indirect tank deterioration

got a triangle tube phase three smart40 that I got off a job so it doesn't owe me anything. it purportedly leaked although I never saw the leaking installation, but I put it in as a heatexchanger next to an old snowman with straight high low connections to the boiler water external 'tank' that is carbon steel (as opposed to inner tank stainless steel) that has high and low side taps. so it circulates boiler water thermally and i've got infloor radiant running off the interior stainless tank (that radiant is from before the daze of oxygen barrier, indeed some of it is from before the days of pex, its polybeautiful).

so ten years to my installation I noticed leaking around the upper nipple from the boiler last year. the connection is above the low water level for the boiler and it was minor so I just let it be til the end of the season but getting ready for next season. I was worried that the black nipple right attached to the top tank tapping that showed the most corrosion might have rotter through; but upon disassembly it still had enough integrity to back out of the pipe threads in the tank in one piece, can't really tell if it has a leaking path through the corrosion. guess I could set up a test but I'm going to replace it anyway. at first blush i'm tempted to stainless or brass but that would potentially force corrosion toward the tank which might itself have the pinhole near this tapping already, or toward the steel nipples in the short run to the boiler.

hindsight being 50/50 i'm thinking an annode would have been smart but because the entry is tangent to the tank from the side there is only maybe 3/4 of an inch before you would hit the stainless inner tank so i'm wondering if there is annode style that I could use in this case, perhaps in/as the first pipe nipple? i see various powered annodes as well but they mostly seem to still have a form factor for some insertion into the tank. I supposed if one of those had a flexible probe I could slide that between the inner and outer tank walls through the tapping.

on the one hand it is handy that the corrosion is happening closer to or in the indirect tank so I am less worried about any corrosion on the boiler end of these short lines that could hazard my ability to connect. and maybe this is occuring because of the stainless tank? and that is always going to be proximate to the carbon steel outer shell of the phase three tank. getting to wonder on a tank that retails notably over a grand why they wouldn't just make the outer shell stainless also . . . yeah, might add a few hundred more but if I were actually buying one instead of repurposing stuff I collect on the job I'd prefer to protect the investment and there doesn't seem to be a good annode option in that design.

of course there isn't even a drain for the inner tank, i had to pump that out so I could twist the unit to work on it once loose. but putting a drain with a tee into the inner tank still wouldn't really solve getting an annode into the fluid of the boiler side jacket. maybe a top connection that goes down into the outer jacket would provide for annode installation. not really sure if annode has to be, or preferably would be, in the boiler fluid or if installing an annode into the inner tank radiant floor fluid siude would attract the dissimilar metals corrosion away from the outer tank anyway.

couple of weeks b4 i gotta have the heat working so I'm just weighing what materials to use to put it back together. thanks, brian

Comments

-

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

So to be clear you have this tank and it is connected to the boiler with carbon steel and iron pipes and fittings Correct? The inner SS tank is connected to a floor piping system with no oxygen barrier Correct?

Where is the corroding pipe nipple you are concerned about? On the top tapping that enters the inner tank? That all needs to be non-ferrous metal along with non-ferrous pumps and accessories. That is because the PEX and “Polybeautiful” pipes are allowing oxygen migration into the stainless tank with the ferrous metal nipple.

OR …is it on one of the side tappings that connect to the closed system where the boiler water is? That should not need any special non-ferrous piping

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

He said the corrosion is happening on a side port. Even the "sausages" anode wouldn't work. I think the newest TT tanks now DO have both inner and outer tanks as stainless steel.

0 -

@EdTheHeaterMan its side port as @psb75 noted. the circuit with pex and polybutyl radiant is all non-ferrous near boiler piping. the area where I am experiencing leaking is the top side tapping. as of yet I don't know for sure if it is the first nipple that exhibits a significant corrosion on the outside or the tank immediately adjacent to where the female pipe tapping is welded on.

this hyrdronic circuit receives actual boiler water from the cast iron steam boiler and the upper and lower tapping on the TT were particularly convenient to come straight off a couple tappins on the boiler for thermal circulation. now that water doesn't have lots of exchange but I do use some makeup water and of course there is air over the water in the boiler so I would imagine you would get some dissolved oxygen when the water is sitting and not heating. But the circuit it is entirely steel and cast iron excepting that this water flows over the outside of the stainless tank in the TT indirect. So there has been very modest ubiquitous corrosion as you see inside a steam system but nothing leaking and the boiler is maybe 75 or 80 years old. whereas this nipply displayed distinctively different extent of corrosion. i wish I had taken a picture b4 I took it apart but I'll see if I can line up the pieces although i've knocked some scale off the nipple looking to see if I could detect a crack or pinhole, which i couldn't.

so my first inclination was to put a stainless or brass nipple in place and put it back together, but then I thought that if this is for some reason the focus of galvanic corrosion in this system–perhaps being the hottest water connection located the closest to the stainless, i.e. the only significantly dissimilar metal in that boiler water loop–I would likely just be moving the focus a little rather than eliminating the problem. so maybe I should just put a new steel nipple in, but I got wondering if there were a flexible or compact annode I could also install.

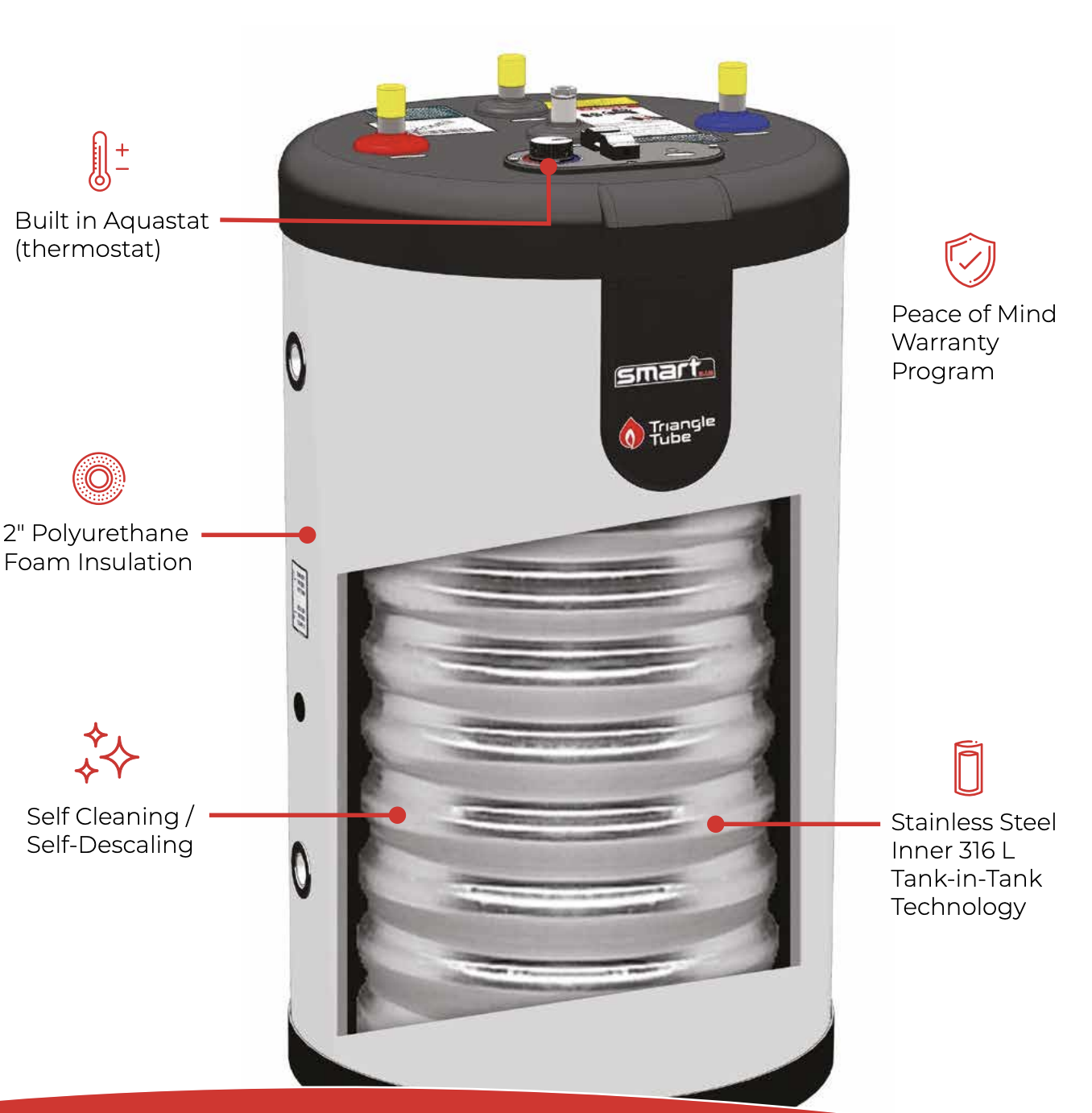

would be nice if both tanks on news ones are stainless as @psb75 is thinking. I could surely come by another used tank to take me through another 10 years but the placement and spacing of the tappings is particularly convenient to this installation to the point where I might justify buying another TT if I thought I was getting more of a lifetime tank. Although the pic from the sell sheet pic ed posted notes a stainless inner tank stainless but doesn't mention the outer tank making me think it is not stainless, but not sure how old those promotionals are.0 -

@archibald tuttle said "this hyrdronic circuit receives actual boiler water from the cast iron steam boiler"

Their in lies the rub…. Steam boiler water is an open system, therefore lending itself to constant oxygen infusion into the boiler water. That nipple may have been made of material that is less resistant to the perils of oxidation lending itself to a greater instance of corrosion that other parts of the hydronic system. Or perhaps that was the only fitting that rendered a small leak to allow the rust to make itself visible on the exterior of the pipe whilst the rest of the wet portion of the system has only interior signs of rust and corrosion. This is typical of steam boiler systems below the water line. Perhaps a boiler water treatment plan can be implemented to retard the corrosion process, as is done on many steam boiler systems.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

If it is a snowman boiler it is more like 100 years old, mid 80s at least. In the 30s they started being replaced with jacketed boilers.

The target market for that tank is modern hydronic systems which are closed so there is no need for stainless or an anode.

0 -

@mattmia2

"target market is modern hydrnoics systems . . . no need for stainless or an anode"

welcome to my world, I always gotta do it different!

"target market is modern hydrnoics systems . . . no need for stainless or an anode"welcome to my world, I always gotta do it different!

@EdTheHeaterMan"Perhaps a boiler water treatment plan can be implemented to retard the corrosion process"

since this seems to be a sacrificial nipple and the rest of the system isn't suffering i'm not likely to go way out of my way to treat the water. i gotta look around and see if I got any of the basic additive. i know the water is acidic. but meantime what say you (all) about material to replace the nipple (top nipple to the left side of the union in the photograph (i'm gonna change the union out too.

0 -

with everything rusty on the outside there either you have a lot of moisture in that basement or the boiler isn't drafting well.

0 -

@archibald tuttle asked: "but meantime what say you (all) about material to replace the nipple (top nipple to the left side of the union in the photograph (i'm gonna change the union out too."

Answer: A new one!

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

@mattmia2 draft is good, got spill switches and ck. chimney. basement is damp on its own and various water lines like to let go (mostly my original sweated brass copper tubing to pex converters. just had one go today. i've repiped the house like 3 times. the copper was pinholing when i got there and i replaced it all with ridgid K back inn late 1980s and now few problems with the tube although mostly with those fittings where I went over to pex up to sinks and stuff like that. so now i'm going to plastic fittings, little bit less flow but the water is acid. it's great water and not too much iron or sediment but its rock water.

and i'm slowly angling towards home run pex but currently its 3/4 copper mains and 1/2 tangents.0 -

@EdTheHeaterMan i reckon it will be new, but black iron or stainless or brass?

0 -

stainless might be the most compatible.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Powered anodes are a lot smaller, if you add in a longish nipple and a T you can get one into the top port, just make sure when tightened the anode does not touch the inner tank.

0 -

stainless was my first instinct but in theory it is further from steel than brass on the galvanic series when its passive but closer when it's active. i'm not really sure how that translates into it contribnuting to the corrosion of adjacent steel fittings or whether, if its passive, i.e. coated with an oxide of chromium i think, it is nonetheless effectively the active agent in encouraging corrosion elsewhere because of the greater distance in the galvanic series.

i talked to triangle tube, and the new units are stainless tank inner and outer. tech said some folks put an annode in the auxilary tapping , but that goes into the inner stainless tank, doesn't afford you a tapping to the outer jacket space. so I don't know if that would still help systemically and how much versus having the anode in the boiler water side but i would have to put it in a tee with a long nipple where the best I could hope for by carefully sizing the tee is for the end of the annode (powered or passive) to protrude into the flow from the boiler from the branch of the tee. my installation does not all me to put the boiler flow on the branch and the annode on the run so it would just protrude into the tank (and the space between the inner and outer tank isn't really anymore than like 3/4".

i stock stainless nipples so I can go either way. i called my friend the chemist who is at breakfast but is going to call me back to think about how close the annode needs to be located to the point of corrosion and or to the dissimilar metal that might be accelerating it. any corrosion engineers out there who got ideas?0 -

Oh! you want specifics!

- Stainless Steel is very good due to chromium oxide passive layer. Highly resistant to oxidation and many chemicals. On the other hand Brass is good, especially in atmospheric and freshwater environments, but susceptible to dezincification in some aggressive media. As a result of several hours of intense research and contrast and compare testing in the laboratory I have come to the conclusion that it doesn't really matter ,and based on personal observation of different materials over my vast career in the nipple business, many different nipples of all shapes and sizes can fulfill the needs you are inquiring about.

- So to sum up, It probably does not matter as long as you use the proper joint sealing compounds for the task at hand.

- I hope this helps!

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

@EdTheHeaterMan

so i stock brass nipples too so i just have to make a call. seems to me that they have gone through an industry shift toward dezinicifcation in brass alloys. IIRC 'red' brass has zinc and 'navy' brass doesn't or . . . ?0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements