Static Plate confusion (firing down Utica SFH3100).

More tech training please :)

I was firing down a Utica SFH3100 that was short cycling and had high stack temp to a SFH365. The burner is a fixed head AFG.

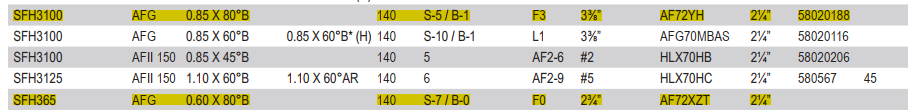

The OEM guide call for a .85x80B nozzle, an F3 head and a 3-3/8 static plate for the 3100 and an .60 X 80°B nozzle, F0 head and a 2-3/4 static plate for the 365. Both 140 PSI pump pressure.

When I started the swap with a new F0 head and the included static plate I found that it was a 3-3/8 plate. The original (3100) configuration was a 3-3/8 plate matching the spec.

I did not have a 2-3/4 plate but I continued with the conversion leaving the existing plate. I was able to get good combustion, nice run time and dropped the stack temp from 650 to 490.

When I got home and was researching the mismatch I noticed the AF/AFG manual indicates the F0 head should use the 3-3/8 static plate and F3-F22 (higher firing rates) all call for the 2-3/4 static plate. I'm assuming the smaller plate allows more air to pass for the higher firing rates. Then why the swap in size in SFH3100 and SFH365?

Comments

-

The use of the larger plate with the F0 head is a general rule, but there are always exceptions. An OEM spec like this was put together just for that boiler.

The Beckett part number for the 2-3/4" plate is 3383. You can probably find one online. I might even have a couple lying around.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

Actually looking deeper in the OEM spec, and table "R.W. Beckett Air Tube Combination Code Listing" I see there plenty of configurations that deviate from Figure 3 in my original post. I think I should get the correct plate and re-tune and see if that provides and improvement in the combustion.

0 -

Sent you a PM.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

-

@HydronicMike , that model boiler does tend to show high stack temps at its full rating. A 160° reduction is no small thing, as long as the house heats well.

@Robert_H , I agree we need to see all the combustion numbers. What model analyzer do you use?

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

160 degree drop in the stack temp will increase the combustion efficiency even if the rest of the #s were garbage.

@HydronicMike said

Your high stack temperature has almost nothing to do with firing rate

I mean really?. The boiler size is fixed and will only absorb so much heat. The harder you fire it the more goes up the stack. The less you fire it the lower the stack. Assuming = combustion #s

2 -

Here are the combustion results. I'm using a Testo 310II and a Bacharach Smoke tester. I keep a spreadsheet updated with the CA from my personal customers. I review it before and after each service.

Comments at the bottom of the table indicate smoke. the results in the first column are the final reading from the last service.

Brilliant me, showed up without a 60-80B nozzle I was planning to use hence the 65-80B

<!--td {border: 1px solid #cccccc;}br {mso-data-placement:same-cell;}-->

date

2/26/25

10/28/25

10/28/25

10/28/25

10/28/25

Time

10:25

9:28

11:35

11:40

11:44

Customer

Eloy

Eloy

Eloy

Eloy

Eloy

MFR

Utica

Utica

Utica

Utica

Utica

model

SFH3100

SFH3100

SFH3100

(365)

SFH3100

(365)

SFH3100

(365)

nozzle

85-80B

85-80B

65-80B

65-80B

65-80B

Pump Pres

140

140

140

140

140

Head/setting

F3

F3

F0

F0

F0

Firing Rate

= 1.01

= 1.01

= 0.77

= 0.77

= 0.77

Draft Breach

-0.04

-0.04

-0.04

-0.03

Draft OF

-0.03

-0.03

-0.02

Tstack

650

608

439

456

489

O2

5.8

6.3

4.5

5

6.7

CO

29

37

42

41

42

EFF

78

78

84

84

81

ExAir

36

40

25

29

45

CO2

11.35

10.98

12.33

11.95

10.68

AT

53

48

56

56

56

Comment

Trace-1 CO2

Pre check

1.5 Smoke

Trace

Trace - 1.5 CO2

Last Season

The excess air is higher than the pretest but last year I only dropped the CO2 1% from Trace. I dropped it 1.5 this time.

0 -

-

Trace of smoke is not really acceptable. Should be true zero smoke.

Ed, excess air and draft have more to do with stack temperature than firing rate. I have boilers firing 4 gph with stack temps in the 400's, and I'm sure you've seen it too.

And then there's condensing equipment.0 -

I not sure I understand why you say a trace is unacceptable. I cut the air back until I get at least a 1 Smoke, then I increase air to get down to a trace which to me is barely perceptible. Then I knock the CO2 percent off and then retest smoke and confirm its Zero. As I have read in many instructions.

1 -

You're saying 2 different things On your chart you state trace of smoke, and now you said you 'retest smoke and confirm it's zero'. So you set it to true zero smoke.

0 -

The comment in the last column, the furthest to the right, is "Trace - 1.5 CO2" But you're right I don't spell out the retest step on my spreadsheet.

0 -

@HydronicMike That's the way I took it. He tests to a trace and then increases the air to lower the Co2 1-1.5%

2 -

-

"Trace of smoke" is one of those hoary traditions that refuses to die. No properly-installed and -tuned flame-retention burner has any business making any smoke whatsoever.

I was taught this way, by @Firedragon , @Alan R. Mercurio and others: When tuning a modern burner we first look for the point at which the burner starts making smoke, then open the air gate just until the smoke disappears and you have a nice clean test paper.

Then we add enough air to reduce the CO2 percentage by one point. For example, if the zero-smoke point is at 13.5% CO2, we'd set it for 12.5%.

This gives a bit of headroom, also called a margin, to allow for changes in fuel or air supply. Both air and oil get more dense as they get cooler, and if the burner is set too close to the edge of clean combustion at the servicing, these seasonal changes can cause it to make smoke or soot.

The proof that this works can be seen the next time we service that unit. There is little to no brushing and vacuuming to be done. The unit has therefore maintained its efficiency throughout the season, the customer is happy, and the oil supplier probably isn't (but I don't work for the oil company).

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting2 -

I was taught 0-trace and then open the air band to drop the Co2 1 point. Just about the same thing. You have to get smoke to find out where you are. Trace to perfectly clean is a judgement. You could be too far open on the Airband. but we are splitting hairs.

I agree with modern burners little to no soot after a year. Can probably go 3-4 years without cleaning.

Margin allows for sawdust from the guy's wood shop or nasty cat hair (hopefully)

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements