Install Time!

So you fellows have provided me with great information in the past months! Now it is install time.

To review I have a radiant floor heating system retrofit that used a coal stoker boiler. I am switching to a NG CI Weil-McClain boiler. The old boil is out and the new is sitting and ready for install.

I am very fortunate to have a former hvac company owner that will help me with the installation! In fact he did the coal boiler 16 years ago.

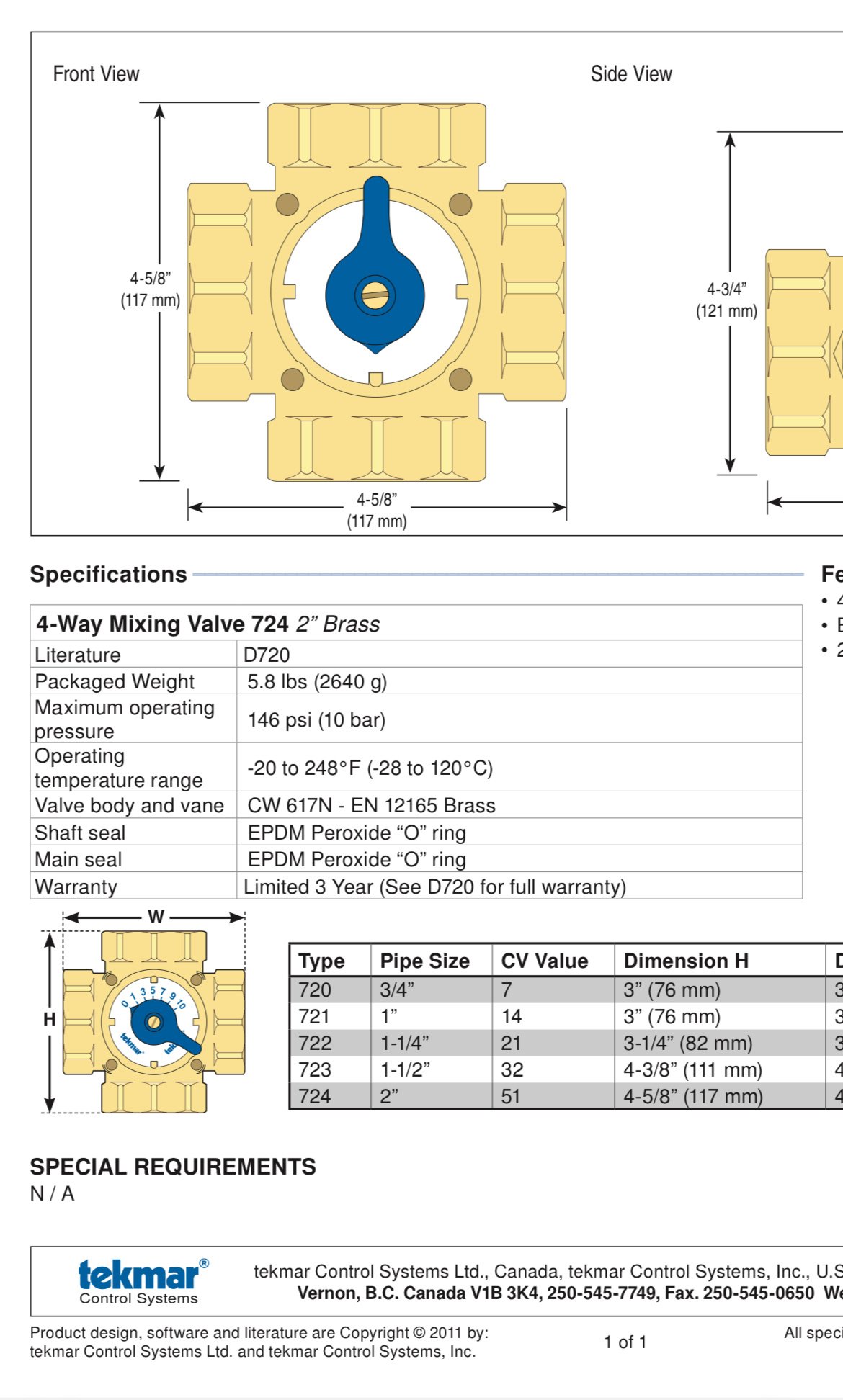

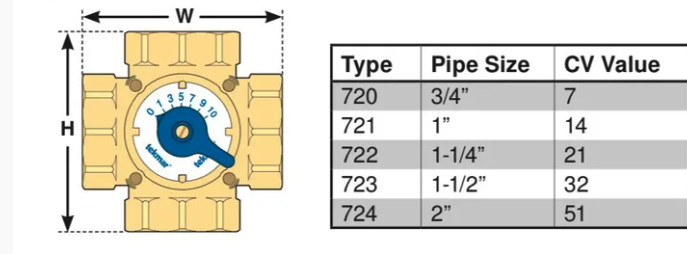

So here is a question. Yesterday we were looking at the setup and as will need a 4 way mixing valve I mentioned that I would get a Tekmar. He wasn't overly thrilled. So I was wondering what alternatives I have?

It needs to be 1.25",I want outdoor reset also.

I started looking at Taco but 1.25" doesn't seem available.

Suggestions would be great!

Thanks

Comments

-

the valves and actuators are all about the same. Its the control that drives the actuator that is key. Tekmar is probably the most common, been around for 25 years or more

The rep in Denver for tekmar is one of the best.

Are you sure you need an 1-1/4?

You size a valve by the Cv number not the connection size.

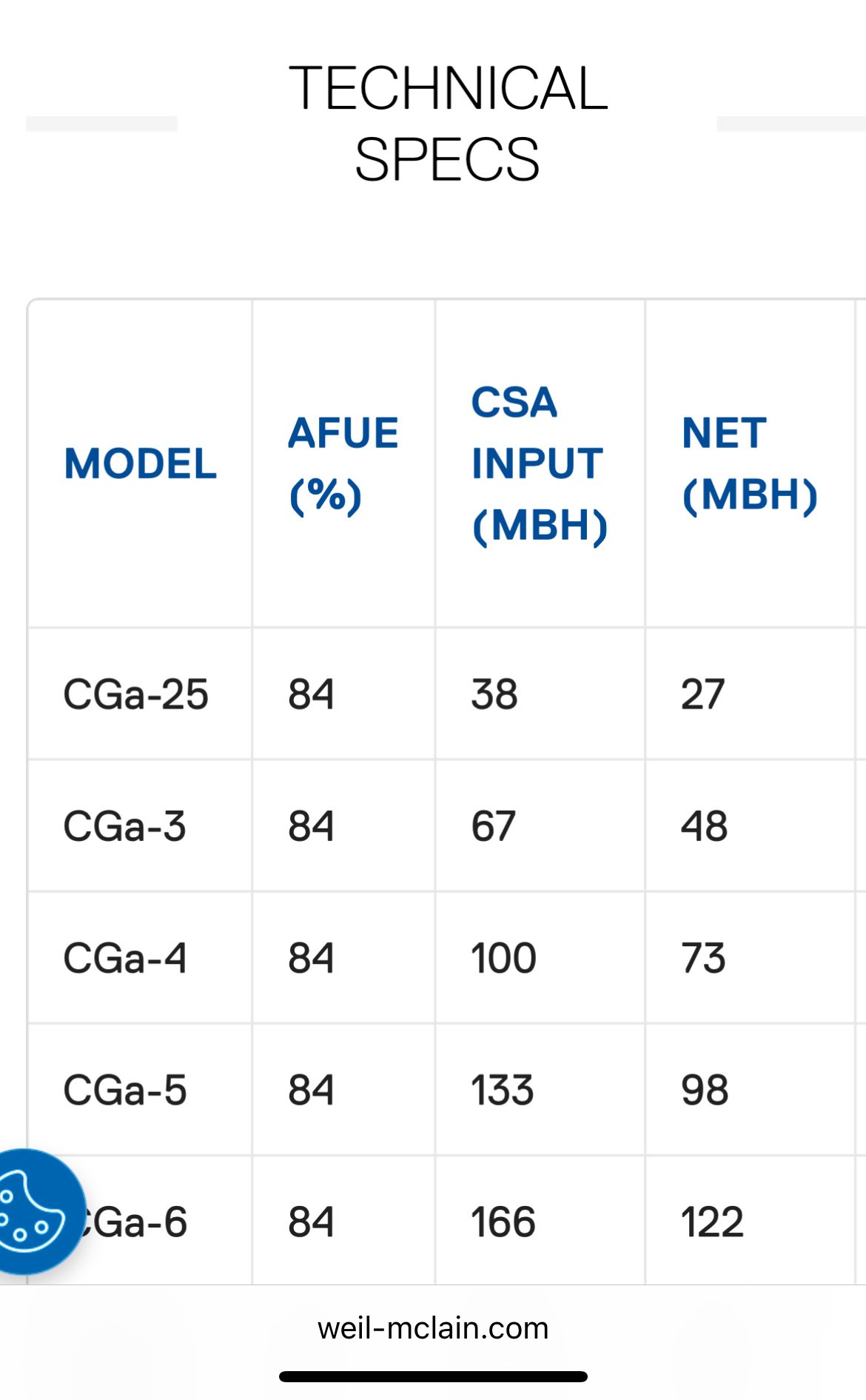

The 1” tekmar is a 14 Cv so14- 18 gpm without a problem. That would be a 140,000 btu/ hr boiler, what size do you have?

I have not used the Taco, I think it has a few dip switches for prigramming choices. The tekmars generally have a digital readout and more programming options, if that matters?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Bob,

Thanks for your reply. The Weil-McClain CGa3 is 67,000btu. The reason I was thinking 11/4" is the old 3 way is/was 11/4" and the copper piping is also 11/4".

So it appears I can go down in size even though the piping is 11/4"?

Tom

0 -

is 67,000 btu/hr input or output? you need about 1 gpm per 10,000 btu/hr so if that is output of the boiler you'd need a valve with a Cv of about 7.

0 -

It is 67,000 input.

0 -

look at the output number on the boiler and then take the altitude derate. I think you are in the mountains above Denver?

48,000 is the net output taking into account the 84% efficiency

Then derate 4% for every 1000’ altitude above 2,000’

I’m not sure the calorific content of NG is out there these days, if you are on NG?

Actually a 3/4 valve has a 7 Cv4 gpm may move all that boiler will give you

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Bob,

I live in NE Ohio

0 -

Sorry, confused with another DIYer. Use the 48 K number to size around.

You always want to size any control valve close to the gpm load. If not the valve hunts around loses it's resolution.

It may seem silly, but a 3/4 tekmar 720 is the correct valve for a 5-6 gpm load. They are a pretty wide open valve, not much flow resistance.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Bob,

Thanks again for your advice and help.

So it is reasonable to use a smaller 4 way mixing valve even if the piping is a larger diameter?

0 -

yes, everything in the system, pipes, fittings, valves, pumps should size to the load, defined in gpm

Cast boilers often have large connection as those sections get used in larger output boilers

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Had a good conversation with the Tekmar rep! All set.

The Callefi auto fill valve arrived yesterday and that's my project for today!

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements