Professional opinions please

I know enough to be dangerous!

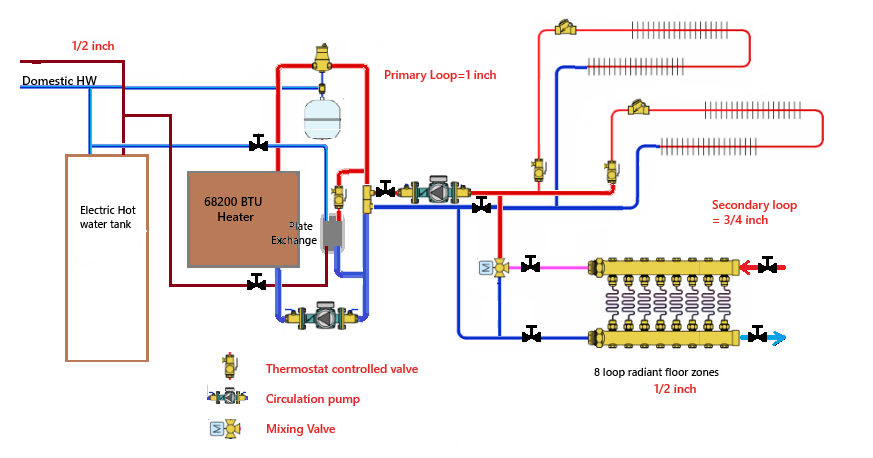

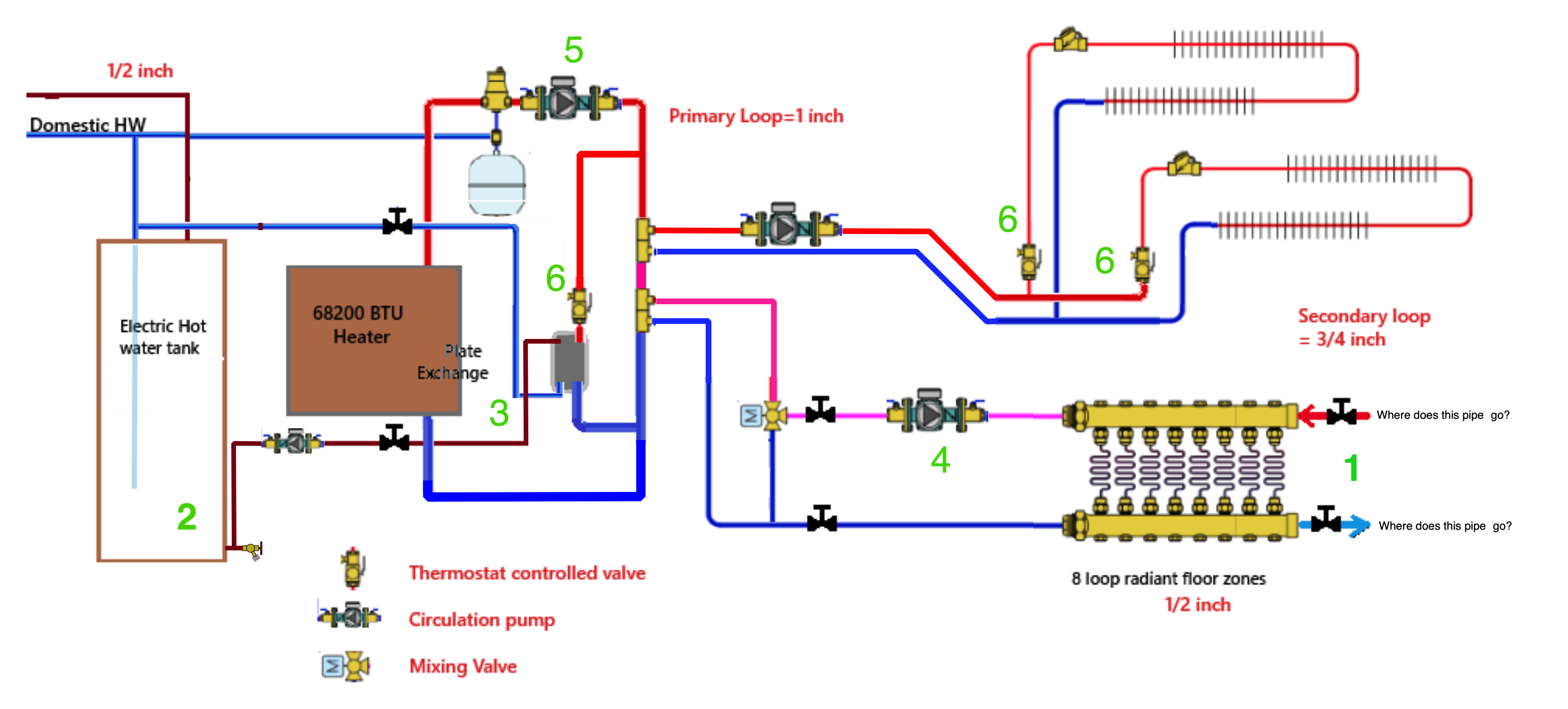

What do you think of this design. The heating/load loops are existing so there's nothing I can do there.

My concerns are the primary/secondary loops and pump layout as well as top up feed and tank location

Comments

-

Your secondary circ is backwards. And when you do turn it around you may have an issue with the mixing valve.

Your primary circ is ok but I would move it to right after the air eliminator.

And unless there are some more valves I don’t see a way for your cold water to want to go thru the heat exchanger, then on the way back it just bypasses the tank.Caleffi Idronics have many free resources regarding proper, proven, best practices, hydronic piping, all free.

0 -

-

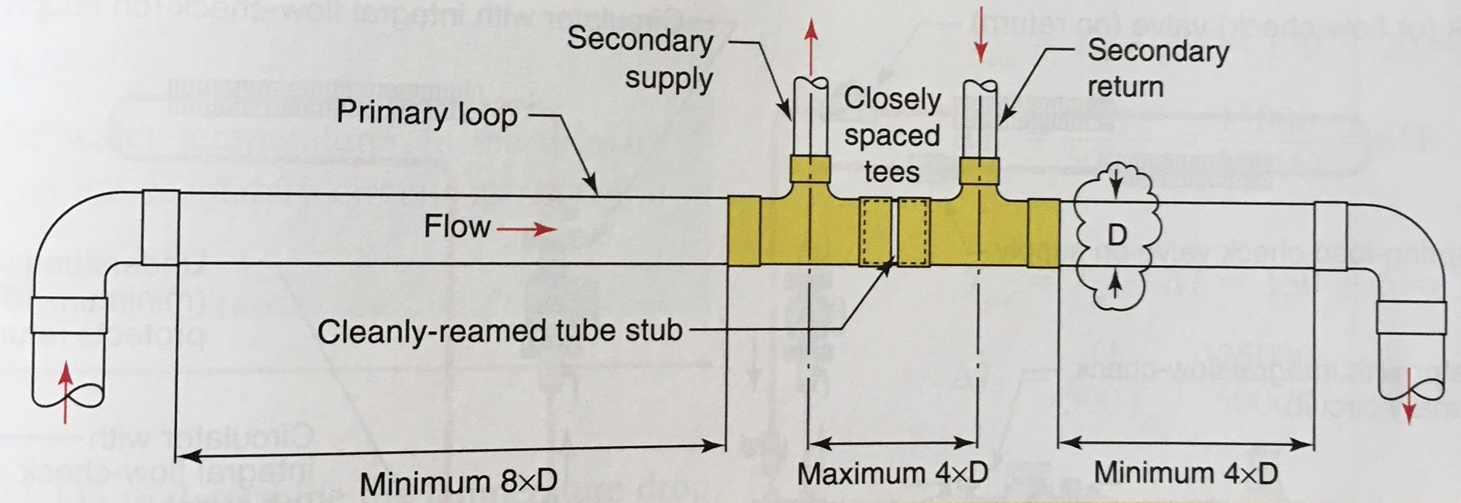

Are you showing 2 Closely spaced Tee's right beside / one after the other.

I wasn't away this was possible

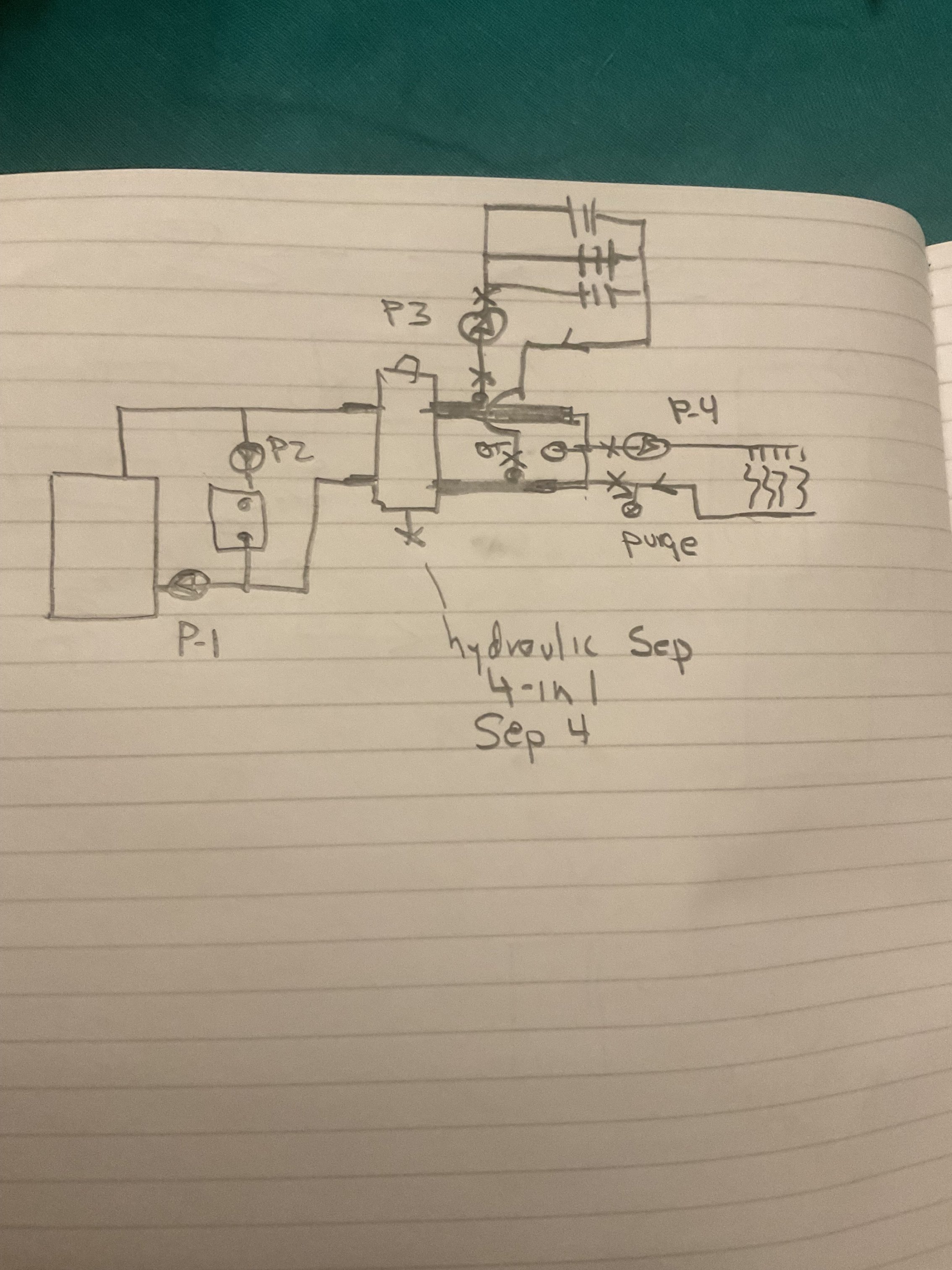

I see lots of inaccuracy with my drawing …..the mixer is a manual set mixer0 -

My Primary pump is a variable speed the secondary I'm not sure how to spec because I don't know anything about the piping and layout in the existing building.

This is true for both the column radiators upstairs and the in=floor down stairs.0 -

that is how primary secondary piping works.

0 -

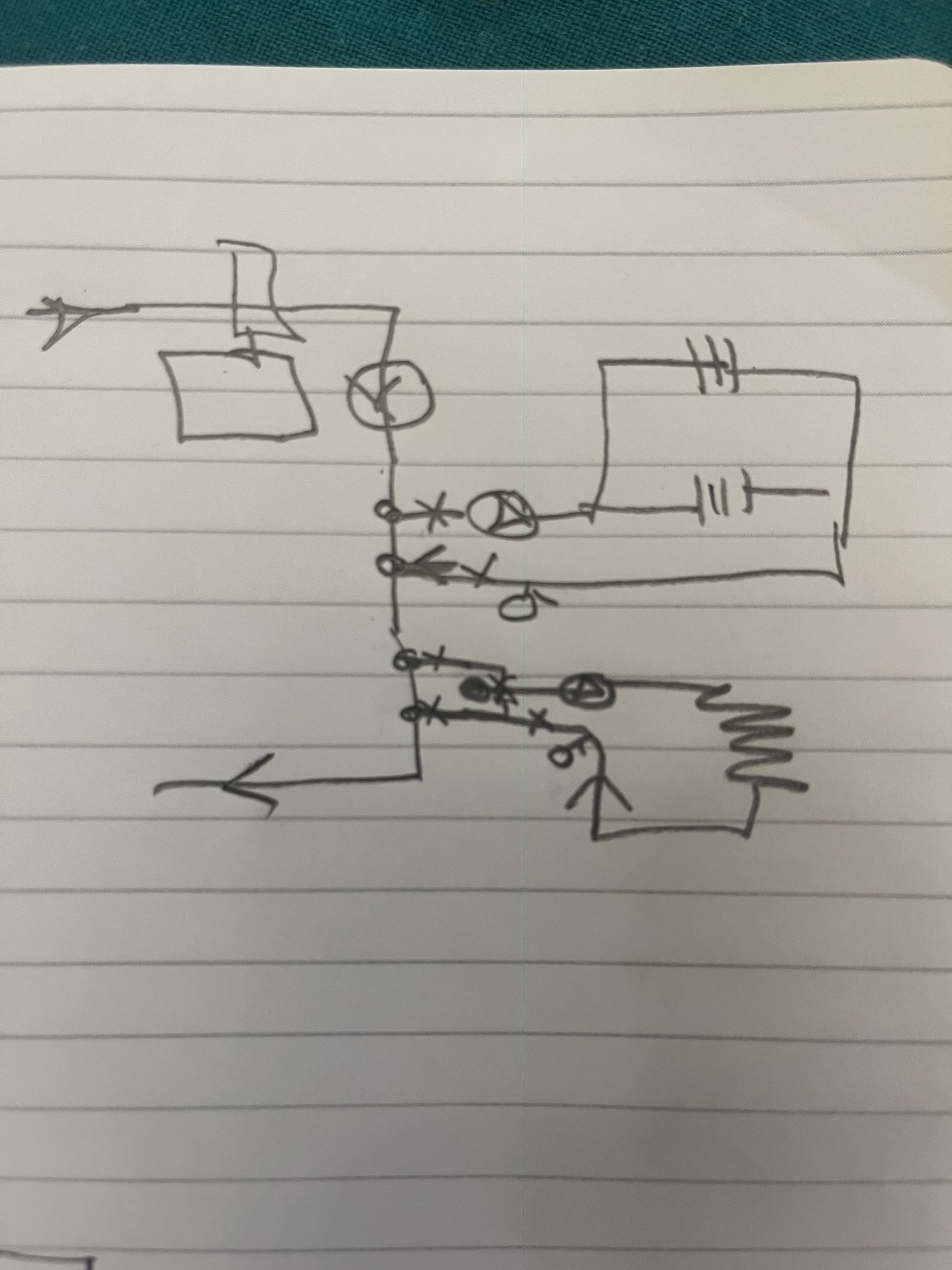

This is my intention but HotRod is suggesting two of these to create two secondary loops

0 -

a hydraulic separator is a great option. It gives you air, dirt, magnetic, and hydraulic separation in one device. Quick and simple to pipe.

I added a HX pump, I’m not sure how or when that circuit is operated? Does it just maintain the hw tank temperature?Expansion tank connects at either of the lower sep connections

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

If you use an oversized plate HX, it will have very little pressure drop so you can put it right on the primary loop. You will need a small circ on potable side as well. This is pretty close the setup I run. The aquastat on the tank triggers the boiler once the loop is up to temp, the tank circ turns on.

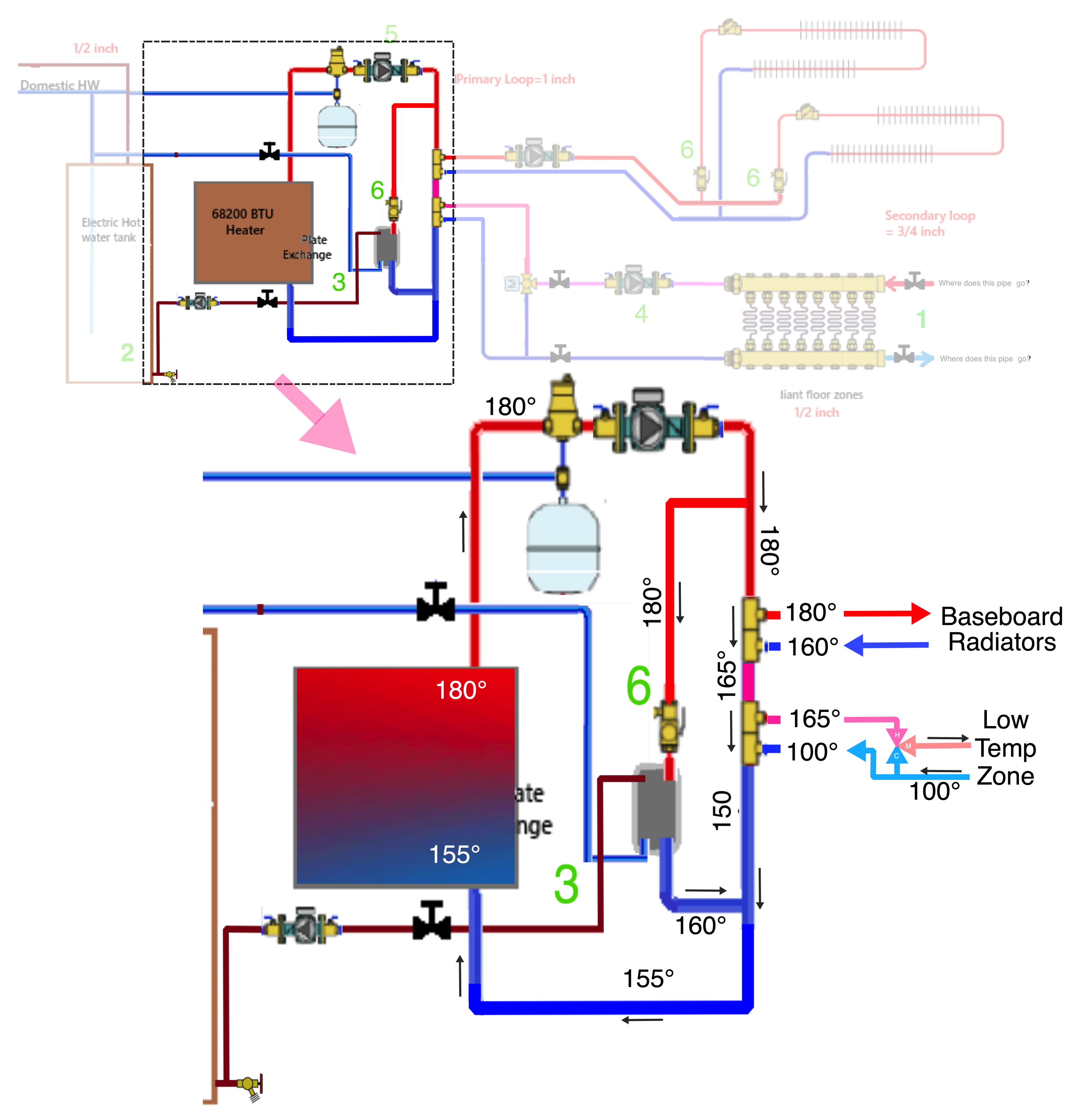

I like @hot_rod first sketch this way the floor heat can use the return water from the high temp loop. If this is a modcon, that will help lower the RWT which improves efficiency. If this is not a modcon, you will need some condensation prevention control on the boiler side.

0 -

I know enough to be dangerous!

I know enough to be more dangerous!

- Where do the valves on the radiant manifold go to?

- I 'm not sure this is the best design but I like to put the HX potable water heat at the bottom of the tank and let the heat rise to the top of the tank until the bottom thermostat shuts off the pump. If needed the 220V top element and thermostat can be there in the event the HX can't keep up and the top of the tank gets cold water that high, while the bottom thermostat keeps operating the HX heated water. The top and bottom thermostats are wired with different voltages and the bottom electric element is abandoned.

- I think the HX flow needs to be reversed on one side for best results

- Need Circulator to move water from Mix to the radiant floor

- Best practice is to pump away from expansion tank for air control

- What is the model number of the thermostatically controlled valves? Are they just regular 24v. electric zone valves?

I think this is close to @hot_rod Bob's first drawing.

I hope this helps.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

-

I would like to take full credit @Intplm. However this is the OP's drawing with some modifications. I find that using the original drawings from the OP (any OP) makes it easy for them to understand the minor changes that improve the design.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

You can definitely have more than one secondary loop off of a primary loop. It can be done when you have a higher temperature loop as the first takeoff from the primary. When that loop returns cooler water to the primary loop the water temperature will be lower. Then you can take the next secondary loop off of that lower temperature primary loop water to feed the lower temperature radiant loops. It works out great for your application. If you are also using an indirect water heater, then you would want to place that loop first, the radiators second and the radiant third because you want the hottest water to provide the greatest recovery to the indirect tank.

Here is how it might work. These temperatures are examples and may not be your actual temperatures.

- As the 180° water leaves the boiler and reaches the first secondary loop,

- The circulator for that zone will draw 180° water and use the heat in the zone and…

- Return 160° water to the primary loop.

- The primary loop temperature will then drop accordingly depending on ∆T and flow rates. That may result in 165° water for the next secondary loop.

- Since that needs a lower temperature, that is not a problem, the 165° primary loop water will then feed the low temperature loop mixing valve with 165° water

- To the Hot side of the mixing valve

- The temperature will drop to 120° to the low temperature zone and return at 100°.

- The 100° water will mix with the 165° water to yield the 120° low temperature water required by that zone.

- The balance of the 100° return water will then enter the primary loop and drop the temperature that returns to the boiler.

- That might be 150° in this example.

- That will then mix with the water returning from the HX for the DHW tank.

- That will then return to the boiler at 155°

It's all quite simple and I hope that you can see everything as clear as mud.

Yours Truly

Mr. Ed

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I'm still looking for your publishing 😉

0 -

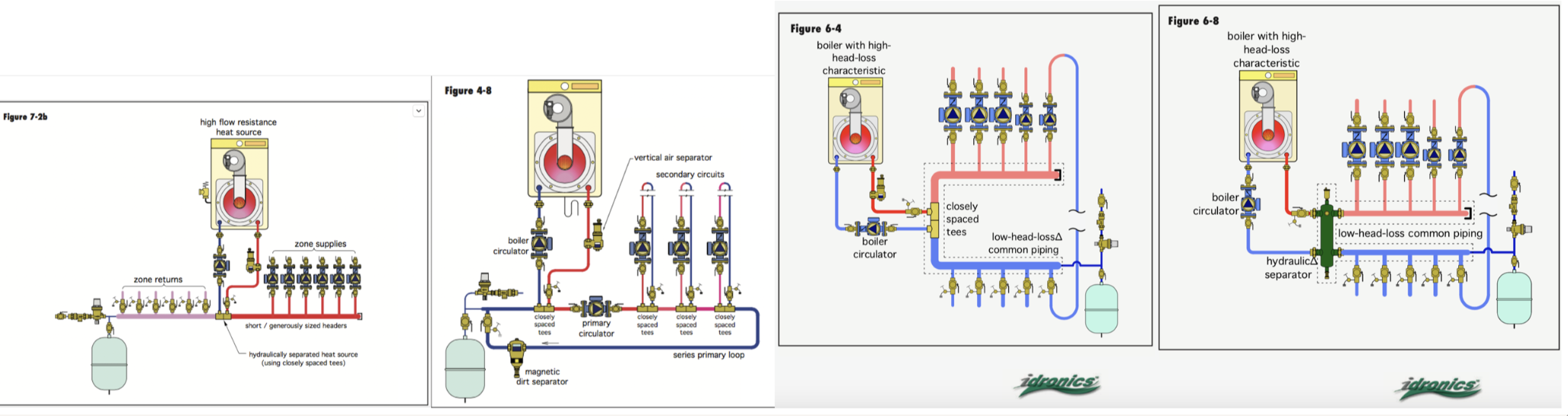

The series primary loops have pretty much gone away. The temperature drop from sets of tees only works when all three zones are activated, and it cost you one more pump, to circulate the loop.

With any of the parallel piping, all zones always get the same temperature, the mixing device lowers any zone needing low temperature.

Here are some P/S examples. Second from left is the series P/S.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements