Snowmelt magician!

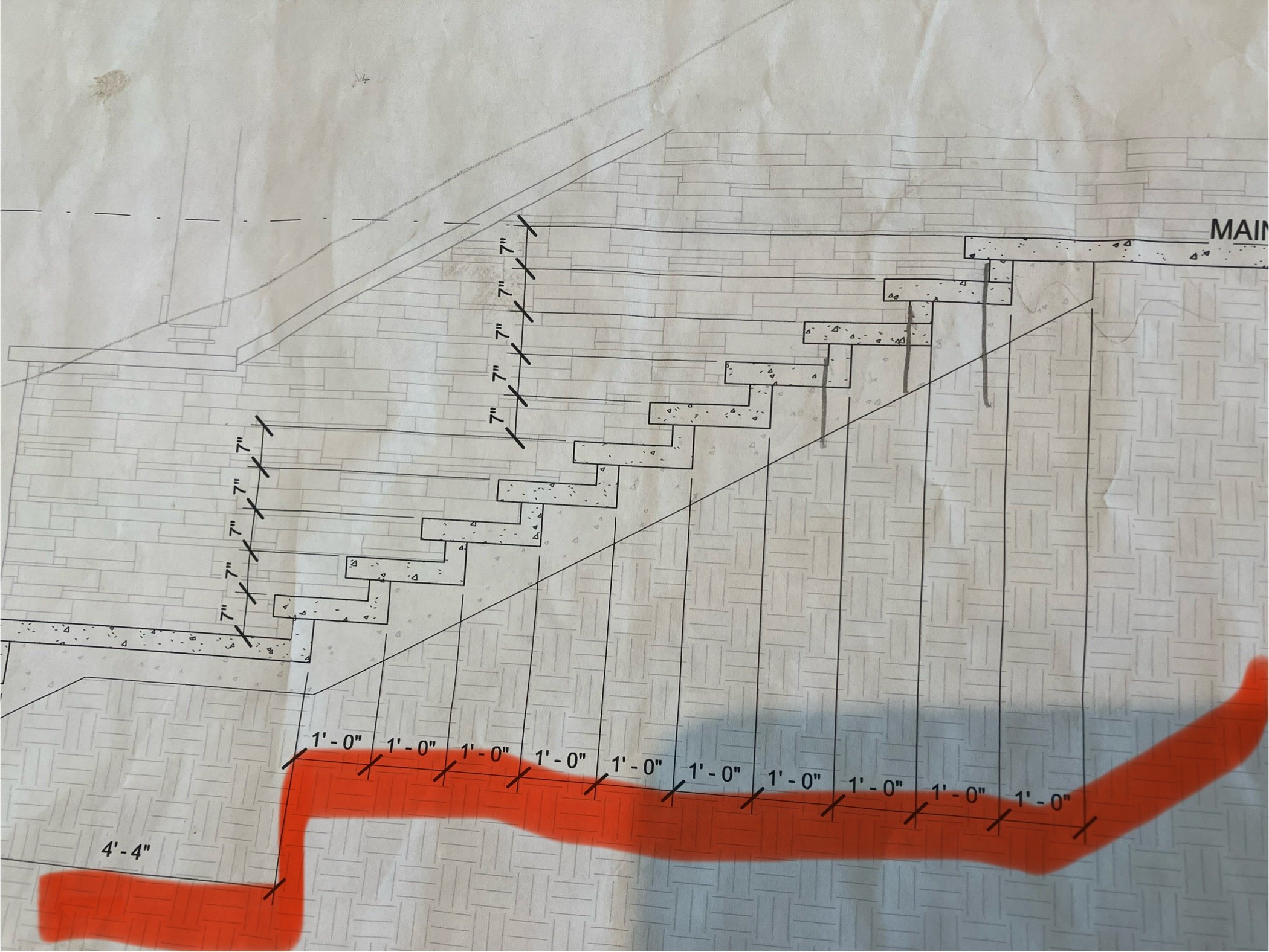

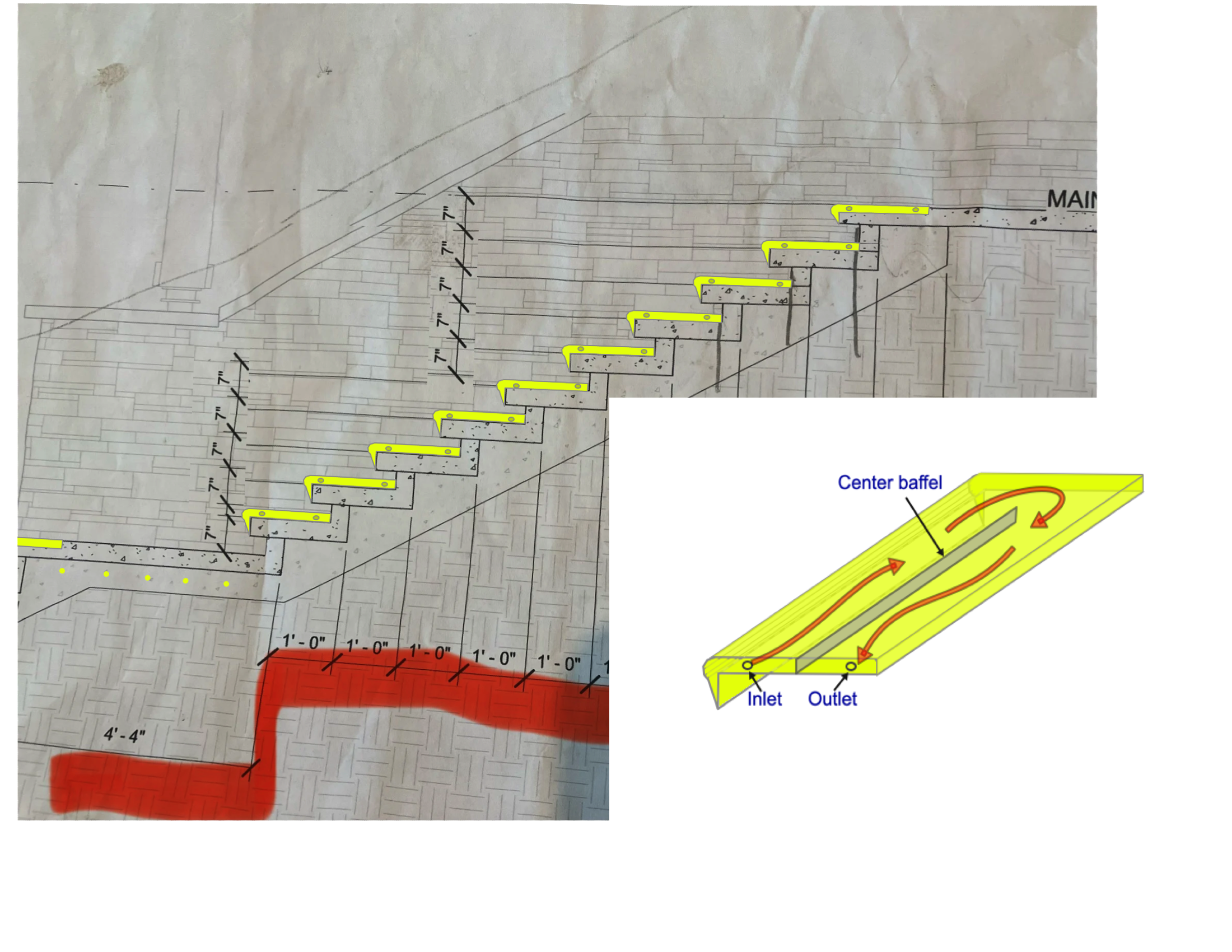

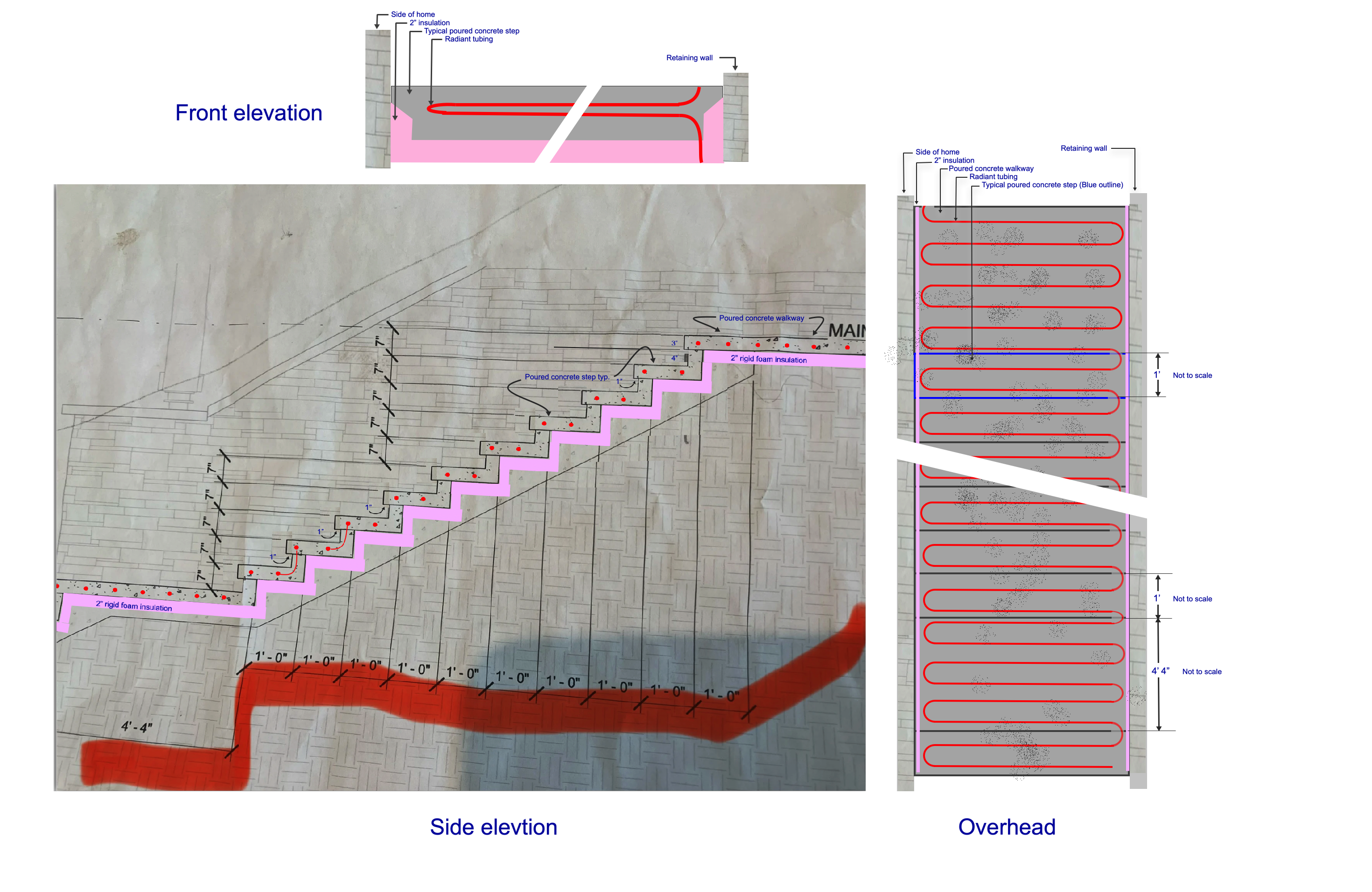

I heard the phrase I am a technician and not a magician. Well now I understand. This picture show the homes entry stairs detail. I have to tube the stairs and some how melt them. The insulation is 2” down, shown by the red line. Also, I am not able to run tube in the bull nose detail due to lack if concrete and lighting detail. Not sure how I am going to melt and control this. SMS will be in the easy to melt landing spot. Concrete will be exposed on all sides bottom. Lots to overcome here.

Jeffrey

Comments

-

-

1/2” tube @150’ loop length 6” on center.

Jeffrey Campbell0 -

Hi, If the steps were pre-cast, could tubing be placed in the forms and all connected together after the steps were set in place? 🤔

Yours, Larry

0 -

Is it outside uncovered, so it sees full snowfall?

Are both sides of the treads exposed? If so that will be a big load (btu/ sq ft.)

If not I like Larry's idea and header each tread loop. Exposed on all sides will present a high load on the stairway.

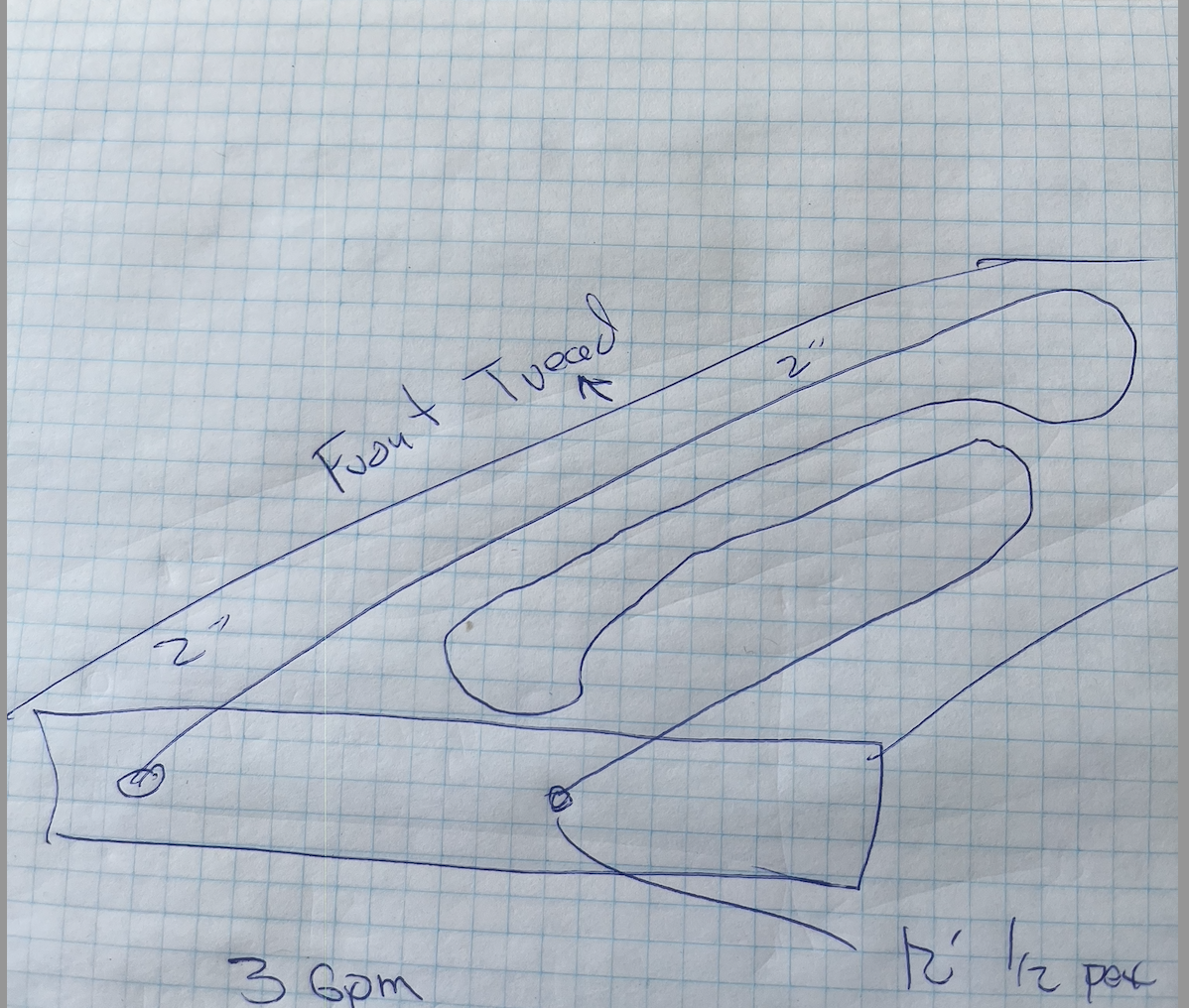

If you can header each tread consider 1/2" pex. It can bend to a 8D radius, .625 X = 5" radius.

get 4 runs in a 12" tread. A 12' loop of 1/2"/ pex 110° of 40% glycol, you could run 4.5 gpm

As you know that front edge melt is crucial. If snow or ice does not melt at the nose of the tread, it is a slip and fall concern. So 1st run 1.5- 2" from nose.

I think maybe 100 BTU/ sq ft, minimum so you need to get at least 300 btu/ out of the tread!

If you can get the tread to 100°, 100° tread at 30° ambient 70X 2 btu/ sq ft/ •°∆= 140 btu/hr/ sq ft. You have 3 square feet per tread perhaps?

I would certainly put some disclaimer on a system if you cannot get adequate BTU to it. At some point YOU need to tell the contractor how it needs to be done :) and what to expect.

Maybe Lance will add some thoughts

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

-

Hi, I'm going to agree with @EdTheHeaterMan . If you cannot make the stairs safe, along with a built-in safety margin, don't accept the job. I might suggest some sort of awning, so snow cannot get to the stairs in the first place. Then add electric heat tape to the stairs and people will want to spend time on them 🤠😁

Yours, Larry

2 -

Ok Ok… Lets suppose ypu wantthe rest of the mechanical work at this project, and you have an owner that says "money is no object, how would you do it?" Then I might come up with an aluminum insert that would fit on top of the step. It can be painted or coated with weather proof wear resistant and traction grit to be safe for walking on when wet. This 1" thick insert would have the finish look the owner is looking for in the finished produce but have next to nothing that will keep the heated water from the surface of the step, since the surface of the step is the water holding vessel.

It's amazing what you can do with aluminum and welding equipment. Of course you will need to pressure test each step insert to 90 PSI for safety reasons to be sure it will hold up under any real conditions that a boiler with a pressure rating of 30 PSI might encounter.

If the staircase is exposed on one side or both sides, you can design a railing system that will incorporate the connecting piping in the lower section of the railings. If both sides of the staircase are covered in masonry or below grade, than the connecting piping can be placed after the inserts are set in place then insulated, before back fill is added to complete the project.

That is of course if the building owner really wants to spend the $$$ and you really want the rest of the work.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I'd stay away from aluminum, some day someone may sprinkle ice melt on them. After they get the fuel bill for heating that stairway?

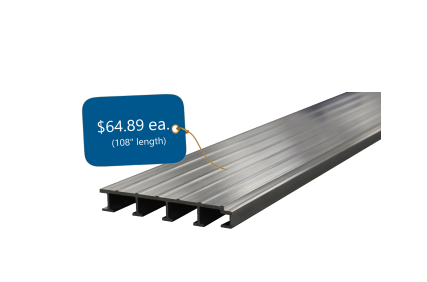

If aluminum was the final answer, get some extruded aluminum plank, insert tube and pour concrete around them.

There are a lot of extruded plank designs with no slip surface.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

when it’s all said and done these steps are going to cost more than my house. I proposed using watts flex plate to the tube closest to the bull nose. Flex plate is made of graphite and is very thin and conducts heat very well

Jeffrey Campbell0 -

-

This is for your home…. Can you redesign the step detail to make the snowmelt work better. Like install the insulation closer to the tubing and reduce the bullnose to a manageable projection. You are going to need to live with this design for a long time and pay for the fuel to operate the system. I might look at this as a redesign.

Just one idea.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Electric mat in each step? A modulating control for energy savings :)

I'm not sure a suspended slab like that will get warm enough?

Wind across it and around it will really drive up the load. Same as the wind effect on a driveway SIM, but you have 4 exposed surfaces. And some vertical concrete "risers?

IR heat above it is not a bad idea @Larry Weingarten A long CoRaVac tube

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Ed

This is definitely not my home. It’s an elaborate 3rd home with form over function. Money doesn’t seem to matter nor do any of my ideas to make the system operate appropriately! Thanks for input. House is almost complete so adding electrical options is not an options. Kinda funny, the owners chose to use air to water HP for the primary heat source inside because “it’s the right thing to do” and then they are using NG to melt the snow instead of shovel. 🤷🏼♂️

Jeffrey Campbell3 -

-

Call Therma-HEXX. The 11.5 “ wide hydronic ThermaPANEL was specifically designed for steps. It is capable of snowmelting 8” thick granite slabs, concrete, synthetic decking, Ipe, open grate systems, pedestal mounted surfaces and asphalt. The full size ThermaPANEL is used in everything from high rise ob decks, the North American Missile Defense System to driveways and interior radiant heating and cooling from the ceiling and floor. It is a very high output system.

www.therma-hexx.com

1 -

The stair riser / nosings detail doesn't meet code and is dangerous. Underside of nosings must be curved or sloped with no sharp edges. Somebody with a prosthetic leg could get their toe caught under that lip and pull their prosthesis off. Anybody wearing sandles will tear the top of their foot on the underside of the lip. You may think this is not your problem, but if there is a problem everyone who had anything to do with the steps will get hauled into the law suite.

0 -

-

-

Hi Mark and thanks for the video….i will watch it. Well this is the best I could come up with between the builder and concrete contractor. The slab sensor was placed in an area where the concrete is 8” thick so that will help the stairs melt given the long warm up time of the 8” concrete landings. The things we are doing for the uber wealthy is challenging in so many ways.

Jeffrey Campbell1 -

That doesn't look like a lot of pipe for a pretty big piece of concrete but maybe the most you can get with the layout.

Both mesh and pipes will work better if raised on chairs above the rigid.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements