Advice Needed: Should I Pipe Backup Gas Boiler Directly into Buffer Tank or via Indirect Coil?

Hey everyone,

I’m looking for some expert input on how best to integrate a gas backup boiler with my air-to-water heat pump and buffer tank setup. I’ve seen a few different opinions out there, and I’d love to hear what this community thinks based on experience.

My setup:

- Primary heat source: 60k BTU air-to-water heat pump

- Backup heat source: 67k BTU Viessmann Vitodens 200-W gas boiler

- Buffer tank: 300L (80 gallon) with two internal heating coils (25 mm / 1” diameter, ~30 m / 100 ft each)

- Distribution system: ~5000 sq. ft. of radiant underfloor heating

- Operating temperature: around 50°C (122°F)

- Primary circuit: 1-1/2” piping between the heat pump and buffer tank

The question:

For the backup boiler connection, I’m debating between two options:

- Direct connection to the buffer tank (same as the heat pump, on the main water volume)

- Indirect connection through one or both of the tank’s built-in heating coils

My thoughts:

- The direct connection should allow for full boiler output transfer to the system water. However, it is more complicated for me to make the adjustments to the existing system and I assume I’d need to add check valves to avoid backflow or unwanted heat migration between the boiler and heat pump circuits.

- The indirect coil option is a much easier install and would might provide hydraulic separation and protect against mixing or thermal interference, but I am unclear whether one or two coils will provide sufficient heat transfer, especially if I need the full 67k BTU output for backup. I understand short cycling and efficiency are considerations there.

Has anyone here set up a similar dual-source system?

Would the internal coil be too restrictive for the boiler’s full output at ~50°C operation temps?

Any rules of thumb or Viessmann-specific recommendations would be appreciated!

Thanks in advance for any insights — I know there are a lot of folks here with hands-on experience balancing heat pumps and boilers in hybrid systems.

— Matthias

Comments

-

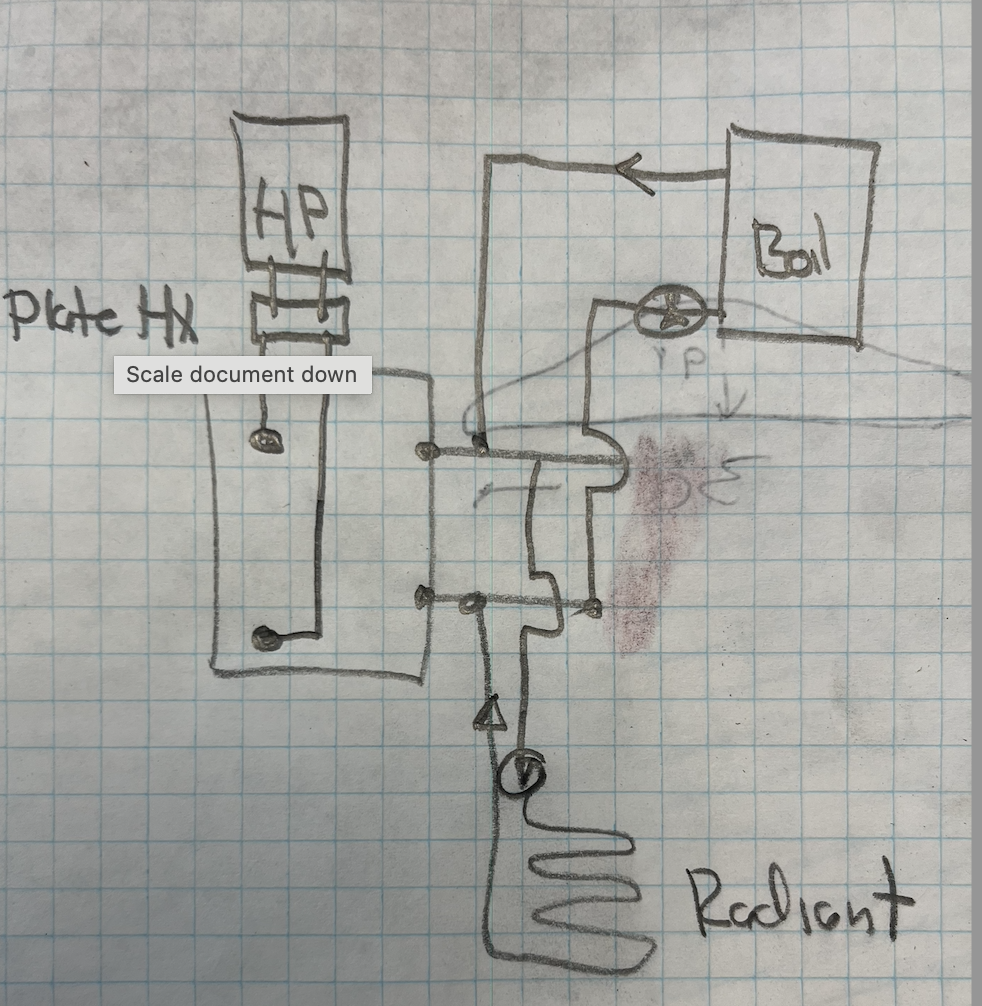

I have that system. My HP has glycol, so I put a plate HX between the HP and tank. To avoid the large amount of glycol.

I had a 4 pipe buffer, the Viessmann Vitocell 100E so from the plate to the tank. then two headers off the tank for boiler feed in, radiant take off.

I'm not sure an indirect is the best match for a HP, I run mine at 120F. But it could work off a 3 way valve in the HP. Or connect into the header so either boiler or HP could heat it

With an indirect you need a lot of coil surface. Ideally both the tank and coil are flowing for best heat transfer. Plate HXers are much more efficient, two pumped flows.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements