3/8" vs 1/2" to panel radiators

Currently in the process of designing/installing new panel radiators in my house. I added a buffer tank to the design so that I can do per-room zoning. The house was built as all-electric and has insulation in all interior walls. The fireplace would also throw off a per-floor thermostat.

Using a 30-degree supply/return delta T, zone GPM ranges from .29 to .83 GPM. This puts the https://tools.uponorpro.com/calculator/ velocity at .97 to 2.77 ft/s for 3/8" Uponor hePEX. I read recommendations of 2-4 ft/s for air elimination, plus ease of installation and decided on 3/8" over 1/2" despite fitting availability, ironically increased cost, and increased head.

Should I have stuck with 1/2" despite velocity being lower? The radiators can bleed air from on top unlike baseboard.

Comments

-

I'm gonna say that 1/2" would be the smallest PEX I would use to feed panel radiators. If you properly configure your system with the specifications of this book, Pumping Away, You do not need to entrain the air bubbles in order to vent them from the system. You will be using Boyle's law to remove the air over time. You just need to vent enough air to move some heat thru each panel radiator. As long as water is moving thru the system, air will be vented.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

it is more about the length of the loop when you go with 3/ 8 pex

If you sized with the Uponor data you will be fine

The 4 fps is a guide to avoid velocity noise, at excessive velocity the air doesn’t move along with the water

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Longest loop probably 125' for 0.4 GPM or so.

0 -

I've always sized with a 20°Δ which gives me some buffer. Half inch will supply up to a 15,000 BTU radiator easily and out West here, those are few and far between.

Running three-eights tubing borders on play vs. work and I see the attraction. No reason not to unless length and output are not exceeded.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

I pulled up that calculator and at .85 gpm and 125 ' your looking at 16' of head. Pretty high.

0 -

Full math of velocity and head for 3/8" and 1/2" - maybe a mix of both sizes is appropriate?

Radiator Qty

Radiator Per Each 160F

Home Runs

Lg Loop (ft)

3/8"

1/2"

GPM Per

GPM Total

Velocity

Head per 100

Total Head

Velocity

Head per 100

Total Head

2

6246

0.62

1.25

50

2.08

6.58

3.29

1.13

1.54

0.77

2

5730

0.57

1.15

36

1.91

5.66

2.04

1.04

1.33

0.48

1

9149

0.91

0.91

63

3.05

12.85

8.10

1.66

3.00

1.89

1

6246

0.62

0.62

100

2.08

6.58

6.58

1.13

1.54

1.54

1

5252

0.53

0.53

34

1.75

4.86

1.65

0.95

1.14

0.39

1

4775

0.48

0.48

68

1.59

4.12

2.80

0.86

0.97

0.66

1

4298

0.43

0.43

118

1.43

3.43

4.05

0.78

0.81

0.96

0 -

There is nothing wrong with running the smaller pipe. When I was working overseas I saw a lot of heat with either 8mm and 10mm pipe. If you don't need the GPM, the smaller pipe is fine. The panel rads are often run at higher delta T which further reduces return water temp without reducing output all that much which increases the efficiency of a modcon.

The cost of the fittings is annoying, but the install is much easier.

@EBEBRATT-Ed The op is only looking for 0.4GPM which is around 4' of head.

0 -

Even moving to 20°Δ from 30°Δ gives me the ~4 ft on longer runs you mention. I'm thinking that I could go to 1/2" for the few that push head to 6-8.

Head for home run loops is the largest not additive, correct? I can't find where I saw that.

0 -

In home run the highest loop resistance sets what your pump needs to supply. Standard deltaP circ is about 10' of head, so anything less than that should be OK as long as not too many extra fittings. The 9000 btu loop does feel a bit close, I would run that in 1/2.

0 -

Small diameter soft copper or PAP is very common in Europe for panel rads. I've seen panel radiator retrofits in some rooms of the old castles with tube as small as 10 mm.

Caleffi makes 10,12,14, 15 & 16mm copper compression fittings. PAP up to18mm

The first step is identifying how many BTU you need to move through the tube.

30- 40° delta is not unheard of in panel radiator systems, which help minimize tube size as Kaos mentioned.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I would prefer to run 3/8" A Pex over 1/2" for the neatness and the better movement of air bubbles . I would not use the cheaper 3/8" crimp type Pex , if they make it for some dumb reason . If you do use the 1/2" only , the inside diameter of the 1/2" fitting is close to a 3/8" opening . The lack of 3/8" manifolds means we have to add adapters .

There was an error rendering this rich post.

0 -

Uponor hePEX with the expansion fittings was my plan. It's worked out well for plumbing.

Seems I need to use (1-1/2"?) copper (or I suppose iron/brass) between boiler and buffer tank and buffer tank and boiler header to zone circulators.

0 -

Pipe is always sized by the amount of flow you intend to move through it.

When doing headers for multiple boilers, loads, the pipe sizes for the total gpm at around 2 fps.

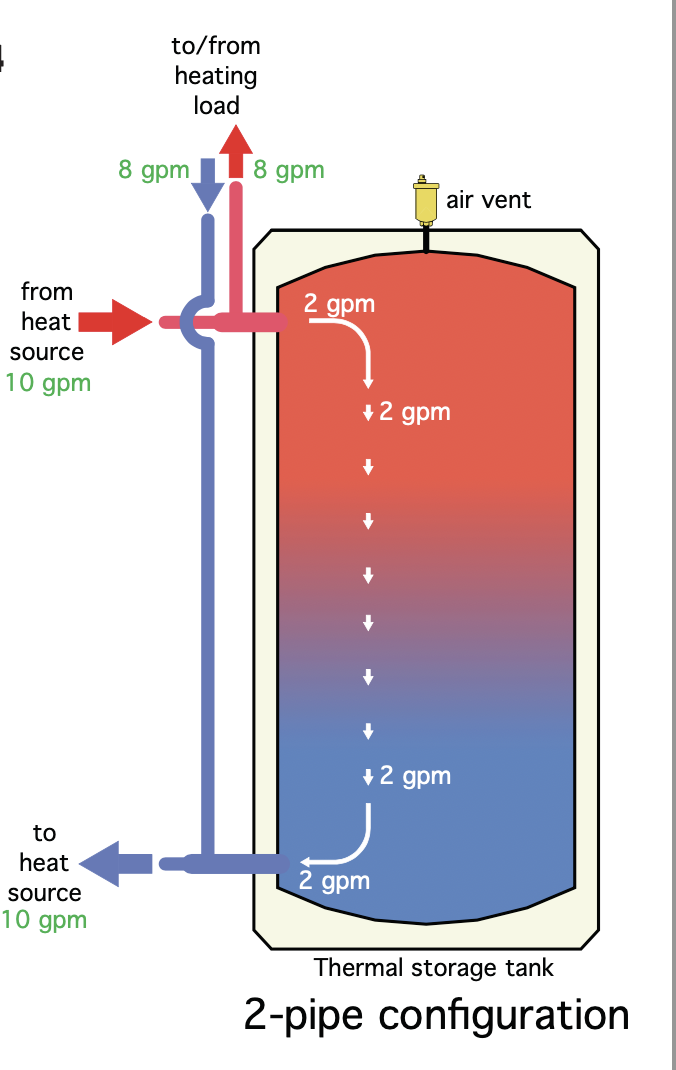

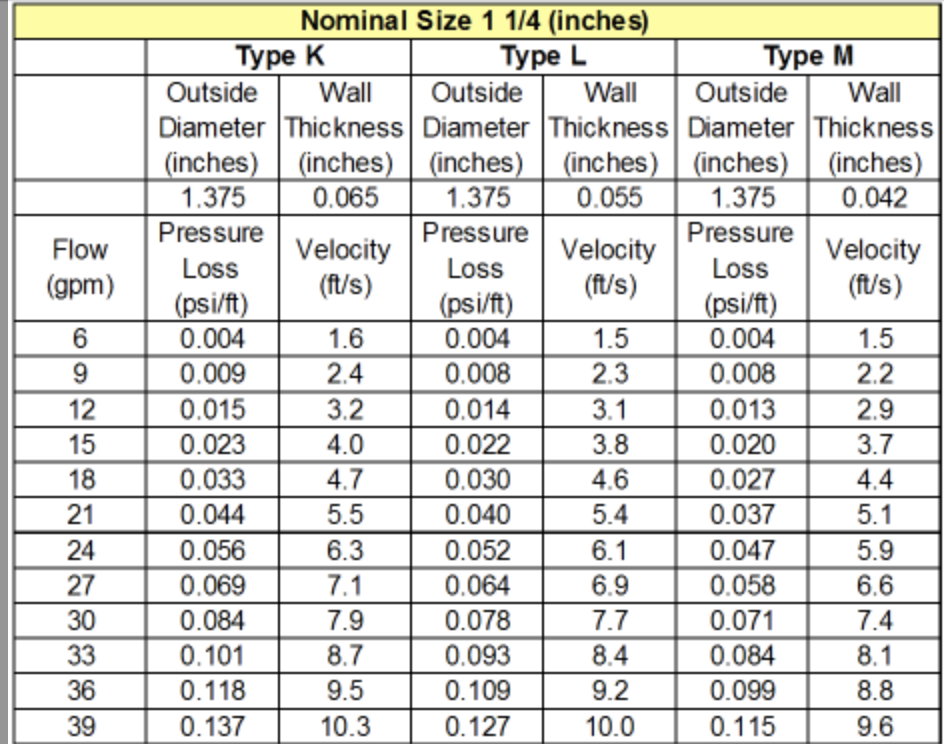

If you do a 2 or 3 pipe buffer, the connection at the tank needs to be sized up, as it is the hydraulic separation function. In this example at least 1-1/4" for the 10 gpm requirement.

The EngineeringToolbox has good flow sizers. for

e

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

@Kaos the information is spotty. The original post said .29-.83 gpm with no length given. Second post said 125' @.4gpm.

So what if the second longest length is 110' at .83.? I was looking at worst case. You need length and GPM to size the pipe and he said he was using 3/8 for everything

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements