Replace an aging Beckett RWB oil burner?

Are Beckett burners interchangeable or device-specific?

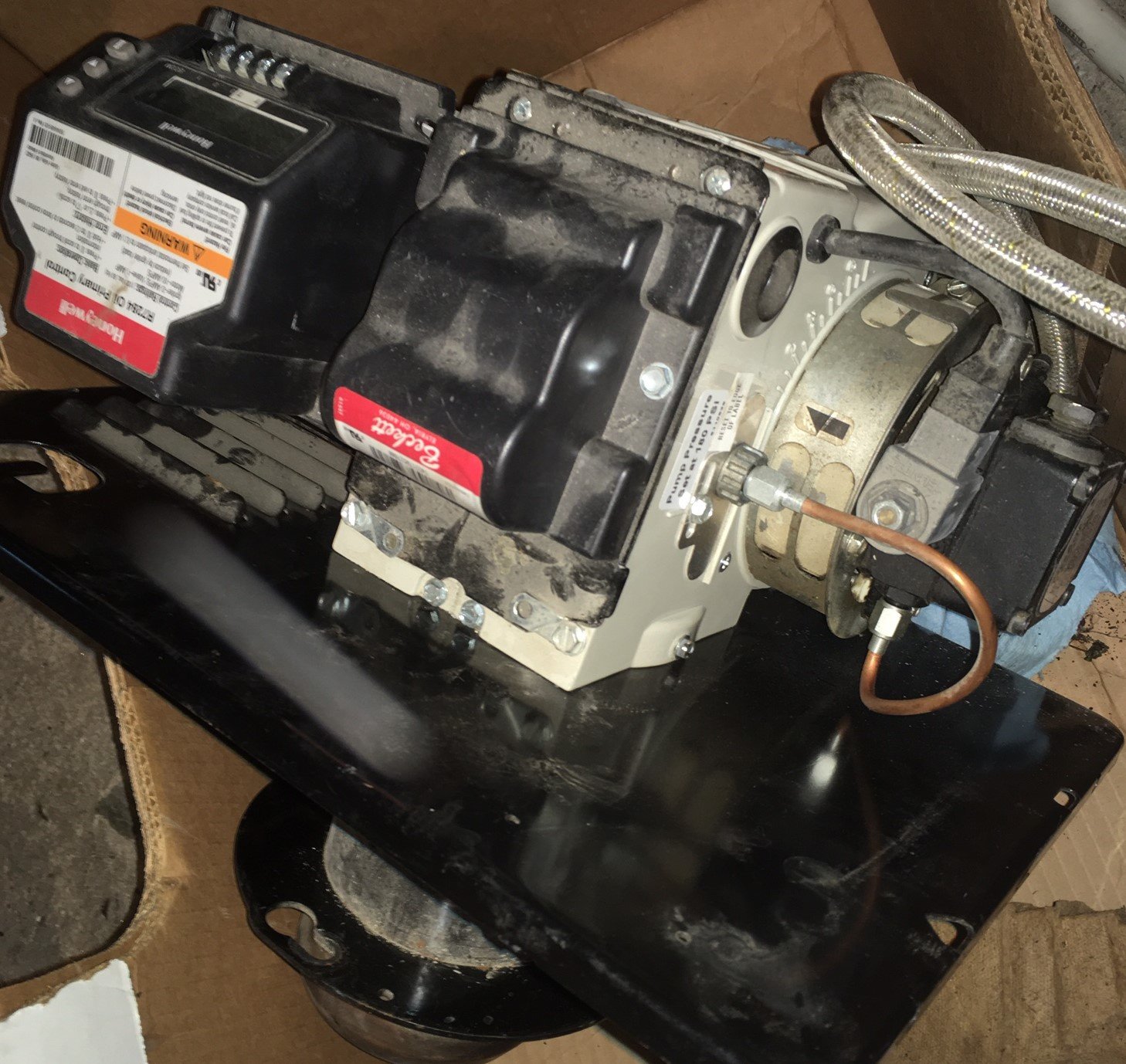

My old Beckett RWB burner with Sunstrand J2bb 300-3 pump and Sid Harvey t1-15 ignition transformer has lived a long life. I see these new Beckett burners with more modern pumps and ignitors. But will any just any AFG burner fit? What specs need to be aligned? My neighbor switched to gas and left me a "new in the box" AFG. Is it as simple as having a technician swap these out?

Comments

-

That "new" burner is 20 plus years old, that being said, yours is at least 50. You need a flange, airtube and someone who knows what they're doing. It is an upgrade

0 -

I wouldn't change the entire burner. I would just install a new Carlin 70200 interrupted ignition primary control, new electronic igniter and electrodes and a new Beckett clean cut oil pump.

The oil pump would need to have the pump pressure set. The primary control would need to be setup for 10 second trial for ignition, 15 second pre purge and 30 second post purge. Install a new burner nozzle and oil filter and perform a combustion analysis and you should be good as new.

0 -

That "NEW" Beckett is from a water heater. the firing rate may be set up for 0.60 GPH and your Beckett SR burner with 1725 RPM motor and fuel pump may be firing more than that. Look at the firing rate or the BTU input or I=B=R NET output of the boiler or furnace you have to determine if that firing rate is compatible. The air handling parts of the new Beckett may be to restrictive to allow a larger firing rate without modification.

Another problem with water heater to boiler or furnace swapping is the flange location on the air tube. That "new" Beckett appears to have a welded flange. That flange can not be adjusted for the proper insertion depth. If you are looking for a "plug and play" where you just bolt the "new" burner to the old heater… It is not that easy. Need a Pro that knows oil burners to get it right. Some additional parts may be needed.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

This is helpful information. My service company is unlikely to want to touch anything that they don't sell to me directly. I had a service all last year when they did not have "parts on the truck," so having some backup parts would give me peace of mind and save me the cost of a second service call or one of those dreaded "no-heat" ($$) service calls that I had during COVID, that was very expensive.

0 -

As @EdTheHeaterMan said the old burner is a Beckett SR 1725 RPM burner sold around 1970s. Different animal from the new burner you have.

The SR is a flame retention burner so upgrading to the other burner isn't going to save fuel

0 -

The other burner the neighbor gave me looks similar. However, this one he had used. It looks similar to the other Beckett and says "AFG" and is set to 150 PSI. Must be another hot water heater burner I suppose. He did have an oil-fired boiler before the upgrade, these must be from his hot water system.

0 -

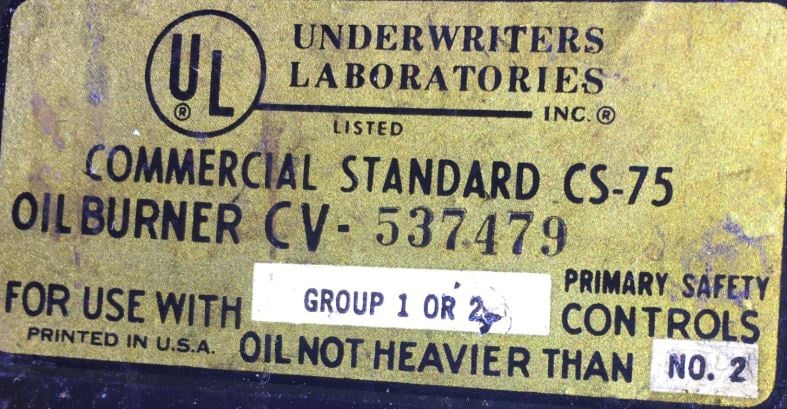

The oil burner with the serial number that ends in 01180 came from a Burnham MPO boiler that was rated up to 87% AFUE and may have been energy star rated when it was installed in your neighbors home. the welded flange means that you can not adjust the insertion depth. If you remove the SR oil burner using. the three bolts that hold the flange on to your heater, you can measure the insertion depth of the SR burner. if the insertion depth is the same or within 1/8" in or out, you could most likely use that burner on your heater.

You will still need about 5 years experience with combustion testing instruments in order to select the proper nozzle, and make the proper adjustments for your heating appliance. still not a DIY job if you have no oil heat experience.

I would venture to say that the primary control on the newer burner that came with the Burnham MPO boiler is a better primary control than the primary control you have on your existing SR burner. So hold on the that Honeywell R7284 control. There are diagnostic features available that are not on your existing blue primary control

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

@Jack M , what model boiler is your current burner installed on?

I would want to see what firing head is on that burner. For those not aware, a long time ago Beckett made a non-flame-retention model called the "S" before fitting it with the then-new flame-retention head to make the SR (which they also did with the original model A to make it into the AF). As long as it has the flame-retention head, runs cleanly and efficiently and is a good match for the boiler, I see no need to replace it.

We can still get all the necessary replacement parts for that burner- even an electronic ignitor. The CleanCut fuel unit mentioned above won't work on this one if the motor is 1725 RPM, but Beckett does make a stand-alone solenoid delay valve which will do the same thing.

I've even upgraded a couple S burners into SR units. They ran great.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting2 -

I think (could be wrong) that the SR and AF used the same heads although the firing rates may differ for each head because of the difference in fan speed.

0 -

You're right.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Yes, this 2.6 amp Emerson S60KXD motor is rated at 1725 and 1/8 hp. I looked through the service tags for the last 20 years and they all reference the Becket Burner as "Model S"

0 -

And, what model boiler is it?

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

The boiler is a Crown Model UPCS-4. It would be nice (peace of mind) to have a spare for the pump (Sunstrand J2BB 300 3) in case I have a service call and they tell me a replacement pump is not available.

0 -

You can get a 1725 'A' pump. You'd have to replace the coupling as well.

0 -

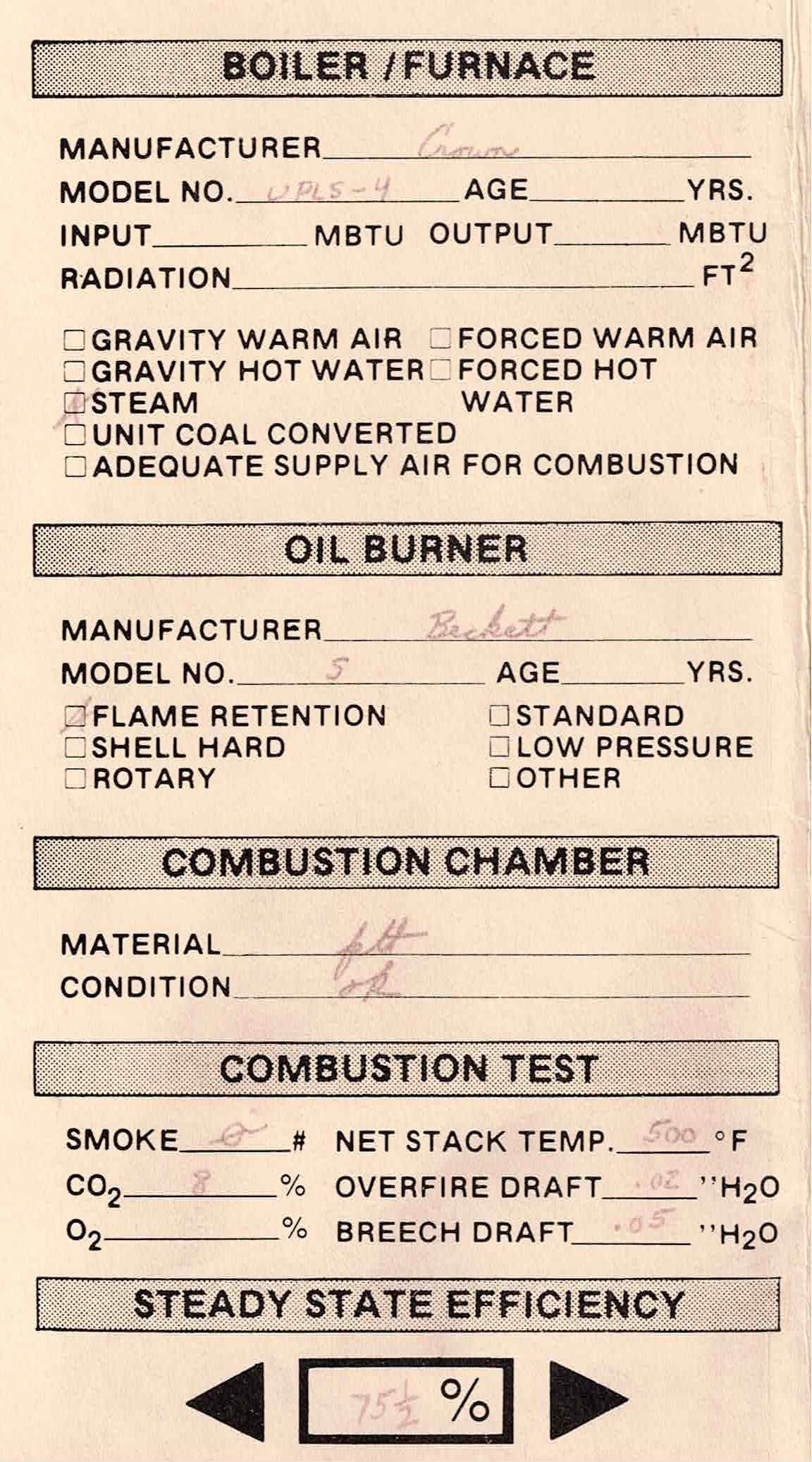

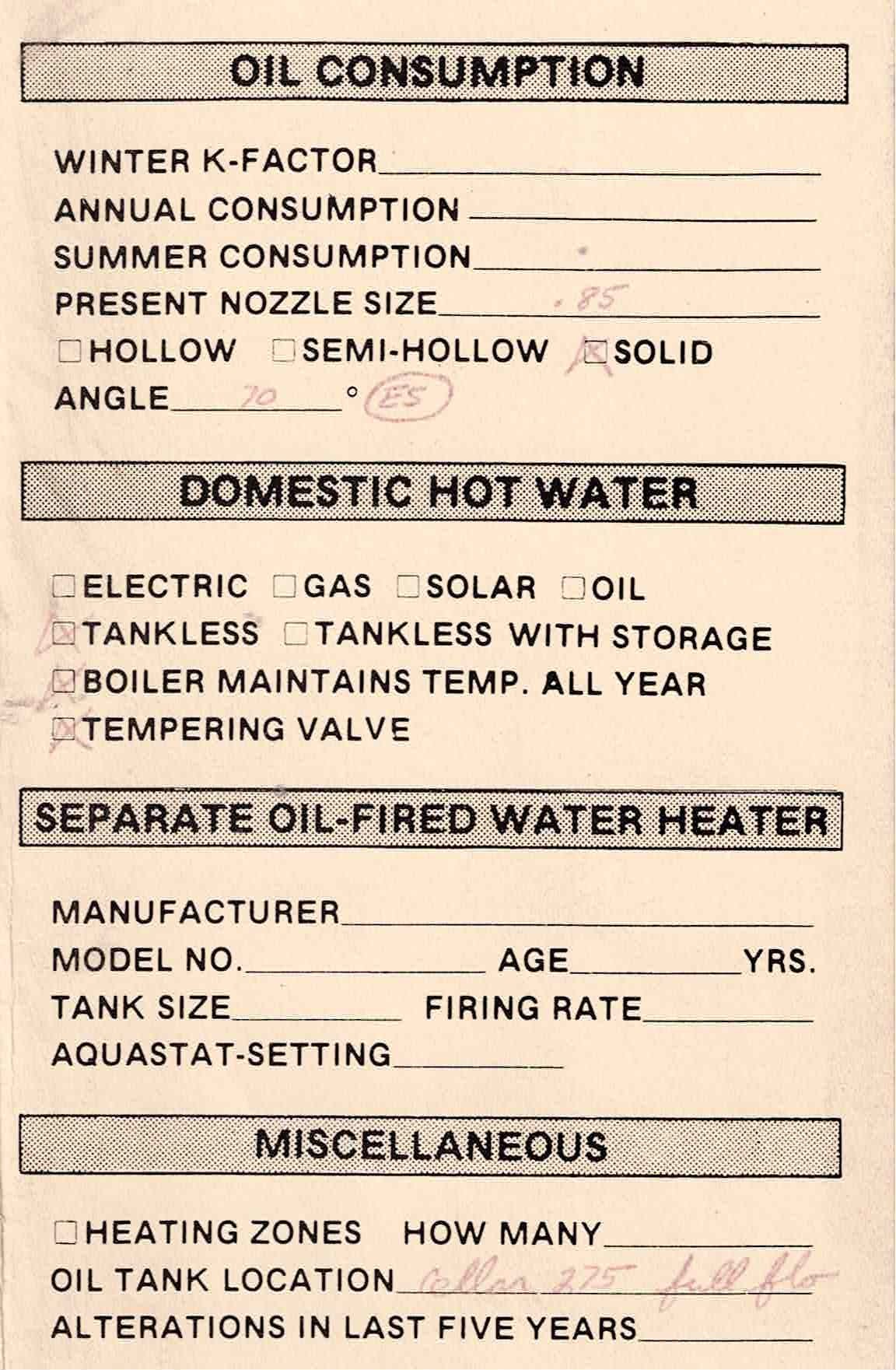

UPCS-4 doesn't show up anywhere, and none of the models in the Beckett OEM guide show the SR. Can you post a pic of the label showing the ratings, model number and serial number? Also a view of the boiler from a few feet back?

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

-

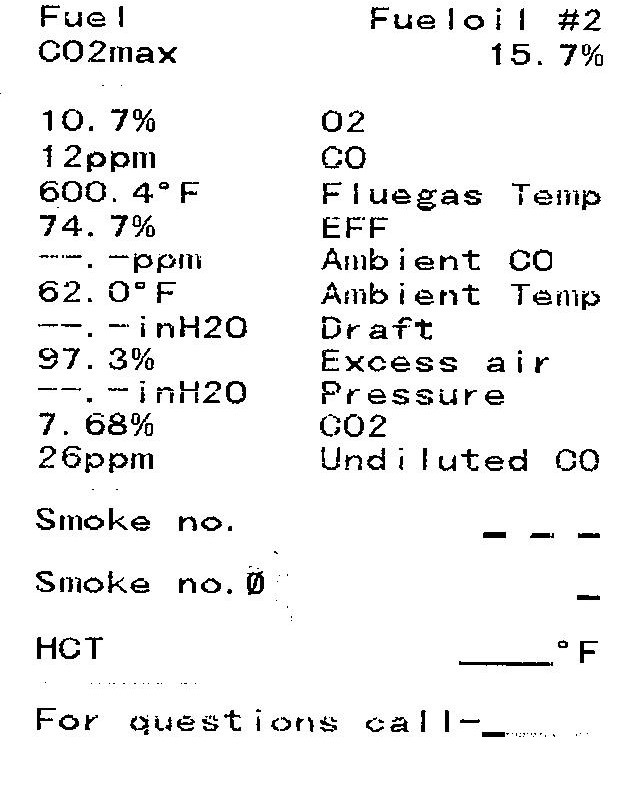

Here is a photo of the boiler from a few feet away. The previous owner bricked over the cellar hatch to build an addition. The service tech said the old boiler (and oil tank) in the basement would need to be broken into pieces to be removed. I have no idea if the replacement would arrive in the same way. Here is a photo with the newly installed ignitor (the old one just died). The efficiency has dropped from 80 percent to 74.7 for some reason.

0 -

stack temp is a little high, if whoever is setting up the burner could get it down a little i think the efficiency calculation would give you a higher number but those with experience adjusting combustion without a computer can comment more on on how that number is calculated.

0 -

I think that's a re-branded Utica or Dunkirk.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

It is a Dunkirk. Those were good boilers. I installed quite a few of those back in the day including one with a Beckett SR. Nice and quiet and burned well.

You can use an "A" 3450 pump at 1725 rpm. No issue. See the attached

0 -

-

isn't the 600 f stack temp pretty high too?

0 -

-

@Jack M , what are you trying to achieve? The boiler won't be more efficient by changing burner parts. As others have said, that's a Dunkirk 1352. It'll outlive us all. But it's 2025, and if there's retort cement holding the side clean out doors in place, and the draft hood is warped and not sealed, there are systems that will drop your fuel consumption considerably. 600° stack temperature is a waste. The boiler is filthy, or not drafting properly, or both. When the boiler is clean, it should be no higher than 450° net at steady state. I didn't see any draft readings. Do we assume a smoke test was done? Let's say "allegedly". There's also a front clean out above the inspection door. Pop that middle plate off. See what's in there.

What makes domestic hot water? Can't see if there's a tankless coil in the back.

0 -

Tankless coil on those is on the opposite side.

Your efficiency is down because the burner may be misadjusted. Co2 should be around 10%

Sounds like you need a better technician. What's your location?

0 -

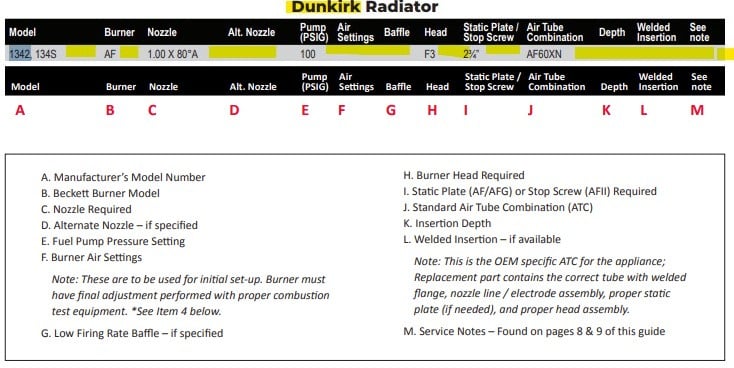

The Beckett OEM Spec Guide shows the following setups for the 1352:

Burner- AF Head- F6 or F12 Static Plate- 2-3/4” Nozzle- Delavan 1.35 X 80°A at 100 PSI

The F6 head would easily support the 1.35 firing rate, not sure why they also mentioned the F12. @Jack M , what firing rate is shown on your boiler's rating plate?

Note that the spec calls for a HOLLOW nozzle. If someone put a solid one (as Delavan "B") in, that will degrade the combustion.

I suspect this boiler originally came with a different burner and the SR was a retrofit.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

I installed a few of those boilers. At least 2 of them were SRs. I remember because we usually installed AFs on conversion jobs and I was surprised to see a low-speed burner, but it ran fine. This was 1975ish. Some of those boilers we installed were rebranded Texaco and came with AF burner painted red.

Might be a series 13 boiler.

Dunkirk also sold those boilers to H B Smith who sold them with the Smith name

0 -

The "handwritten ticket" that goes with the computer printout reads "net stack temperature" is 537 degrees F😀. I reviewed annual service tickets for the last 15 years, all are 500 (net) except for two that are 550. Took the front cleanout plate off, and it is immaculate, no soot at all. It was just vacuumed out as part of the annual service. I pull that cover off every once in a while ( it is usually clean) because one time the air mixture was set incorrectly and the whole thing sooted up (you can see from the discoloration on the front of the boiler what a mess this one event caused to what was pristine). As I mentioned, having "backup" parts on hand allows me to have a prayer of getting the system up and running in the event a part breaks and the oil company says "these old parts are impossible to find, we don't carry things like this on our fleet of trucks, this is a huge ask, we are a big company and do not have time be sourcing parts" (note: we don't talk about prices for any of this on this forum) I don't begrudge anyone, this is all fair, I am just one small insignificant customer fortunate to have a oil company to service my boiler (and a forum like this to learn). The steam heat is very comfortable (like standing in sunshine), the floors are warm, and endless showers for teenagers. I would add that there are never any problems, but I'm afraid to say that because I will jinx myself. My "converted to heatpump" friends cannot say anything like this.

The boiler is rated for 315 square feet of steam and a capacity of 1 gallon per hour. The service person wrote '85 x 70 B" at the top of the sheet, and the nozzle description has been labeled the same with the word "solid" on the sheets for the last 15 years (at least).0 -

That's probably a rebranded 1342 then, it has that firing rate. F3 head, 2-3/4" static disk, and believe it or not, either a hollow or solid 80° nozzle. Go figure………………

What I'd do is try both nozzle types and see which gives the best results.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Interesting. How long ago was that? Reason I ask is, I dug out a 1991 OEM Spec guide and while the SR was a current model then, it doesn't show that burner for that boiler…………….

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

that's steam, right? where's the lwco and the pressuretrol/vaporstat?

0 -

This was back in the mid 70s with the SR. Think Dunkirk switched to the AF around the same time.

When we did conversions back in the early 70s we were putting AFs in mostly and an occasional CRD.

People were so used to the old slow speed burners they were quiet and the AFs were noisy in the old Snowman boiler and most of those old chambers were hard firebrick. We had to line them with cerafelt if they complained or rip and put in insulating fire brick so on a few jobs we used SRs. I know in 73 when I got out of school we were all given a Smith catalog and it had the smith (rebadged Dunkirk) in it.

0 -

0

-

Those boilers were sold with different burners. If yours is an SR I see no problem keeping it. If you want to use the AF which is a little more modern you can get the parts you need to make any changes to the other burners you have.

Putting the AF in and bumping the oil pressure up and dropping the nozzle size will be good. Don't forget those specs were written 50 years ago.

0 -

The oldest service tag dates back to 2000, when we moved into the house (25 years ago). The tag reads "Becket Model S" (not SR) and has a flame retention head (which others have acknowledged).

0 -

Service tickets are not always right.

The model "S" was not flame retention if I remember right the "SR" is flame retention that is what the "R" is for.

@steamhead will comment.

0 -

Correct. But I've seen Beckett chassis marked "A" that had flame-retention heads. I always double-check when I see that.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

@EBEBRATT-Ed said "Putting the AF in and bumping the oil pressure up and dropping the nozzle size will be good. Don't forget those specs were written 50 years ago."

I've bumped the pressure and dropped the nozzle size on a couple SR burners- works as well as on the AF.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Don't know why it took the residential burner MFGs so long to increase oil pressure from the standard 100psi. This trick has been known for years. Burkhardt mentioned this in his book which dates to the 60s.

We sold Iron Fireman commercial burners back in the day they were owned by Dunham Bush. They were running 300 psi at the nozzle back in the 60s the first company to do so I think. It took Power Flame and others a while to catch on but not as long as the residential burners.

More pressure = smaller oil droplets which creates more surface area for the oil to mix with the air.

We had old Petro oil burners made in the 20s that I serviced back in the day and they were not very good. Boosting the op to 120 helped a bit

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements