1920s Two-Pipe Direct Return System?

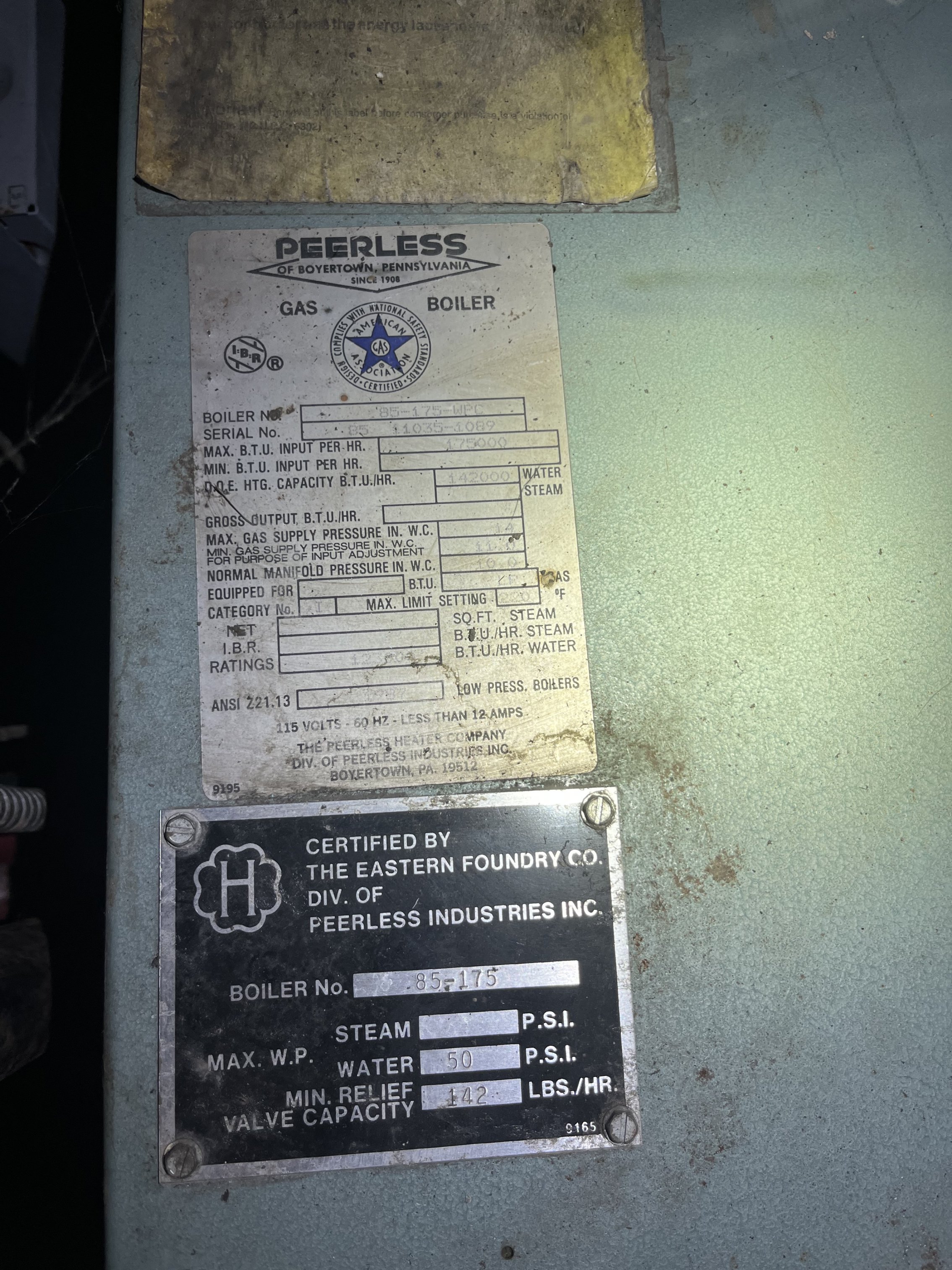

I have recently purchased a 1925 - 4,000 sq ft house that has a vintage hot water heating system using a gas (LP) fired Peerless boiler (IBR 123K BTU). The house has original CI column rads on both main and second level with a total of 20 rads and total EDR value of approx. 1,420. The system volume is roughly 400 gal.

90% of the radiators are piped bottom to bottom with the original valves while some are piped top to bottom with supply on the top side. All have bleeders located at the top of the rad. The system currently operates on 1 tstat and heats all rads uniformly with one or two rads on the second level warming only slightly. One of which will typically have a decent amount of air trapped. Once the air has been bled, it will warm but does not get as hot as other rads in near proximity.

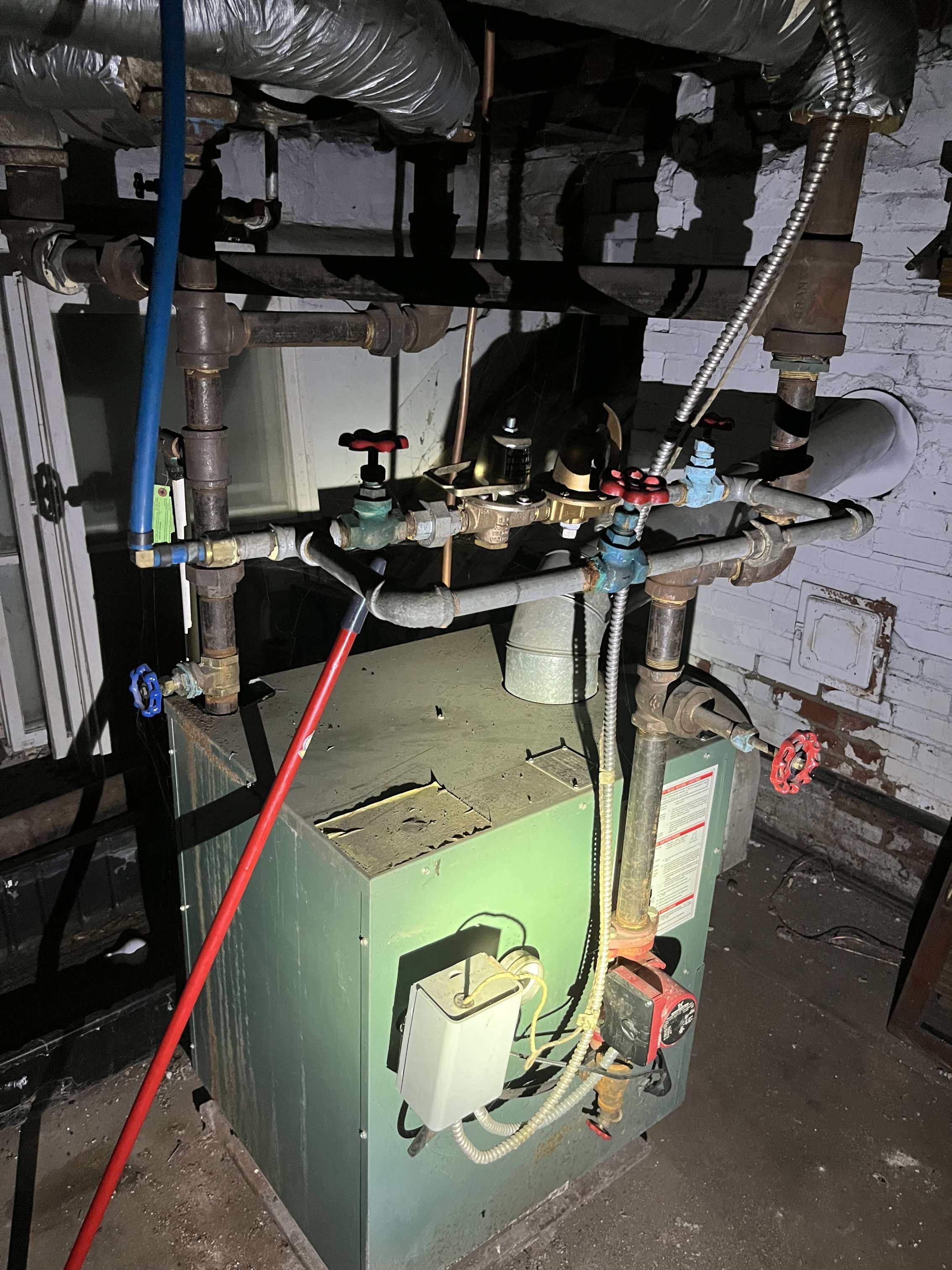

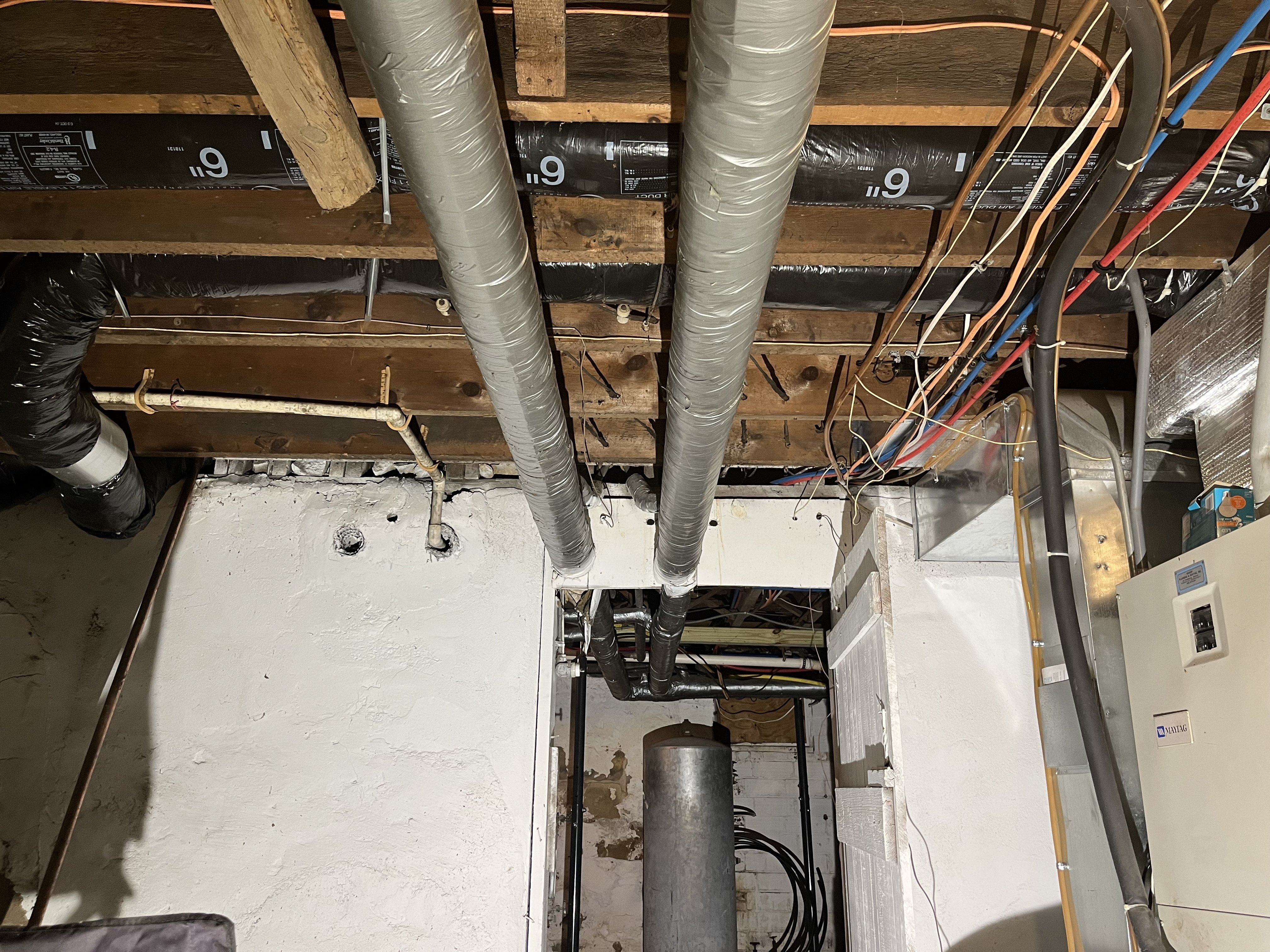

The system currently has a closed-type steel expansion tank in the basement piped off of the vertical supply main directly after a tee (no inline air separator). There is an airtrol tank fitting connected in the middle of the tank with a drain valve directly connected to it. At some point a Grundfos UPS15-58 circulator was added to the return piping and set to 'high' setting. The near boiler piping is 1-1/4 and 1-1/2 which appears to increase to 3" or 4" mains servicing the supply and return for the system. Is this a two-pipe direct return system?

I have learned a lot from this website by reading multiple discussions and utilizing Dan's literature - How come and pumping away. I wanted to share with everyone with hope to continue to learn about my current system and hopefully convert to circulated system with a HE mod/con down the road!

I am located in SE Nebraska and have spent some time trying to find a pro to no avail. Any input is appreciated!

Thanks in advance!

Comments

-

What a beautiful radiator. That's the Rococo model, made by American Radiator Co up till about 1920. A classic.

If both mains parallel each other from the boiler out to the last radiator, it's 2-pipe direct return. It originally circulated by gravity- there was no circulator. The smaller near-boiler piping works because you now have a circulator.

Adding a good air separator and piping it to the Airtrol fitting should cure the air problems you're having.

Peerless makes good boilers- I wouldn't look at replacing it now unless it's leaking.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

If the radiator valves are not stuck you can use them for balancing.

What is that patch in the floor in front of the radiator?

Can you show us how the compression tank connects to the system? I don't see it in that picture.

Is that part of a stoker back in the corner?

0 -

Thank you for the replies!

Steamhead, I have attached some additional pics of the piping layout that is accessible. Not sure if it matters with a converted gravity system but the 'supply side' of the above pictured rad w/ valve is labeled and connected as a return in basement piping? With the system running, I have noticed that some of the opposing union elbows are hotter as if they are the supply while the valve ends are the return. Almost as if part of the piping has been reversed.

I believe it was once a 2-pipe direct return! Would you recommend accessing the attic to see if there's any exposed piping or possible remnants of a exp. tank?

Mattmia2, yes I believe it is! I will try to get a pic and post later. Unfortunately, most of the valves are stuck. The 'patch' is a black register vent.

As for the connection to exp. tank, I have outlined it in red. It is piped directly off of the main riser with a tee (after the supply is split into another main). - IMG_2020(1). It is directly fastened into the bottom of the tank.

0 -

the pipe goes directly in to the tank instead of through the airtrol fitting?

0 -

Yes. Why wouldn’t the previous installer use it as intended? Can I repipe it correctly using an inline air separator to the airtrol? Would it need to be piped horizontal?

0 -

the air separator usually needs to be in a horizontal section but the pipe would then rise vertically from the air separator in to the airtrol fitting. the airtol fitting stops gravity circulation of the cold water out of the tank which because cold water can absorb more air than hot water will pull the air out of the tank and in to the system.

0 -

In the B&G instruction manual, it is possible to connect exp. tank off of the vertical pipe with airtrol boiler fitting. Not sure if this is still manufactured or recommended? Ideally, this should be placed below the tee separating the two supply mains, correct? If by re-routing the piping to accommodate an inline air separator in horizontal run, is the minimum clearance 18" from the nearest fitting?

0 -

-

-

Microbubble air separators that work with standard steel tanks are getting hard to find. B&G has discontinued the EAS series as well as their standard inline units.

Taco's smaller air separators don't have a tapping to connect to a standard steel tank, but those 1-1/2" and up do:

https://www.tacocomfort.com/documents/FileLibrary/101-007.pdf

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

a microibubble air separator would be far superior. i think spirovent and a few others have an not thread on the vent outlet. might be easier to use a piece of 5/8 soft copper tubing to connect it to the tank. a taco air scoop would work ok too as long as you follow the instructions about how much horizontal pipe it needs before and after.

0 -

Thank you both! Is there a way to find the date of the peerless boiler? Serial number? I was able to find a tag on the stoker. It is an Oil-O-Matic - Model G.

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements