one really does the necessary maintenance on them until it is too late and there is on heat. I happen to become the waste oil burner guy in Cape May and Atlantic county NJ for about 10 years before I retired. The manufacturer will tell you how to clean them but will not show up and get dirty to do it for you. Your customer needs to have a in house mechanic that is comfortable with:

- getting their hands dirty

- talking to tech support

- understands basic mechanical procedures

- has plenty of time to take it apart clean out the crud and reassemble it.

There are no free lunches: You are getting free fuel and maybe saving on disposal costs too, but you need to stay on top of the maintenance and that time you spend costs you $$$ in that mechanic not repairing the stuff he was paid to fix to generate revenue. (assumes you have a repair shop since you have lots of waste oil)

But you have a good plan and you can make $$$ if you want to learn to work on waste oil heaters. Not to many of those guy's out there.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

Any competent car or Diesel mechanic can handle anything on a waste oil burner maintenance. Its just a matter of them keeping up with it. Mad Dog

0 -

Tom, note that HotRod indicated in his drawing a circulator for the mod con boiler. Your drawing does not include this. Is there an internal circ. in the boiler you have chosen?

0 -

Cleaning frequency depends a lot on the fuel they run. I installed a Clean Burn waste oil boiler in a New Holland tractor dealership. They allowed any of their customers to dump oil in the tank.

All sorts of fluids got dumped in, oil, paint thinners, gear oil, glycol, who knows what else.

It was a monthly job for the apprentice mechanics to open the boiler and clean it.

It was a coil type HX, so quite a chore to clean. If they build up too much they tend to over-shoot temperature when the burner goes off. All that carbon in there continues to glow.

Need to wear a respirator when you deal with that ash!

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thankfully they have a service contract with the dealer they are buying from. They will come clean as needed. My job is the gas, and the piping.

I know it shows no pump, there is an internal, that sketch was make quickly just to spit ball, but thanks for the heads up, its a pain when you are installing a boiler that doesnt have an internal and you open it to find you are headed to the wholesaler!

Tom

Montpelier Vt0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements