Layout Design Feedback

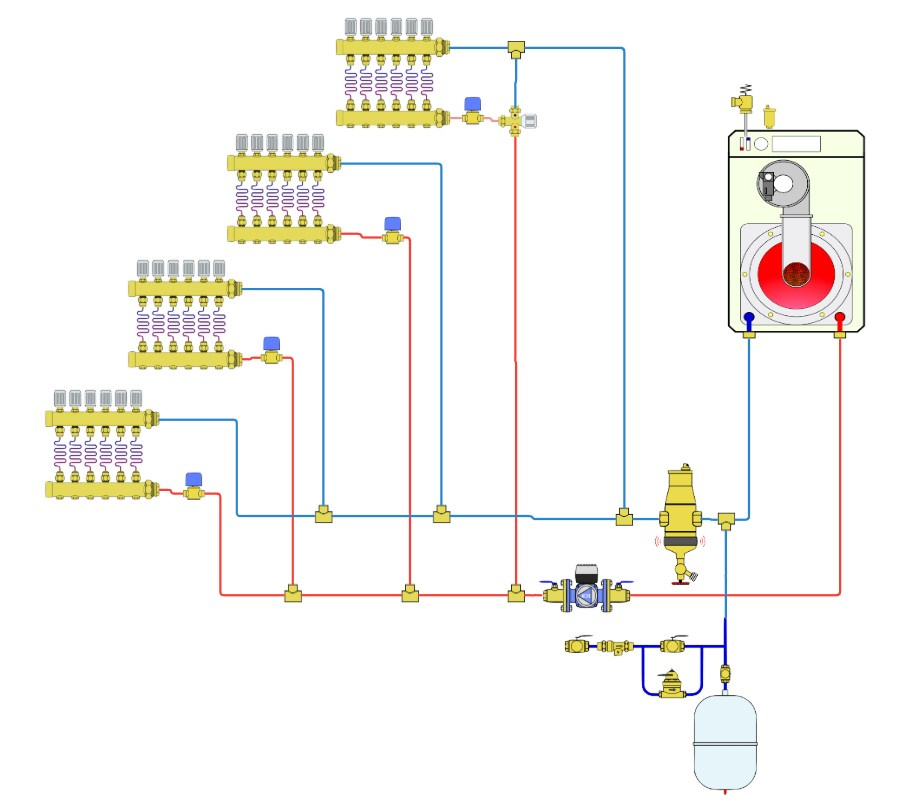

Looking for some feedback on this layout. We had a full system replacement but wanted to keep the original cast iron radiators in the house to maintain the history (also we do kinda love em). We did go for an in floor heat option for areas with tile, we also went ahead and added some modine unit heaters in the basement as we utilize the space year round as a shop. There was also an additional zone added for an area that had been built on that was using an under cabinet heater, we also wanted to leave space to add additional ones in the future. We went ahead and did home runs from zoned manifolds to everything. In terms of BTU and sizing we are comfortable but want to make sure as we throw equipment on the board we dont miss anything.

Equipment planned:

NTS FTVN Boiler

Caleffi manifolds 668S1 with purge valve and auto air vents

Taco 4 zone valve control panel with priority

Taco sentry zone valves

Taco thermostatic mixing valve

Taco 0013 Variable Speed Delta-T Cast Iron Pump

Ideally we want to keep it as simple as possible and need to move as quick as possible given the time of year! Any input is greatly appreciated.

Comments

-

Sounds like the system is being layed out as a two temp system..

While this is great the piping techniques on the low temperature side should be Changed/rearranged

We would install a additional circulating pump based on the required flow

This Circ would be "upstream" from the Mixing valve (Mixed temp side)

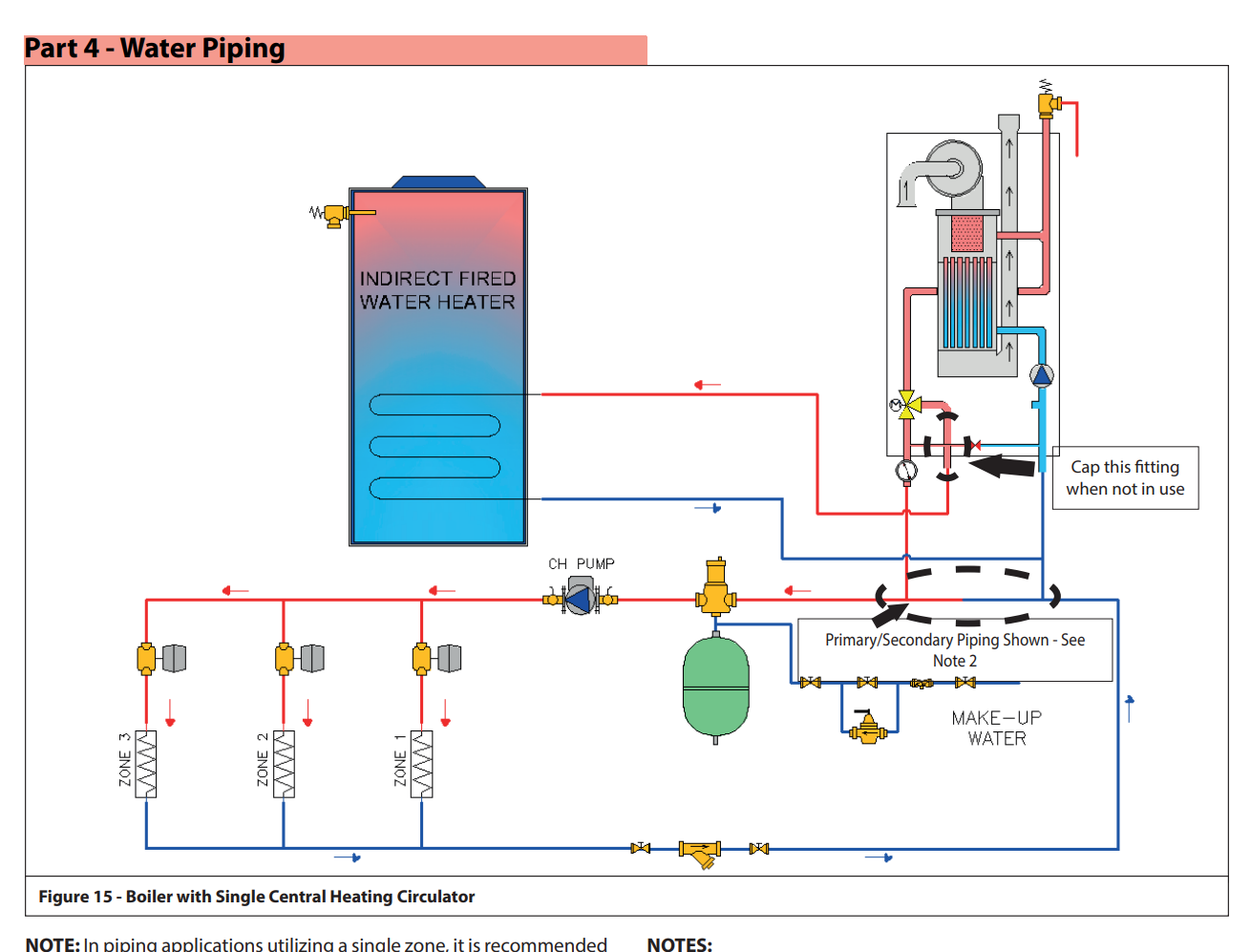

This "low temperature Branch" would be via Closely spaced (Primary/Secondary) Tees preferably Downstream from the high temp rads.(Return to Boiler).

Hope this helps.

Edit: The expansion tank and fill should also be on the point of no pressure change which is perferably prior to the circ. (Inlet)

0 -

-

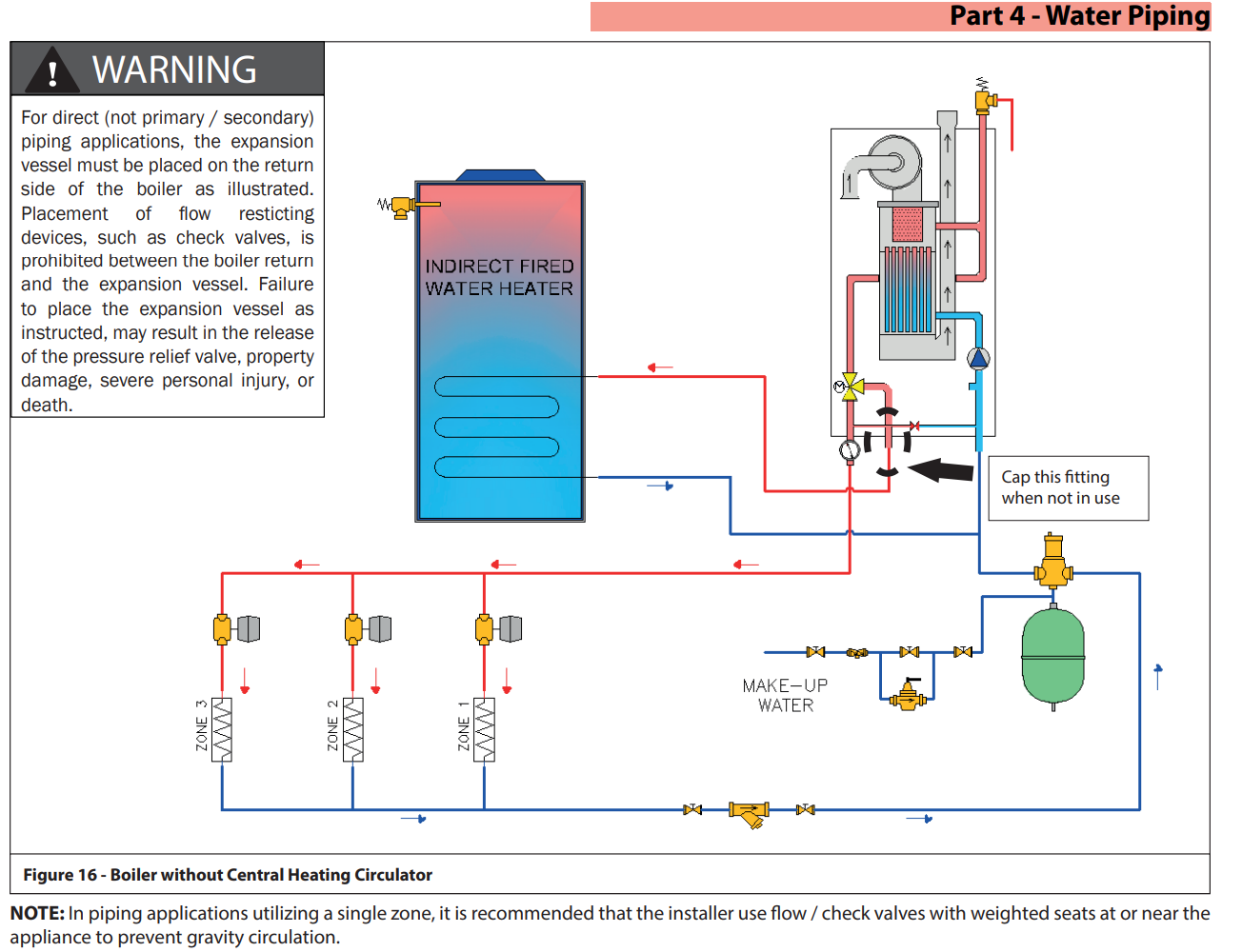

I would look at the install manual. It shows two common ways of piping this up. If your smallest zone's flowrate is around 2GM, you can go direct to load (kindof what you have sketched, but the pump is built in so you don't need an external one).

If your zones are smaller, you can go with primary secondary piping. Unless you a very large system, the 0011 is overkill.

In either case, as others have said, you need a separate pump after the mix valve for the low temp zone.

0 -

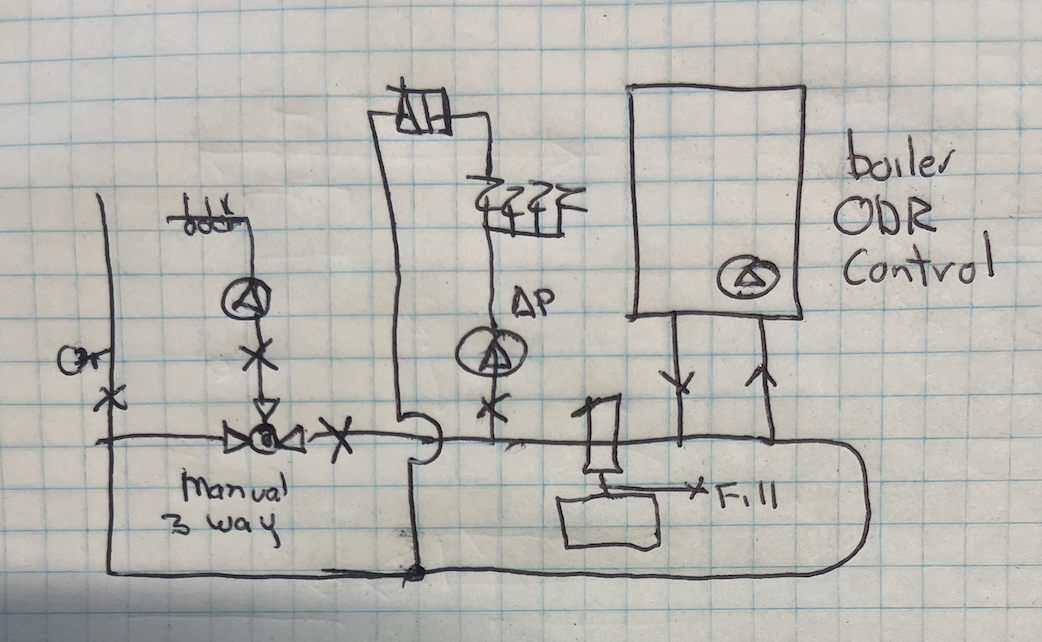

Here is a piping option that I have used.

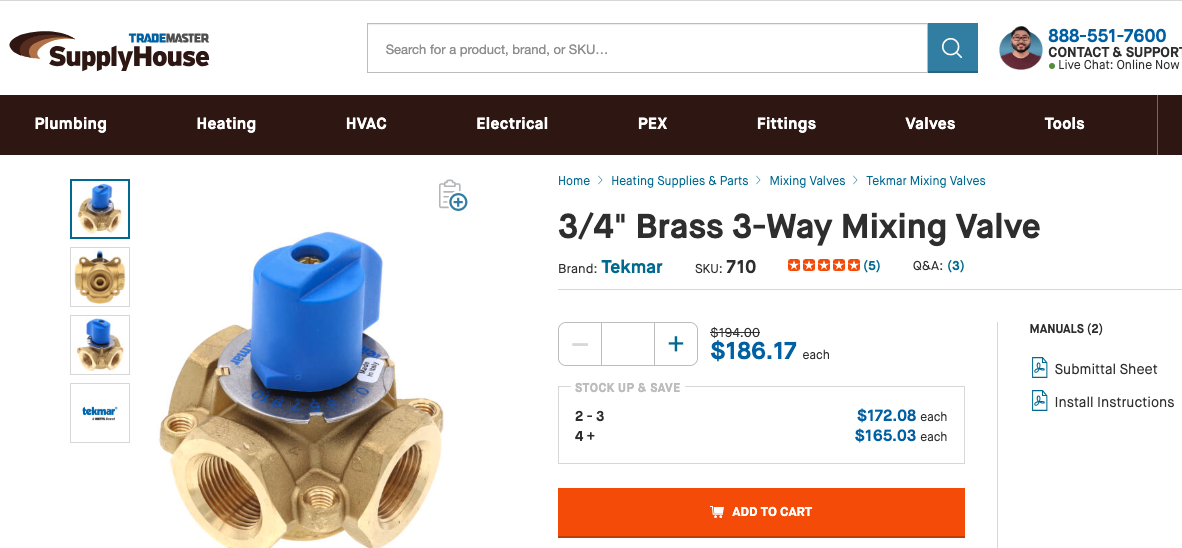

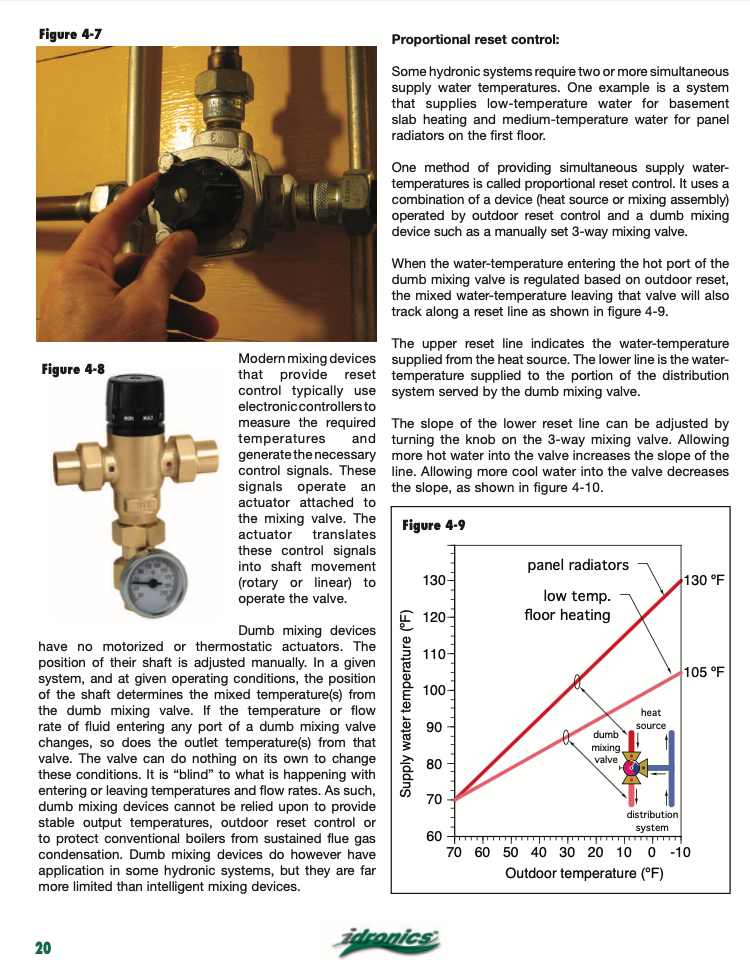

It uses a manual 3 way mix valve with a proportional reset logic.

Basically the boiler runs on outdoor reset control, adjusting to the temperature needed for the radiators.

The radiant is fed through a basic tekmar 3 way mix valve. It's output temperature floats along with the boiler temperature adjusted by ODR

I believe that boiler has a pump inside? Check the manual online.

I would use a delta P, pressure regulated, circulator on the zone valves, and also on the radiant manifold if it is zoned?

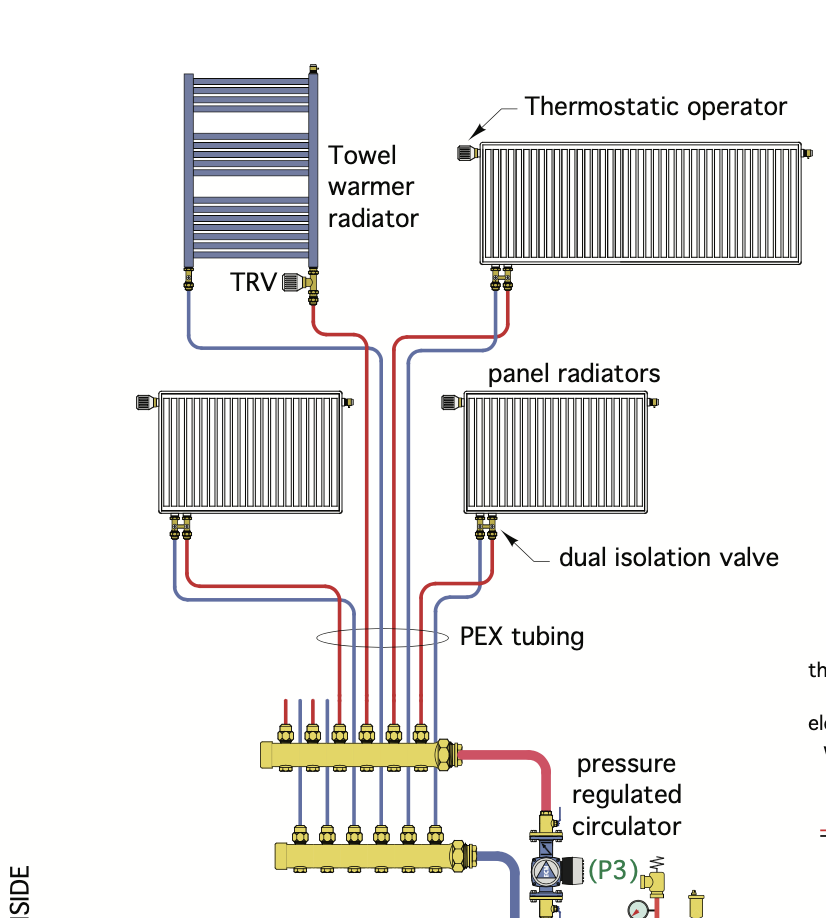

Radiators could have TRV individual controls also.

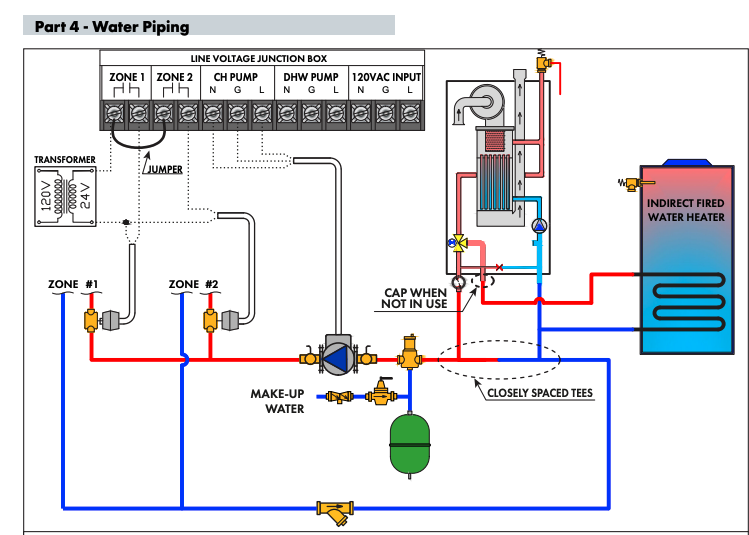

Attached is a page from the NTI manual showing primary secondary piping.

Piping showing TRVs on radiators

A sketch with the 3 way

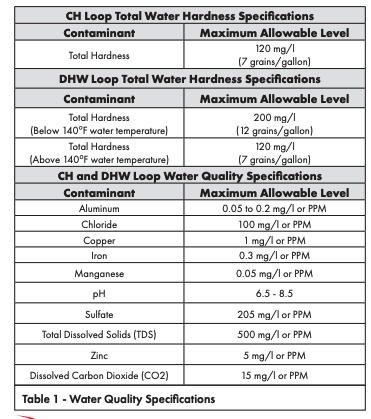

Water quality page

Details on proportional reset control from Idronics 4

I'm partial to Caleffi components :) but what you describe will work;

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements