Staged boiler retrofit design questions

Hello all,

I have a job coming up for a church in a remote village in Alaska. The existing system was designed by one of Dan Holohan's "Dead Men", a mechanical engineer in 1993.

The overall job is the replacement of two oil fired Burnham V78s with two new oil fired Burnham EMP336s. It is not in the budget to do a full mechanical room overhaul, and the engineer's I consulted were also not affordable for the congregation, so I am going to have to work with what the Dead Man left me:

A return manifold of circulators pumping towards the pressure tanks and boilers. A Tekmar 252. The current boilers are not piped as primary/secondary and upon inspection, the tekmar was never actually wired to the boilers. The low voltage wires were run to the boiler's controls, just not actually landed.

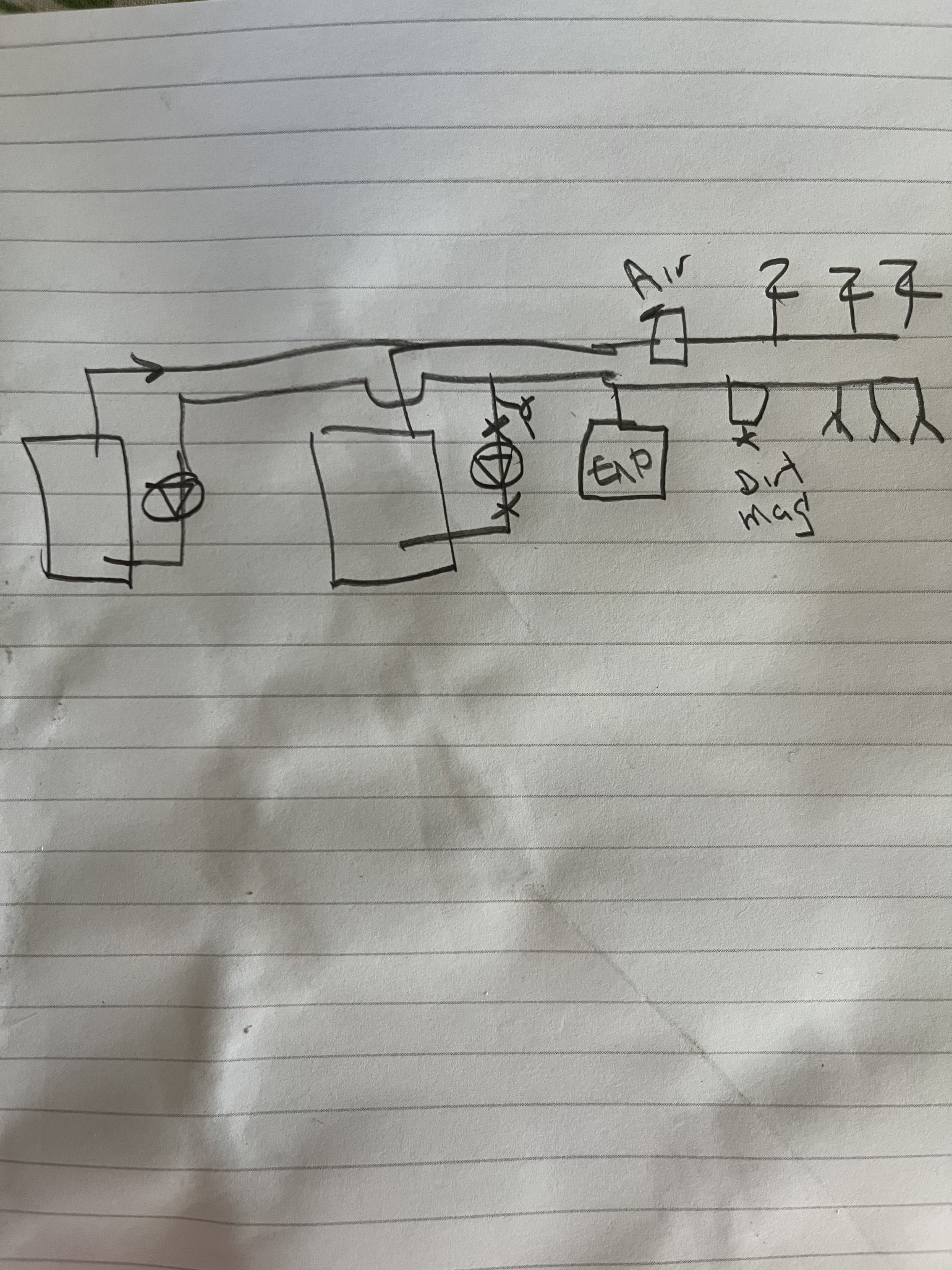

From my self-education using Dan's books and Siegenthaler's book, I am thinking that this should be a relatively simple enough installation to accomplish, as far as building a primary/secondary loop system goes. The new boilers will be flipped 180 degrees from the old ones, and as far as I can see, I should be able to run a design similar to the one on page 135 of Dan's book "Hydronic Radiant Heating" where each boiler is it's own individual secondary loop that can fire using the Tekmar to cold start when it's that boiler's turn.

My hang up is I am not understanding if I would still require a primary circulator or would the zone circulators accomplish that task? Also, being that the circs are pumping into the manifold, how would I pump away from a pressure tank, unless I built a circular race track with a primary circulator installed downstream of the PONPC?

Here are some pictures that I took and a hand sketch with sizes.

I would appreciate any knowledge or tales from those who have experienced similar design situations.

Thank you!

Mark

Comments

-

-

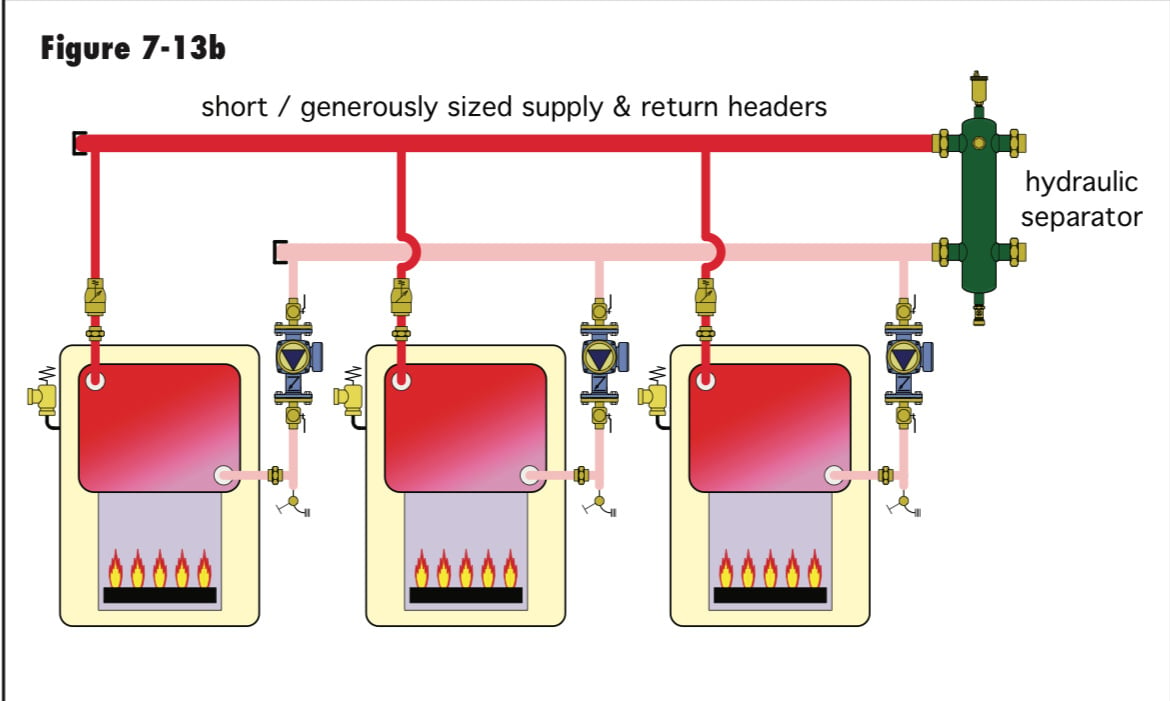

If you don’t need multiple temperatures or have high pressure drop boilers, parallel piping is fine, and they can still stage

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

You're exactly right, they have what we called "knockout spools" in my big pipe days. It's pretty common in the bush from some well meaning handyman to do anything they can to get a boiler running based on their knowledge. Especially when it's -40!

By the way that's a very nice "crude" drawing!

0 -

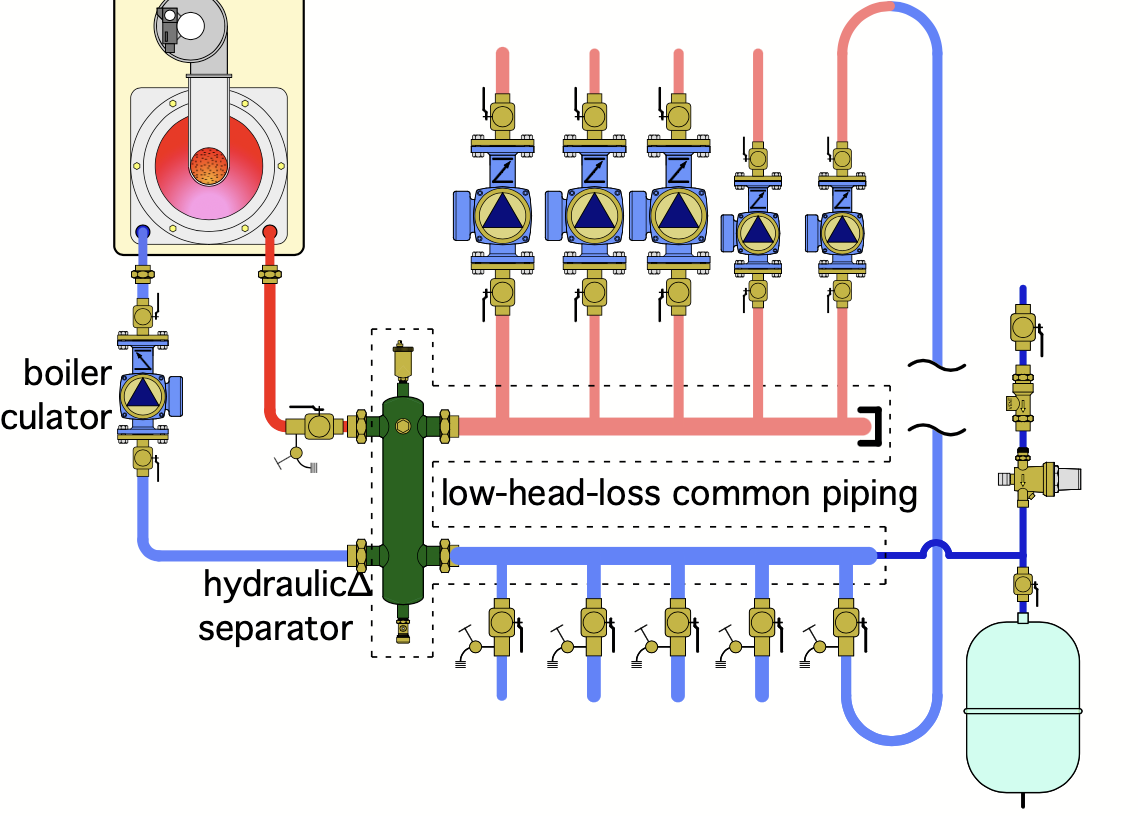

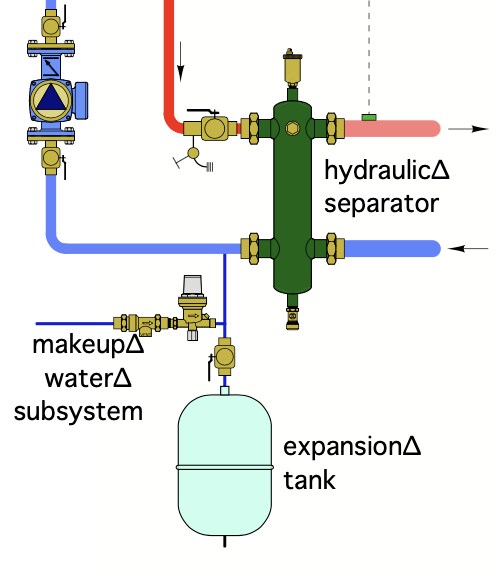

You have some flexibility with expansion tank placement when using a separator. Often it is right at the sep on either return.

Or at the end of the header, this works well with base mount expansion tanks for example.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

I would not pipe with parallel flow only with that many zones and circulators. I know many say that a cast iron boiler does not care about flow. But I care about flow with any heat exchanger. I would use primary secondary of some design. I think any HX especially a direct fired one should have full flow through the boiler. JMHO

0 -

-

Thank you for the suggestion. I will read up so I fully understand how to accomplish this.

0 -

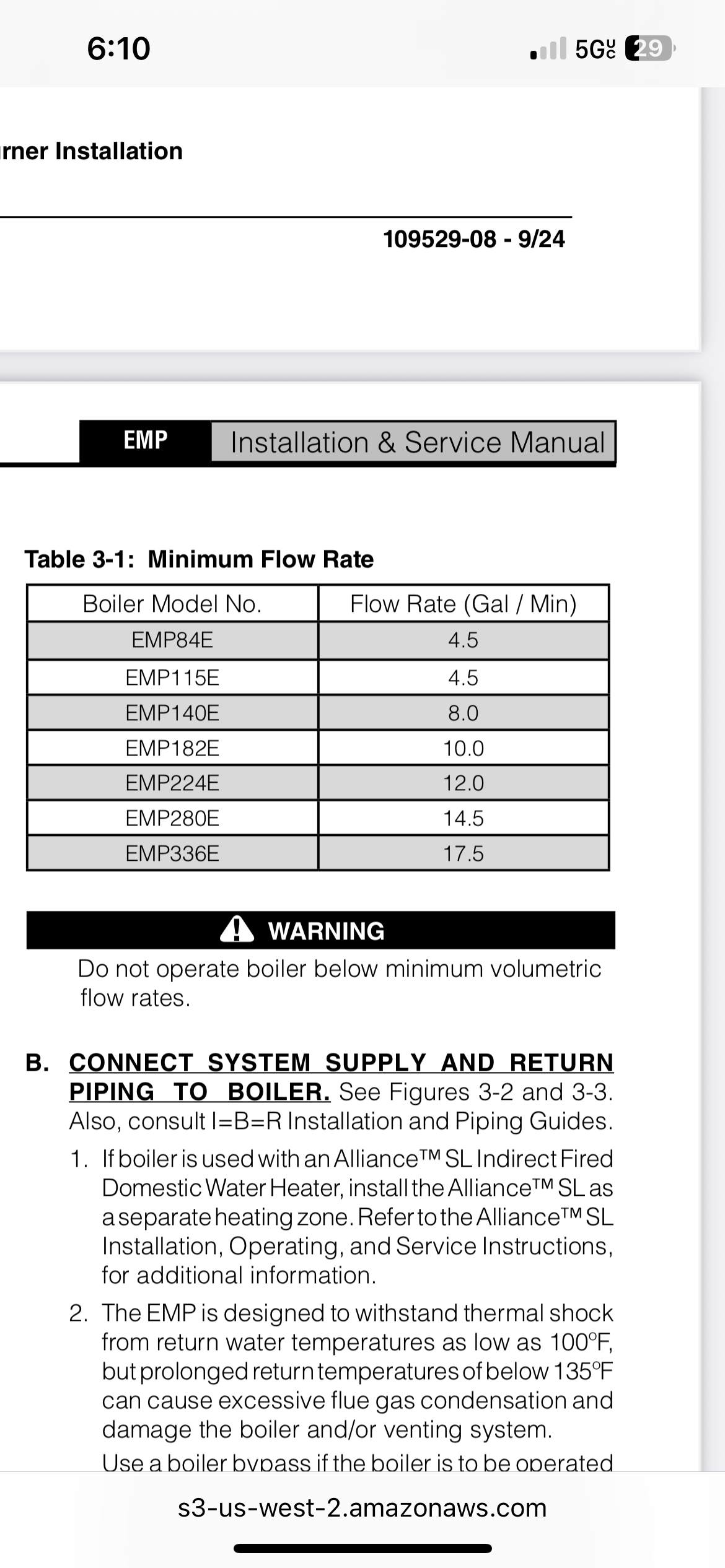

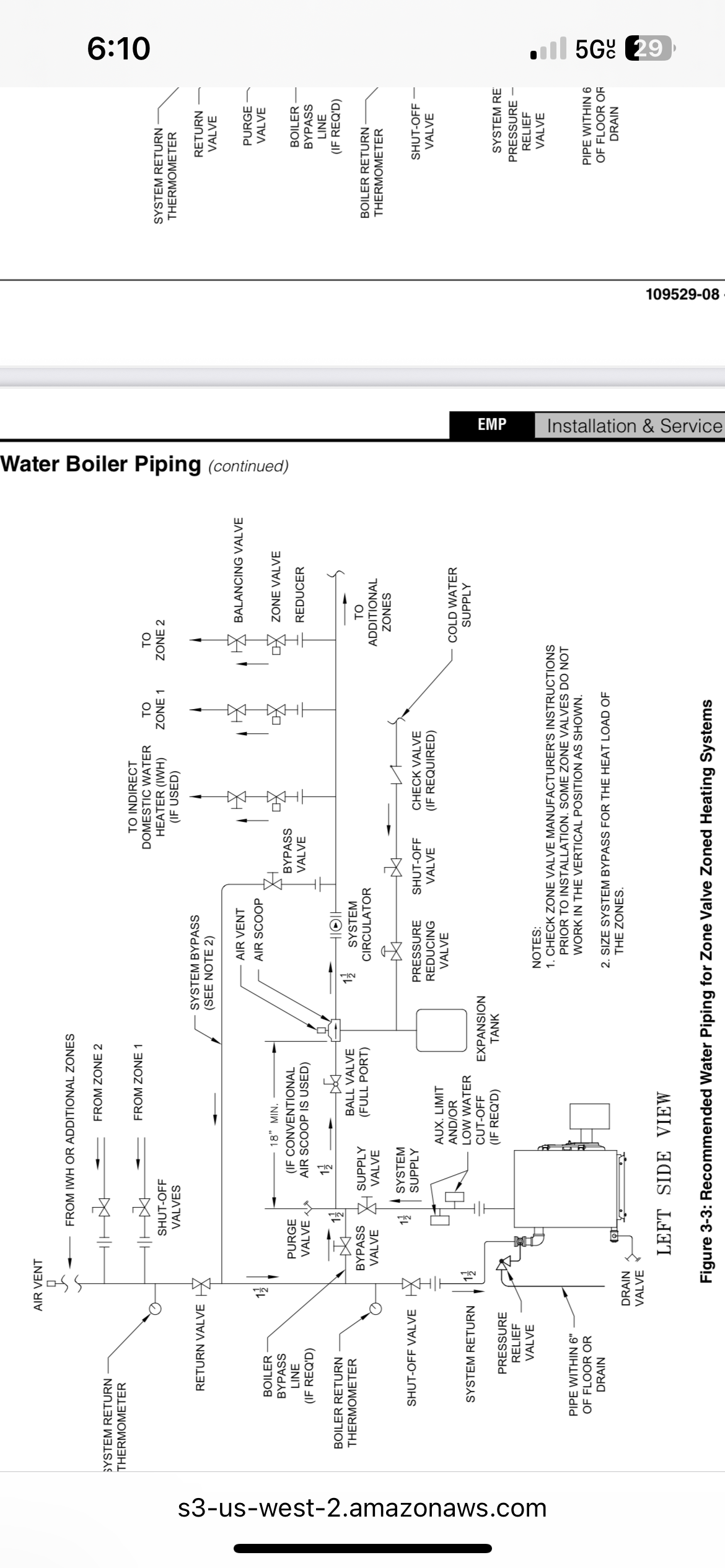

the manual shows piping options and suggested flow rates

A hydro sep would assure adequate flow same as the bypass piping they show

You could confirm piping designs with Burnham tech support

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

two boilers, two pumps into a hydrosep and you are fine

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements