1929 House -- decrepit waste plumbing

Learned Friends:

This forum has been super helpful over on the Strictly Steam Discussion, so I'm trying my luck here. This is about a plugged sink drain in our upstairs bathroom. The picture below is from ten years ago or so, where the SUPPLY plumbing was coming apart. Pay no attention to the missing hot-water spigot…

Now we're talking about the sink drain. After several years of working fine — and being vigilant about keeping hair out of the sink — I noticed the drain had slowed considerably. I got out my trusty drain auger and went to work. VERY carefully, since I know that the plastic "nut" that provides the compression fitting to the cast-iron pipe in the wall is sitting on maybe two remaining threads, and the less disturbed, the better. It's circled in orange.

I supported the P trap from below and got the snake in there, running hot water as I go. It backed up pretty badly. Pulled out a hairball, no improvement, went in deeper to where I should be connecting with the the shower drain. All of a sudden, the water gurgles and drains. Success! I think about what to do for a moment, stupidly decide to move forward maybe another foot, and then come back.

Needless to say, somewhere along that process, and even though I did pull out a second small hairball, the sink is now 100% stopped up. The shower drains fine.

I theorize that I mostly pushed a large hairball deeper into the pipe, and when I got to the "T" with the shower drain, the water could flow around it. When I pulled back, the plug got pulled back a ways and stayed behind and sealed things up but good.

Does that make sense to you pros?

My plan:

First, buy a new snake with an intact head; mine is like a short and wide cork screw with three turns and a 3/8" diameter…it got mangled a couple of jobs ago. A smaller with more turns would probably dig into the plug better.

If that does not work, I will once again remove the sink and start over. A new P trap and all new hardware, preferably chromed made-in-USA material. I'm done with big-box stores for this type of work.

I'd love a recommendation on what and where to buy.

Any advice on how to deal with the corroded waste pipe? I'd love to be able to cut more threads but there is just enough room for that white plastic fitting.

It's not that I'm in love with the pink-and-purple tile, but it's original to the house and so period correct that it would be a shame to mess with it. If I can't get the fitting on there properly, the next step involves a chisel or a sledge… I'd like to avoid that another year or five. It's not money in this case, it's other jobs I need to do first.

BTW the other side of that wall is not accessible; there's an outside wall with brick veneer.

Thanks in advance for any suggestions.

cheers -matt

Comments

-

Quality plastic tubular waste is much more durable than brass if you don't mind the look, brass corrodes and cracks eventually, pvc usually only gets damaged if there is physical damage. it is slippery so it doesn't clog as easily either.

Can you show a close up of the fitting in the wall, all you can see of the outside and inside of it?

What kind of wase pipe is in the floor? If it is from the 20's it could be lead which is soft and brittle and pretty easy to break with an auger.

If it is steel there is a good chance it is rusted through and will start leaking somewhere.

The tile is probably on mortar on metal lath and will outlive all of us, i'd do whatever I can to keep it.

3 -

» The tile is probably on mortar on metal lath and will outlive all of us

That is the plan.

Not a lofty goal now that i'm over sixty :)

FWIW all the piping I've removed/replaced in this house has been steel. I'm pretty sure, anyway, lead didn't occur to me.

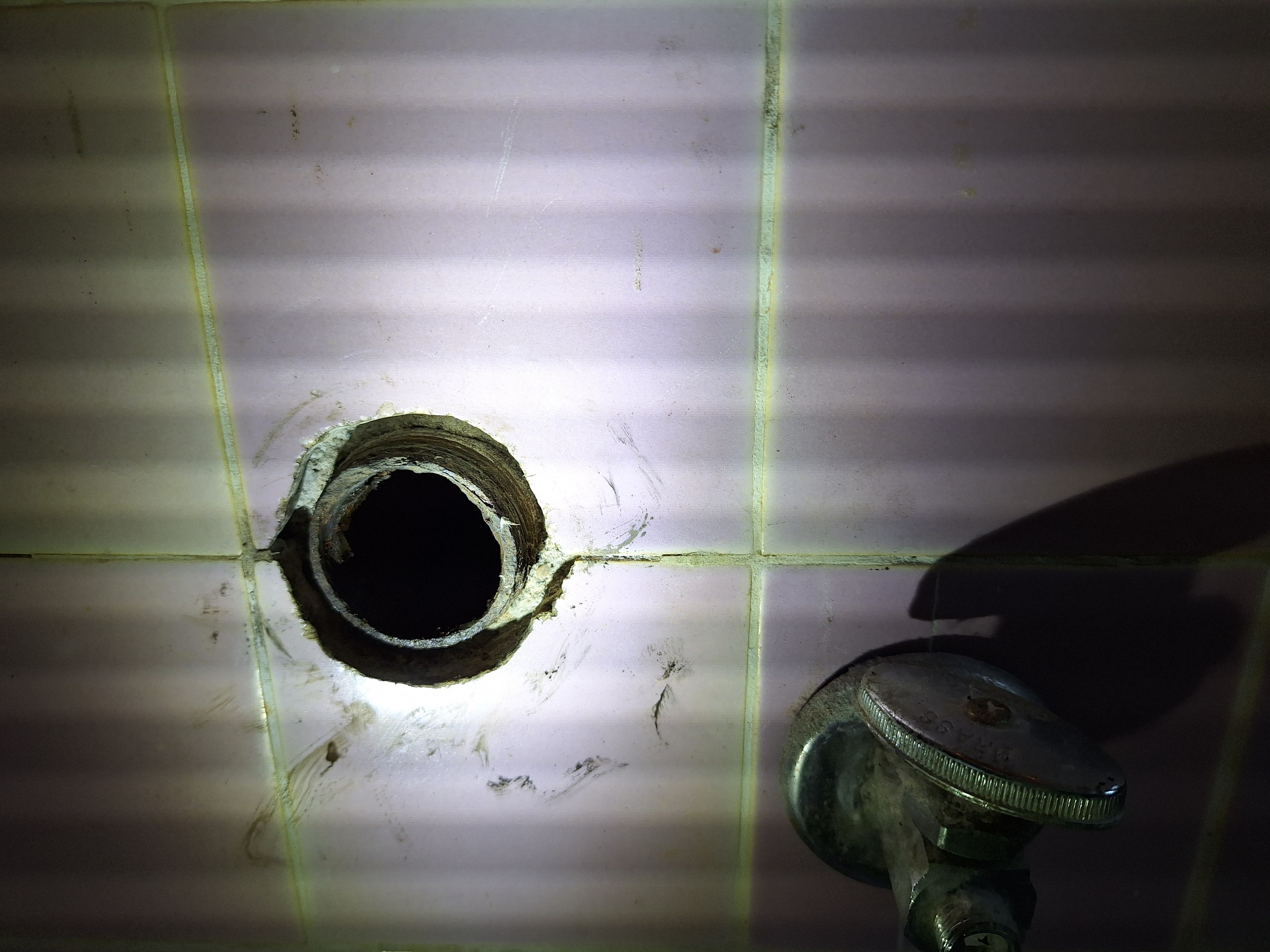

I had pictures of the drain pipe as it sits in the wall, with the fittings removed. Just wasted an hour NOT finding it. I did find the pictures below.. they're from an earlier iteration but you get the idea. Like I said, maybe two threads left and no room to cut.2 -

is that a piece of pvc pipe without a fitting sticking out of the wall or is that some sort of sleeve someone stuck around the pipe?

lead waste will have wiped joints, it won't have fittings, it will be cur and welded together with a blowtorch.

if tubular brass emanates from the wall without a fitting, i would suspect it is lead wiped in to brass.

1 -

The pipe comes out of the wall more or less flush with the tile…there are outside threads, and they are of course seriously rusted.

That PVC-looking thing is a bicycle inner tube that I thought would help seal. Still don't know whether that did anything but it didn't seem to hurt.0 -

For sure someone has been in there before.

0 -

» For sure someone has been in there before.

Meaning that someone has already done a repair and that's why the hole in the tile is uneven?

I'm thinking it's supposed to be covered with a flange and it's awfully close to the pipe.

What makes you say that?0 -

you could chip a little grout out so that you can slip a fernco over it and put a piece of 1.25" pvc with a pvc to tubular adapter in the other end of the fernco, might have to measure the od and match up the fernco.

you can get a deep eschaton that will cover the fernco and pvc.

0 -

oh, wait, the white thing is a pvc jam nut threaded on a steel nipple?

0 -

@mattmia2

Bingo.

0 -

you can either thread a correct tubular adapter on there, possibly with hardening thread sealant or jb weld or wicking or put a fernco over it and go pvc to a tubular adapter. 2 washers in the jam nut or using a 1.5" wall tube and trap and putting the 1.5-1.25 washer at the tailpiece might do it too.

2 -

that hole in the tile looks like how tile was cut with nippers and scoring tools before diamond saws and drills were a thing.

0 -

-

-

Before I go for the major surgery i might try both a 1.5" washer and a 1.5" x 1.25" washer or ferule under the jam nut and see if that gives it enough to compress before the nut bottoms out. You could try cutting the pvc jam nut shorter or try a metal jam nut too.

0 -

@mattmia2

I'm not following…it's not leaking.

My major worry is preserving the remaining threads in the steel pipe.

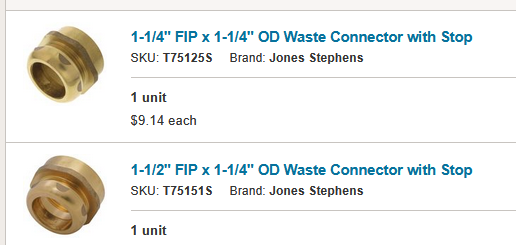

Either a brass adapter as shown, or as @Intplm. suggested, a PVC adapter will engage with the threads and hopefully protect them a few more years. The brass piece is thin enough that it will probably fit in the opening.

The idea being, I'll never have to touch those ancient threads again if I need to take anything apart.0 -

The pvc adapter is solvent weld, @Intplm. thinks that rounded out jam nut is a stub of pvc pipe like I did. You won't have to worry about those threads much longer, 75 years is usually around where that galvanized waste rusts out and starts leaking. What kind of siding is on the building? It is probably easier to cut in to the outside wall to replace it than to search for matching tile.

0 -

» What kind of siding is on the building?

A full course of brick…

I'd have to start with bulding a header, then creating a hole, then working through that.. the walls are over a foot thick.

But that still leaves the complication of where to stop replacing the old pipes. This is headed towards a full-on remodel, including the piping down to the basement. Open walls upstairs AND downstairs.

0 -

PVC fittings to do this exist… need a solvent connection to a trap adapter.

0 -

-

unfortunately brick is still easier to take apart and put back together without damaging it than mud job tile.

usually the cast iron holds up, it is just the steel pipe that rots out after 3/4 of a century or so, so you would just have to replace it to where it goes in to the cast iron. The vent will be fine because is doesn't see water, you only have to go down, not up from the tee at the sink.

Are the outside walls wood with brick veneer or are they structural brick?

0 -

You have a PVC pipe shown stubbing out from the wall. How will you be soldering the ones that are pictured above?

0 -

that is a plastic jam nut over a galvanized/iron nipple with a 1.5x1.25 reducing washer or ferule.

the trap adapters he shows are brass with female thread connections.

0 -

-

Alright, Campers, there's been progress.. if that's the word I want.

In taking stuff apart, I re-learned what I did ten years ago: Instead of properly installing a 1-1/2" drain pipe, I instead wrapped a bicycle inner tube around a 1-1/2 gasket and "installed it" against the ancient iron pipe. Then I used a hose clamp to put a 1-1/4" drain pipe through the opening. That worked ca. ten and then again four years ago, so I was tempted to just leave it.

One nice feature is the physical disconnect between the sink and the drain pipe; it's unlikely that a lot of force gets transmitted to the drain pipe, which has to be a good thing. But I know from inner tubes, and they don't last forever, and now is a better time to deal with it than the dark depth of winter. So I took things apart.0 -

Now the $64,000 question: Assuming I can screw on a PVC fitting, do I use Teflon paste or tape? If paste, I'm thinking lots of it.. if tape, how many layers? There is thread left, but the definition is not good. I'll stick a piece of tube into the solvent weld end to guide me straight onto the pipe, but once I start using force, it's gotta be all forward and no looking back.

If that doesn't work, the last chance is epoxy, and Lord knows whether that will adhere to the rusty iron. I'm using a tooth brush to get all the loose stuff off at least.0 -

Can you take a picture more straight in to the wall with light in the wall? that kinda looks like what's left of a nipple that broke off in the middle of the threads a long time ago.

you can clean up the threads with a wire brush on a drill. there are also files with the pitches of various threads although it looks like 1"-2" npt is 11.5 tpi which is an odd pitch for a file.

0 -

ball wicking in the threads and a little bit of tape or dope would be your best bet. a thick layer of take tends to make the diameter of the pipe bigger and put a lot of pressure on the pipe and the fitting. with plastic unless the steel is really disintegrated that is likely to split or strip the plastic. if the steel is really bad it could collapse that but if it is that bad you're only buying yourself a few months anyhow.

0 -

-

-

looks like all the thread is there but some mortar is in the way. that should take the female adapter if you use a small chisel or screwdriver to carefully chip that mortar out of the way. pvc seals pretty well with no or minimal dope or tape if it threads on far enough

0 -

I see what you're saying but I don't think that's it. Depth is hard to capture in photos. I'll leave it like this for now™ and start planning for a remodel…it's definitely coming.

Thanks! -m0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements