What is Boiler Draft, this weeks video

Boiler draft is often misunderstood and it can impact the operation, safety, and efficiency of boiler. Hope this video clears up some of the mystery.

Boiler Lessons

Comments

-

Thanks for that, concise and interesting. We coal guys love our draft gauges and barometric dampers.

I never thought about combustion being best once the chimney is brought to operating temp, how long does a typical oil burner or gas burner take to stabilize for consistent or efficient combustion?

0 -

When I was taught to use the old Bacharach (Wet Kit) combustion testing equipment, I was told that I should wait for at least 3 minutes before taking the test. 5 minutes is better but if your system has short cycles, you don't always get 5 minutes. That is one of the reasons that short cycling boilers are not as efficient as properly sized equipment that have longer run cycles. If you short cycle off of a limit switch of some type because your burner is oversized for the connected radiation, then your boiler that is on for 2 minutes and off for 3 minutes, never gets to the steady state efficiency if might achieve if it were able to operate for 10 to 15 minutes per cycle.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

With coal stoker stoves, furnaces and boilers that have forced draft or induced draft the low water column pressure gradients are your friends.

When the Dwyer Mark II manometers water column pressure on the low pressure side starts climbing it is always time to clean the fly ash trap.

Having a Tee and an end cap at the flue breech lets you quickly pull out the fly ash and put the cap back on and keep the idle fire/hold fire going.

With my flue pipe rise, the fly ash that is blown up the near vertical flue pipe will fall back down when the heat call has ended.

I still need to invest in a buffer tank and I am hoping I can invest in a New Horizons 490 gallon fully insulated rectangular storage tank as I only have 44 gallons of useable hot water in the boiler and the 225 feet of 3/4 baseboard-not including the 10 gallons of water in the steel compression tank.

I had a great deal of unburned coal that fell off the left side of the flat grate stoker and as it turned out the leveling plate had warped enough that a large amount of rice coal was being forced up and over the left side plate of the flat grate stoker and we fixed that by bending it back down below the top edge of the side plate yesterday.

With that minor repair I know I will be putting even less rice coal in the hopper during the 2025-2026 heating season.

0 -

do you think short cycling could be reduced by running off the low limit with a wider differential? Or decreasing the cycles per hour?

@leon, I think adding a buffer tank that huge will work against you unless you can insulate it to the hilt. Lower water mass is your friend. You might not have unburnt, but you'll be burning more. That's a discussion for another time and place.

We recently had our church furnace looked at since the barometric damper was set as open as possible. The tech checked it with a gauge and now has it set properly, that is pretty much all the way to the other end of the scale. He said he didn't think we'd notice much fuel usage difference! Does that sound true for a system using over three hundred gallons of oil per month?!

0 -

@RascalOrnery said: …do you think short cycling could be reduced by running off the low limit with a wider differential? Or decreasing the cycles per hour?

Since the original discussion comes from someone that is an expert on Steam systems for both space heating and brewing, I assume that this will relate to steam systems. For the most part an oversized steam heating system does not have a low limit control per se. There may be two high limits on one boiler. One of those limits will be called the operating control that is designed to keep the boiler within the most efficient operating pressure range. The second limit is set at a higher pressure and will only open in the event of a failure of the operating limit to open (also known as Cut Out) when the desired pressure is reached. Those high limits often have a manual reset that requires human intervention to get the burner back up and running.

At the point when human intervention is required, the human boiler operator should investigate the reason the operation limit failed to keep the boiler pressure from activating the High limit. So your term of Low Limit is incorrectly used in this case.

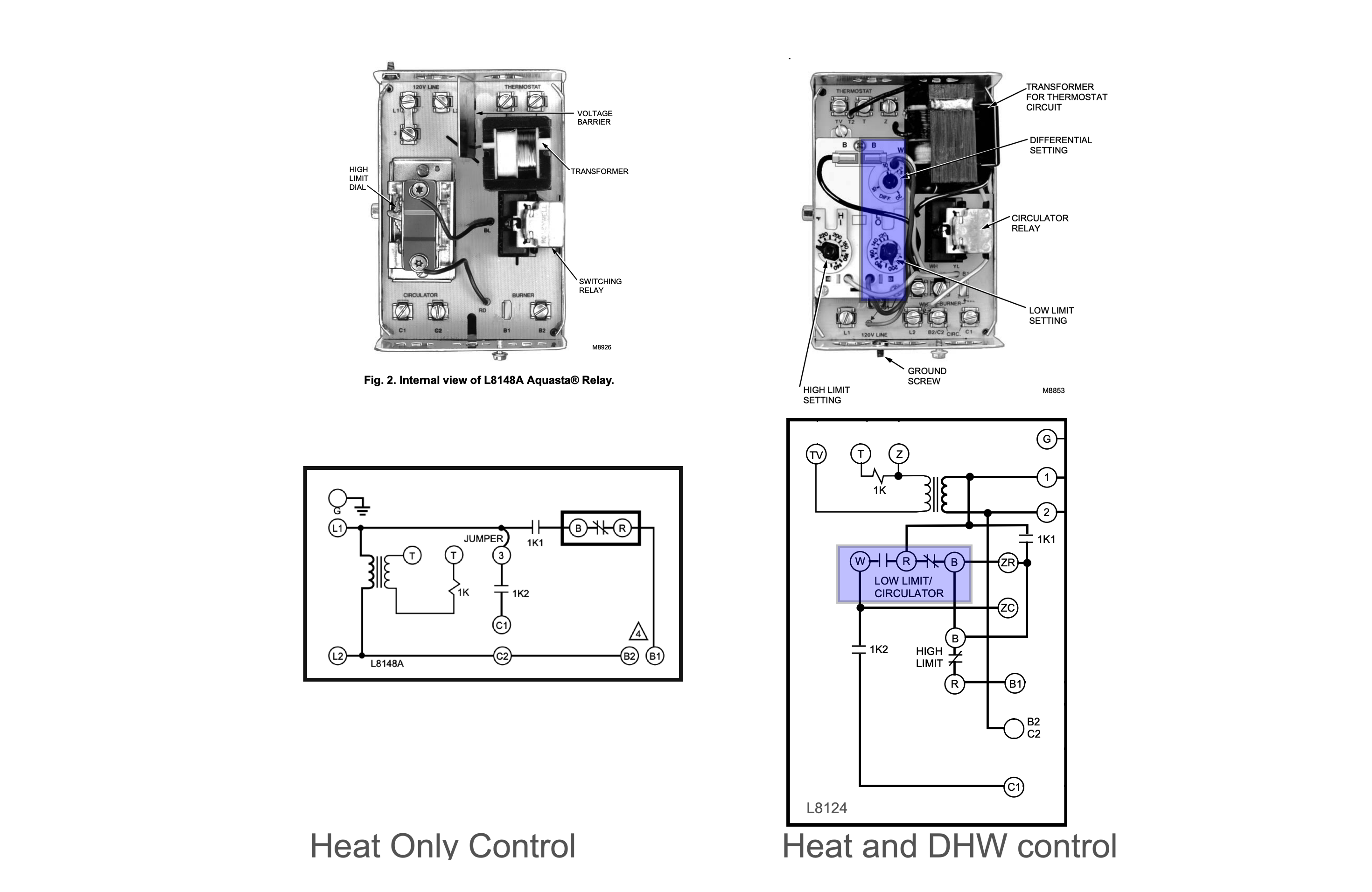

When referring to a water boiler that also has a Domestic Hot Water DHW) coil the term Low Limit means that part of the control system that stops the boiler temperature from reaching the high limit setting. The low limit will maintain a boiler temperature that will be sufficient to provide DHW, say around 160°. Only when there is a call for heat will the Low limit get bypassed by the relay that operates the circulator in order to make the boiler water hotter than that needed for DHW and allow the boiler temperature to go as high as the High limit which may be set as high as 200° or more. You don't want to waste fuel by maintaining the High Limit temperature all summer when the low limit temperature is good enough for DHW, but you may want to get 200° water for the radiators in the winter. So that is the reason for a low limit and a high limit.

So if you are referring to the lower set limit known as the operator on any steam or hot water boiler, making the differential greater will increase boiler run time. That is because it takes less burner run time to make any quantity of water increase in temperature only 10° or raise the pressure 8 ounces of steam pressure, while it takes more burner run time to make that same amount of water increase 25° in temperature or increase in steam pressure of 1.5 PSI. That is common sense. What you name the particular control that the differential setting is on, has bearing on how the control operates. What you call a particular control only makes a difference in communication to other tradesmen as to what you are referring to. So calling an operating control a Low Limit may be confusing to someone because the term Low Limit usually refers to something different that what I believe you are referring to.

I hope I have made myself as clear as mud on this subject

EDIT

Pictures are better at explaining stuff. This represents a Hot water boiler control system that will operate both the Burner and the Circulator pump

Only one of the controls here has a Low Limit. It is indicated by the shaded Blue area. The control on the left has no Low Limit because this boiler has no DHW tankless coil in the boiler, so no need for a low limit to maintain boiler temperature for DHW. Only the control on the left has a Low Limit with an adjustable differential from 10° to 25°. Adjusting this Low Limit to a 25° differential will have no effect on the burner short cycling during a call for heat. That is because the call for heat will bypass the Low Limit and only the high limit will keep the burner from operating above the high limit temperature. The oversized burner/boiler will have no change in operation by adjusting the Low Limit. I can go into more detail if you believe that you can make a burner stop short cycling during a call for heat by adjusting this differential.

I hope this answers any questions about the operation of a Low Limit.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I know pretty much nothing about how steam works, and my question was strictly referring to a hot water system. Sorry, I should have been clearer to spare you the book.

My question was if a boiler is so oversized to be short cycling would it be a reasonable alternative to eliminate the entire usage of a high limit and allow the boiler to run off a single set point with a wide differential. The thermostat would be connected to a zone controller that would have no connection to the boiler controls. This would be in a situation using a tankless coil, so cold start not an option. This would cause longer burn times since running temperature would be lower and would allow for longer circulation and hence longer burner times.

Since the boiler is already oversized I don't see how domestic water could be terribly starved in the case of a simultaneous heat call.

0 -

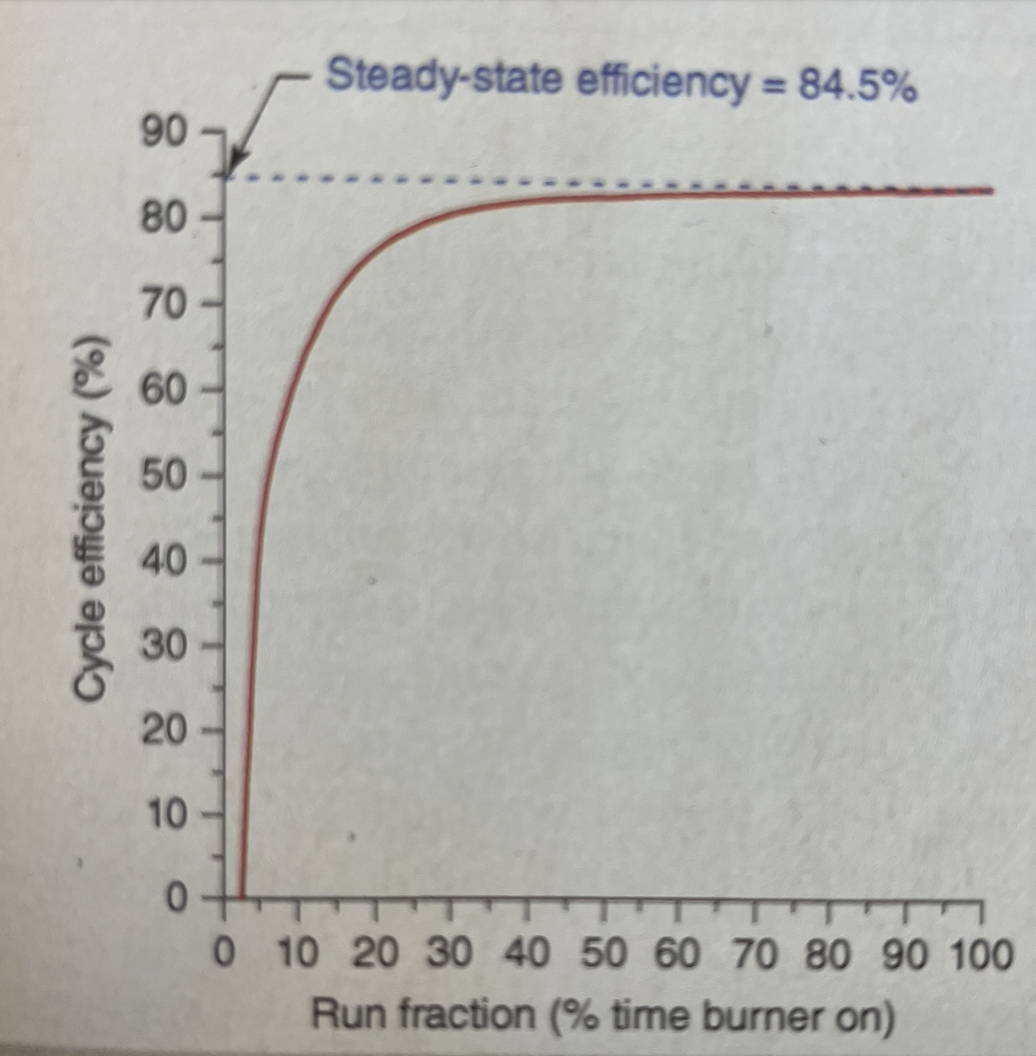

The Run Fraction tells more of the story.

If a boiler runs for 2 minutes, followed by a 10 minute off, then 2÷12= 0.166 or 16%

Use this chart to determine efficiency.

16% on bottom axis, runs up to under 70% Cycle Efficiency.

Commonly you will hear a minimum 10 minute run to dry out the combustion chamber and flue. Followed by a 20 minute off gets you into the 80% range.

10÷30= .333 or 33%

A perfectly sized boiler would run 24/7 on design days to give you the best efficiency, Steady-state Efficiency.

With a large buffer you would run steady-state while charging, then the boiler gets the best efficiency, when it is not running at all :) for the period of time the buffer depletes.

Pipe the buffer "direct to load" then the boiler does a % of heating and a % of buffer recovering. If the load is large, maybe coming out of setback, all the boiler output goes to the load.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Greetings RascalOrnery,

The New Horizons 490 gallon rectangular storage tank is fully insulated with a sheet metal skin exterior holding the insulation.

Using the lowest side tapping as Bob described with the hot water pushing from the circulator into the tank bottom would be the way to manage this and allow it to act as a dump zone and storage at the same time as the top center or top front tapping would be used to feed the hot water to the single 225 foot baseboard loop.

AHH, to have a surplus 8,000 gallon insulated tank car to plumb in and enjoy the thermal thermal mass after the heating starts by heating the full tank car first with 12 gallons per minute and then circulating 4 gallons per minute between the tank car and the coal stoker when the heating season starts.

0 -

The chart is neat!

But now you have me confused, buffer tanks? Would it be correct to say that a buffer tank is always a plan b to make a system change without changing the boiler and secondly a proper boiler sizing will never require one?

I was under the impression low water volume was the new thing, and higher volumes were starting to be the old fashioned method, but now here we are talking about buffer tanks, and Leon is talking about installing a basement swimming pool! 🤣

so am I correct in saying a buffer tank is usually a fix of sorts rather than a plan a strategy?

0 -

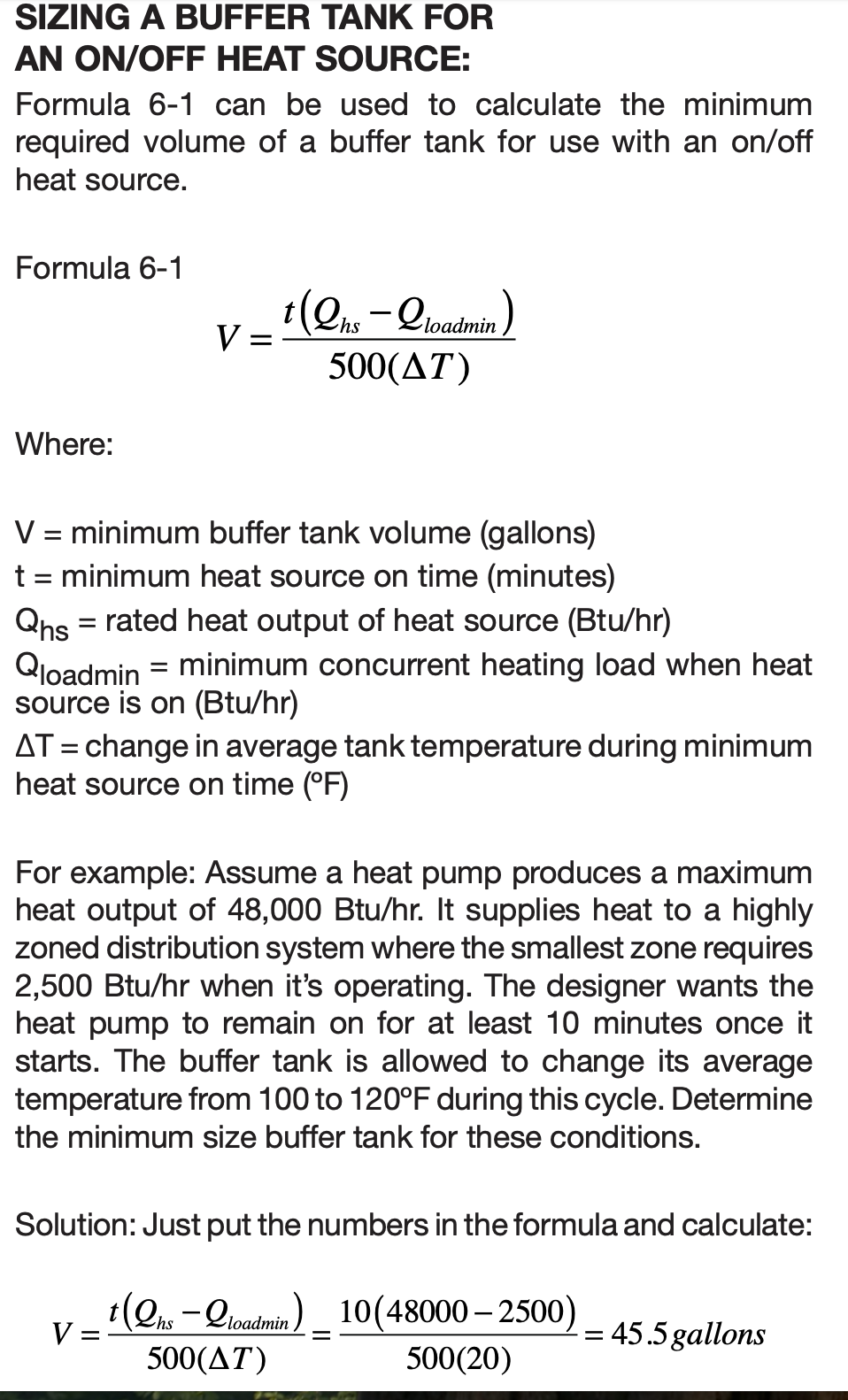

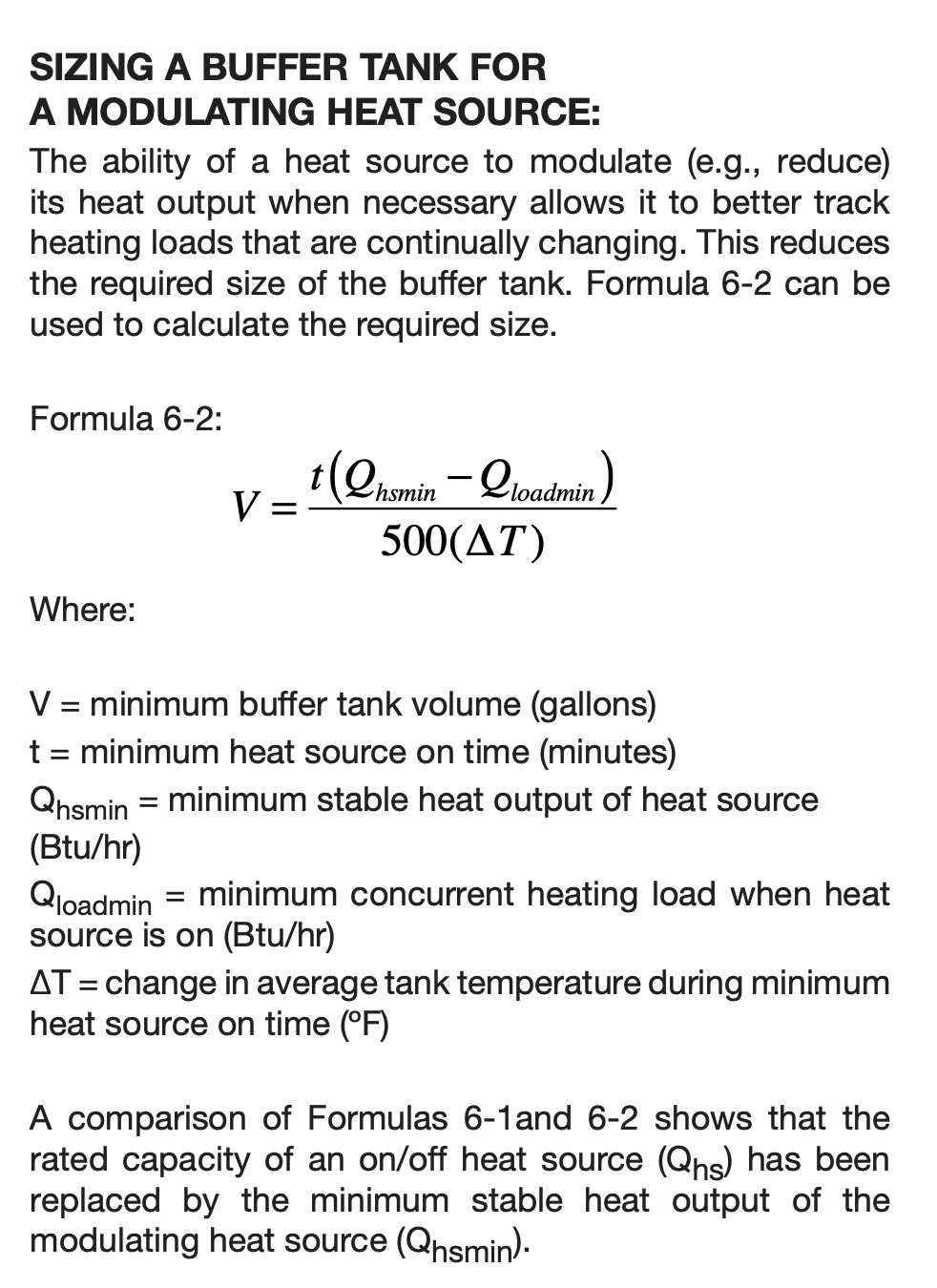

some systems get designed with buffer tanks to maximize efficiency and reduce cycling. Solid fueled boilers, large chillers are examples.

More and more we see heating and cooling equipment that can modulate, which helps reduce the buffer capacity required. Pellet and cordwood boilers now have some modulating capacity, so the buffer tank sizing has gotten smaller

There are always trade-offs. Large pressurized, insulated tanks are $$. Heat loss is a concern, space requirements also.

A buffer is an option for oversized boilers also, is the cost going to off set the poor efficiency, or extend the boilers life those are some of the decisions.

Micro and multi zoned systems with non modulating boilers are often a good match for a buffer tank.

Gravity systems with cast radiators had the buffer built into the distribution system. The boilers mass and large water content also are part of the buffer

The perfect hydronic boiler could modulate from no load to 100% load, think of a variable speed drill motor , now that would be ideal

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Thanks hot rod!

0 -

micro zoned systems will usually work better with a moderate sized buffer tank because even a modulating boiler usually can't modulate down to the load of the smallest zone or 2, especially if it is using odr and it is difficult to get the control right to match the firing rate to that single zone. in milder weather there is likely to be one or 2 zones calling at a time with a reduced output.

0 -

-

Thank you Ray, Bob, Ed and RascalOrnery,

I knew I was still on the right track/siding in my seeking to add a large buffer tank.

0 -

Hello RascalOrnery,

Do not think of a buffer tank as fix of sorts, it is always money in the heat bank, The high school I attended built in 1961 had and probably still has gas fired boilers and all the buildings had single pane glass windows and the buildings were either too hot or too cold because of the rubber roofing and poor insulation.

The boiler room building had and probably still has two or three 10,000 gallon insulated hot water storage tanks as the entire complex was heated with pumped hot water heating using 1 inch piping in access tunnels with copper fin tube baseboard and there was no air conditioning at the time other than opening the windows in the classrooms. The access tunnels had the domestic hot water and sanitary sewer piping as well as far as I know and the building roofs had scupper drains.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements