help design plan for hydronic and wetback on fireplace

Halo, glad I came across the website for dedicated technical information. Would anyone be interested to help me design a hydronic plan to take care of existing and future radiators and in slab heating with a wetback on a fireplace and incorporate a back up heating eg, heat pump or gas boiler?

I'm in Sydney, I would appreciate any leads either to a local person or distant to help me with design.

Many thanks,

Comments

-

Safety first! Most of the wood heat system these day are open unpressurized systems, to avoid steam explosions.

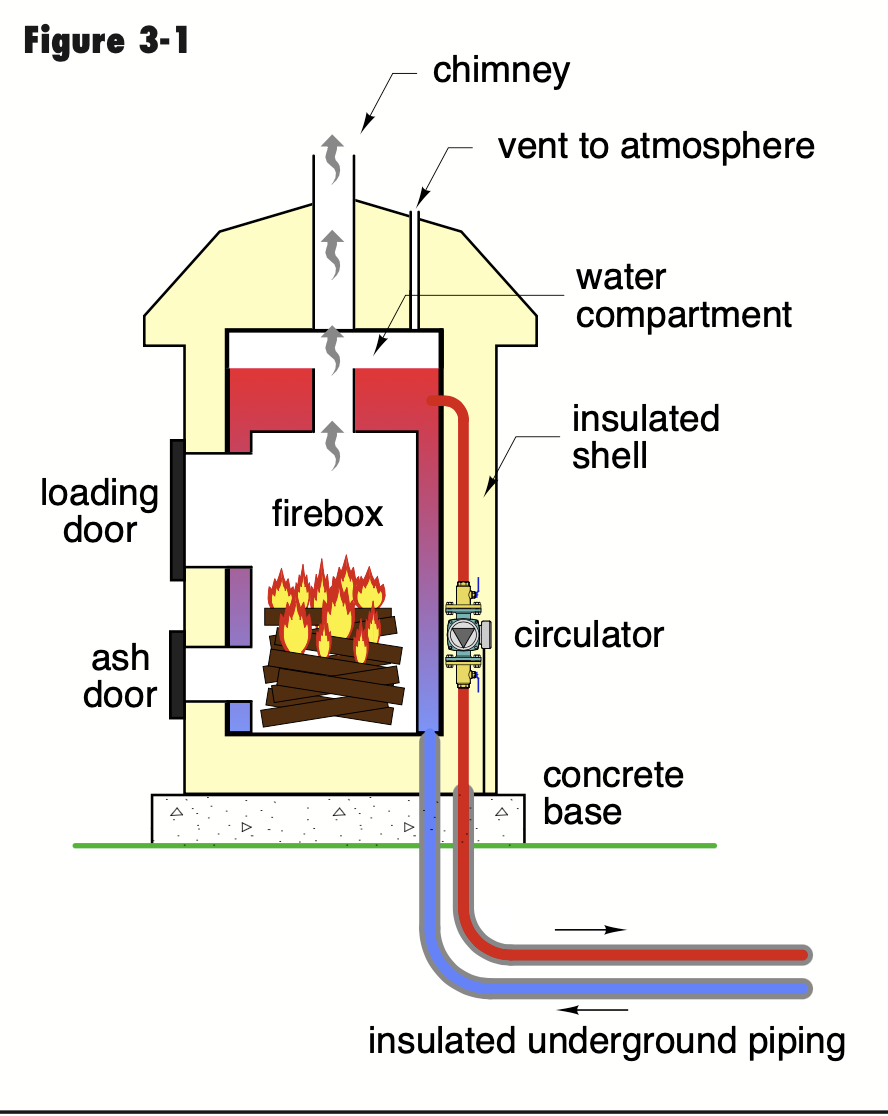

Typically we see outdoor type wood burners to keep the mess and smell outdoors, like this. Basically a fire under or in a barrel surrounded with water, open to the atmosphere.

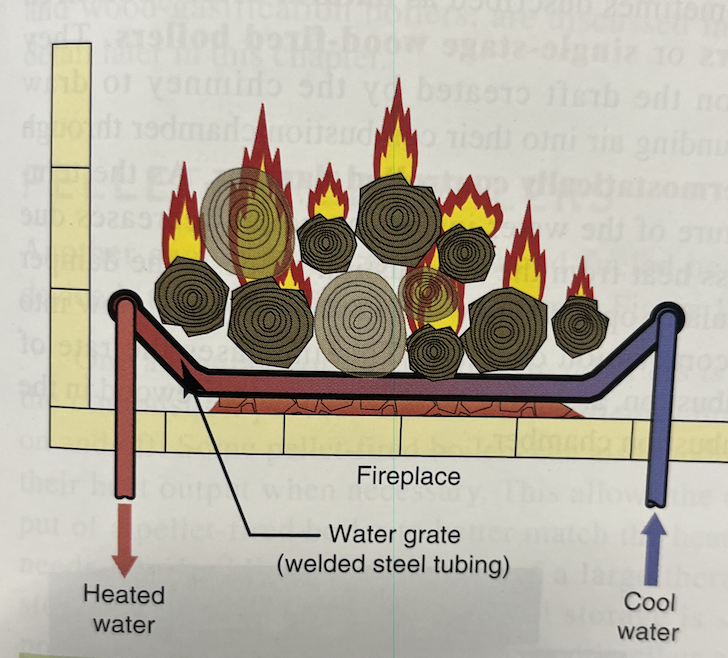

Back in the 1970 there were many add on or add in products. The Hydro Heat was a tubular wood rack that went into the fire place, build the fire on top, to heat the water. Weld or bend, I would not use threaded connections.

I build a number of barrel stoves with coils wrapped around the outside.

What size fireplace and how much heat are you needing?

I would pipe any fireplace heat exchanger to a buffer or storage tank. This give you some overheat protection and storage to run through a no- fire condition. With a tank next to or above you can thermo siphon without needing a powered pump.

Pump from the tank to the heat emitters.

With any homemade device you need to be careful not to pull too much heat from the fire which will cool the gases and form creosote quickly. I like to keep a thermometer on the stove or stove pipe to keep an eye on burn temperature.l

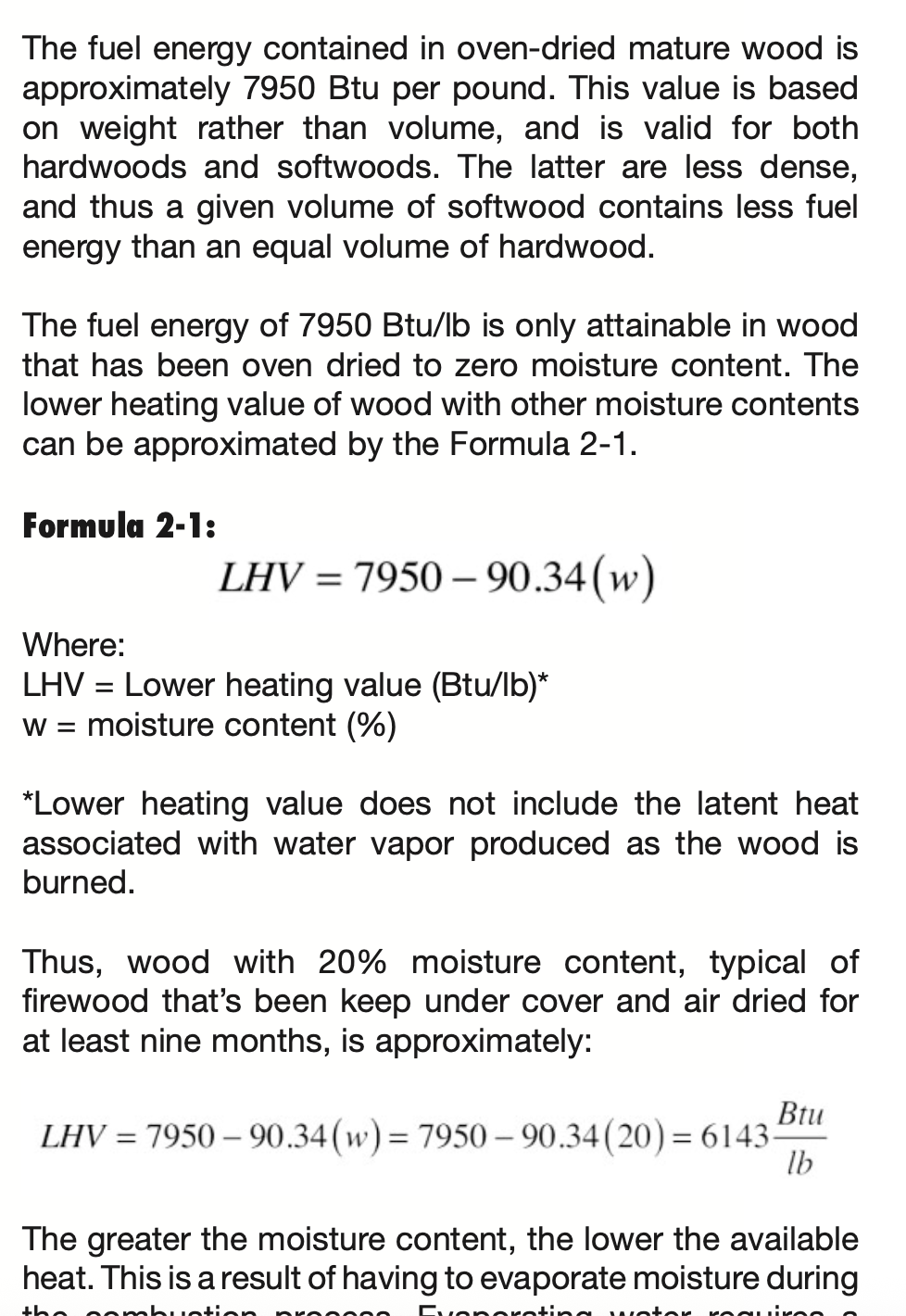

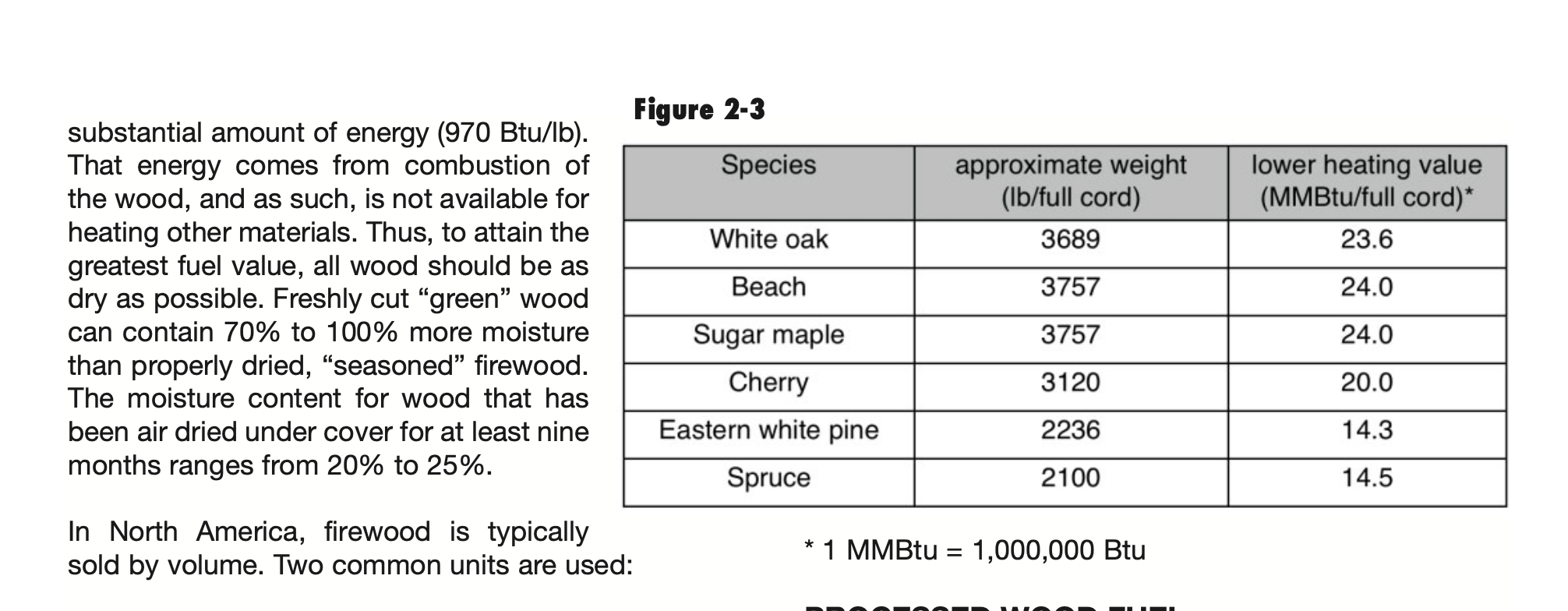

Here are some examples of how much heat you could expect from various wood types. Dry wood is much more user friendly, more heat, less creosote potential.

The distribution loop from the tank to the heat emitters can be as simple or complicated as you want. A back up boiler ties in downstream of the tank

I would start with a calculation of how much heat the building requires. Do you want to heat 100% with wood, or depend on a supplemental source?

Do the system need to be automatically controlled, if the fire dies the back up kicks in?

Some ideas here on technology, formulas, piping and control options.

The 850 page! "bible" of Renewable Systems with all the info from load calculation to final design

Go to the "boiler room" at a website called The Hearth, lots of homebuilders over there. www.hearth.com

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Thank you Bob, that's a lot of info. I'll take some pictures to help see what I'm planning.

I have thread coming off the wetback and I was concerned the plumber connecting to it, I will take a picture.

0 -

0

-

looks like you have some good components

Does the wetback go in the flue piping?

I know some plumbers down under, let me ask around

Or are you going to tackle this on your own?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks for othe reply. The wetback is a stainless steel tube, maybe 10mm thick gap and acts as the first part of the flue. I have a local plumber i work with who is not familiar with hydronics. I would like to form a proper schedule or layout so I can work with the plumber but it might be easier with someone who is well versed with the ideas in this forum.

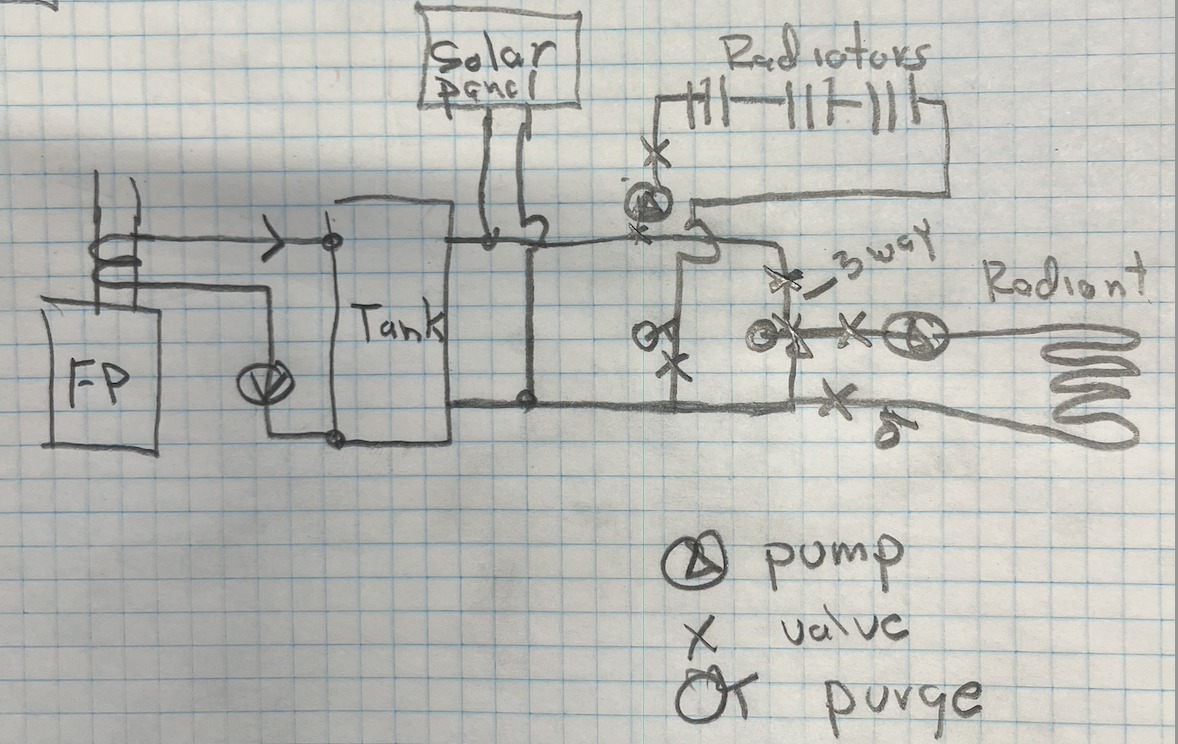

I should sketch a rough layout, would you be able to comment on it as a guide?

0 -

I can help with some concept drawings, sketch up what you have in addition to the tank and heat exchanger.

My wife has been down to your area twice in the past 6 months doing contractor software training. She had 160 plumbers from across Australia at their event, so I could maybe find some hydronics knowledgable companies.

Someone familiar with that type of system, I'm sure others have systems like that.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks, Bob, I'll come up with a good sketch in the next few days and if you come across a hydronics plumber you can pass on my details,

0 -

I'm doing the sketch , here are some images . I have 3 radiators running on a baxi combi boiler and in the ceiling(see image) I have a diversion to slab and chrome radiator on wall in bathroom. The bathroom underfloor doesn't get warm enough, maybe I need to throttle down the last raditor before it enters the loop for bathroom . Someone sold me a diverter valve that never got installed 15 years ago.

Anyway I'm wondering if I commission the fireplace plus water jacket, boiler etc and tee into this setup ,( the new addition is upstairs) I can run the heating for this existing setup from the new set up.

I had a look at the Hearth. Many thanks for your help. Sketch to follow.

0 -

Design intent I tend towards the elaborate, I like things to work and have capacity or redundancy, having said that, if I can lay pipe myself to save, that would be good.

I should send a photo of the living upstairs and utility and bathroom for UFH . The windows in the new addition are double glazed. If the wood burner is not on it would be nice to flick a switch and have the gas do it's job, maybe I can relocate the existing Baxi Boiler.

0 -

There are a dozen way to pipe these type of systems.

This shows the tank as the "hub". any heat source can add to the hub, any heat emitter can take off the hub.

Solar panel is input, cmbi boiler pipes along side it as input.

If the tank also generated hot water? then it needs to be kept hot. Or just grab hot water from the combi, let the indirect tank just pre-heat if it is warm.

I did talk with Scott Irwin at Network plumbing. I can send him some info. Where exactly are you located?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements