Dual Roth Tank Oil Level

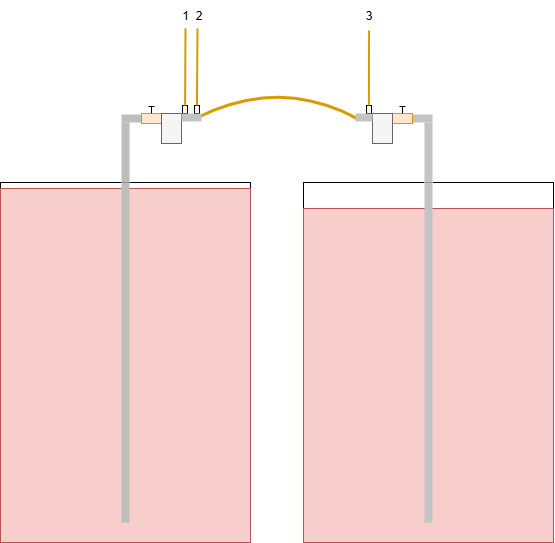

Recently I had two Roth 275s installed. Each tank has its own fill and vent. The tanks feed three burners: a water heater (#3 on diagram) and two furnaces (#1 and #2 on diagram), and each burner has one line and a Tigerloop.

Only the water heater has been running and I've noticed that only one tank's level seems to be dropping. After review, I realize that the supply piping is not in accordance with the Roth manual.

Learning from advice on this forum, I didn't have any old oil transferred. When the burners were initially primed, all valves were open and first the water heater (#3) was primed, then the two furnaces. No issues with lockouts though only the water heater has been running regularly.

I've attached a diagram: each tank supply comes up and goes to a Firomatic, spin on filter, then a tee. Left tank supply lines go to furnaces and right tank supply line goes to water heater, and there is an equalizing line between the tees.

I understand that the tanks may not draw equally with this configuration, but shouldn't the tanks at least equalize via siphon if the supply lines are tied together?

My only thought was maybe with the order of priming and having both valves open during initial priming, there is still air trapped in the pickup tube on the left tank and when the furnaces ran, they were pulling oil from the right tank. Is that even a possibility?

Comments

-

The burner supply line between the two tanks is the equalizing line , no filters should be on that line. It seems you have an air leak on the higher level tank suction / supply set up or the fire-o-matic valve is not fully open.. The tiger loop is doing its job of removing the air .

There was an error rendering this rich post.

0 -

I wouldn’t pipe it that way.

I would do 1/2” out of tanks and come together with a tee.

Off of the tee I would make up a small manifold with 3 separate ball valves, and go 3/8 into 3 separate filters.

From there I would drop the oil lines down and where the oil lines are no more than 3 feet above the burner I would install 3 oil safety valves. Then you can do Tiger loops at the burners.

I would also make sure to have two separate fills, and you can twin the vents with separate whistles on each tank1 -

If there are extra tapping's on the top of the tanks I would connect the tanks across the top with a 1/2 pipe or tubing.

Try shutting off the tank with the lower level and let the burners run for a few days. That may get the equalization started

If everything is tight and no air in the lines it should equalize. You may have an air bubble in one line.

1 -

@oil2025, both oil lines out of the tanks must join each other with ONE Tee, in both equal height and equal distance from each other in order to draw equally. Level and plumb. Then one line off the bull of the Tee. After that you can split it into 3 from there.

1 -

I agree that would be best but the tanks should still equalize.

We had 2 inground 20000-gallon tanks at our shop (40,000 total). They were connected together on top with 4" Pipe with a drop pipe in each tank.

As long as the drop pipe in each tank was submerged in oil and no air pocket we could dump a 7000 gallon load in one tank from our trailer gravity feed with a 4" hose and it would equalize as fast as you put the oil in. And the oil went in really fast from the truck

That is why I suggested if he has a spare tapping on top of each tank, he connect them together with a drop pipe on each

0 -

Where are theses 'spare tappings' in a Roth Tank?

4 tappings-Supply, Vent, Gauge, Pickup. At best you could try to equalize thru the duplex fitting, but safest will always be separate fills to avoid fuel spillage when filling tanks and fixing vacuum leaks.

You’ll never convince me that multiple Roth tank setups will always equalize.

I will reiterate a setup like in my first post.

0 -

Any two tanks will equalize if connected across the top with a drop pipe.

If they are not equalizing you have a suction leak.

with a drop pipe in each tank and the tanks tied together and different oil levels in each tank the drop pipe in each tank will have different oil pressure on it at the bottom. When the burner runs it will take oil from the tank that is "easiest to get" which is the one with the higher level. Plus the oil line is a syphon to the burner that is running (usually) this will cause the tanks to equalize if no air bubble.

0 -

Thanks for the advice on this! I hadn’t done anything yet but noticed the other day that the gauge seems to have moved on the tank with the higher level, so maybe equalization is in progress. I’ll keep an eye on it and I’m sure if I have issues I may have a few more questions. Thanks again

0 -

Update: there is some draw from the other tank but it’s still not equalizing as I think it’s supposed to. I have the installers coming back out soon to take another look.

@HVACNUT the option you proposed doesn’t seem too far off from my current setup. Couple questions:

Could the bull of the tee go right to a manifold (like a cross and a couple of elbows), and keep the existing 3/8 lines overhead or does it need to go single 1/2” copper overhead and split into three 3/8” lines closer to the burners?

I’m also assuming as long as there’s the tee first, it wouldn’t matter the orientation of the manifold like whether it’s parallel or perpendicular to the tank piping, as parallel has only one supply line completely centered and each of the 2 other supply lines are slightly closer to one tank or the other. It seems like having the one tee in the middle is the main goal but wanted to be sure.Are the filters problematic where they are with your option? I ask because they installed non Ultra Tigerloops so no filter currently at the burners. So it would seem to me like the only options would be either 3 filter housings at the tank like @HydronicMike mentioned or remove filters at tank and switch over to Tigerloop Ultras/relocate filters at the burners, but doesn’t that also increase risk of lines clogging over time?

Finally, I realized they used 3/8” firomatics at the tank before the filters. With the filter housings there it doesn’t matter anyway but if those are relocated, would 1/2” fire valves be better?

Sorry for all the questions, just trying to learn and make sure I have an understanding of how it should all work0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements