Baffled: Weil-Mclain startup and delay on break relay

Hoping someone might help me figure out an issue that has me completely stumped. I have a Weil-Mclain EG-40 which is a bit oversized for my system. After years of drama, I have fixed every problem in the system, everything works great, except for one issue: The classic short-cycling issue after putting a Vaporstat onto an oversized boiler. This is especially true recovering from a setback, of course. All obvious. Tons of venting, just too much boiler and not enough radiators. After hitting the 12oz limit, pressure falls to zero in about 30 seconds and the burner fires again.

Now, I have seen many threads where people have had success using delay-on-break relays as a simple solution, wiring one in series with the pressure controls to keep the limit circuit open for a few extra minutes after limit pressure is reached. I like this idea very much, makes sense to me to allow the rads to radiate for a bit before adding more steam.

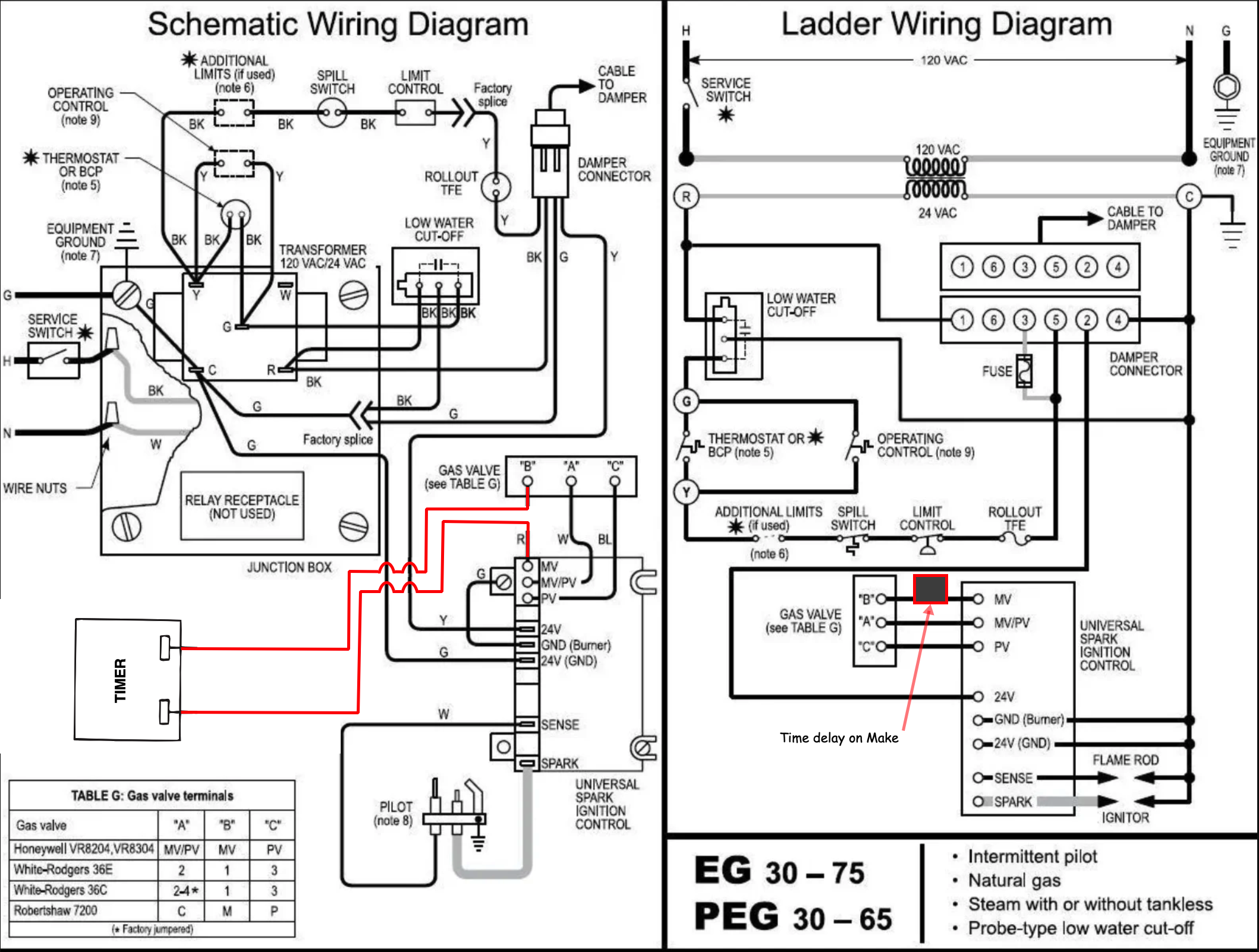

When I attempted to do the same, I was met with a problem: Something about my system's start cycle seems to require a brief opening-and-closing of the limit circuit right as the damper (Field Controls GVD-6) reaches its end switch in order to signal for the firing of the burner. If I add the delay-on-break relay in series the limit circuit, this interruption prematurely triggers the delay, the relay holds the circuit open, and the damper (which has just opened) immediately closes. 5 minutes later, the damper opens, hits its end-switch, something happens on the limit circuit triggering the delay-on-break to hold the circuit open, and the damper again closes. Repeat indefinitely.

I have scoured documentation, read so many threads, and can't find anything on this. Hoping someone here can help me think through this and understand if there's a better way to solve for the short recovery time.

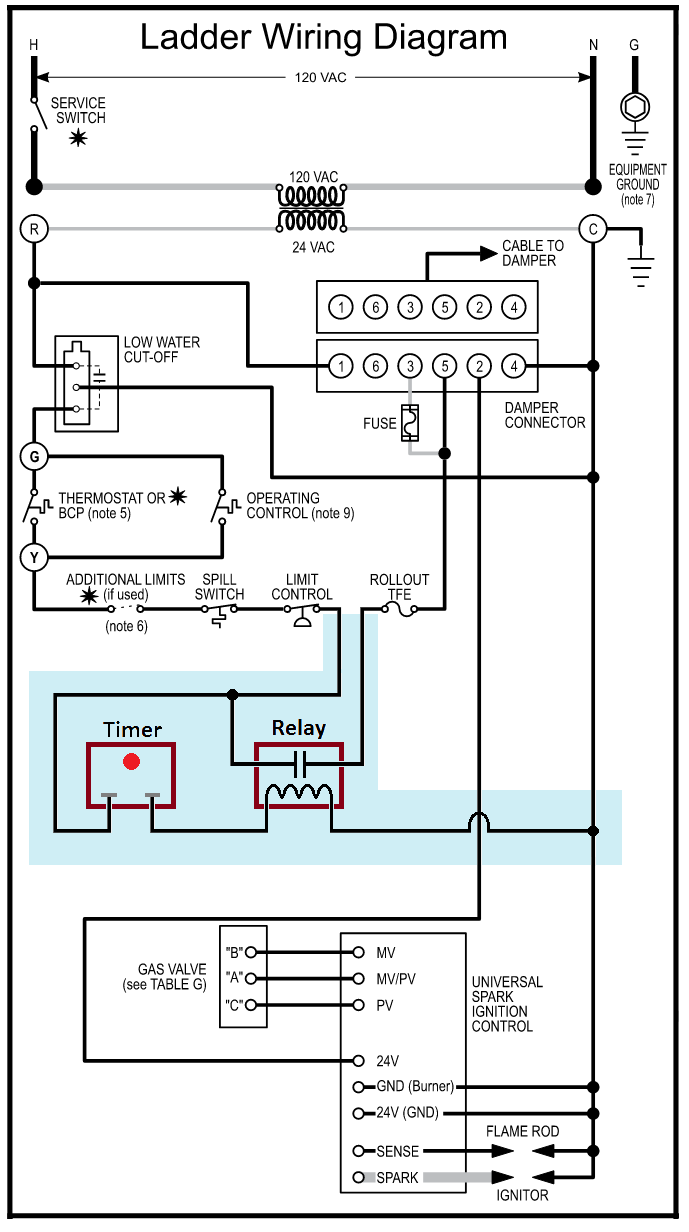

For reference, what I am describing is effectively "LIMIT CONTROL" in the below diagram consisting of the vaporstat, pressuretrol, and delay-on-break in series. (And for the record, the Vaporstat and Pressuretrol each have their own pigtail out of separate ports on the boiler.)

Note: I have not done a deep inspection of the existing wiring, so one assumption here is that everything is in fact otherwise wired appropriately.

Comments

-

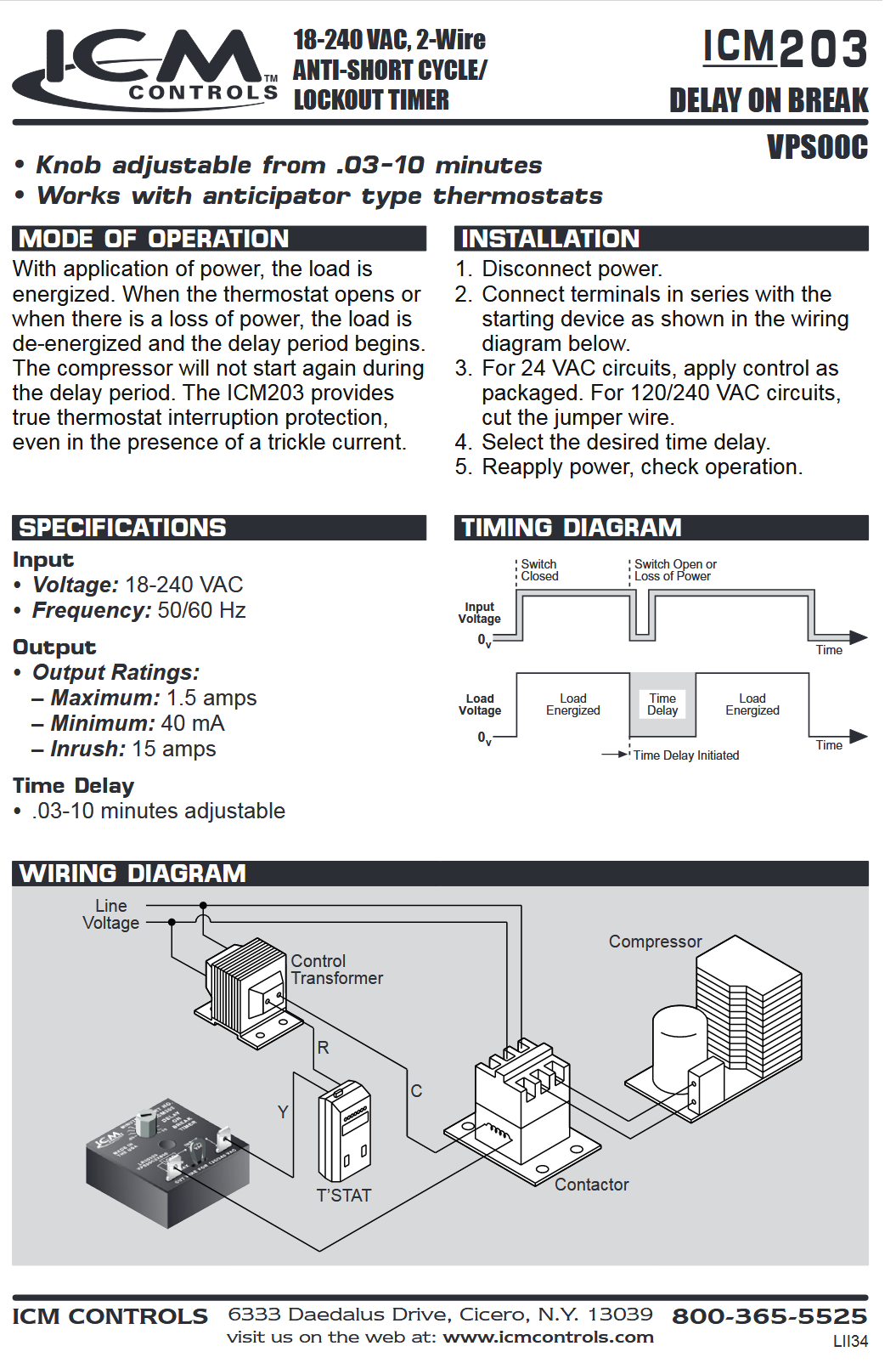

What timer device are you using ? The ICM Controls ICM203 or the ICM206, other ?

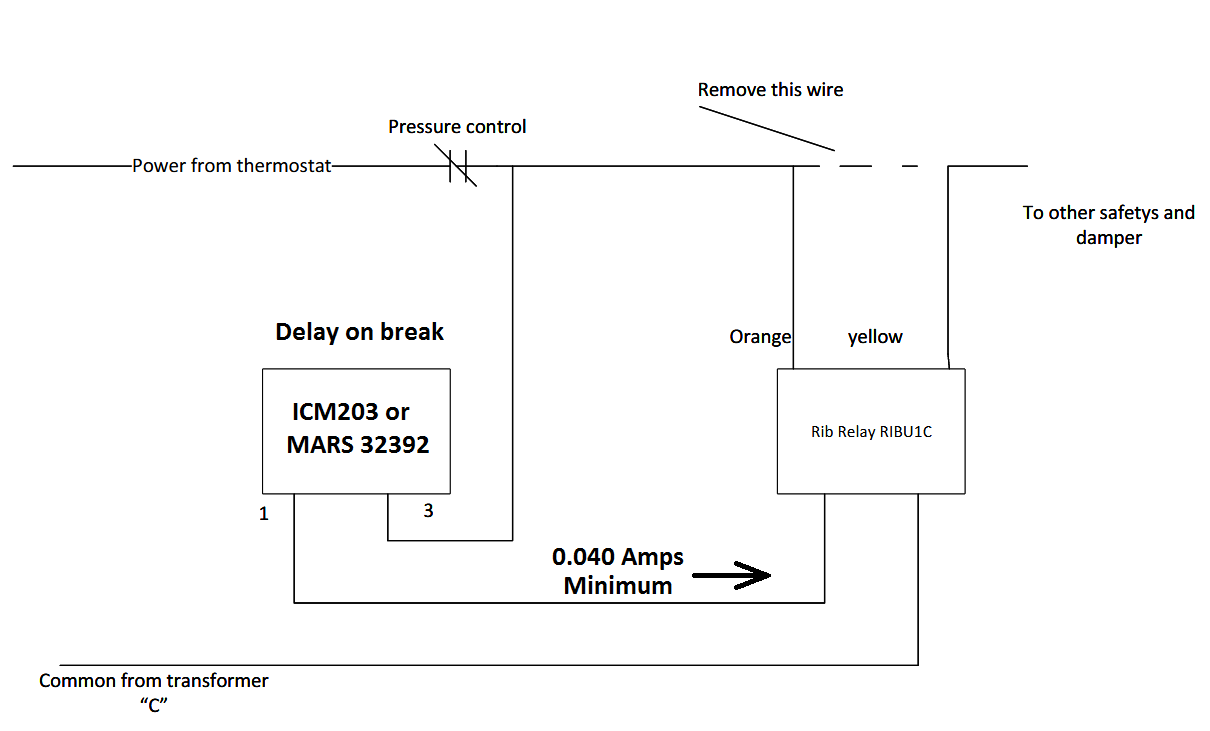

Two things I can think of quickly. Contact bounce (a phenomenon of mechanical switches) is is messing with the ICM203 or ICM206 or the the minimum hold current requirement of 0.040 Amps is not available in that part of the circuit. Although maybe not optimum depending on your point of view have you put the timer in series with the 24 VAC feed to the Intermittent Ignition Control module ? Which may not be possible with the ICM206, I'd have to look into it more later.

There are other ways to get the same result but it would probably cost more to set up than a ICM203 method.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I am actually using an equivalent of the ICM203, the MARS 32392.

I’ve got a MARS 32391 (delay on make) and 32395 (bypass) on hand as well as I had the idea to bypass the 32392 for the duration of the startup sequence, but that just held the sequence in a lull with the damper open and the burner never firing.

0 -

-

OK its later, but not what I really meant. Anyways the MARS 32392 and the ICM Controls ICM203 looks like the same basic device as you said. Since it may be exactly the same device inside like I said above still applies.

Since it is a two wire device I would try;

" Although maybe not optimum depending on your point of view have you put the timer in series with the 24 VAC feed to the Intermittent Ignition Control module ? "

I'l be back later for an update, if any.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

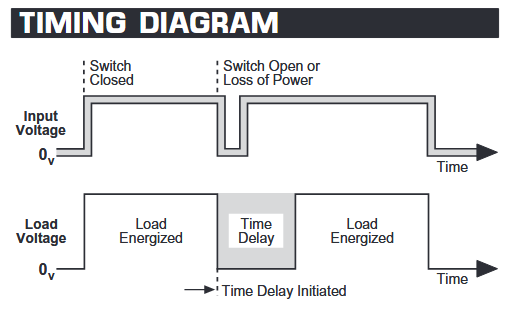

Your using a 'Delay on Break"?? I think you need a "Delay on make" If you put the TD in series with the limits after the pressure control the TD loses power when the pressure control opens.

So on a call for heat the TD times out and the boiler starts. (that's a downside the delayed start) once the boiler fires and builds pressure the pressure trol opens on pressure ….then recloses but the boiler will not fire until the TD times out.

I don't see how you could use a delay on break but I am sure there are other ways.

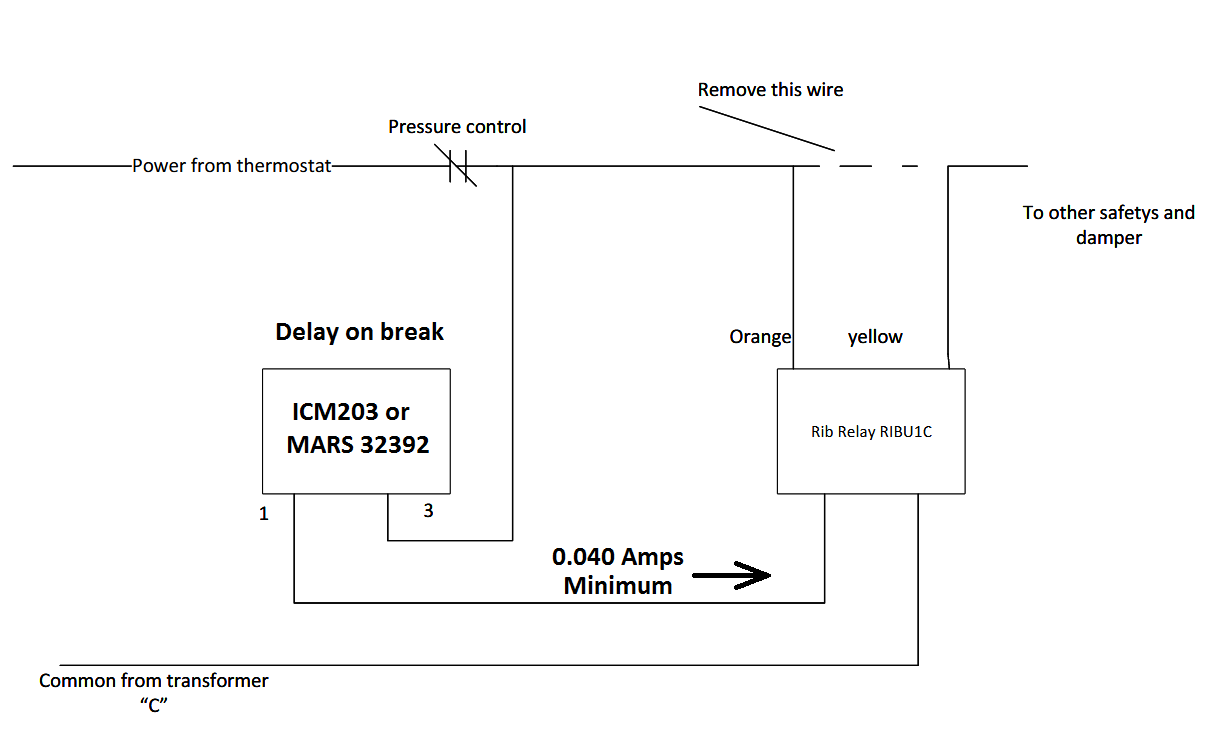

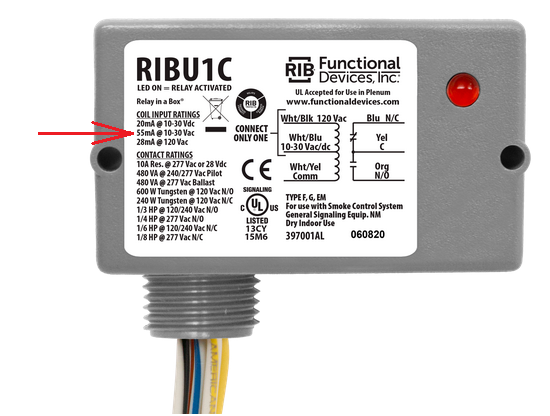

In addition you may have to have the TD pull in a relay as they (time delay) are limited to 1 amp maximum load. See my drawing attached. This should work but there are other ways.

If you still have issues then wire as per the drawing but put yellow and orange from the RIB relay between Y on the damper and 24v on the ignition control

0 -

This is easy

By placing the time delay on make between the ignition control and the gas valve MV terminals you will eliminate all the pre-purge and damper ens switch shutter of other things that will cause the delay to start when you are not wanting it to start. After the flame sensor measures the pilot and establishes it is safe to start the main burner, just delay the main burner. The pilot will stay lit for as lon as the delay is set. then after the delay, the main burner will ignite.

Of course you can also try the delay on break in the same location. That way you won't need to wait for the delay on initial start up, when the delay is not needed. If it does not do the job you need to do, then try the Delay on make. That will just confuse everyone every time the burner is supposed to start because the delay will need to expire every time. That can end up being a pain if trouble shooting some other problem in the future.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I think the delay on break makes the most logical sense. Since when the Pressuretrol trips on pressure its switch opens and at that point the delay starts. The duration of the delay disables the short cycling.

MARS 32391 (delay on make) also has the 0.040 amp minimum latch current.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I don't see a delay on 'break' working. When the pressure control opens the boiler has to shut down….its a safety control.

Besides a delay on break needs an additional wire to initiate operation.

Must have my stupid hat on

0 -

@EBEBRATT-Ed It works I have an ICM Controls ICM203F and tried it (although I don't need it on my boiler), then I reverse engineered the timer circuit. It's an interesting circuit.

Picture it this way, when the pressuretrol opens its switch on pressure the timer (an ICM203F) wired in series or logically down stream also opens its internal switch (actually an SCR) for the programed time period, say for 5 minutes. Now say the pressuretrol re-closes after 30 seconds, the timer's switch is still open until the time period expires (5 minutes). The boiler's burner is off for the 5 minute period from the instant the pressuretrol's switch opened on pressure.

Also in no way does it bypass, defeat or compromise the safety functionality of the pressuretrol, since it is wired in series or logically down stream.

https://fergusonprod.a.bigcontent.io/v1/static/428550_976890_installation

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

To specifically address your concerns in addition to my last post which was edited multiple times.

" I don't see a delay on 'break' working. When the pressure control opens the boiler has to shut down….its a safety control. "

It does work, see post above. When the pressure control opens the boiler does shut down as expected since the ICM203 or MARS 32392 is wired in series with the pressuretrol or logically down stream.

" Besides a delay on break needs an additional wire to initiate operation. "

No it does not, it is a 2 wire device. The timer function of the timer device actually is powered by a capacitor for the maximum delay of 10 minutes.

" Must have my stupid hat on "

I would not say that. The actual electronic circuit is interesting and its 2 wire operation is very counterintuitive. Which is one reason I bought one to play with and to reverse engineer it.

To steal your circuit it would work as you drew it even when using a Delay on Break timer. The only thing is the relay coil has to draw 0.040 Amps (40 milliAmps) or more to satisfy the minimum latch current. I believe the needed minimum latch current is the issue when the pressuretrol is on the control side of the damper. I suspect the control side of the damper is less than the 0.040 Amps latch current. The timer installation as @EdTheHeaterMan suggests on the main valve of the gas valve probably draws more than the minimum latch current.

Looks like the RIBU1C's coil will draw 55mA so it may work. Although I am not fond of adding an extra relay. It does present options.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

Can confirm, the delay-on-break wired into the MV circuit works quite well, with a catch:

- Initial call for heat: System fires up normally.

- Pressure limit reached: System shuts down. Timer begins (set at 2 minutes).

- About 45 seconds later, the pressure drops below diff. System begins startup sequence, opens damper, and pilot is lit.

- Boiler control sees main burner is not lit, and initiates its own built-in 5 minute timer before retrying main burner ignition.

- Pilot remains lit and damper remains open for five minutes, then the main burner lights.

This nets out to about a 6m30s delay between pressure limit shutdown and main burner re-light. Not bad!

An improvement would be a solution in which the MV breaks, triggering a timer which holds open the Limit or Thermostat circuit. This would prevent the damper from sitting open during the holding period. But this would likely mean adding another relay into the mix.

0 -

" and initiates its own built-in 5 minute timer "

That is why I was wondering if the 24 VAC input to the Intermittent Ignition Module would be a better place (in this case). I guess it depends on if the Pilot Value current is enough to latch the timer.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Good point, I missed that- will give it a try. I've got everything hooked up with spades, easy enough to experiment.

0 -

" An improvement would be a solution in which the MV breaks, triggering a timer which holds open the Limit or Thermostat circuit. This would prevent the damper from sitting open during the holding period. But this would likely mean adding another relay into the mix. "

This circuit would basically do that without connection to the MV wiring.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Another personal debate I had is, depending where the timer is inserted, is it worse to have the damper cycling extra flowing the pressuretrol state and the heat loss up the chimney (timer after the damper). Or a better timer circuit on the control side of the damper (in series with the pressuretrol), where your pressuretrol is in this case.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Thanks for the detailed explanation. I did not know those relays had a cap inside. I kept downloading the spec sheet and it tells you nothing. I was looking at Mars but even the ICM sheet you posted above doesn't explain it very well.

I ran into that before about 8 years ago when I was still working, I was sent to replace some Belimo actuators. The old ones were 24v two wire spring return. Easy. Power, it opens lose power it springs closed.

I picked up the new actuators our service manager had ordered and got to the job. No spring return. It said power open power closed so I figured I needed 3 wires. No it only need 2. Drive open take the power off and the cap drives it closed. That was the first time I ran into that. After looking at the spec sheet, I figured it out but called Belimo before I installed them as they were a PITA to change. Didn't want to do it twice.

Using the delay on make I think avoids some issues and except for the delay on the initial start you're not sitting with the damper open or having the pilot on and the ignition retrying.

0 -

@EBEBRATT-Ed There is no relay inside as a relay is commonly thought of. Its all solid state circuitry inside, Transistors (NPN, PNP, J-FET), resistors, delay adjustment potentiometer, diodes, Zener diodes, capacitors, and an SCR.

I think one of the zone valve manufactures made a zone valve that closed with the energy stored in a capacitor.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Belimo does but they are more commercial than residential. I am sure others are into it now.

0 -

One of the reasons I tend to pull in relays with a control is because I was trained that way. I used to wire a lot of building automation controls. So, if you have a controller that costs $500 or $1000 that had 10 or 20 outputs used to drive damper or valves to avoid issues each output would pull in a Rib Relay.

That way the field wiring is connected from a Rib Relay to a valve actuator. The probability of wrong or damaged or mis wired field devices like a shorted valve actuator will only take out a $20 Rib relay. Which is mounted next to the controller in the panel. The expensive controller pulls in the RIB coil so the chance of miswiring or damaged wires is limited. It also puts the load on the RiB contacts instead of the controller which only pulls in the Rib coil.

Just less probability of hurting the controller. In this case the tD costs the same as the Rib so it doesn't matter

0 -

@EBEBRATT-Ed Nothing wrong with that. I get it, protect the expensive stuff with the inexpensive stuff (and I have done that too). And often isolation can be a benefit, relays and opto-coulplers are used all the time.

In this case (specifically) a relay would be one way to solve the timer's minimum latch current issue. The need for extra protection of the timer is minimal IMO.

It seems many folks have oversized boilers and if there is an easy, inexpensive (maybe foolproof) way to minimize the short cycling situation I think that would be benefit to add to the system. However, I would venture to say most folks that have oversized boilers have very little electrical experience, so the simpler it is to add a timer device and have it work correctly the better. Many timers and pressure switches are out there, but they would be more complicated than a two wire installation.

Folks could add an EcoSteam ES-25 like product (if you still can find one) or other PLC based control and have fun with that adventure but that is more expensive and more complicated.

In general I like to keep it as uncomplicated as possible. More stuff there is, the more there is to fail (and then figure out) when you need heat.

It just seems to me as time goes on and HVAC controls have become more complicated there has been more problems and possibly less competent folks to repair them.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

@109A-5

It just seems to me as time goes on and HVAC controls have become more complicated there has been more problems and possibly less competent folks to repair them.

Very true. In a lot of cases they are IMHO adding a lot of unnessary crap to newer equipment for no real gain. ECM motor for gas furnaces cost $800 for an indoor blower motor + labor to replace.

0 -

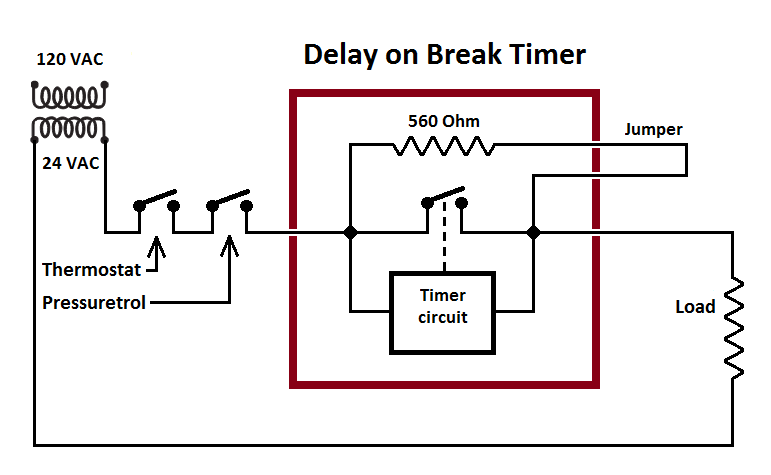

More information about these 'Delay after Break' timers.

Seems they are marketed under a few different band names and various versions (probably over time).

MARS 32392, multiple versions, with different delays, 2 and 3 terminal, all with the same part number (confusing).

Long Term QD-072

SUPCO TD-73 (Sealed Unit Parts Co. Inc.) Shorter maximum delay.

ICM Controls ICM203, ICM203F (wire leads) .03 to 10 Minute delay, rated at 1.5 Amps.

I have a ICM203F and last heating season I connected to my old steam boiler (not oversized) that has a standing pilot and it appeared to work as expected.

The odd thing about the ICM203F and apparently others is the jumper that you have to cut for the higher voltages. With the jumper intact there is a 560 Ohm resistor across the two connection terminals or wires (easy to see with an Ohmmeter). If the higher voltages were applied with the jumper wire intact the resistor would burn up since it is only a 1/2 or 1 watt resistor.

So why the need for the 560 Ohm resistor in the first place for 24 VAC operation ? May never know, I suspect it is not actually needed for 24 VAC operation but satisfied some other need for some other special application and that other special application never made it to the public documentation. I don't see any benefit to having the parasitic current through the resistor and the load when the timer's switch is in the open (or off) state, the circuit seems stable without it.

My experiments so far (24 VAC nominal) with the 560 Ohm resistor disconnected, is the timer works fine from just over 1.0 milliAmps (0.001 Amps) to over 400 milliAmps (0.400 Amps) tested so far, the ICM203 is rated at 1.5 Amps. (it actually works under 1.0 milliAmps (0.001 Amps) but the units burden voltage is higher since the SCR does not fire.

It appears the "Minimum: 40 mA" is simply to overcome the 560 Ohm resistor in parallel with the rest of the circuit, so rest of the circuit has enough voltage and current to work properly.

For folks that want to use the timer before the damper, possibly in series with the pressuretrol, I would cut the jumper. BTW with limited testing on my boiler it still works fine with the jumper removed. Probably better, no parasitic current through the 560 Ohm resistor and the load (in my case the gas valve).

I will continue with more experiments.

A video showing the circuit board of the SUPCO TD-73. Not in depth enough in my opinion.

" Edu1: Delay on Break Timer (Too In Depth Do Not Watch) "

https://youtu.be/g4keOpObPVYHere is a simplified diagram showing the odd use of the 560 Ohm resistor inside the timer.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

As a follow up: I’ve experimented with a few different ways of doing this on the limit circuit, including everything suggested here in the thread (RIBU1C, cutting out the resistor, and a few other variations).

Ultimately the Limit circuit does appear to cut completely out momentarily when the damper hits the end switch. Still not sure why, but it does. This being given, the only solutions will involve a trigger from another circuit controlling a timer on the limit. To achieve this with a break trigger, the combination of controls quickly gets beyond the simplicity that I desire for this application.

So I will be maintaining the simpler solution of one delay-on-break on the MV circuit at least until we see how the system performs in deep winter!

0 -

OK, I suspect a contact bounce type issue with the damper or some thermostat funny business.

Since the timer captures the interruption of power very quickly, about a 1/10 of a second, apparently the damper (control side) has some odd load characteristic.

I will review this more later today, I'm assuming with the timer connected in series with the Pressuretrol it causes the damper to continuously cycle ? Any more information you can add may be helpful.

Did you try the timer in series with the 24 VAC power feed to the ignition module with the jumper cut ? If so what did that do ?

The other method is if you want the damper controlled by the timer, the method that @EBEBRATT-Ed mentioned with the relay should work (assuming it is actually a damper issue and not some thermostat funny business). With the addition of a relay the timer only sees the load of the coil of the relay.

Your thermostat type ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Oops I missed that you tried the RIBU1C, was it wired in like this below in the Lt. Blue area ? This way any contact bounce or strange dropout of the load due to the damper circuitry is not seen by the timer.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

The Field Controls GVD-6 has a relay and cam activated microswitches inside to control the motor, a brief current interruption may be normal at the transition between opening and the end of the dampers travel when fully open. I don't have a Field Controls GVD-6 to prove this.

Since the timer captures the interruption of current very quickly, about a 1/10 of a second, the damper's end of travel transition apparently trips the timer. With the timer's switch now open for the duration of its setting the damper simply closes.

I would think if this is actually what is happening adding the relay (as shown above) would correct this unwanted anomaly, since the timer's load is now only the relay's coil.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

good morning

Just replaced a aquastat with a vapor stat on a Weil McLain eg 45 ( standing pilot) experiencing the same short cycling on initial heating start up

Would this ICM component work on this system as well?

any information would be appreciated0 -

better to start a new thread. You say aquastat and vaporstat. one is a water control and one is a steam control.

what kind of boiler do you have?

0 -

Good news- the RIBU1C works perfectly after all! The trouble was that the delay ended up at way longer than the 5 minutes I had it set for and I was assuming failure on the last test- I finally just let it run; when set for 5 minutes it actually delayed for a little over 9 minutes. Repeated the cycle a few times and it seems to be working consistently.

0 -

I like using Rib relays. Sometimes we don't know what is going on inside the "Black Box" of electronic controls weather it is a time delay or a Nest thermostat or something else. Isolating with a relay is sometimes worthwhile. Yes, there is extra wiring, but I also like the red indicating light.

0 -

OK, good, you had me very curious why with the constant load of the relay coil it did not work as advertised.

Although the delay being longer now has me curious. Since the delay is simply a capacitor discharging through a resistor. The delay being longer seems odd.

With my ICM203F the delays are pretty close to what the knob setting states, as much as I have tested it.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Testing beautifully during this morning’s 62 to 67 recovery. Did the math: What would’ve been 30+ firings with the vaporstat alone took just 3 ignitions today with the timer. The 9 minute rebound seems about perfect- it allows the system to breathe out, all the vents to open, and the radiators are still hot but also just getting ready to take fresh steam on the next cycle. So the “on” period is much longer as well. Really nice.

0 -

Good, it is working to your liking.

Question; 9 minutes delay, if the timer is set for 5 minutes how do you account for the other 4 minutes ? The delay should start as soon as the vaporstat opens its switch on pressure, closing the damper and shutting down the burner. Within that 5 minute period the system pressure should drop off and re-close the vaporstat. When the 5 minute timer delay period expires I would expect the timer's switch to close energizing the relay, opening the damper and the burner to restart.

I could see the extra delay when the timer was on the MV wire of the gas valve, the restart delay of the ignition module, but not now, since the damper should completely de-energize the Ignition Module.

BTW interesting how close you have the Main 10.25 Oz and the Differential 9.5 Oz of the vaporstat for the most delay there.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Probably 4 min to get steam back and moving.

0 -

Maybe, I was not really thinking about the actual time to regain steaming, although with only a 5 minute delay, taking 4 minutes to get back to steaming seems excessive to me. I'll have to try it on my boiler.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

I like @109A_5s diagram adding the RIB. He has a head for this type of stuff! As I have a face for Face for Radio…. Glas this is up and working for now. Perhaps experiment in March just in case

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

@EBEBRATT-Ed I timed my boiler. Boiling for a few minutes, then interrupted for 5 minutes, then restarted, it was boiling again in about 30 seconds.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

You could test it independently of the heating system. Assuming your Mars MARS 32392 is basically the same as my ICM203F the timing circuit should be fairly stable, it is pretty simple.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements